Patents

Literature

114results about How to "Improve driving precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

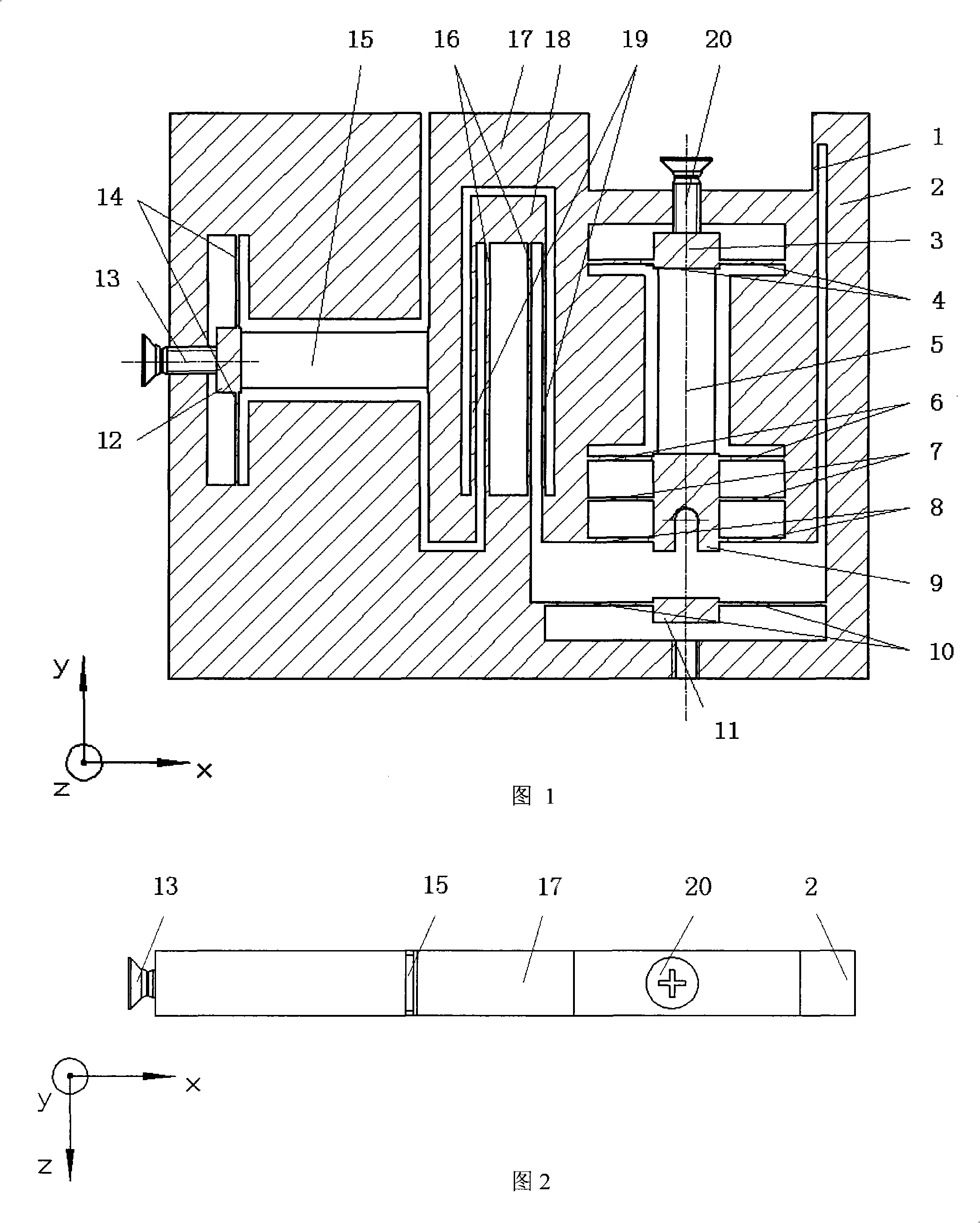

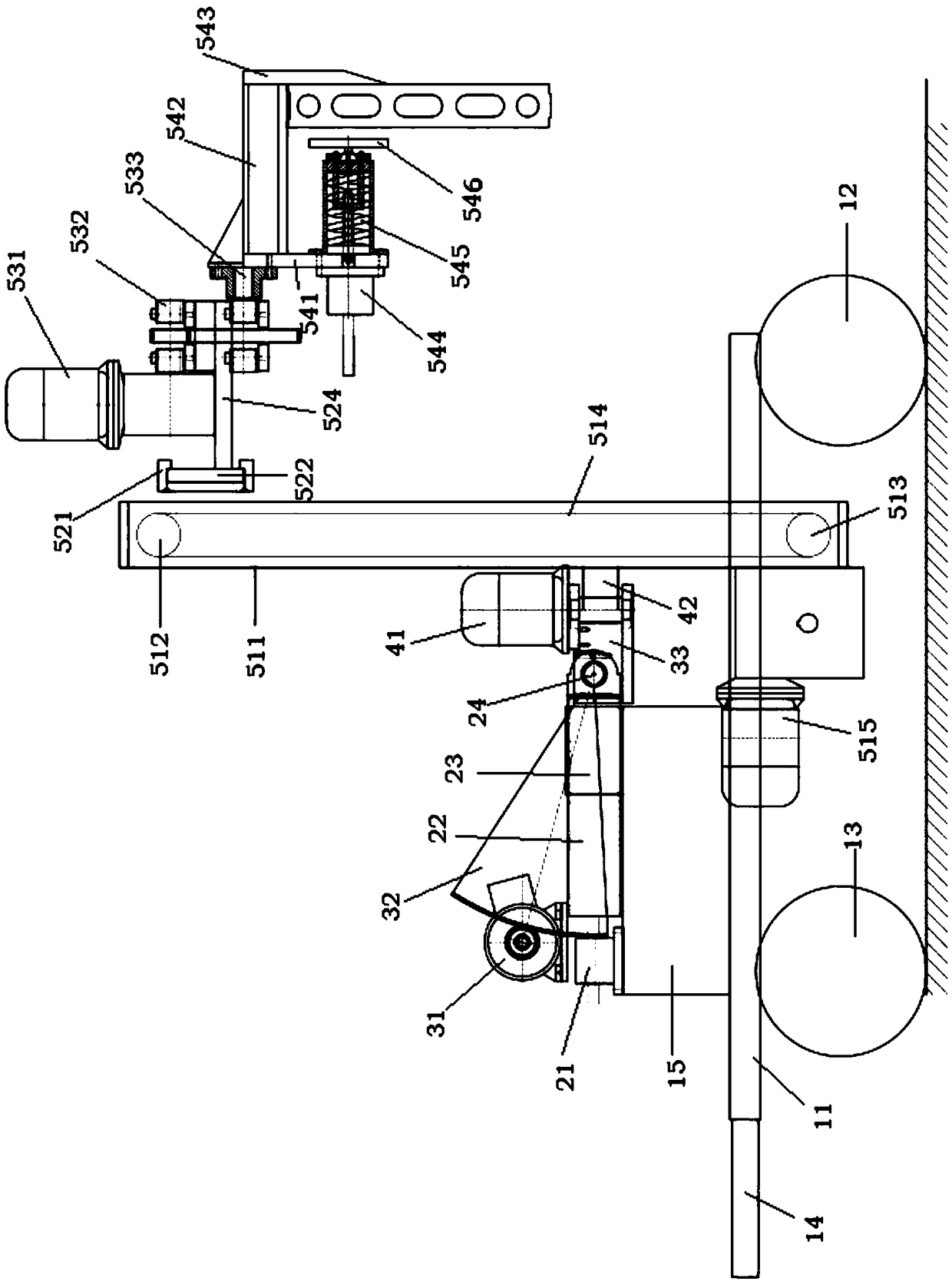

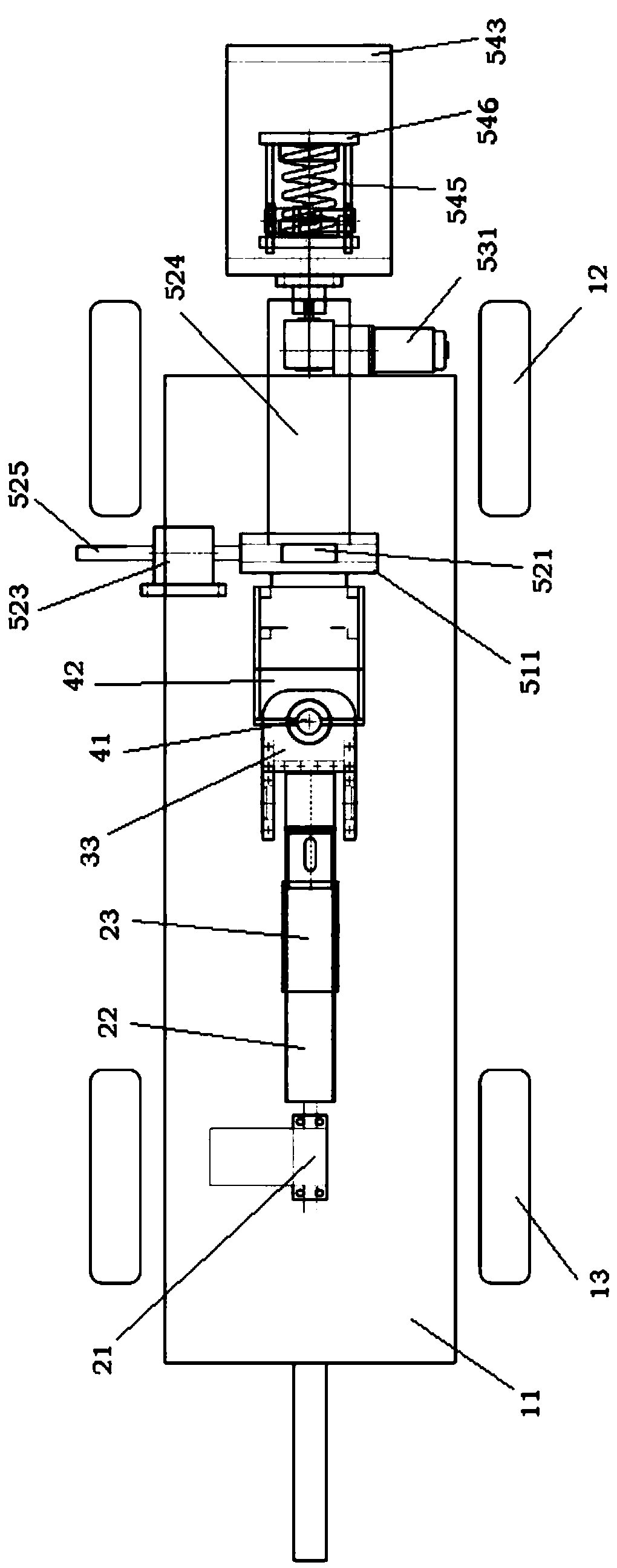

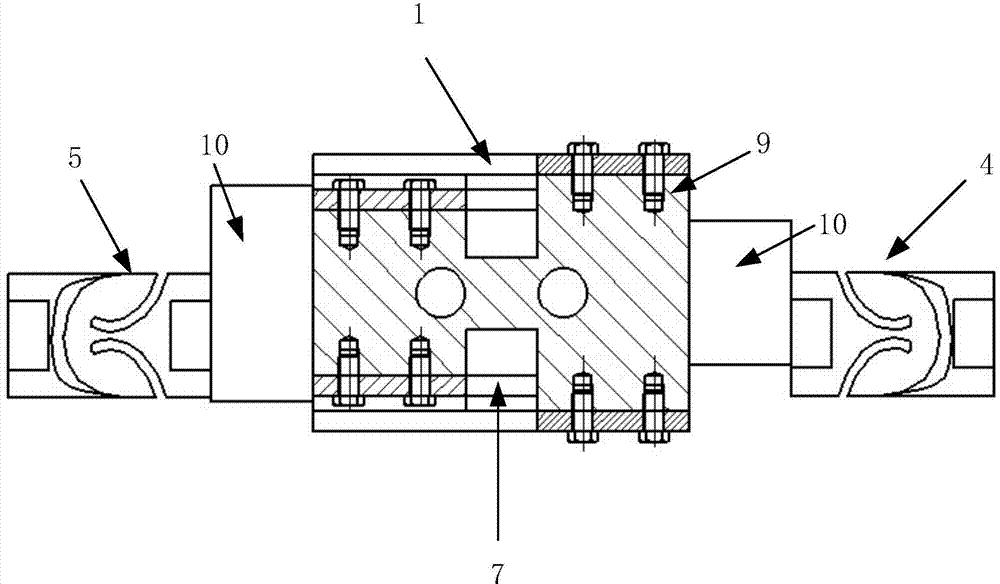

Two-degree-of-freedom large-stroke high-peed and high-precision positioning platform

InactiveCN101858477AImprove driving precisionReduce size and complexityStands/trestlesHinge angleTwo degrees of freedom

The invention relates to a two-degree-of-freedom large-stroke high-peed and high-precision positioning platform, belonging to an electromechanical type. The structure of the platform comprises a guide rail and a worktable which are matched with each other, and the worktable is driven by the guide rail and is connected with a mass block through a flexible hinge; a piezoelectric stack is pre-tightened and located in the flexible hinge through a wedge-shaped block; the guide rail is connected with the mass block through the flexible hinge; and the piezoelectric stack is pre-tightened in the flexible hinge through the wedge-shaped block. The positioning platform has the advantages of greatly improving the drive accuracy of the common drivers, reducing the complexity and the size of the structure, and having low cost, less investment, quick returns, high benefit and the like.

Owner:郑福胜

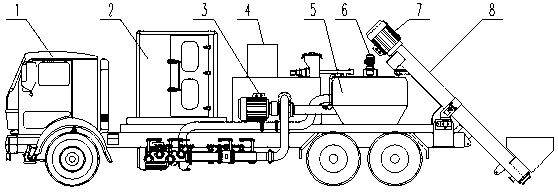

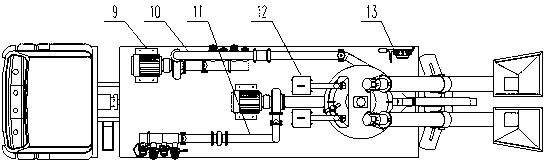

Electric drive sand mixing truck

InactiveCN103912259ASimple structureHigh localization rateFluid removalItem transportation vehiclesAutomatic controlElectric discharge

The invention belongs to the technical field of petroleum drilling and recovery and particularly relates to an electric drive sand mixing truck. The electric drive sand mixing truck comprises a truck chassis, a control room, a transformer, an electric discharge pump, an electric suction pump, a mixing tank stirring device, a sand conveying auger, a dry feeding system, a liquid feeding system, a suction manifold and a discharge manifold. The control room comprises a sand mixing truck automatic control system and a motor drive device. The electric drive sand mixing truck has the advantages that a motor is used as power source; compared with traditional sand mixing trucks using diesel engines and torque converters as main power output, the electric drive sand mixing truck is simple in structure, novel and reasonable in design, low in cost, low in noise, low in discharge, simple to control, high in sand-liquid matching precision, and convenient to popularize and use.

Owner:四机赛瓦石油钻采设备有限公司

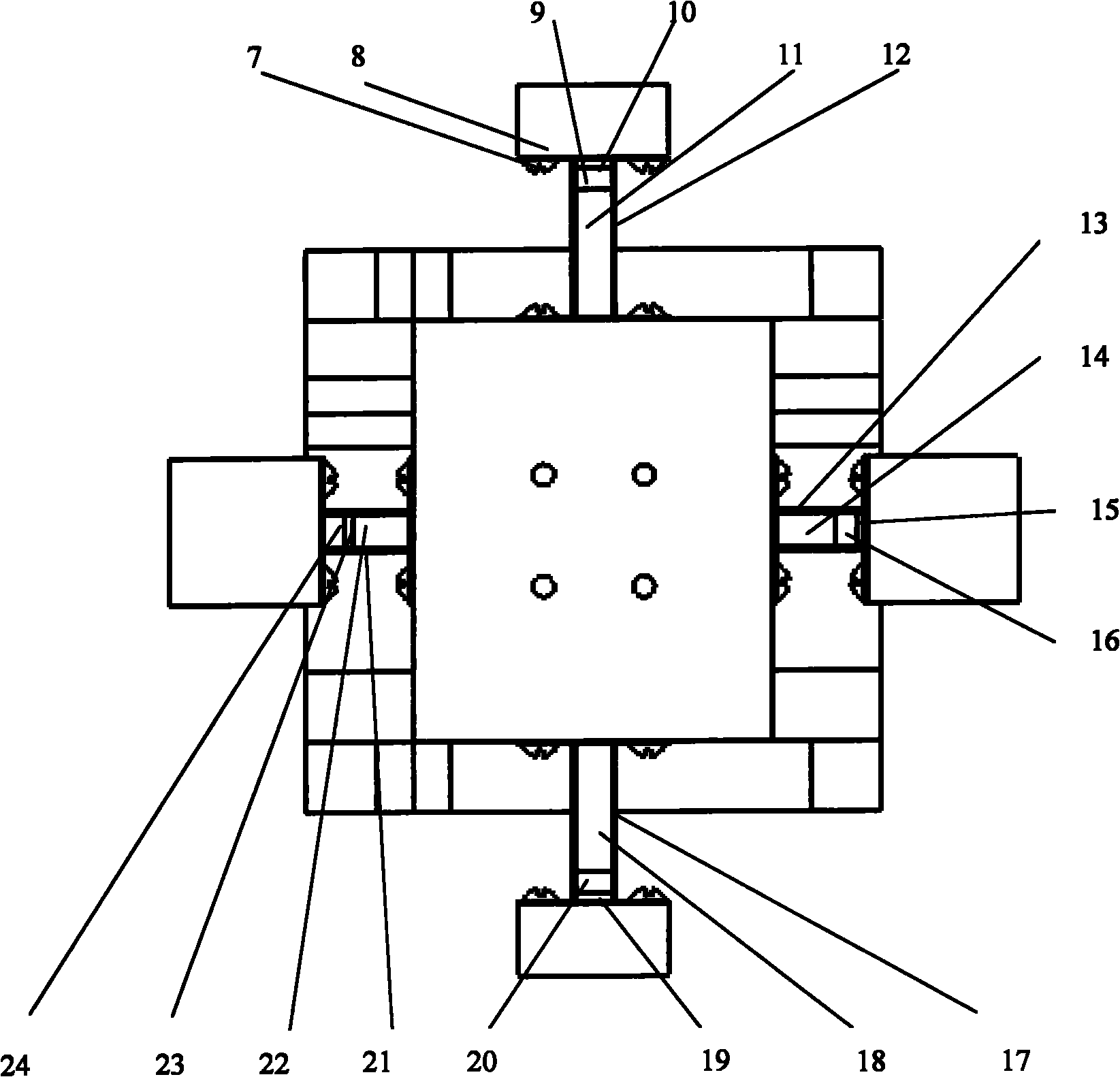

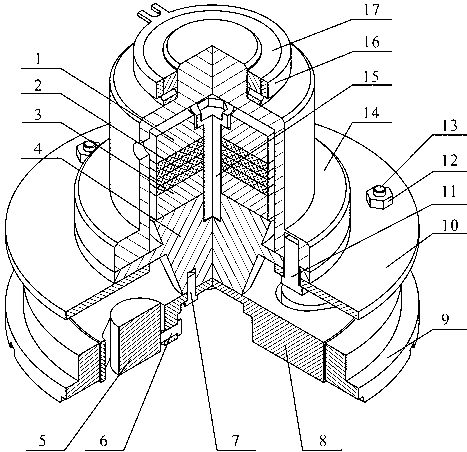

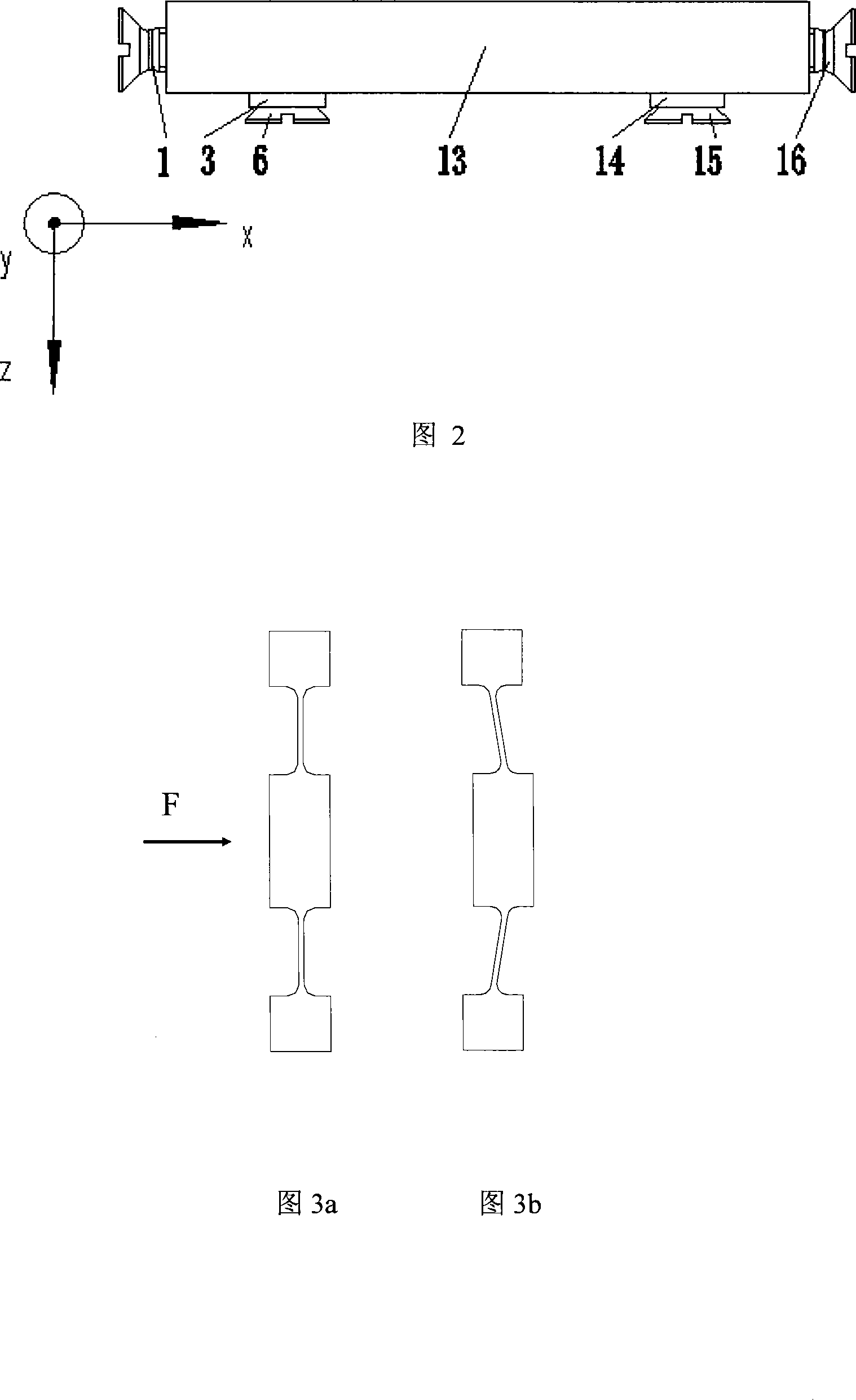

Test specimen fixture for ultrasonic vibration assisted grinding/polishing

ActiveCN103286682AAdjustable shape and sizeShape and Size OptimizationGrinding work supportsSmall amplitudeTransducer

The invention relates to a test specimen fixture for ultrasonic vibration assisted grinding / polishing, and belongs to the field of precision machining and ultra-precision machining. The test specimen fixture comprises an ultrasonic generator, a piezoelectric ceramic transducer, a conical amplitude-change pole, a workpiece clamping system and a trimming ring. Alternating current is converted into ultrasonic-frequency electric oscillation signals by the ultrasonic generator, and the ultrasonic-frequency electric oscillation signals are transmitted to the piezoelectric ceramic transducer by a collector ring. The ultrasonic-frequency electric oscillation signals are converted into ultrasonic-frequency mechanical vibration by the piezoelectric ceramic transducer. The small amplitude of the vibration outputted by the transducer is magnified by the conical amplitude-change pole, and the vibration with the magnified amplitude is transmitted to the workpiece clamping system, so that workpieces can ultrasonically vibrate in ultra-precision grinding / polishing procedures. The test specimen fixture has the advantages that the test specimen fixture is compact in structure, simple in operation and high in efficiency and applicability; the machining precision and the surface quality of each workpiece can be obviously improved; grinding / polishing conditions further can be improved, for example, cutting force and cutting heat can be reduced, and vibration can be eliminated or suppressed; the durability of a grinding disc and the durability of polishing cloth can be improved, and the like.

