Chain tensioning adjusting mechanism

A technology of tension adjustment and chain, which is applied in the direction of belt/chain/gear, mechanical equipment, transmission device, etc., which can solve the problem that automatic tension adjustment cannot be realized, tension adjustment device cannot adapt to harsh working environment, and the reliability coefficient is insufficient and other problems, to achieve the effect of convenient installation and maintenance, prevention of chain drop, and automatic tensioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

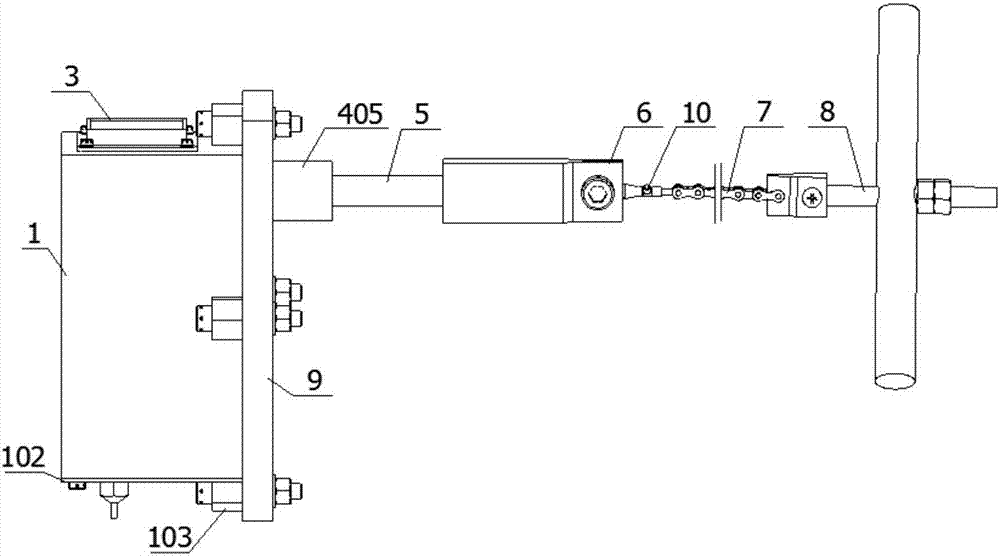

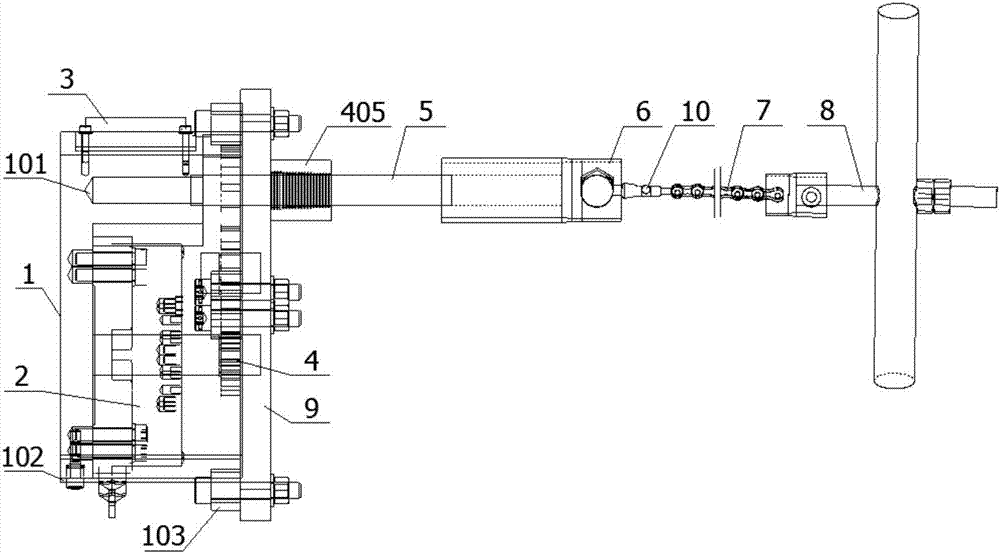

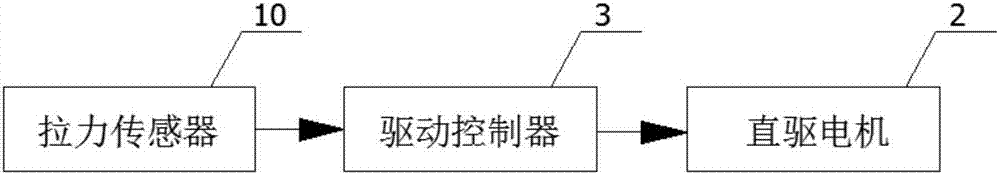

[0046] Such as Figure 1 to Figure 3 As shown, a chain tension adjustment mechanism includes a housing 1, a direct drive motor 2, a drive controller 3, a transmission device 4, a transmission screw 5, a first joint device 6, a chain 7 and a second joint device 8;

[0047] The housing 1 is square with an opening downward, the direct drive motor 2 is placed in the housing 1, the drive controller 3 is placed on the upper end of the housing 1, and the drive controller 3 is connected with the direct drive motor 2 through a line; the outer side of the housing 1 is provided with a support plate 9, the transmission device 4 is placed on the side of the support plate 9 close to the housing 1, and the direct drive The output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com