Owner:JILIN UNIV

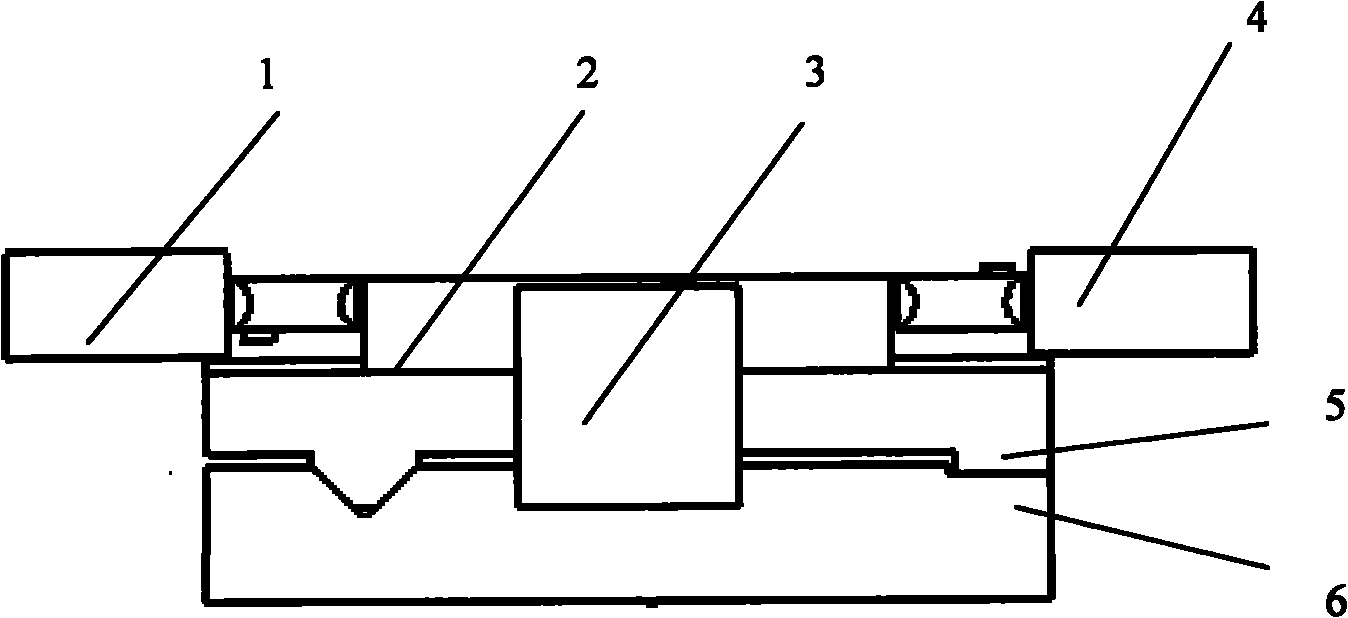

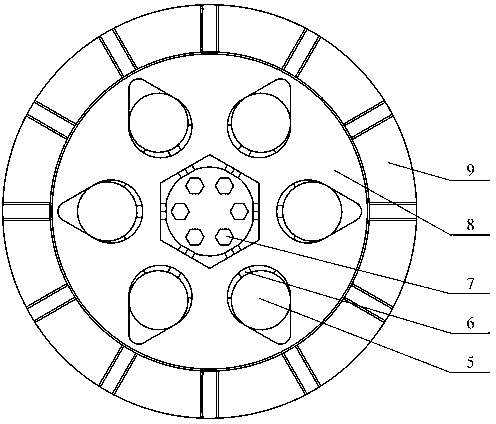

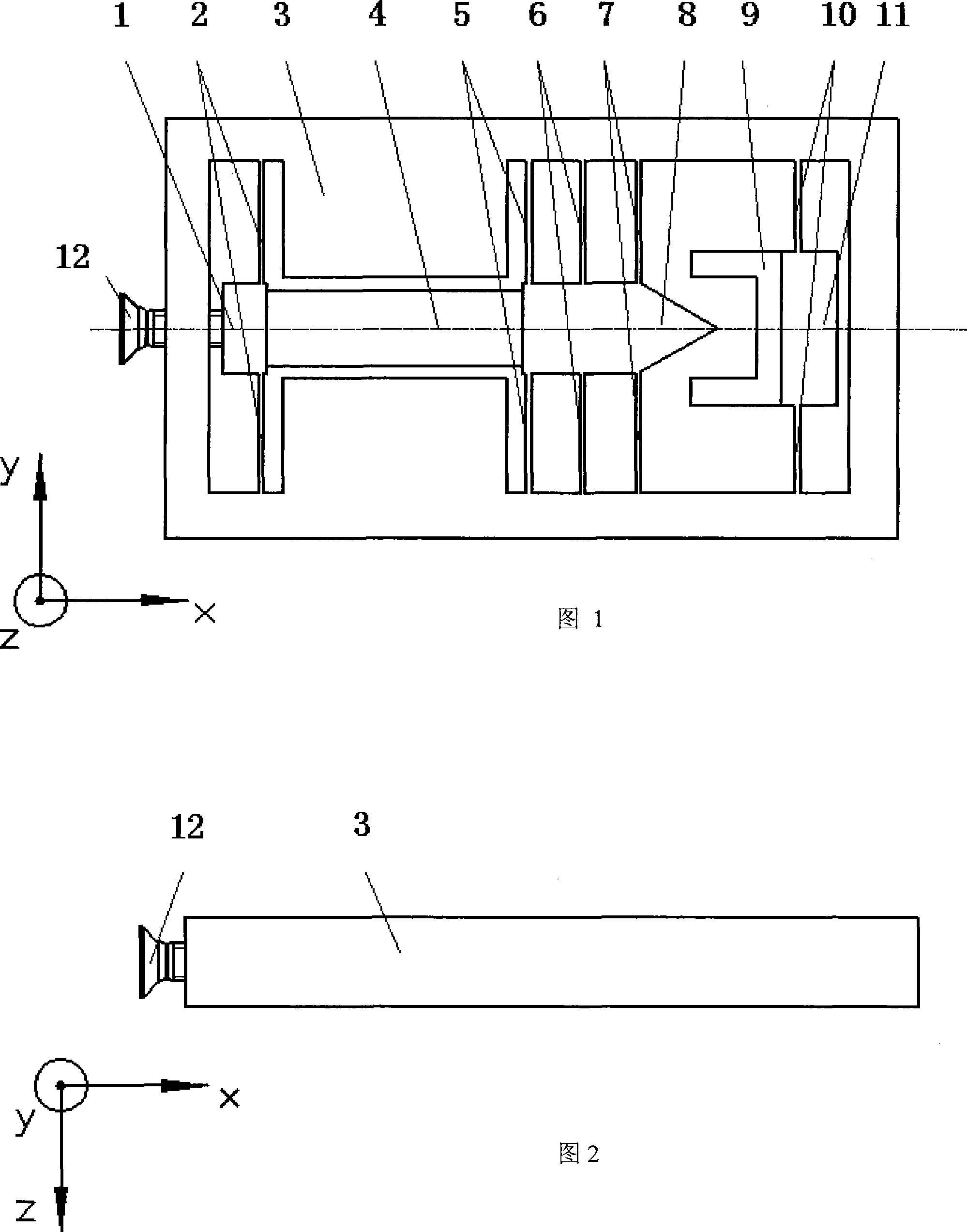

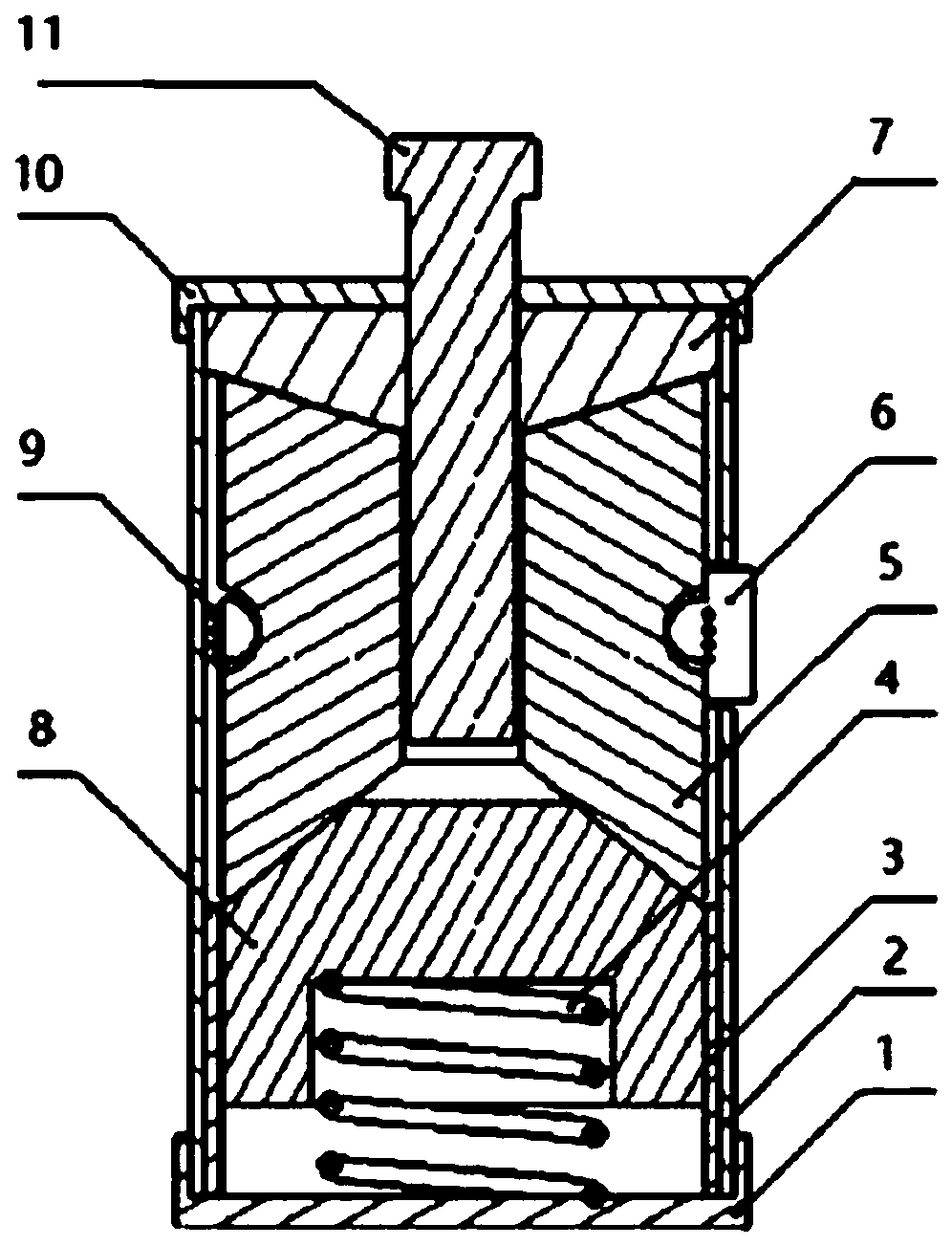

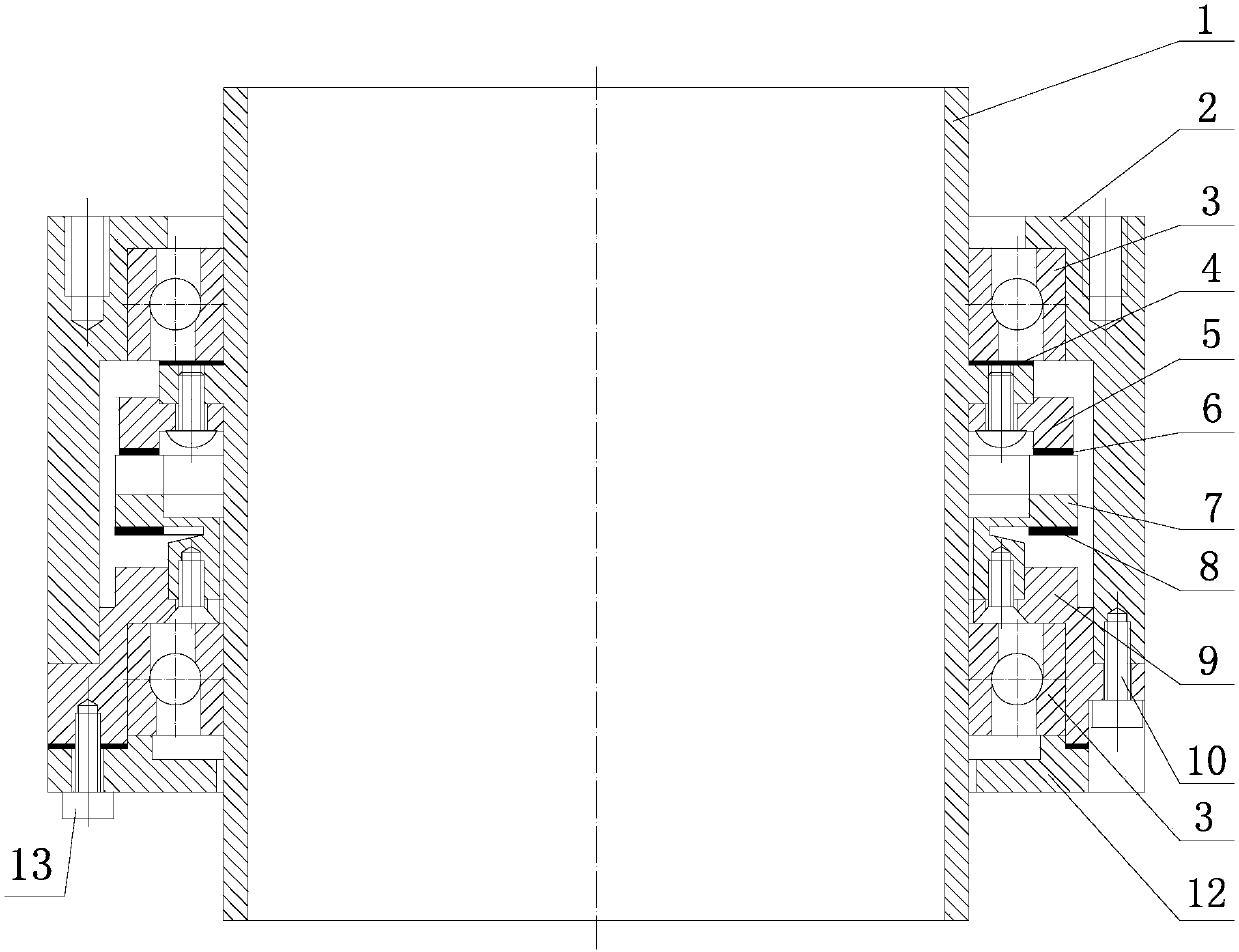

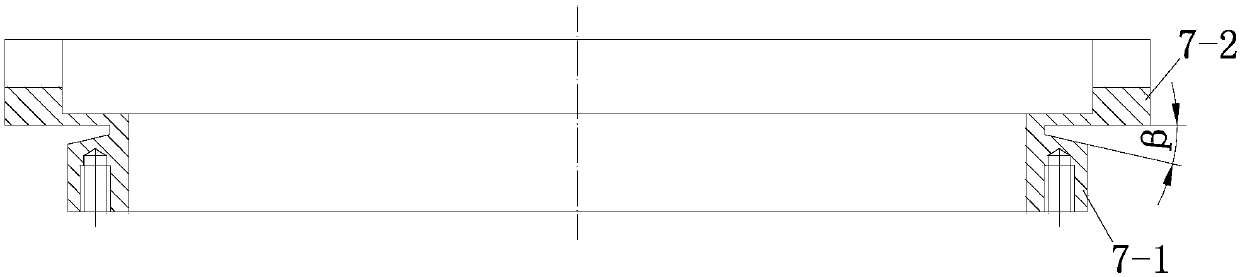

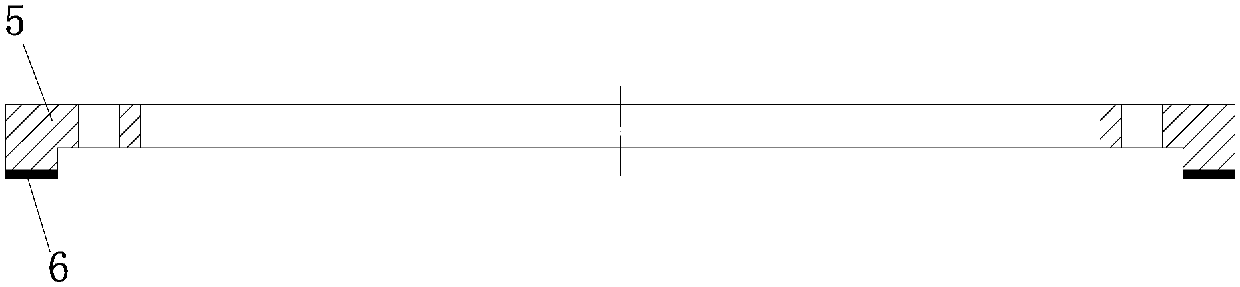

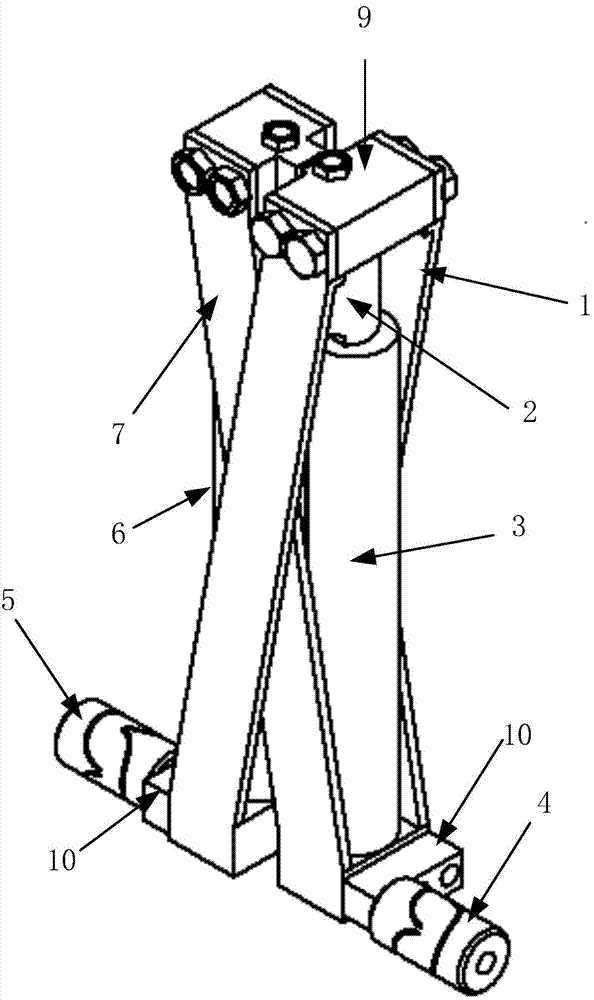

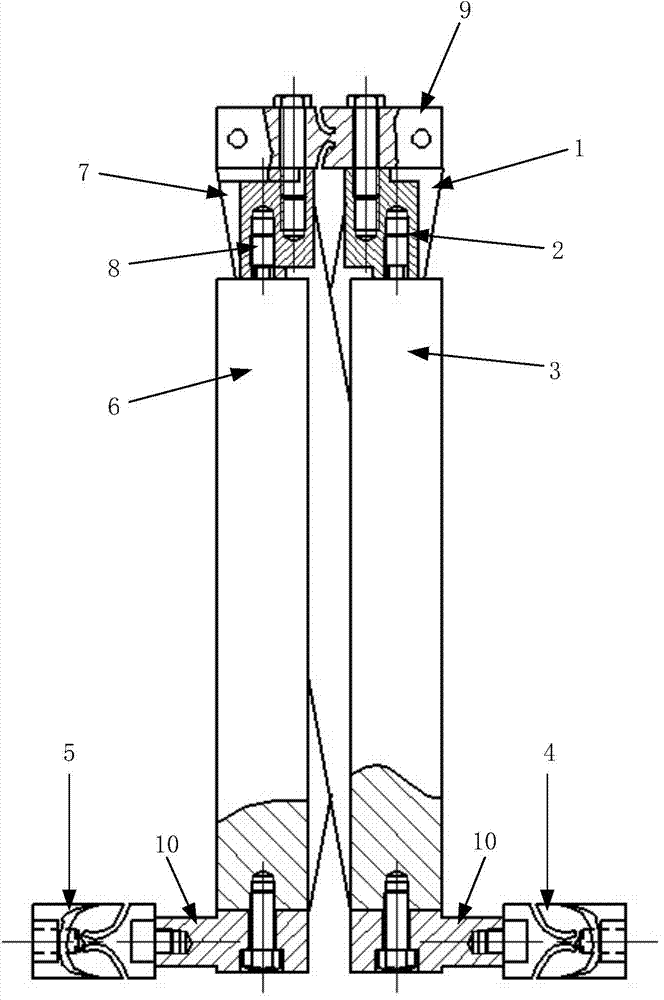

Micro drafting device for testing test piece material nano metric mechanical properties

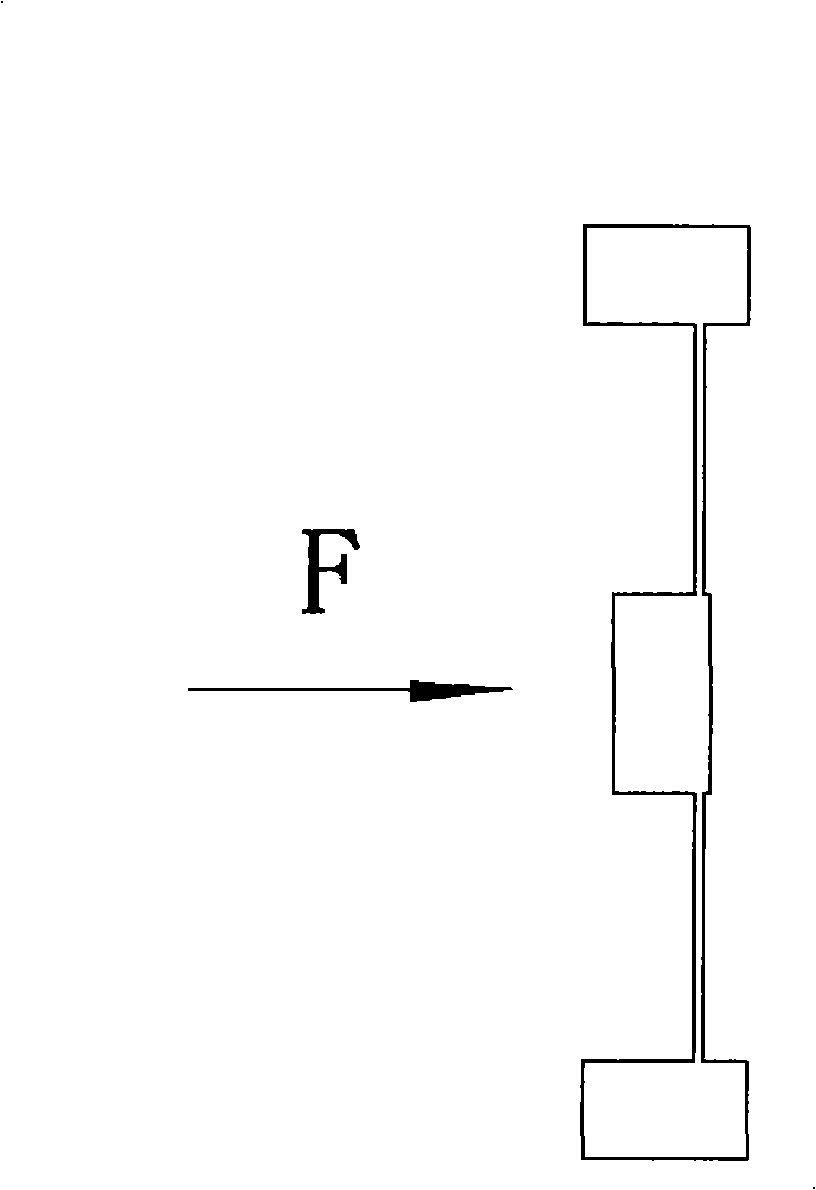

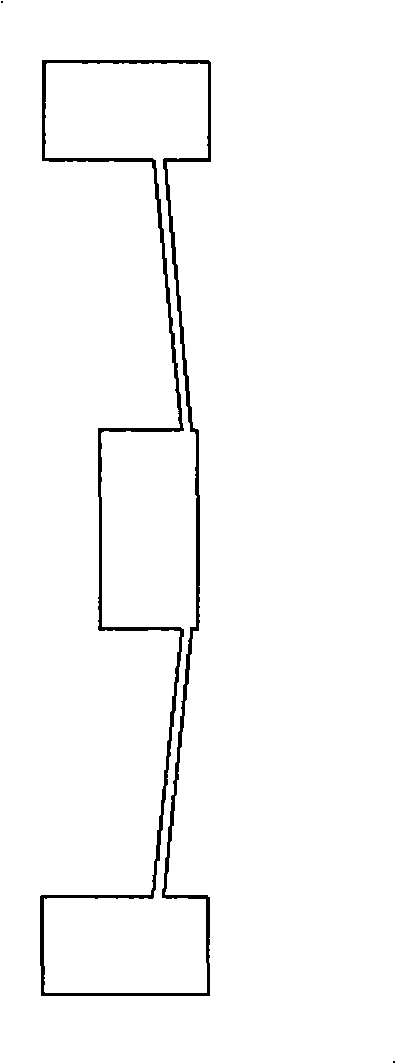

InactiveCN101226120AImprove driving precisionReduce complexityElectric discharge tubesSurface/boundary effectEngineeringTest fixture

The invention relates to a material nanometer mechanical property test device, in particular to a stretching device of material nanometer mechanical property test, for resolving the problems of traditional micro load device at driving and positioning fields, as complex structure, low positioning accuracy and high cost. The invention is mainly composed of bases, flexible hinges, a drive unit and preloading devices, which is characterized in that one base (9) is connected with another base (13) via a plurality of flexible hinges (2, 4, 8), the preloading devices are mounted at two ends of the drive unit (10), one preloading device comprises a screw (1) connected with one end of the base (9), an objective table (5) connected with the base (9) via a flexible hinge (7), another preloading device comprises a screw connected with one end of the base (13) and one objective table (11) connected with the base (13) via a flexible hinge (12).

Owner:长春邦大精密技术有限公司

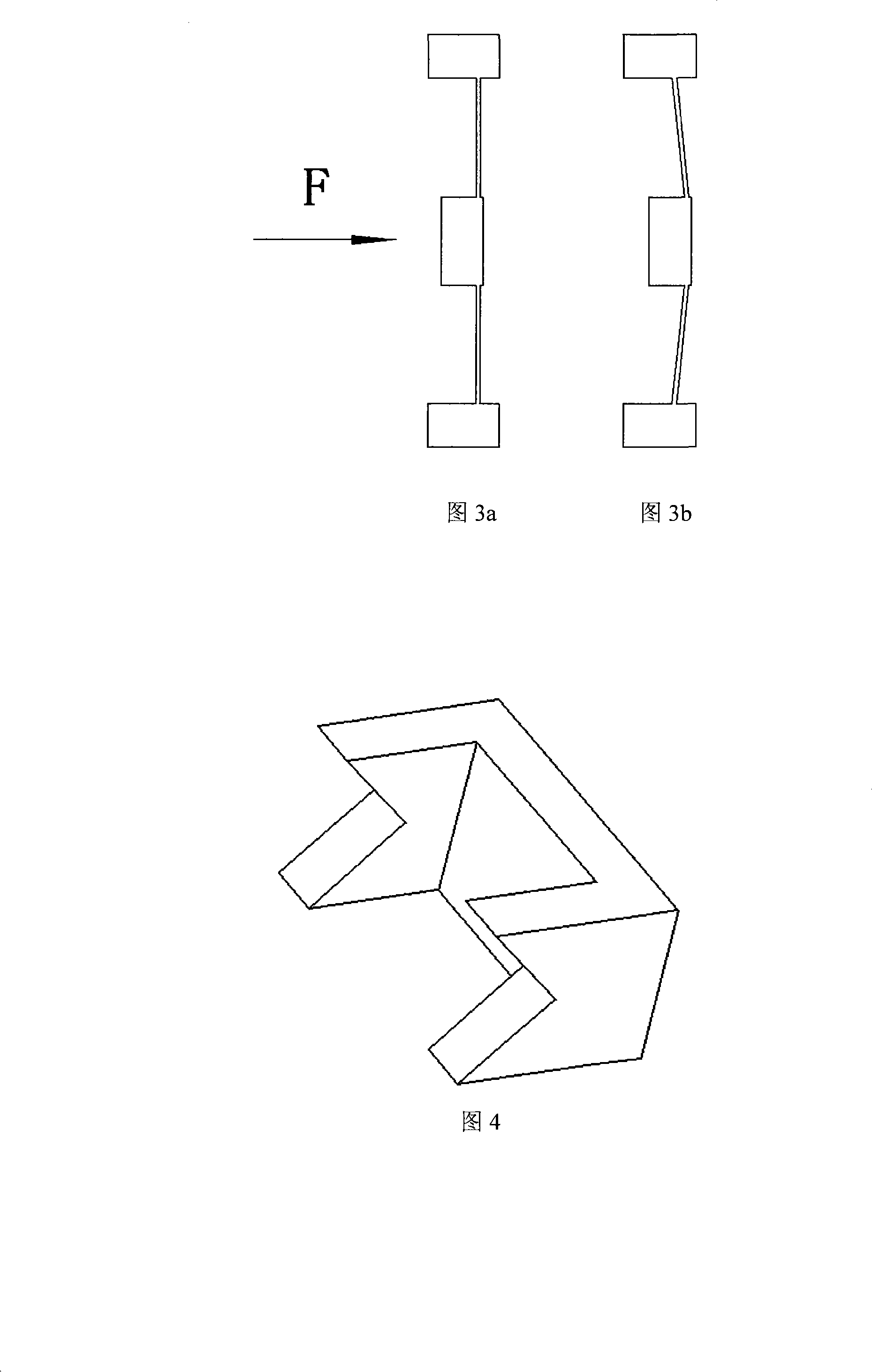

Precision charger for material nano metric bending mechanical properties test

InactiveCN101226121AImprove driving precisionHigh resolutionMaterial strength using steady bending forcesImage resolutionEngineering

The invention relates to a material property test device, in particular to a precise loading device of material nanometer bending mechanical property test, belonging to ultra-precision machining technical field, for improving the drive precision and resolution of loading device, to accurately test loading force and reduce structural complexity and size. The invention is mainly composed of a base, a pressure head, a drive unit and an objective table, wherein the pressure head (8) is connected with the base (3) via a plurality of thin flexible hinges (5, 6, 7), one end of the base (3) via a flexible hinge (2) is connected with a rigid body (1), another end of the base (3) via a flexible hinge (10) is connected with another rigid body (11), the drive unit (4) uses a piezoelectric stack, which is mounted between the pressure head (8) and a preloading device, and the objective table (9) is fixed on the rigid body (11).

Owner:长春邦大精密技术有限公司

A spatial radial unlocking mechanism driven by a shape memory alloy SMA tow

ActiveCN109131951AGuaranteed synchronicityImprove unlocking precisionCosmonautic vehiclesCosmonautic component separationFixed frameShape-memory alloy

The invention provides a spatial radial unlocking mechanism driven by a shape memory alloy SMA tow, a base is fixed on the bottom of the outer cover of the mechanism and an upper cover is installed onthe top, the bolt is inserted through the through hole of the upper cover and is located above the top block, a locate block and two split nuts are sleeve on that outer periphery of the bolt, the outer periphery of the two split nut is provided with a groove, a rigid clamp is arranged in the groove of the two split nuts and an H-shaped fixing frame is arranged at the closed end of the two split nuts, and an SMA shape memory alloy wire bundle is wrapped around the outer periphery of the rigid clamp and fixed on the fixing frame. The invention solves the problem that the impact of the spatial radial unlocking mechanism in the prior art is large, a spatial radial unlocking mechanism driven by shape memory alloy SMA tow is provided, which adopts the radial driving mode of shape memory alloy SMA tow, and has the advantages of low impact, large driving displacement, high driving accuracy, short unlocking time, high moving accuracy, low friction and no pollution.

Owner:HARBIN INST OF TECH

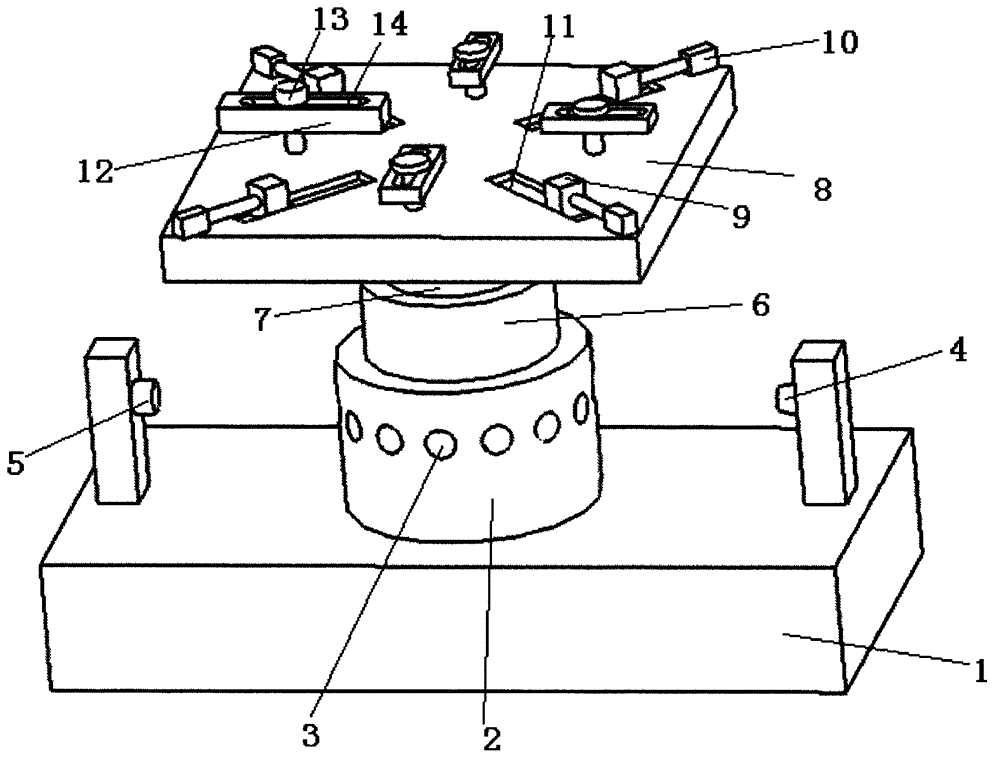

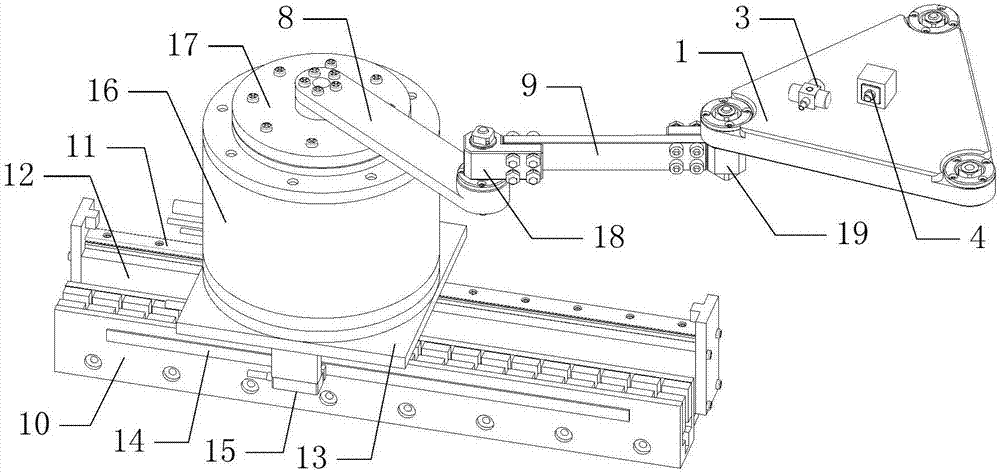

Supporting rotating table for mechanical machining of thin-wall workpiece

ActiveCN104985466AHigh precision driveImprove driving precisionPositioning apparatusMetal-working holdersThin walledEngineering

The invention provides a supporting rotating table for mechanical machining of a thin-wall workpiece. A rotating table is rotatably arranged on a base, and is driven by a motor arranged in the rotating table to rotate; a plurality of through holes are evenly arranged on the side wall of the rotating table in an array manner; a light emitter is arranged at one end of the base, and a light receiver is arranged at the other end of the base; the straight line between the light emitter and the light receiver right just penetrates the radial circle centre of the rotating table so that the light receiver can receive light which is emitted by the light emitter and passes through the through holes; and the light receiver is connected with the motor inside the rotating table, and is used for controlling starting and stopping of the motor. Through the supporting rotating table, the light emitted by the light emitter penetrates the through holes, so that the light receiver controls and drives starting and stopping of the motor of the rotating table according to the magnitude of the received light, and the driving precision of the angle can be greatly improved; and the pressure magnitude of top plates can be ensured well, and the phenomena of workpiece damage or unreliable clamping caused by too large or too small top pressing pressure are avoided.

Owner:ANHUI SCI & TECH UNIV

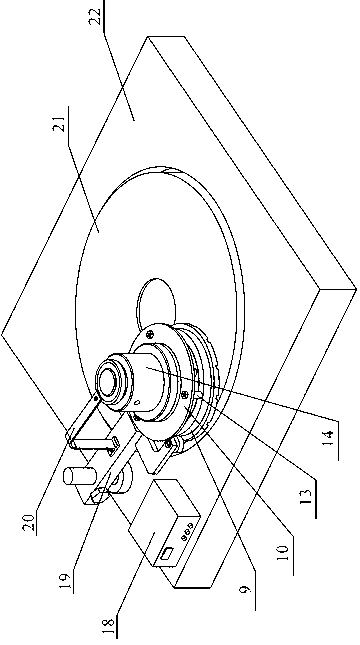

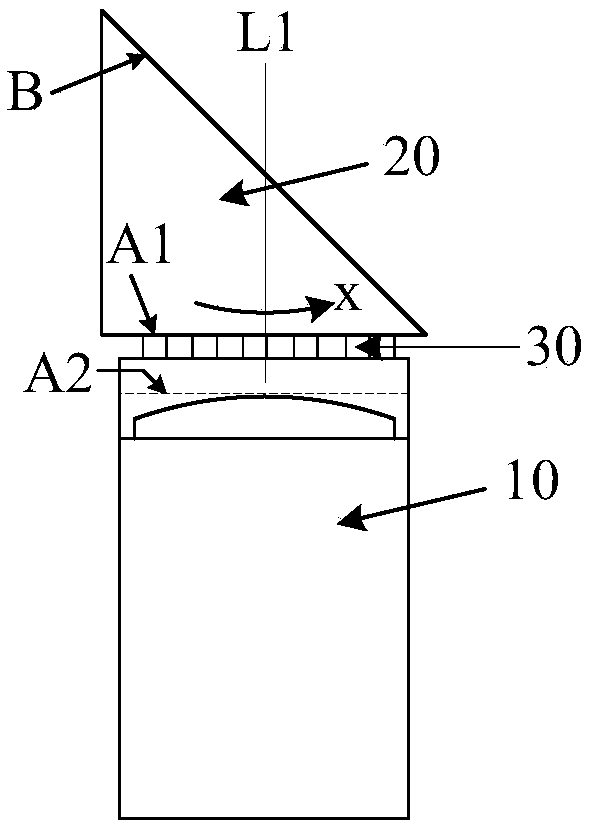

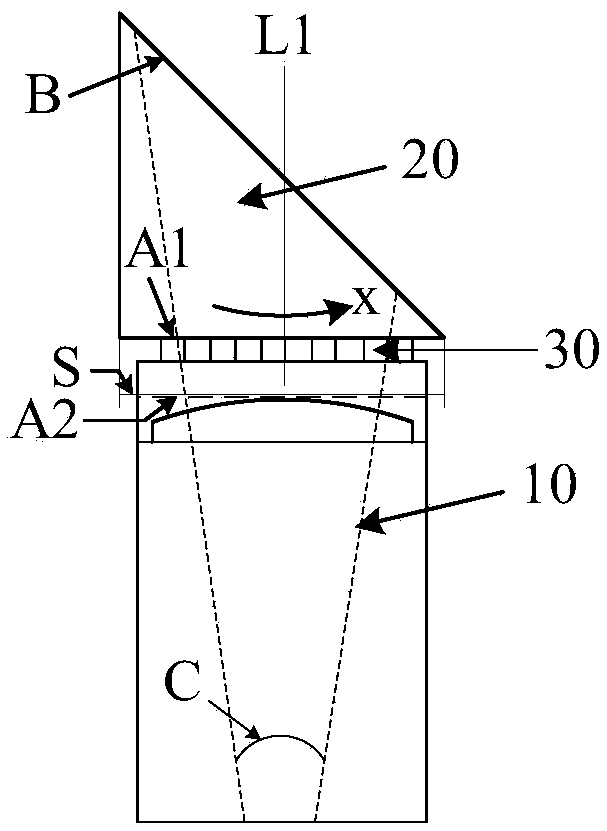

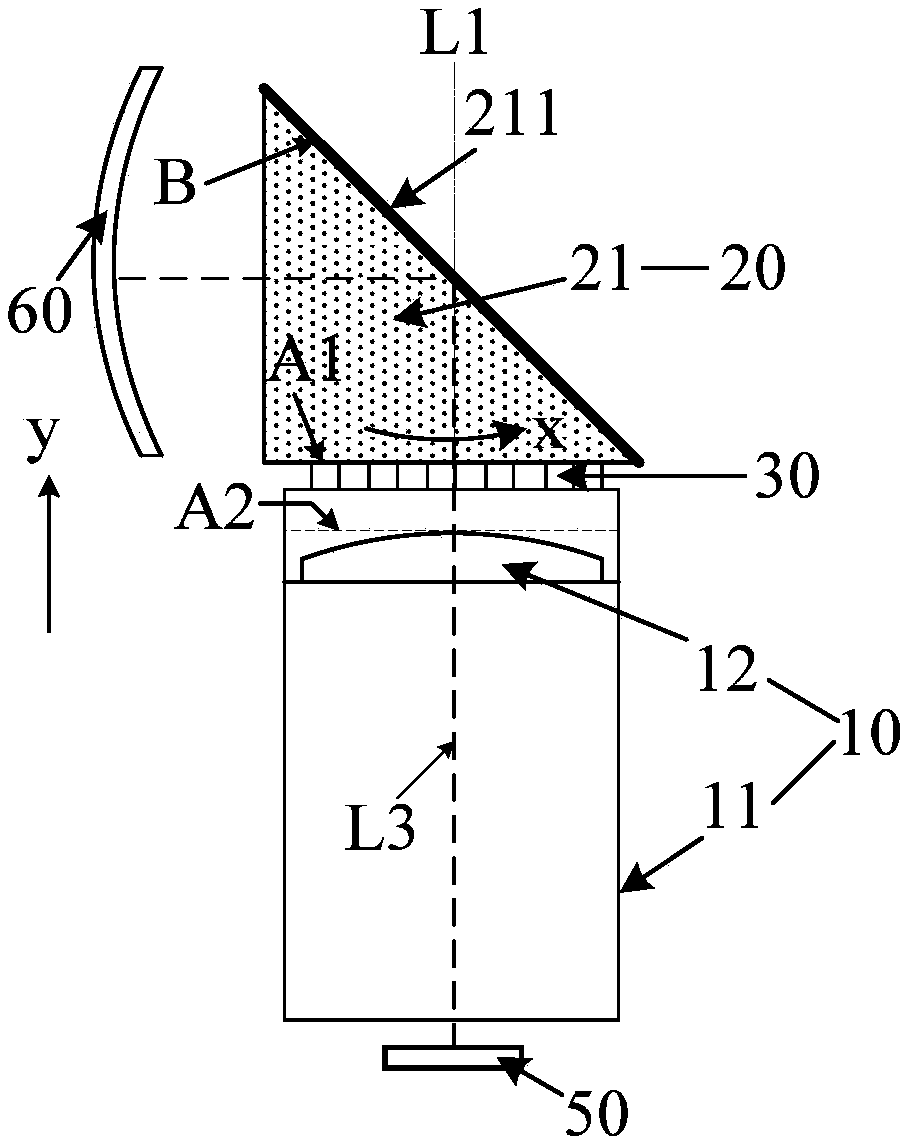

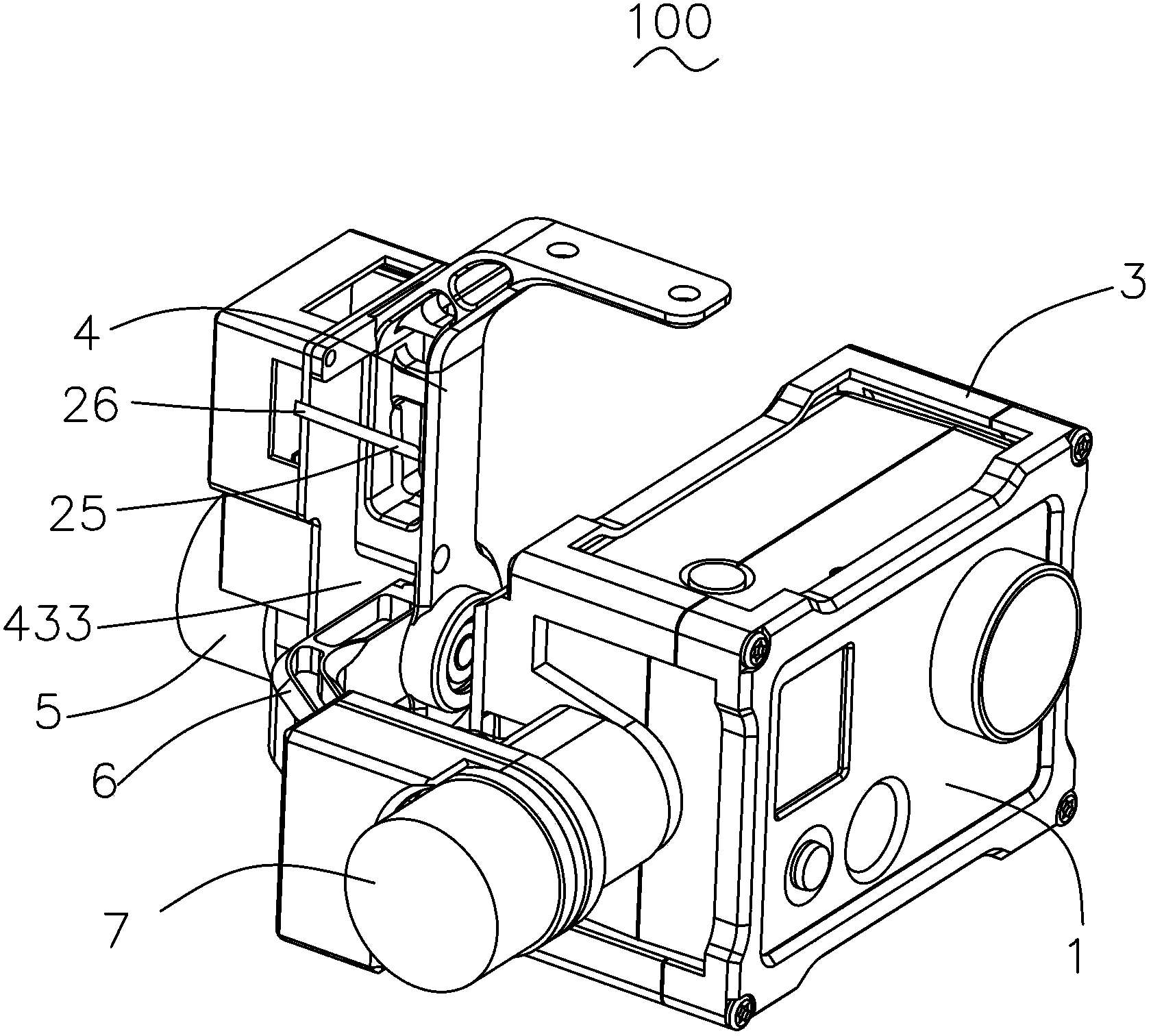

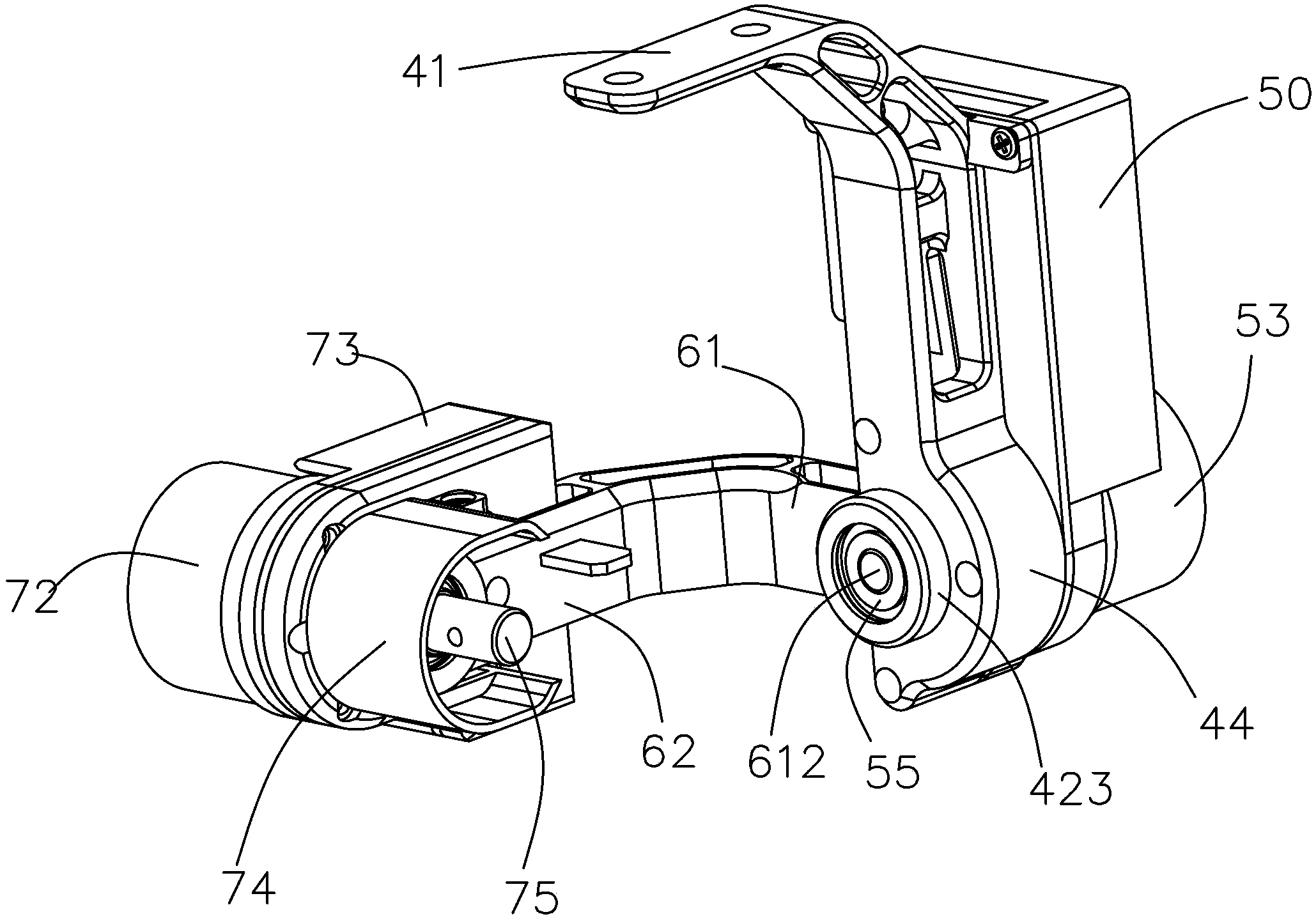

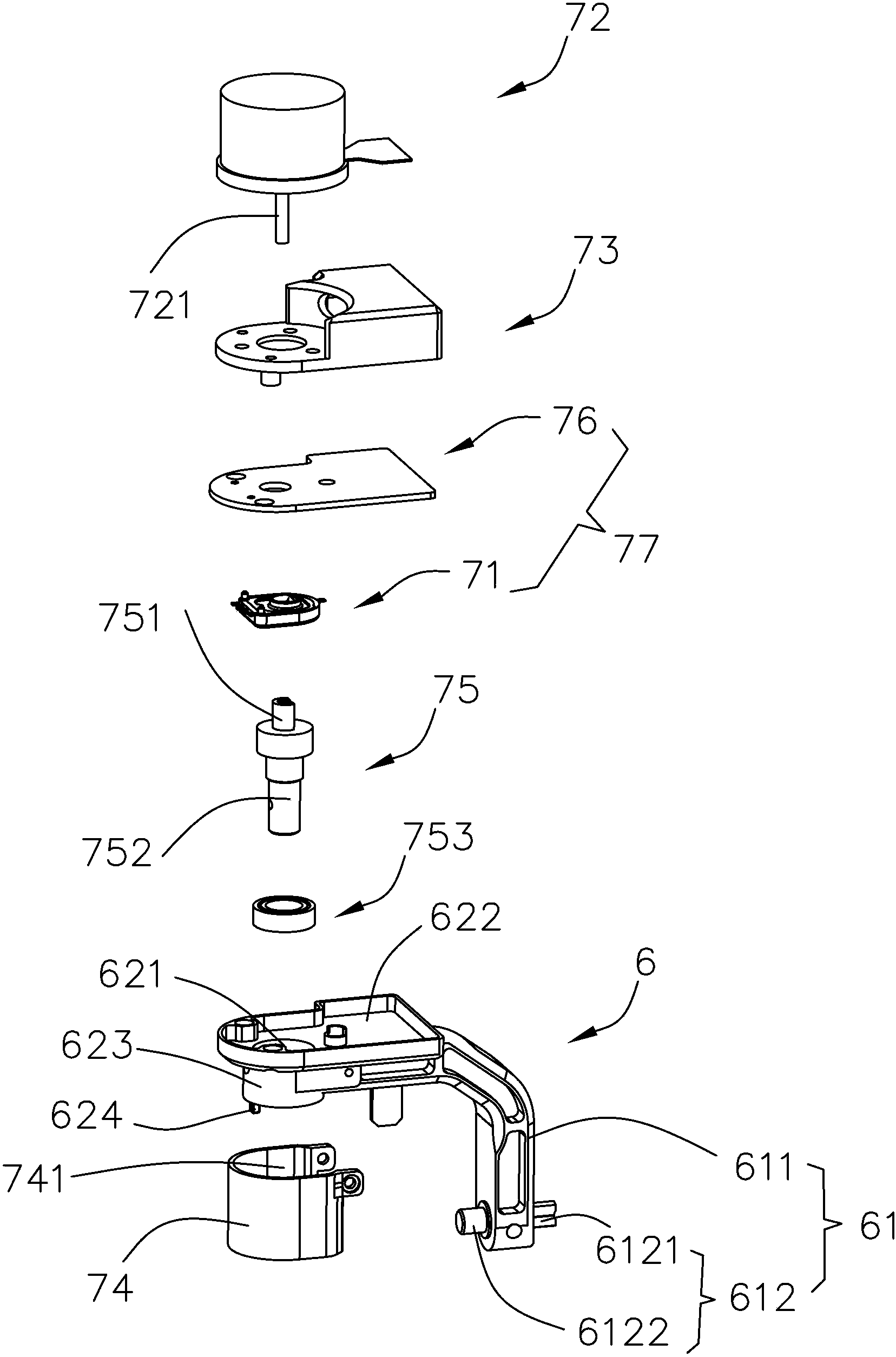

Detail camera and panoramic detail camera

InactiveCN109089019AReduce drive massImprove driving precisionTelevision system detailsColor television detailsVideo cameraSecurity monitoring

The invention discloses a detail camera and a panoramic detail camera, and belongs to the field of security monitoring. The detail camera includes a lens and a first reflection assembly and a rotationassembly arranged at the front end of the lens. The rotation assembly and the first reflection assembly are fixedly connected to each other. The rotation assembly is used for driving the first reflection assembly to rotate around a first axis. The first reflection assembly is used for reflecting light into the lens. The first axis is perpendicular to a light incident surface of the lens. According to the invention, the rotation assembly is used to drive the first reflection assembly to rotate, and so the driving quality of the rotation assembly is reduced, thereby improving the driving precision thereby effectively improving the reliability of the panoramic detail camera. The detail camera is used in the panoramic detail camera.

Owner:HANGZHOU HIKVISION DIGITAL TECH

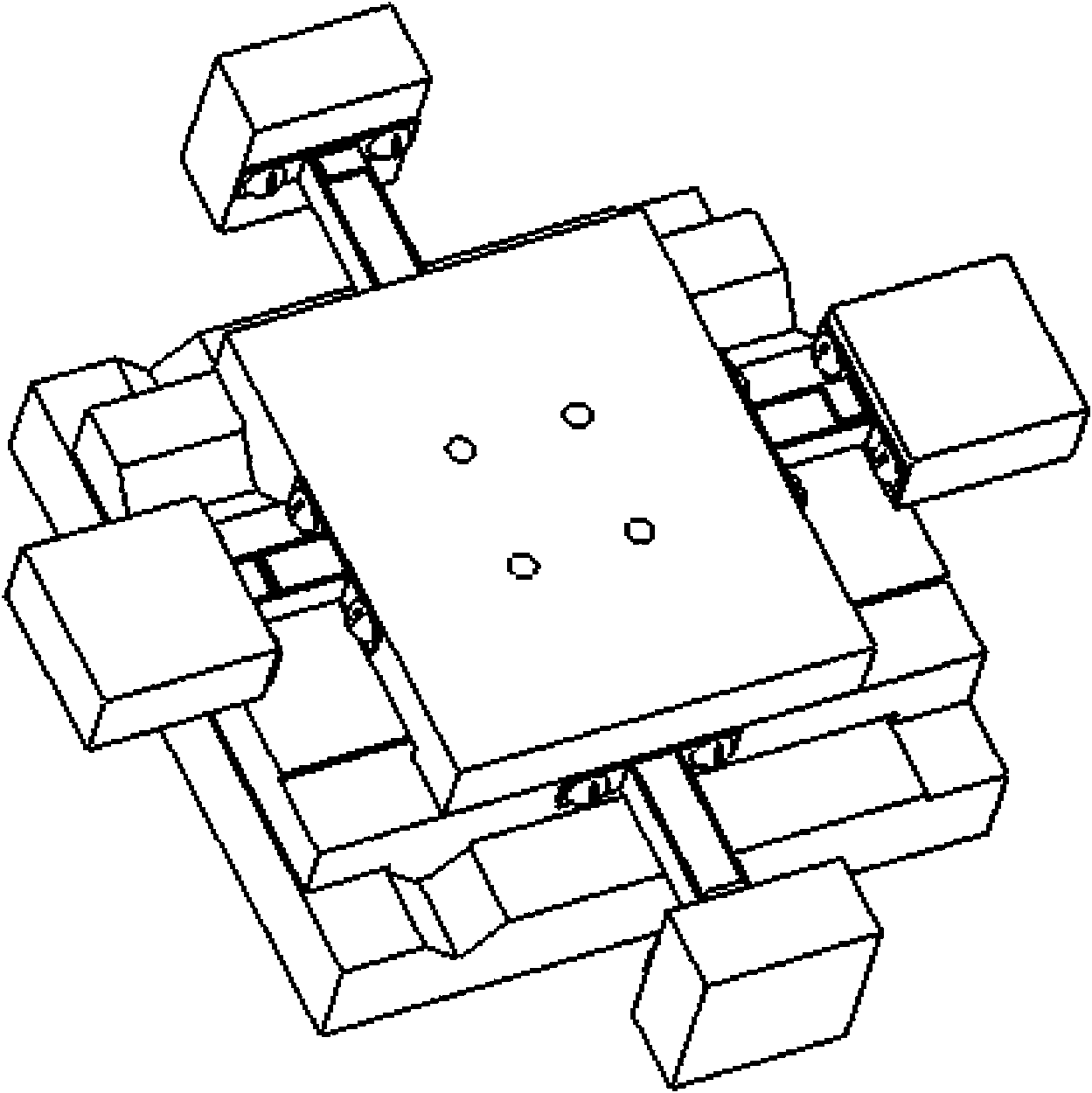

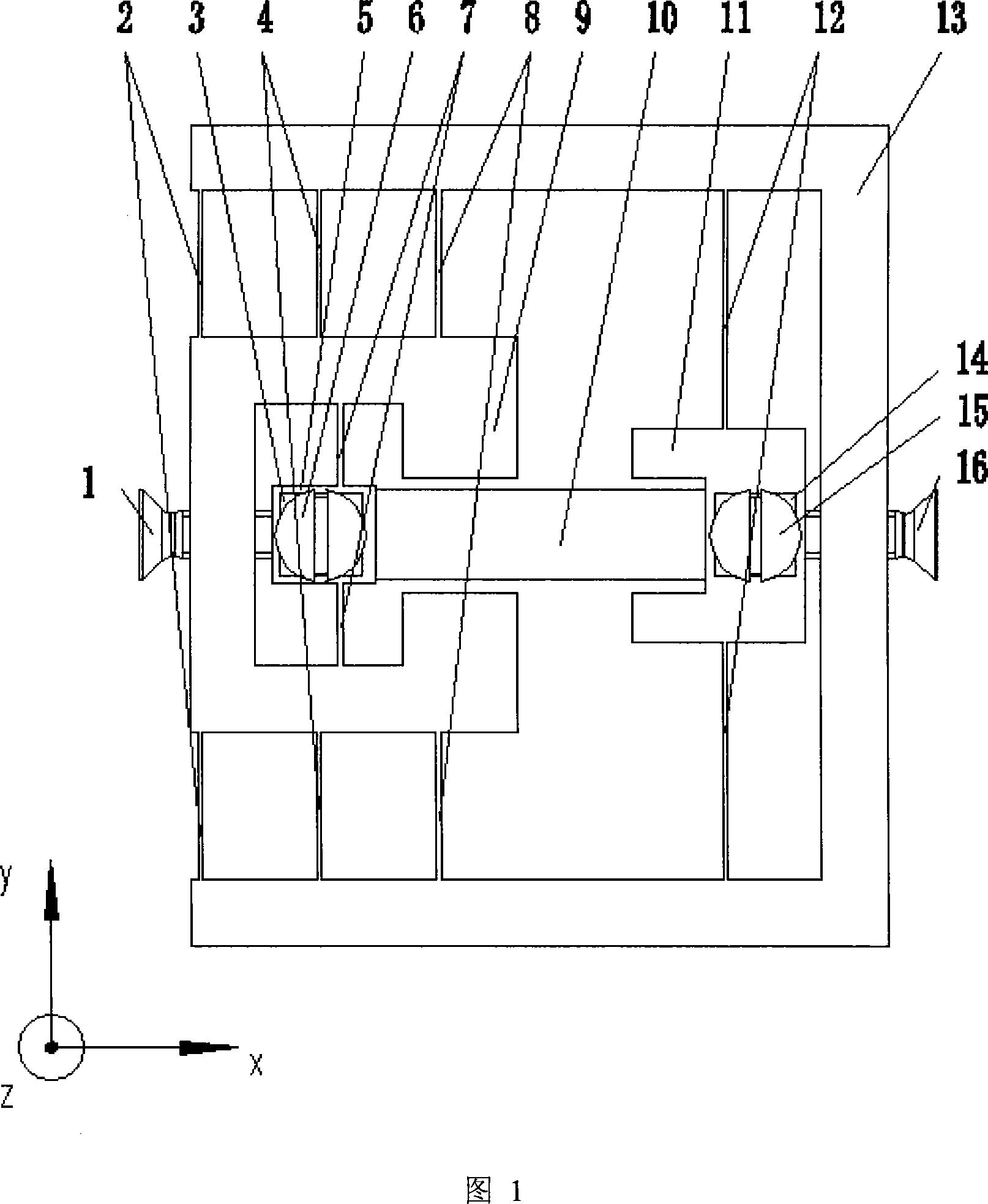

Material nanometer dynamic performance test two freedom degree loading unit

InactiveCN101261206AImprove driving precisionReduce complexityElectric discharge tubesSurface/boundary effectElectricityEngineering

The invention relates to a device used for testing material nanometer scale performance, particularly to a micro-loading device used for testing material nanometer scale mechanical performance. The device consists essentially of a base, an x axial direction motion mechanism, a pressure head, a driving component and a preloading mechanism, wherein, the pressure head is connected to the x axial direction motion mechanism by a plurality of flexible hinges which have thin walls; the x axial direction motion mechanism is connected to a rigid base by a plurality of flexible hinges which have thin walls; the driving component consists of piezoelectric stacks, one of the piezoelectric stack is wholly arranged between an x axial direction preloading mechanism and the x axial direction motion mechanism while the other piezoelectric stack is wholly arranged between the pressure head and the pressure head preloading mechanism, a rigid body used for holding the tested material is arranged at the lower part of the pressure head, and the rigid body is connected to the rigid base by the flexible hinge that is connected with the rigid body. In order to solve the problems that the loading force can not be tested by the prior art, or the testing accuracy is not high, the system structure is complicated and the cost is high, etc., the device of the invention has the advantages of simple and compact structure and low cost, etc.

Owner:JILIN UNIV

Flying probe tester

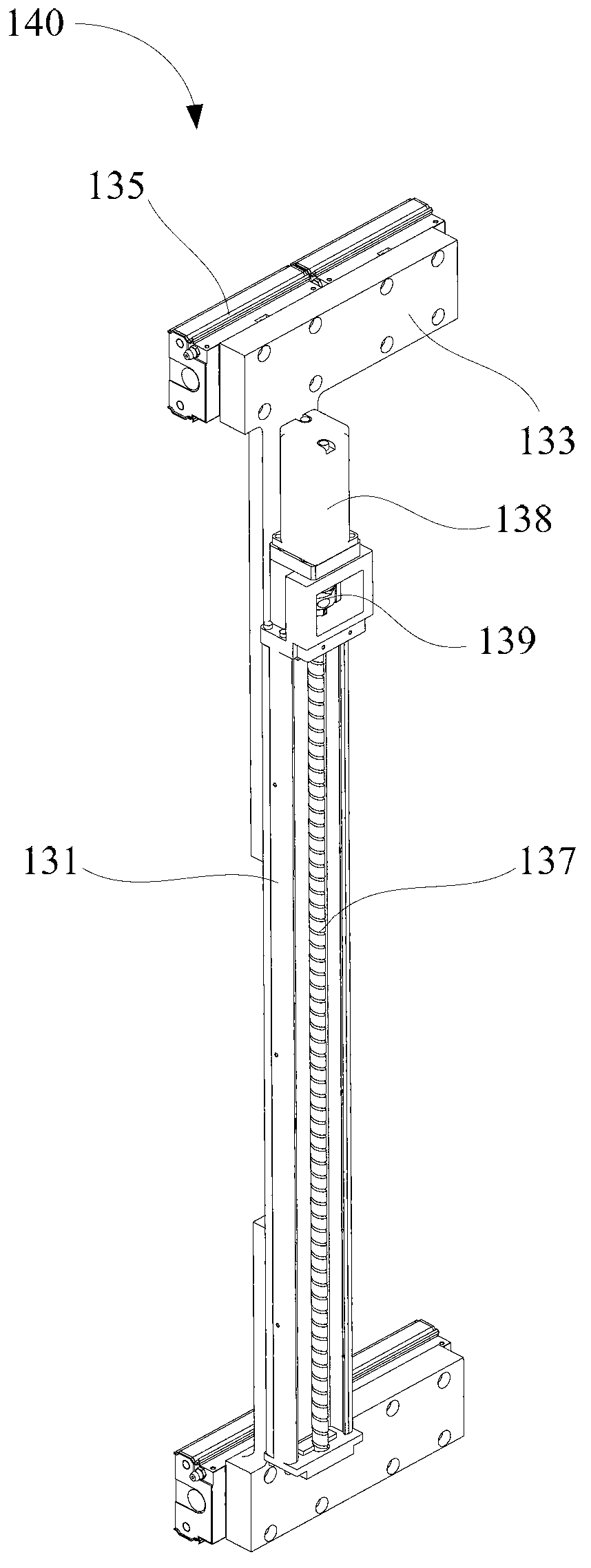

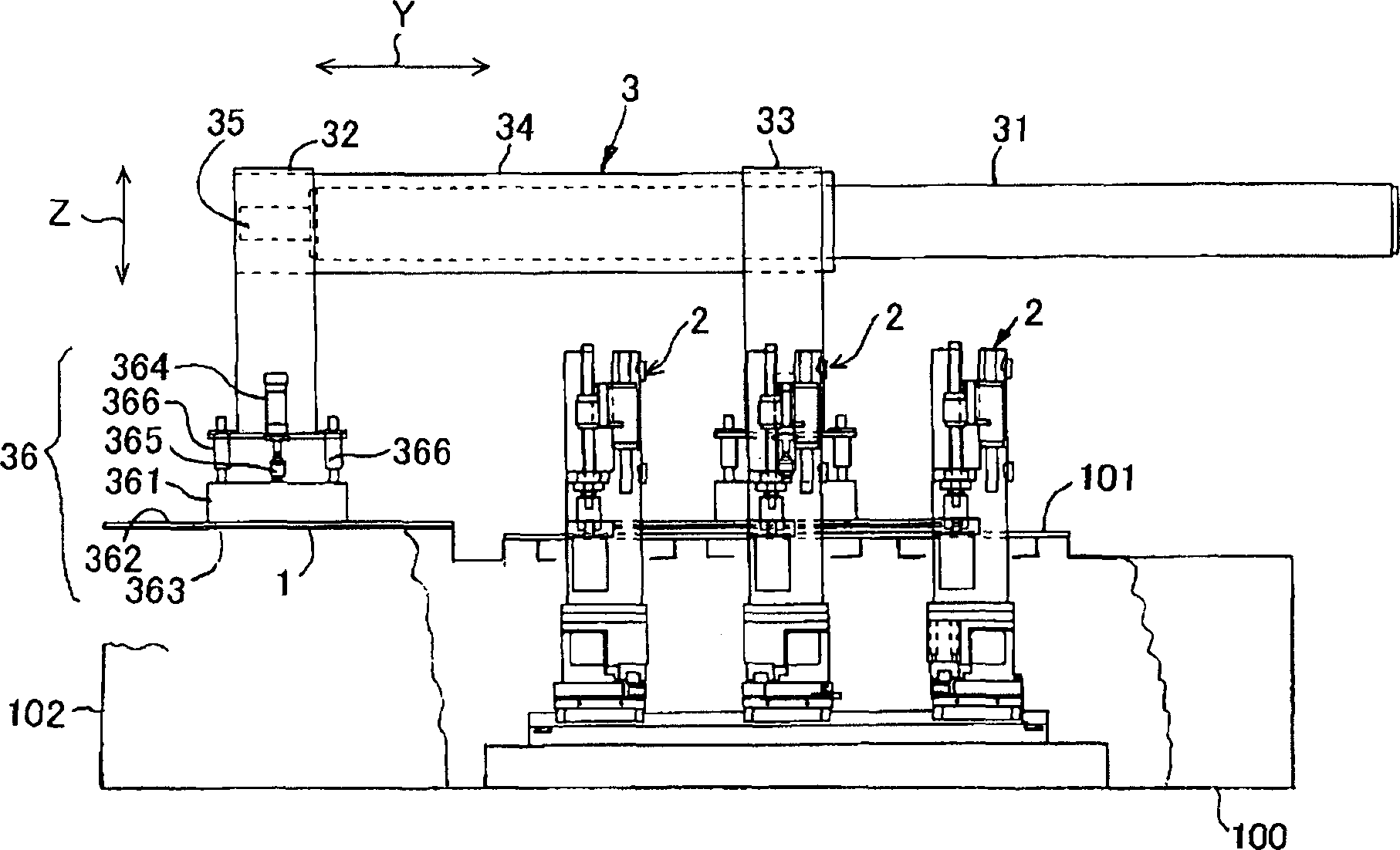

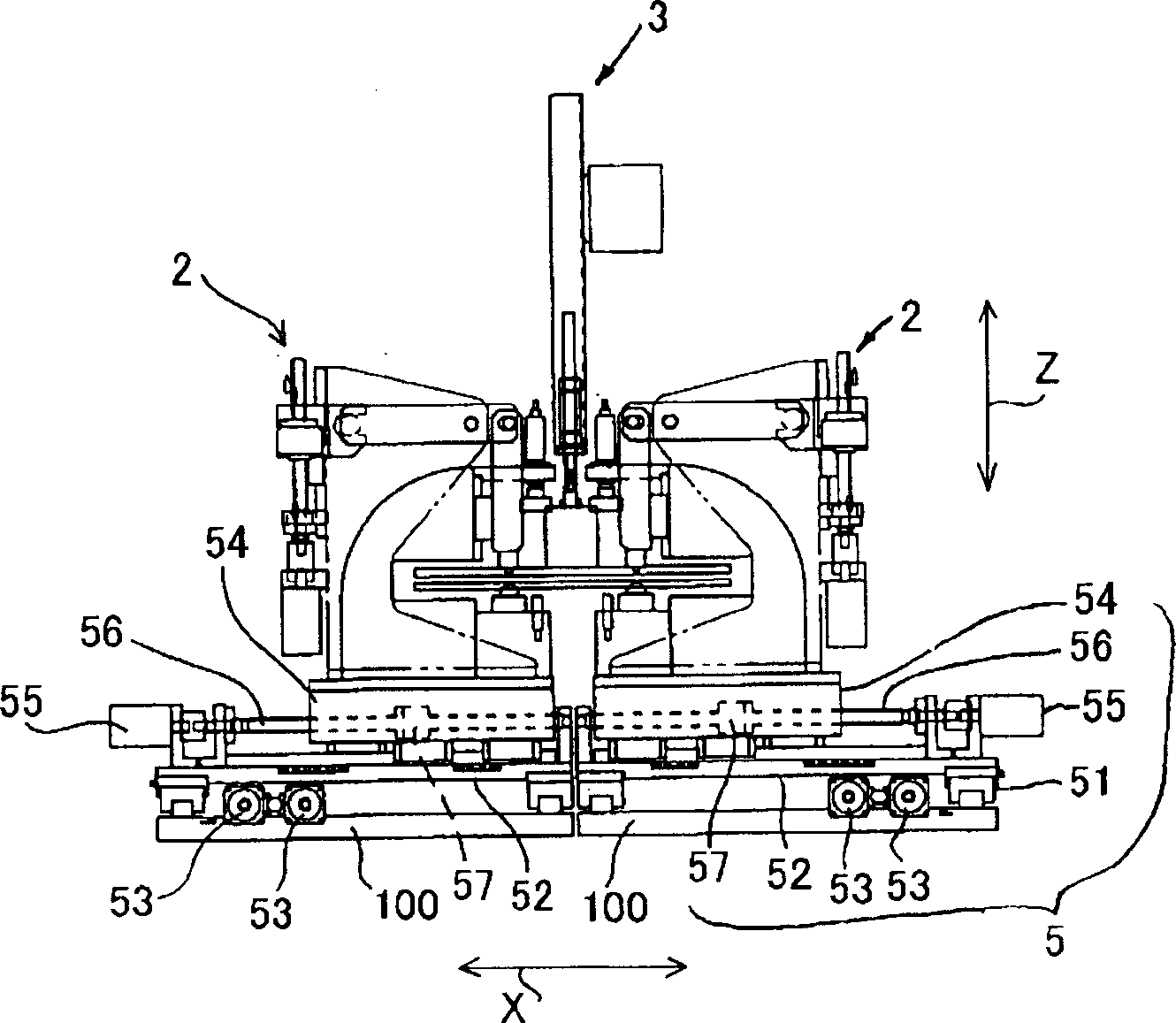

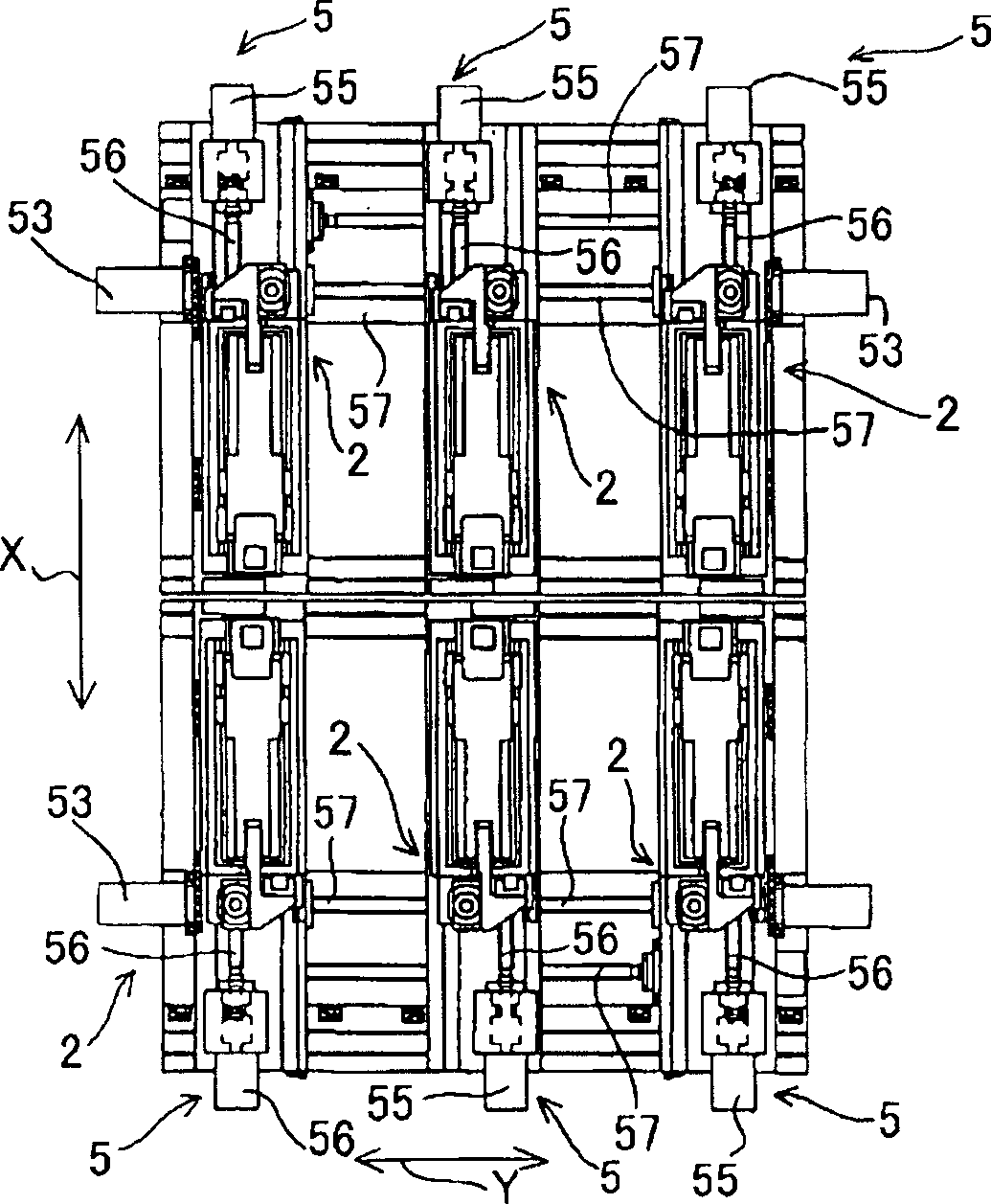

ActiveCN103176121AHigh movement precisionImprove driving precisionElectronic circuit testingDrive shaftEngineering

A flying probe tester comprises a substrate, two parallel X-axes, two Y-axes and two Z-axes. Each X-axis comprises a first guide rail, two first motors and two first screw, the two first screws are parallel with the first guide rail, the two first motors are located at one ends, which are relatively distant, of the two first screws, and a drive shaft of each first motor is coaxially connected with the corresponding first screw. Each Y-axis comprises a second guide rail, two connecting plates and two first slider, two ends of the second guide rail are fixedly connected with the two connecting plates respectively, the two first sliders are fixed on two surfaces, opposite to the second guide rail, of the two connecting plates respectively, the first sliders can slide along the first guide rail, and the first screws penetrate through the first sliders. The two Z-axes are disposed on the two Y-axes. One first slider, close to the corresponding first motor, of each Y-axis is provided with a screw hole connected with the corresponding screw in a threaded manner, and the other first slider is provided with a guide hole allowing for penetration of the corresponding screw. The flying probe tester is low in cost and high in motion precision.

Owner:HANS CNC SCI & TECH

Perforating device

InactiveCN1526523AAvoid edge saggingAvoid breakingPrinted circuit manufactureMetal working apparatusEngineeringMechanical engineering

A punch 22 is driven by a servo-motor 231 and a feed screw 232 or the like rotated and driven by the servo-motor. A stand-by position of the punch 22 before boring and a driving speed are made variable by a control of the servo-motor 231. Thereby, a movement stroke of the punch 22 is made minimum and a boring processing time can be shortened. It can be avoided that irregularity, burr, crack or peeling off is generated on the processing hole by an appropriate driving speed of the punch.

Owner:SEIKO PRECISION CO LTD

Drive device, carrier with drive device and control method of carrier

ActiveCN104076825AImprove driving precisionShort response timeControl using feedbackDrive motorElectrical and Electronics engineering

The invention discloses a drive device which comprises a first drive motor, a first drive module electrically connected with the first drive motor and a first potentiometer. The first drive motor comprises a first stator, a first rotor rotating relative to the first stator and a first rotating shaft connected with the first rotor. The first drive module comprises a first driver driving the first drive motor. The first potentiometer is arranged on the first rotating shaft of the first drive motor in a sleeved mode, the first potentiometer is used for measuring the position relation of the first rotor relative to the first stator to generate a first position signal and feeds the first position signal back to the first driver of the first drive module, and the first driver sends out a first drive signal according to the first position signal, wherein the first drive signal is used for driving the first drive motor. The drive device is high in drive precision and short in response time. The invention further provides a carrier with the drive device, and a control method of the carrier.

Owner:SZ DJI TECH CO LTD

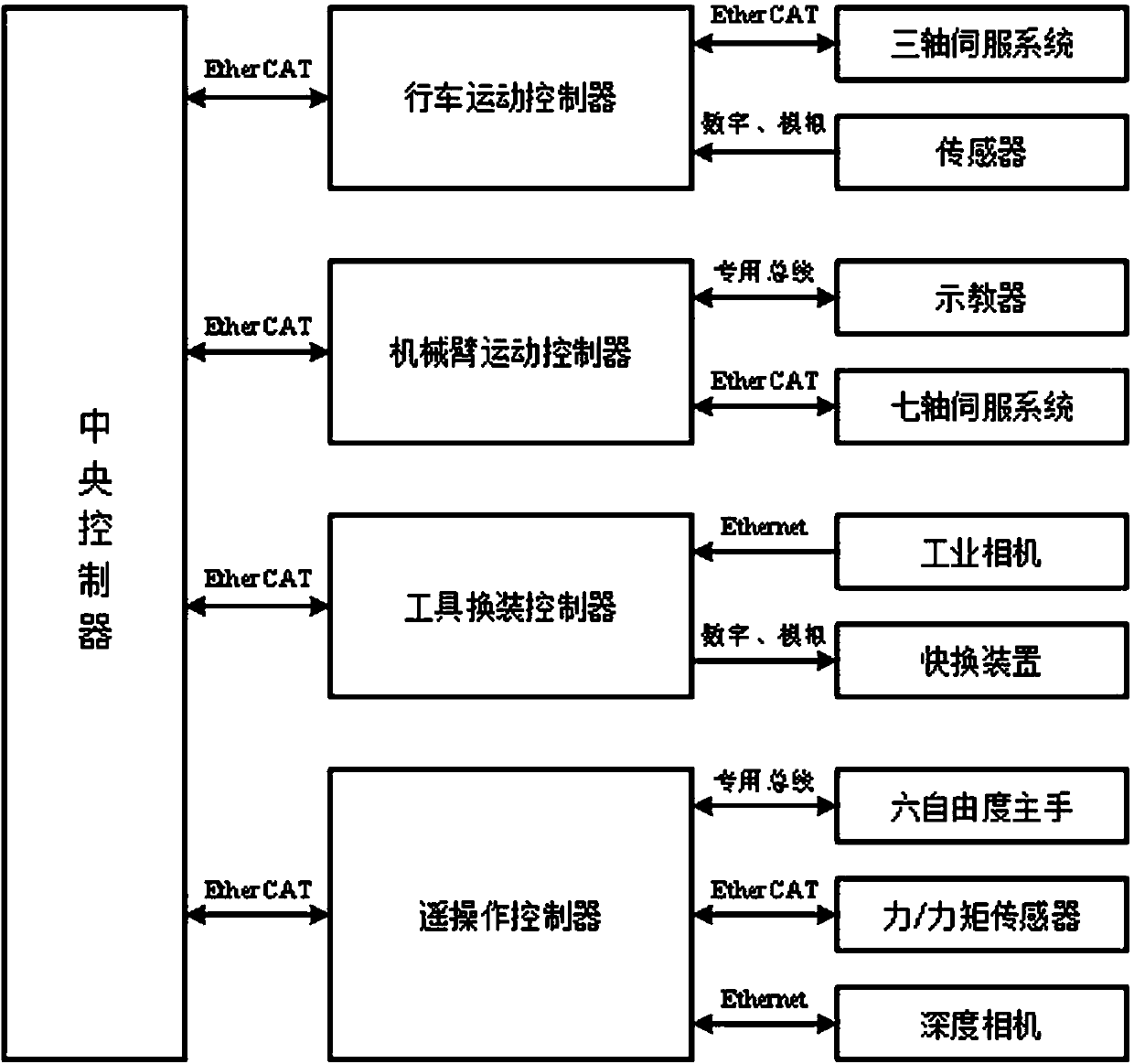

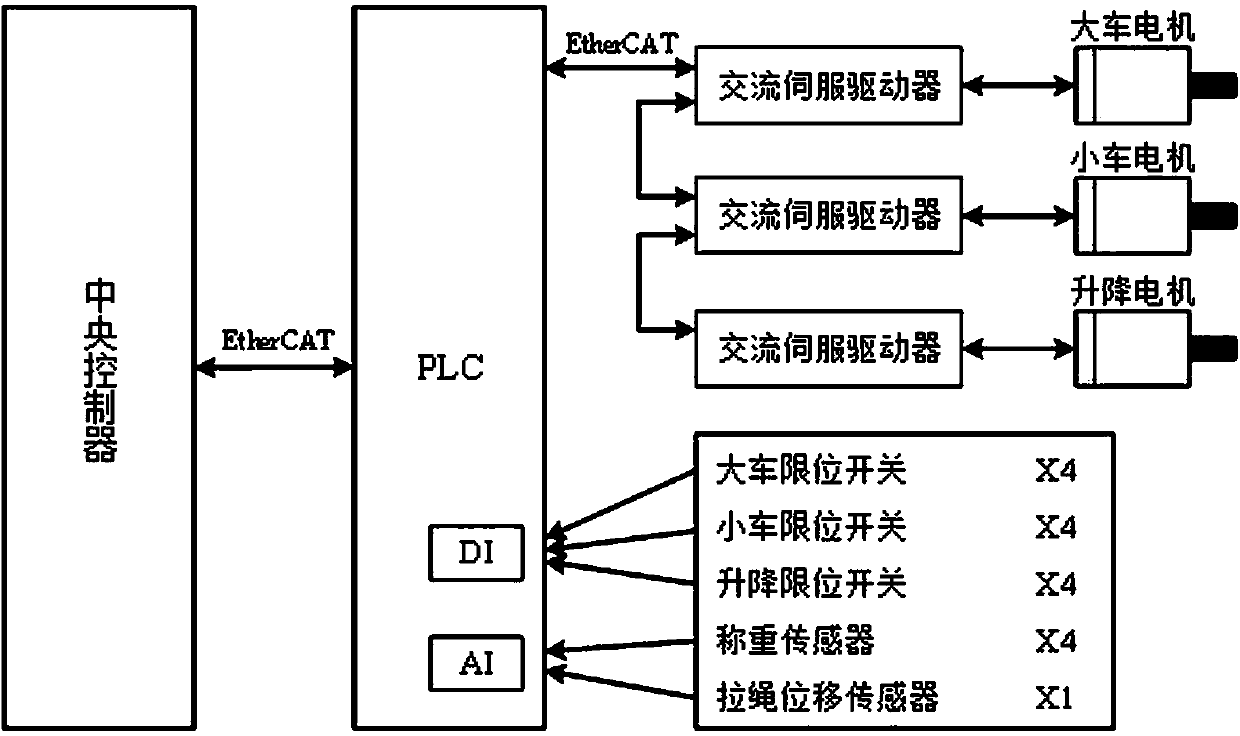

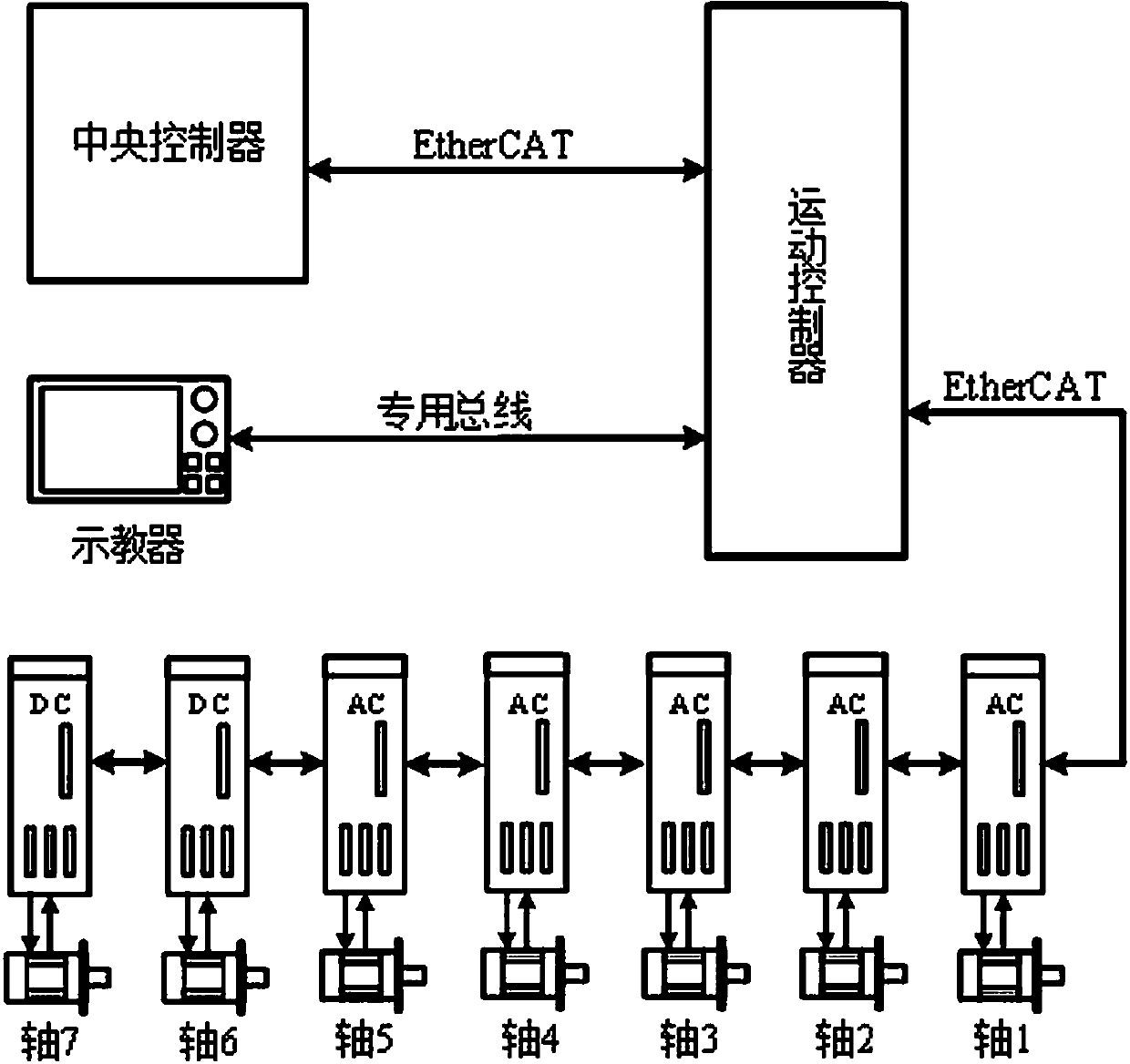

Radiation-resistant power manipulator control system

InactiveCN107662210AImprove control efficiencyImprove work presenceProgramme-controlled manipulatorMovement controlControl mode

The invention discloses a radiation-resistant power manipulator control system. The system includes a central controller and a sub control system, the sub control system includes a vehicle movement control system, a mechanical-arm movement control system, a tool replacement control system and a remote operation control system, and the central control system is connected with the sub control systemthrough communication; the vehicle movement control system includes a vehicle controller, a servo system and a sensor system; the mechanical-arm movement control system includes a mechanical-arm controller, a teaching machine and a mechanical-arm servo system; the tool replacement control system includes a tool replacement controller, an industrial camera and a quick replacement device; the remote operation control system includes a remote operation controller, master manipulator sensor and a depth camera; such control mode as 'centralized management and decentralized control effectively achieves radiation-resistant power manipulator control.

Owner:中国东方电气集团有限公司

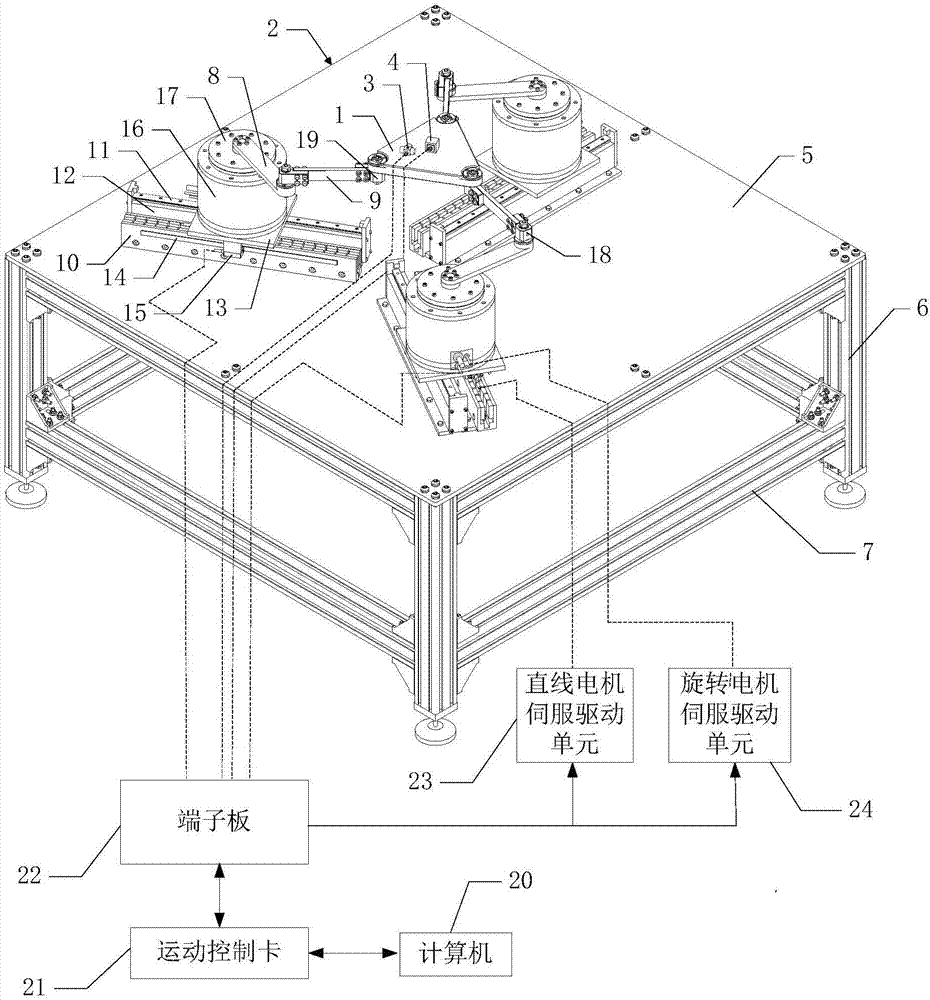

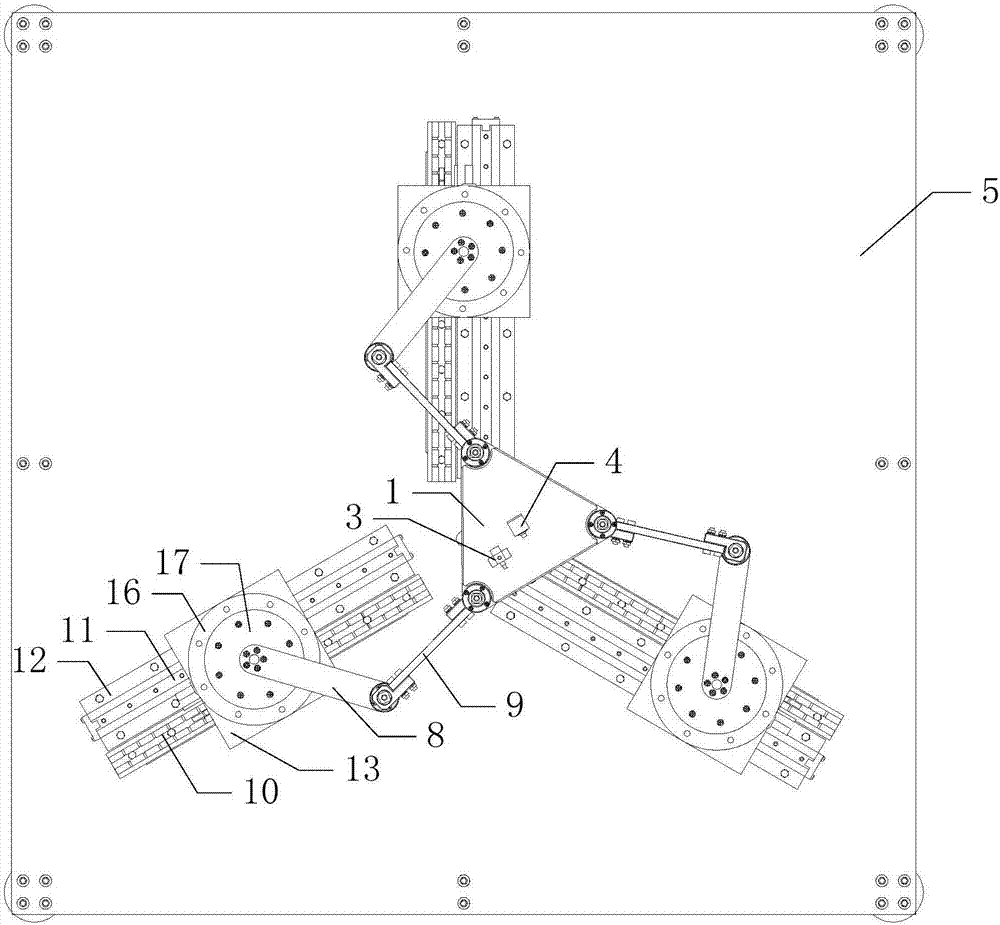

Direct-driven redundant planar parallel mechanism control device and redundant planar parallel mechanism control method

PendingCN107139193AEasy to controlReduce noiseProgramme-controlled manipulatorControl engineeringElectric machinery

The invention discloses a direct-driven redundant planar parallel mechanism control device and a redundant planar parallel mechanism control method. The device comprises a parallel mechanism body and a control unit. The parallel mechanism body comprises a movable platform and three parallel branches. The movable platform is in a shape of equilateral triangle and provided with an angular acceleration sensor and an acceleration sensor. Each parallel branch comprises a linear motor module with a displacement sensor, a rotary motor module with an encoder, a rigid active bar and a rigid passive bar. The control unit is connected with the angular acceleration sensor, the acceleration sensor, the linear motor module and the rotary motor module. Through hybrid driving of linear motors and rotary motors, the working space of the parallel mechanism is enlarged, and movement parameters of the movable platform are measured by means of the multiple sensors to serve as feedback signals, the movement control accuracy of the parallel mechanism reaches the high level.

Owner:SOUTH CHINA UNIV OF TECH

Long-travel two-axis linear fast tool servo device

InactiveCN102615542AHigh positioning accuracyImprove driving precisionFeeding apparatusDiamond turningLinear motion

The invention discloses a long-travel two-axis linear fast tool servo (FTS) device. The device is applicable to the generation of a non-rotating symmetric optical free curved surface by a diamond turning method. The device mainly comprises a matrix, a driver, a disturbance canceller and a tool rest, wherein the disturbance canceller realizes a function of cancelling motion disturbances of the device in an X direction and a Z direction through flexible hinges; and rotors of voice coil motors with ultraprecision driving functions act on a main flexible flange through the disturbance canceller, and drive a diamond cutter to realize the long-travel linear high-frequency reciprocating servo motion of the diamond cutter in the X direction and the Z direction. The device has a simple structure, is low in cost and quick in response, improves the positioning accuracy and driving accuracy of FTS, and can realize the multi-degree-of-freedom, long-travel and high-frequency-response reciprocating linear motion of the FTS.

Owner:JILIN UNIV

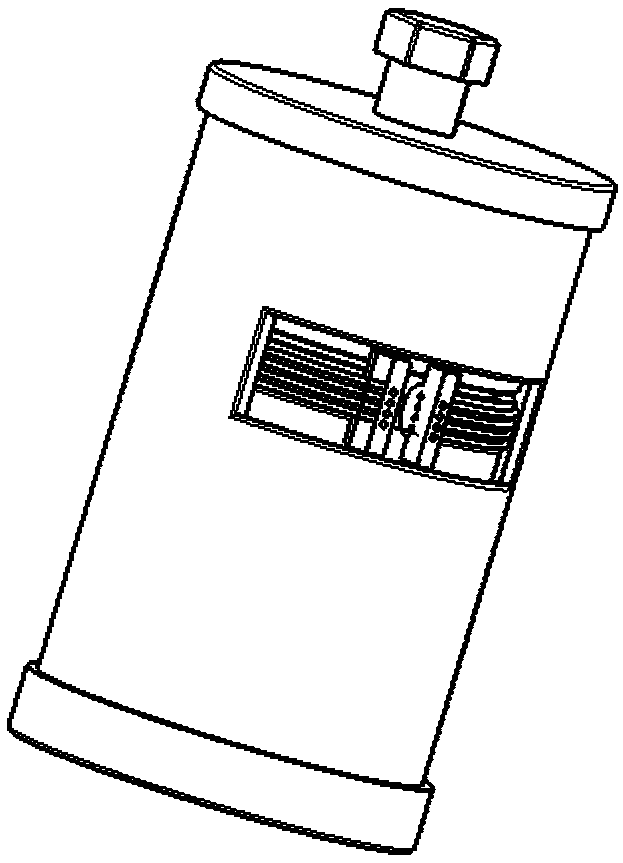

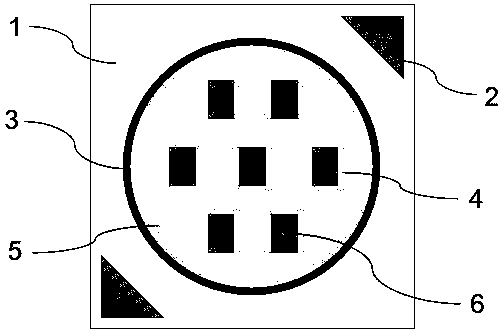

High-precision thin-wall hollow type travelling wave ultrasonic motor

ActiveCN107769609AExpand the hollow partExpand bore sizePiezoelectric/electrostriction/magnetostriction machinesElectricityCeramic

The invention provides a high-precision thin-wall hollow type travelling wave ultrasonic motor, relates to an ultrasonic motor, and solves the problems of small dimension occupied by a hollow portionof the whole motor due to large radial installation dimension of a stator and low revolution precision of the motor due to saved usage of bearings. The motor comprises a hollow shaft, a housing, a rotor, a stator and a base, the rotor is arranged on the hollow shaft, the housing is arranged on the base in a covering manner, a flange end surface of the rotor is provided with a friction plate contacted with the stator, an end surface of the stator, adjacent to the base, is laid with piezoelectric ceramics, the stator is a folding structure with grooves arranged along the circumferential direction of an outside surface thereof, the stator is arranged in a positioning installation groove of the base, the hollow shaft is arranged on the housing and the base, and the hollow shaft can rotate relative to the housing and the base. The high-precision thin-wall hollow type travelling wave ultrasonic motor is regarded as a driver.

Owner:NINGBO UNIV

Slab mounting vehicle

ActiveCN109252686ACompact structureEasy to vacateBuilding material handlingManipulatorManipulatorEngineering

The invention discloses a slab mounting vehicle and belongs to the technical field of laying construction. The slab mounting vehicle comprises a vehicle body, a distance adjustment mechanism, a lifting adjustment mechanism and a slab mounting manipulator. A counterweight bearing platform is fixed on a frame between front wheels and rear wheels of the vehicle body, and the distance adjustment mechanism and the lifting adjustment mechanism are arranged on the counterweight bearing platform. The distance adjustment mechanism comprises a first driving device, a telescopic rod and a guide sleeve, and a horizontal rotating shaft is arranged at one end, far away from the distance adjustment device, of the telescopic rod. The lifting adjustment mechanism comprises a second driving device and a lifting drive part, and the slab mounting manipulator is fixedly arranged at one end, far away from the second driving device, of the lifting drive part. The slab mounting vehicle has the advantages thatthe distance adjustment mechanism and the lifting adjustment mechanism are integrally formed with the counterweight bearing platform and fixed on the frame between the front wheels and the rear wheels jointly, so that the vehicle body is compact in integral structure; the manipulator can ascend and descend partially through the lifting adjustment mechanism so as to spare the work plane for otherprocess steps and other work types.

Owner:广东永基建筑基础股份有限公司

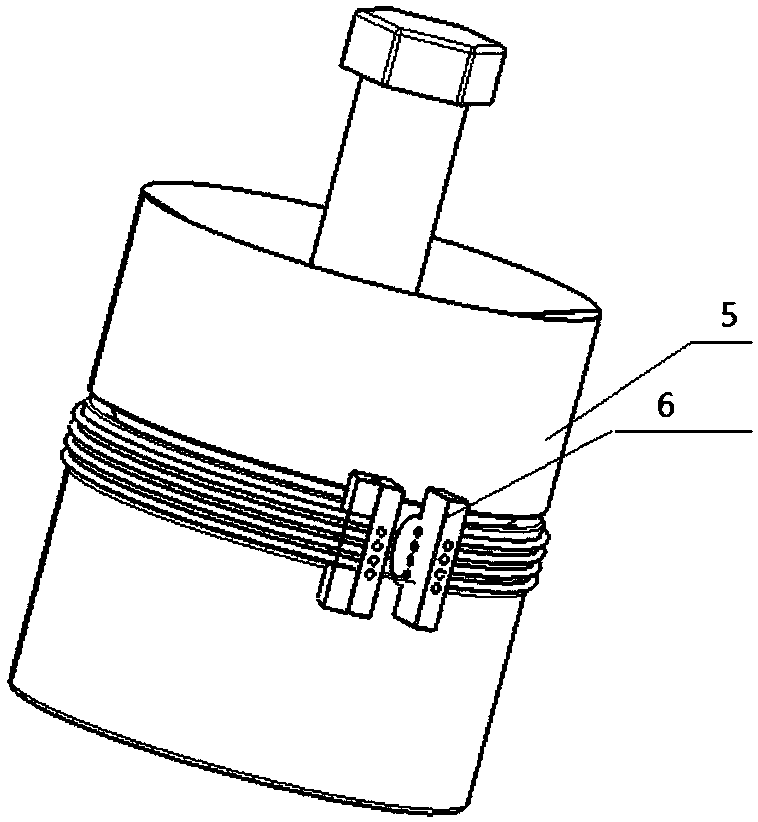

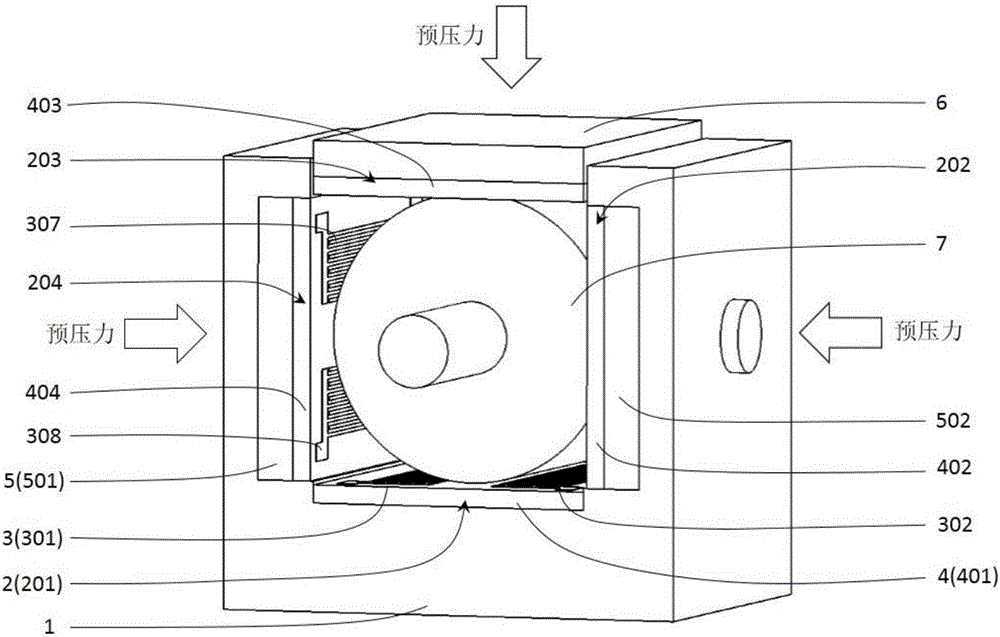

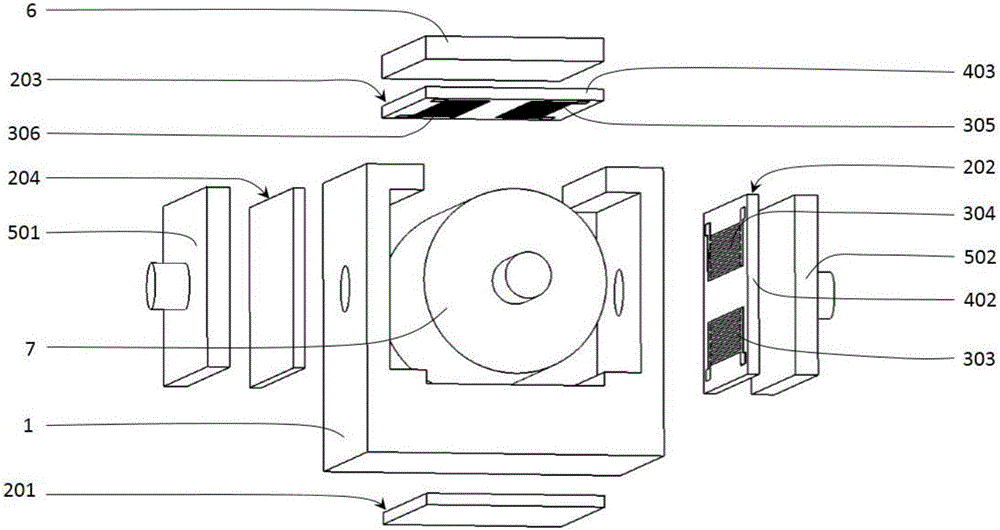

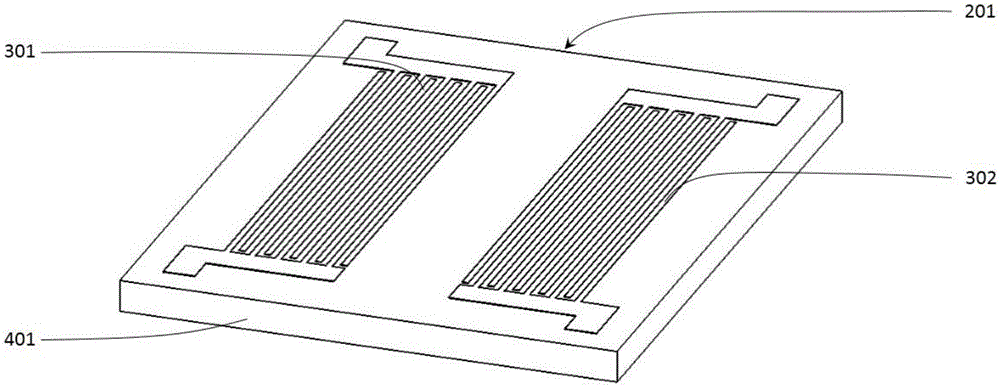

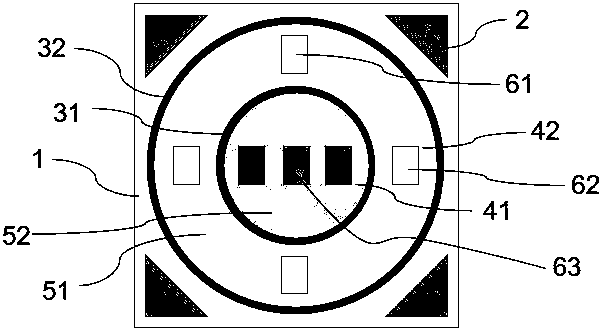

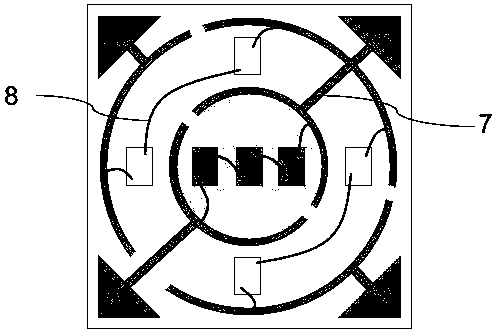

Surface acoustic wave rotary motor

InactiveCN106452170AImprove driving precisionSolve the technical problems that are difficult to achieve nanometer driving precisionPiezoelectric/electrostriction/magnetostriction machinesElectricitySurface acoustic wave sensor

The invention relates to an ultrasonic rotary motor based on surface acoustic wave, mainly comprising a fixing shell, a surface acoustic wave device, push plates, an upper retaining plate and a rotor, wherein the surface acoustic wave device comprises two pairs of interdigital transducers and a piezoelectric substrate. The part of a rotor in contact with the piezoelectric substrate is positioned in an area between the two pairs of interdigital transducers, certain pressure is applied to the left and right push plates and the upper retaining plate, a high-frequency sinusoidal signal is applied to the specified interdigital transducer to excite the surface acoustic wave device to generate surface acoustic wave, and the rotor can be rotated clockwise and anticlockwise by the aid of frictional force between the rotor and the piezoelectric substrate. The ultrasonic rotary motor has the advantages of simple structure, small size, high drive precision, low control difficulty, low cost and the like.

Owner:JILIN UNIV

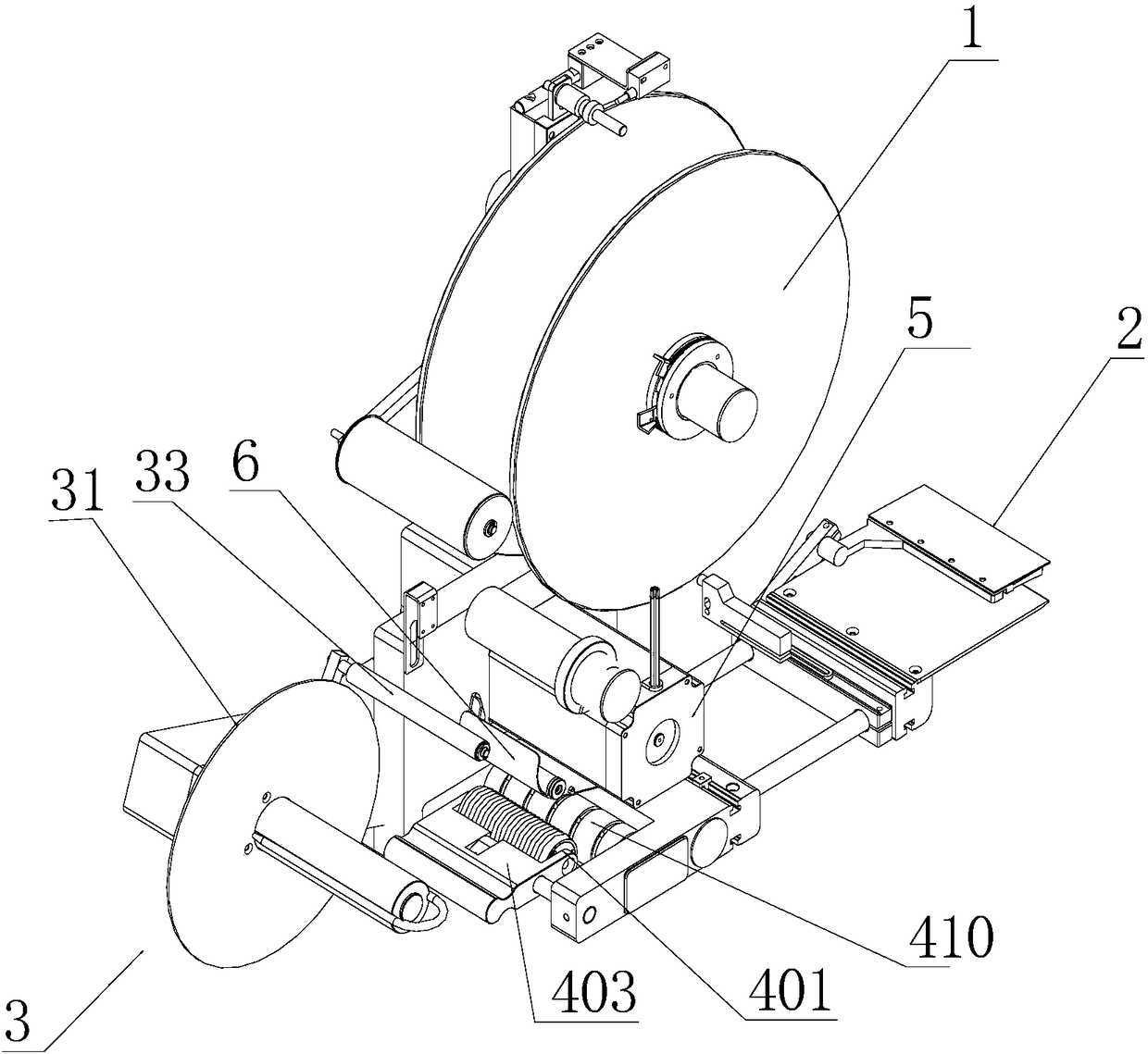

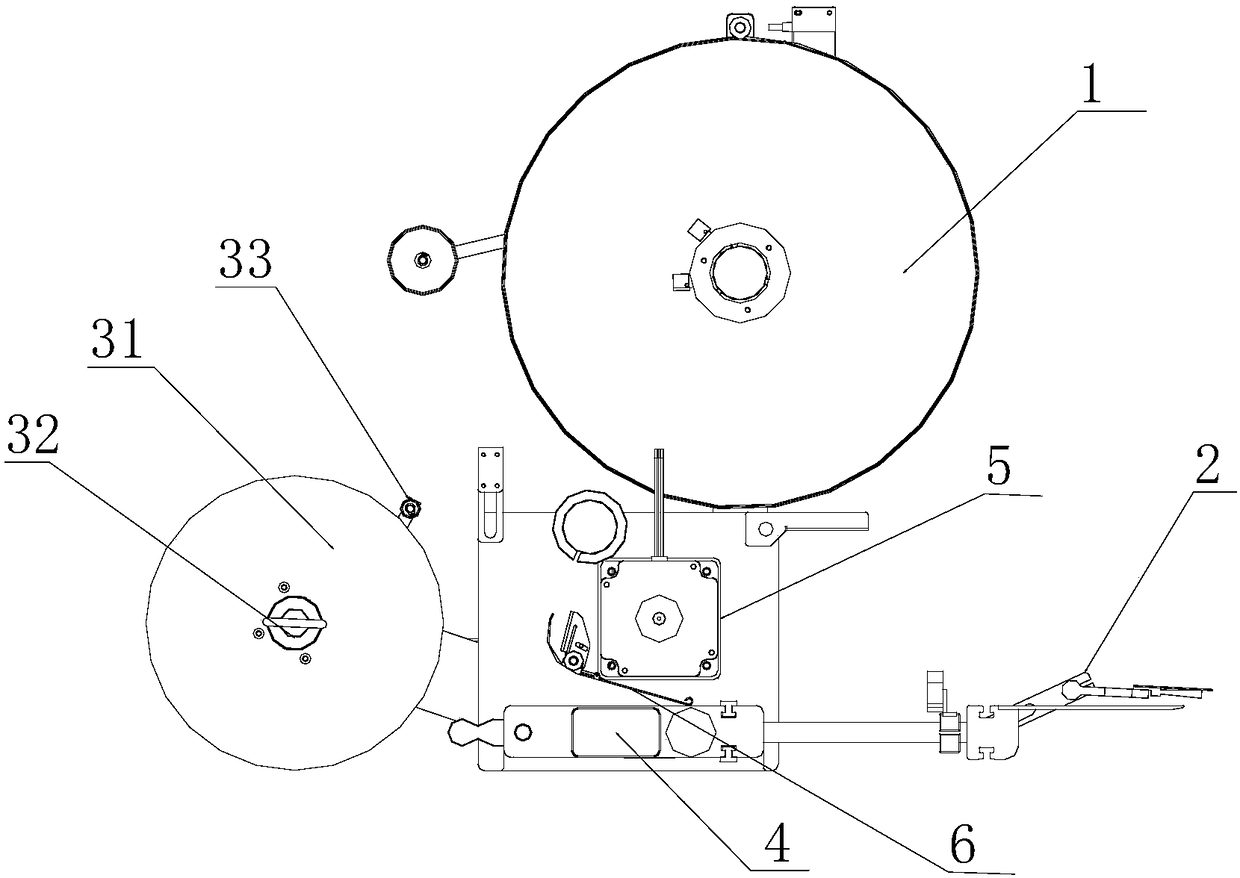

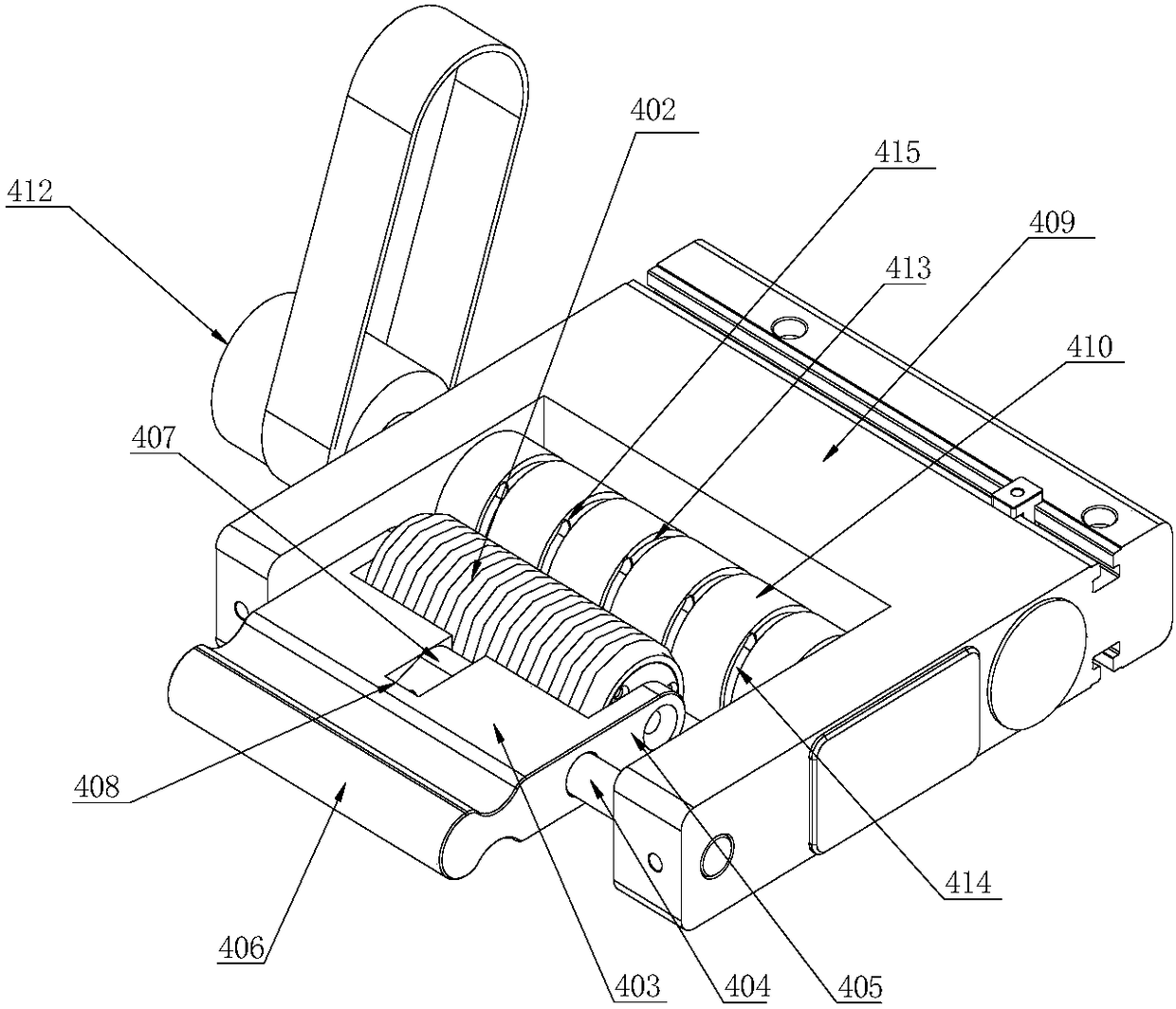

Labeling machine

PendingCN108438405AAvoid inaccuraciesHigh running precisionLabelling machinesPulp and paper industryLabelling machine

The invention belongs to the field of labeling machines and discloses a labeling machine. The labeling machine comprises an uncoiler, a label stripping assembly and a backingpaper coiler and further comprises a backing paper drive assembly, wherein the uncoiler, the label stripping assembly and the backing paper coiler are arranged in sequence, the uncoiler is used for outputting label paper, thelabel stripping assembly is used for stripping labels from the label paper, the backing paper coiler is used for collecting backing paper, the backing paper drive assembly is arranged between the label stripping assembly and the backing paper coiler and used for driving the backing paper to move, and the backing paper drive assembly is driven by a drive mechanism. The labeling machine is accuratein labeling.

Owner:广州劲翔智能包装机械有限公司

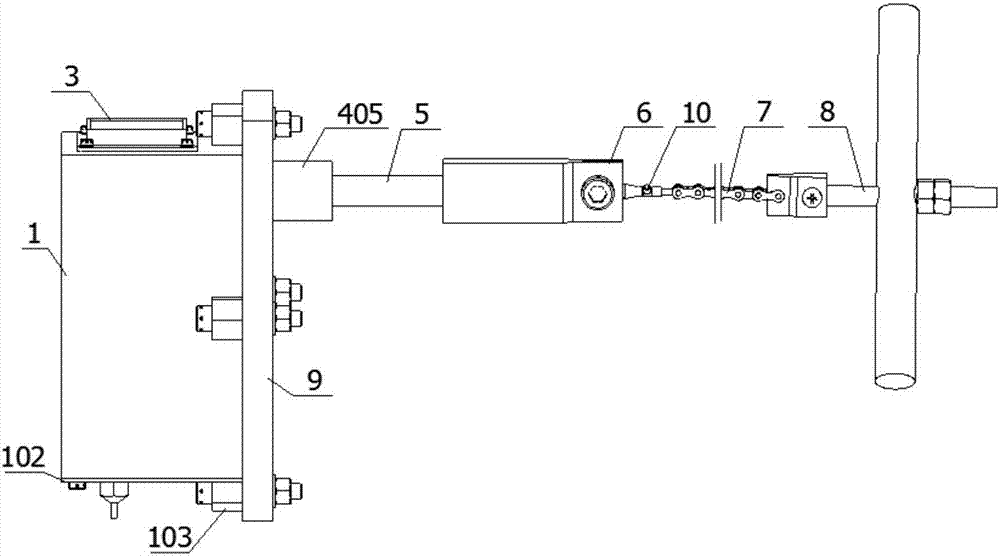

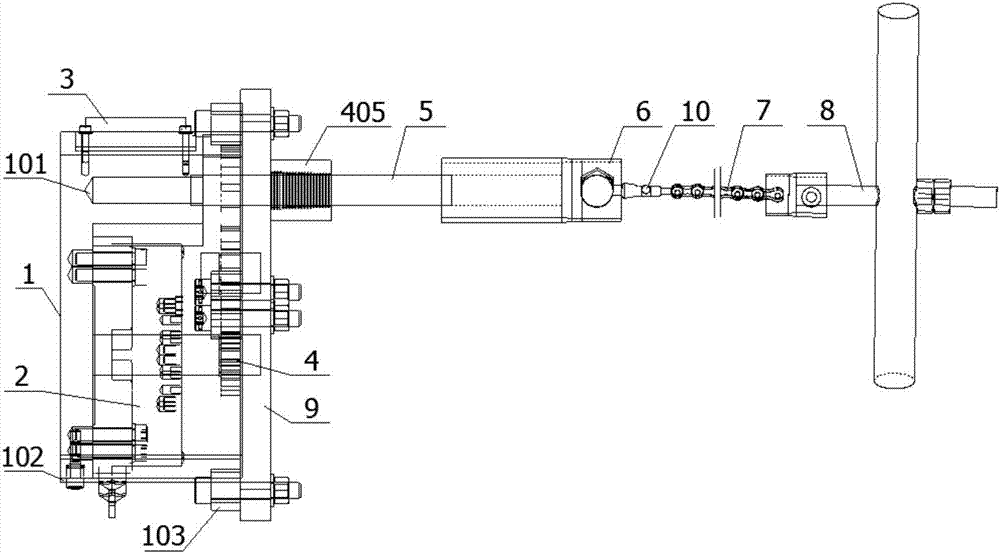

Chain tensioning adjusting mechanism

ActiveCN106931110AImprove driving precisionAvoid chain dropGearingElectric machineryWorking environment

The invention relates to a chain tensioning adjusting mechanism which comprises a shell, a direct drive motor, a drive controller, a transmission device, a transmission lead screw, a first connector device, a chain and a second connector device. The direct drive motor is arranged in the shell, and the drive controller is arranged at the upper end of the shell and is connected with the direct drive motor through a line; a supporting plate is arranged on the outer side of the shell, the transmission device is arranged on the side, close to the shell, of the supporting plate, and the direct drive motor is connected with the transmission device; one end of the transmission lead screw penetrates the supporting plate to be connected with the output end of the transmission device, and the other end of the transmission lead screw is connected with one end of the first connector device; the other end of the first connector device is connected with the second connector device through a chain; and a tension sensor is arranged at the connecting position of the first connector device and the chain and is connected with the drive controller through a line. By means of the chain tensioning adjusting mechanism, automatic chain tensioning is achieved, the chain driving accuracy is improved, chain falling is prevented, the chain tensioning adjusting mechanism can adapt to the wicked work environment, and the reliability coefficient is high.

Owner:GUILIN UNIV OF ELECTRONIC TECH

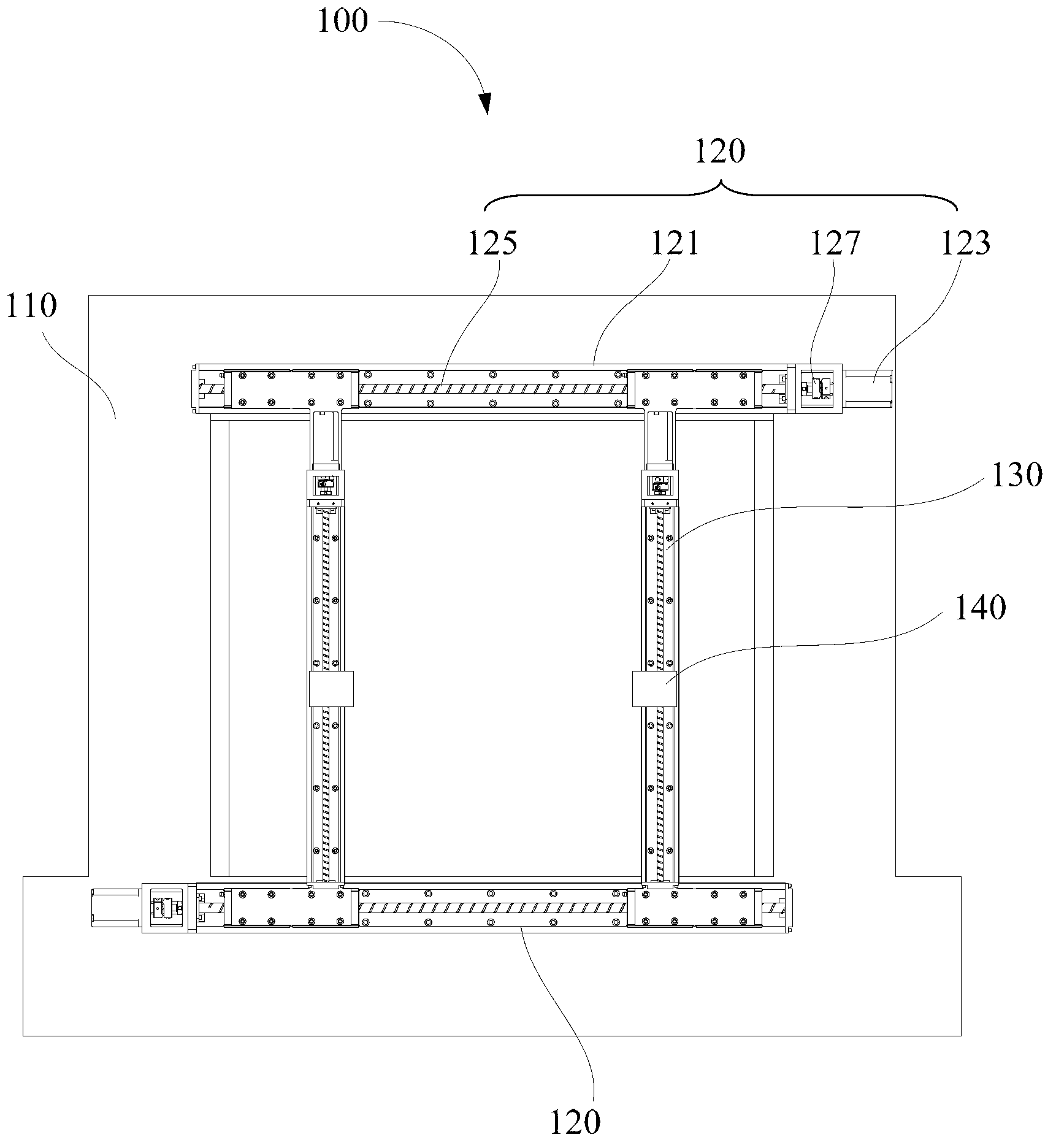

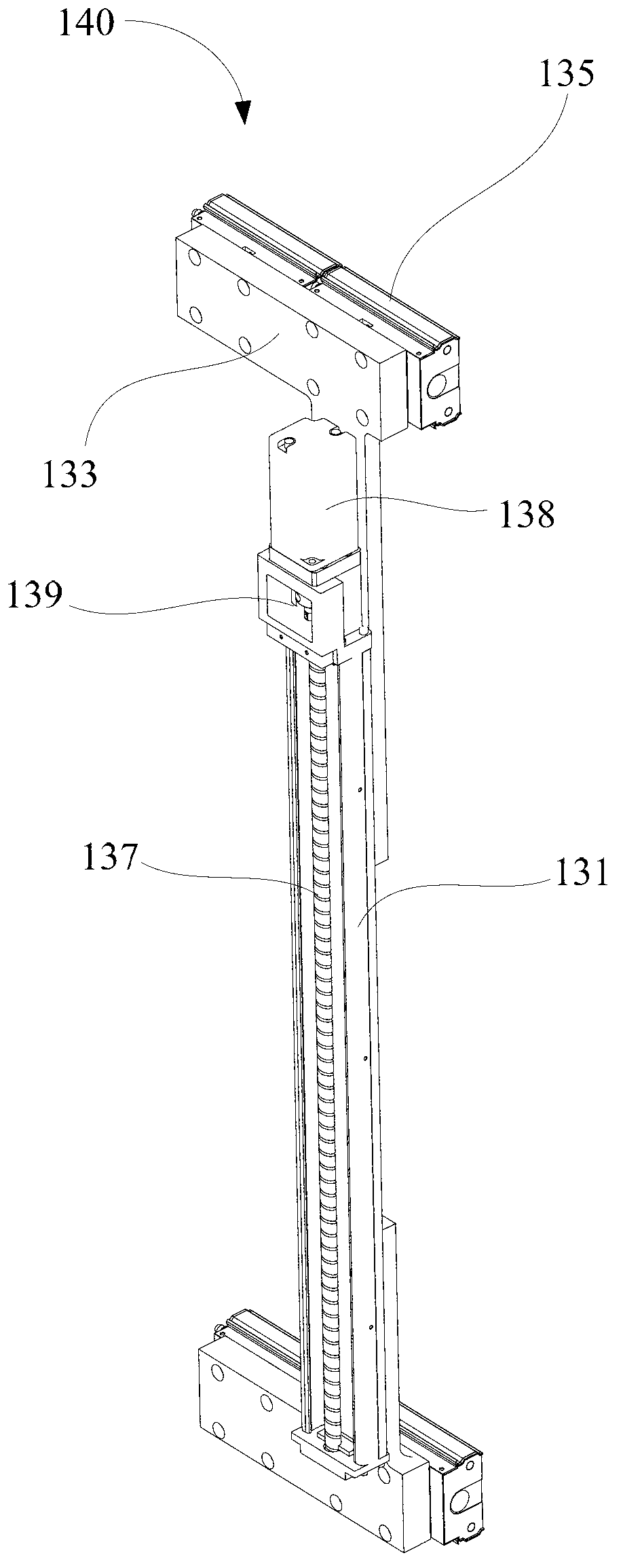

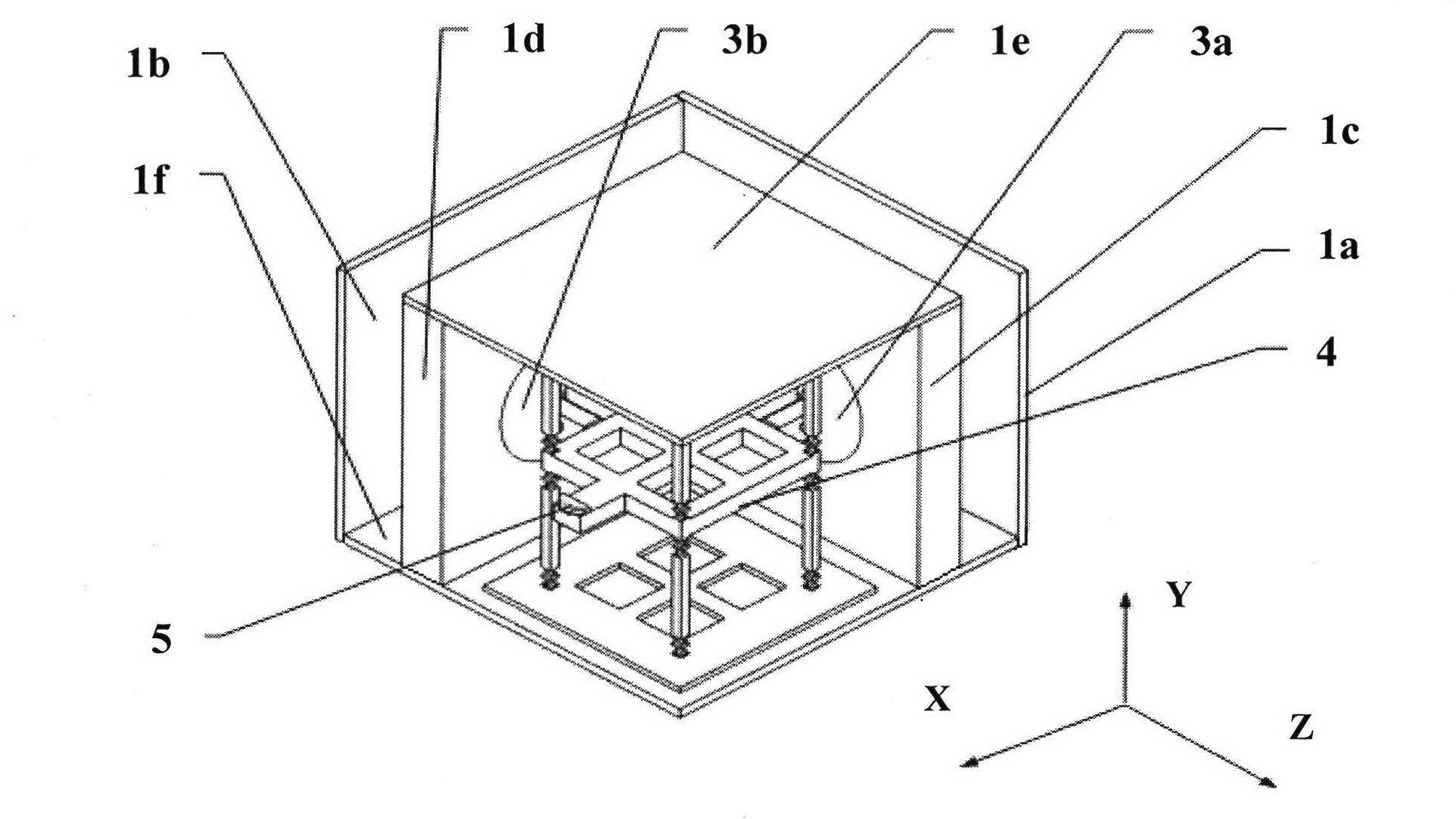

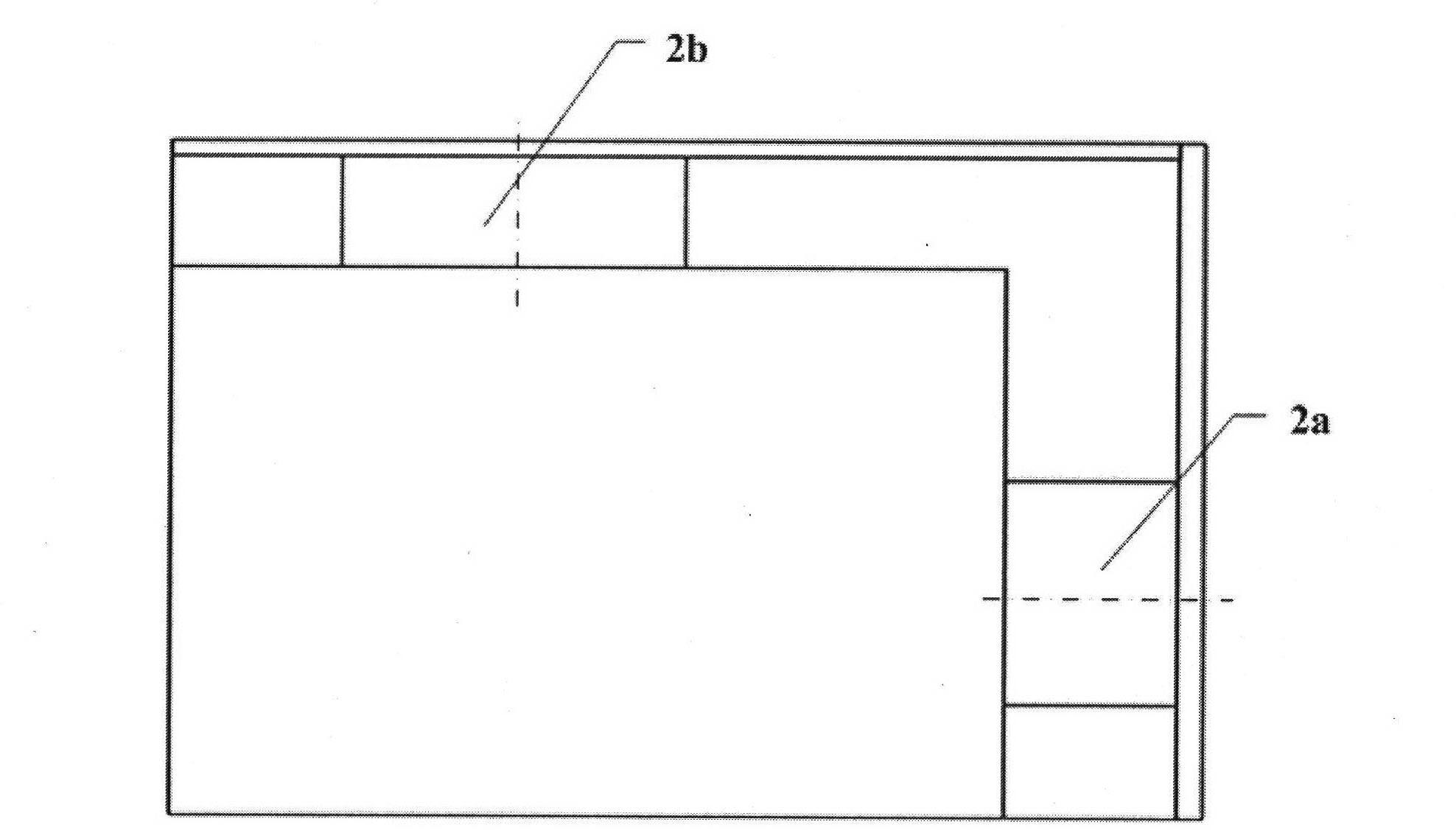

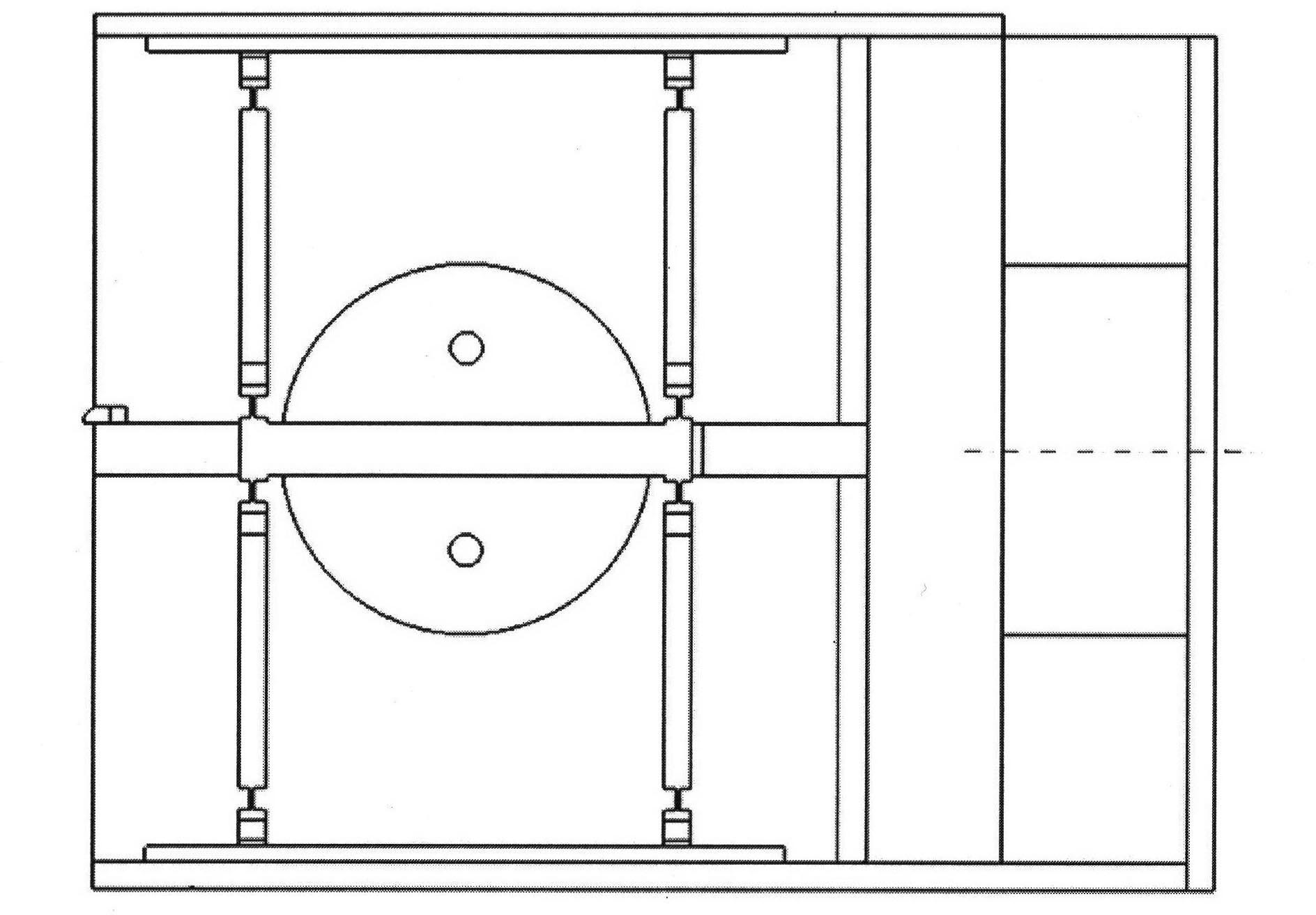

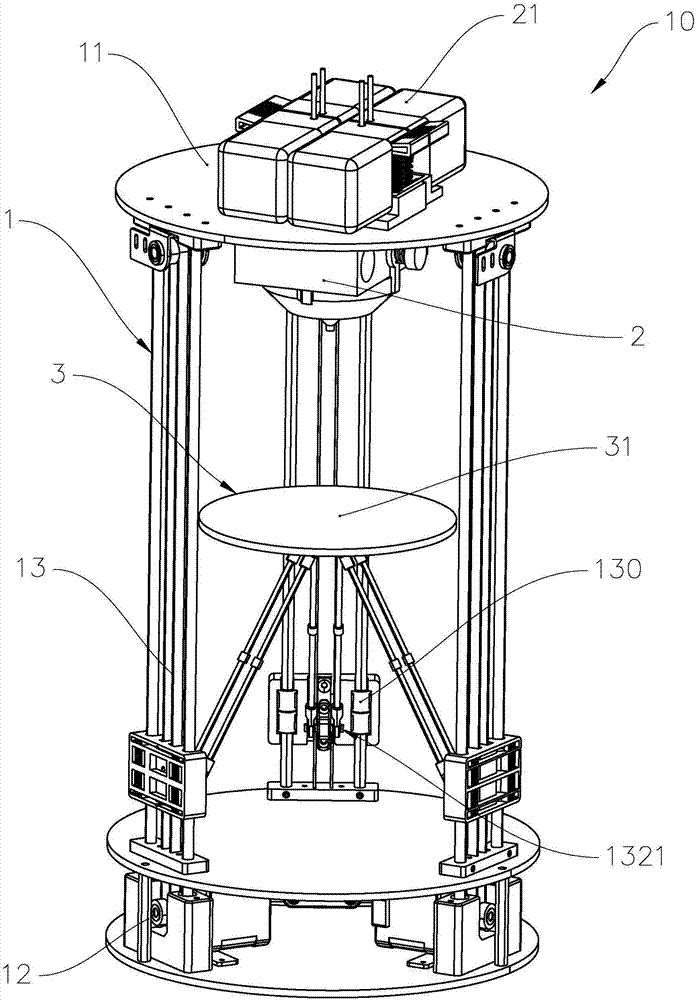

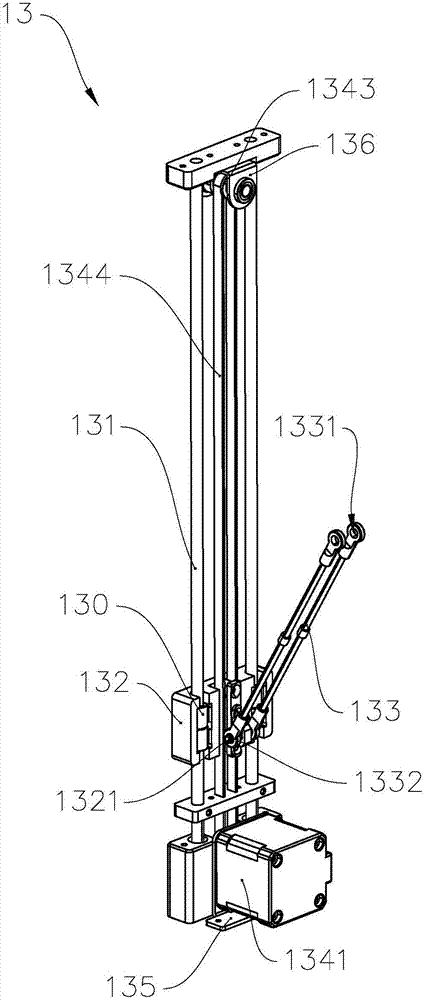

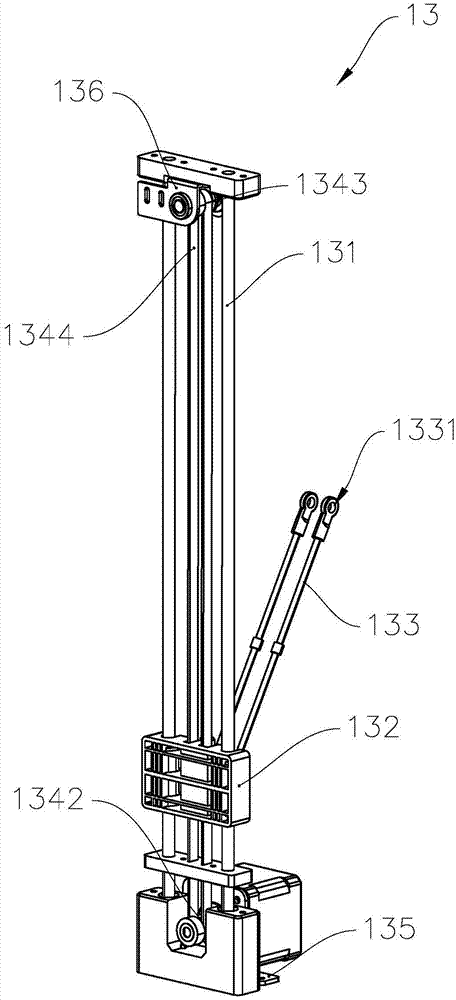

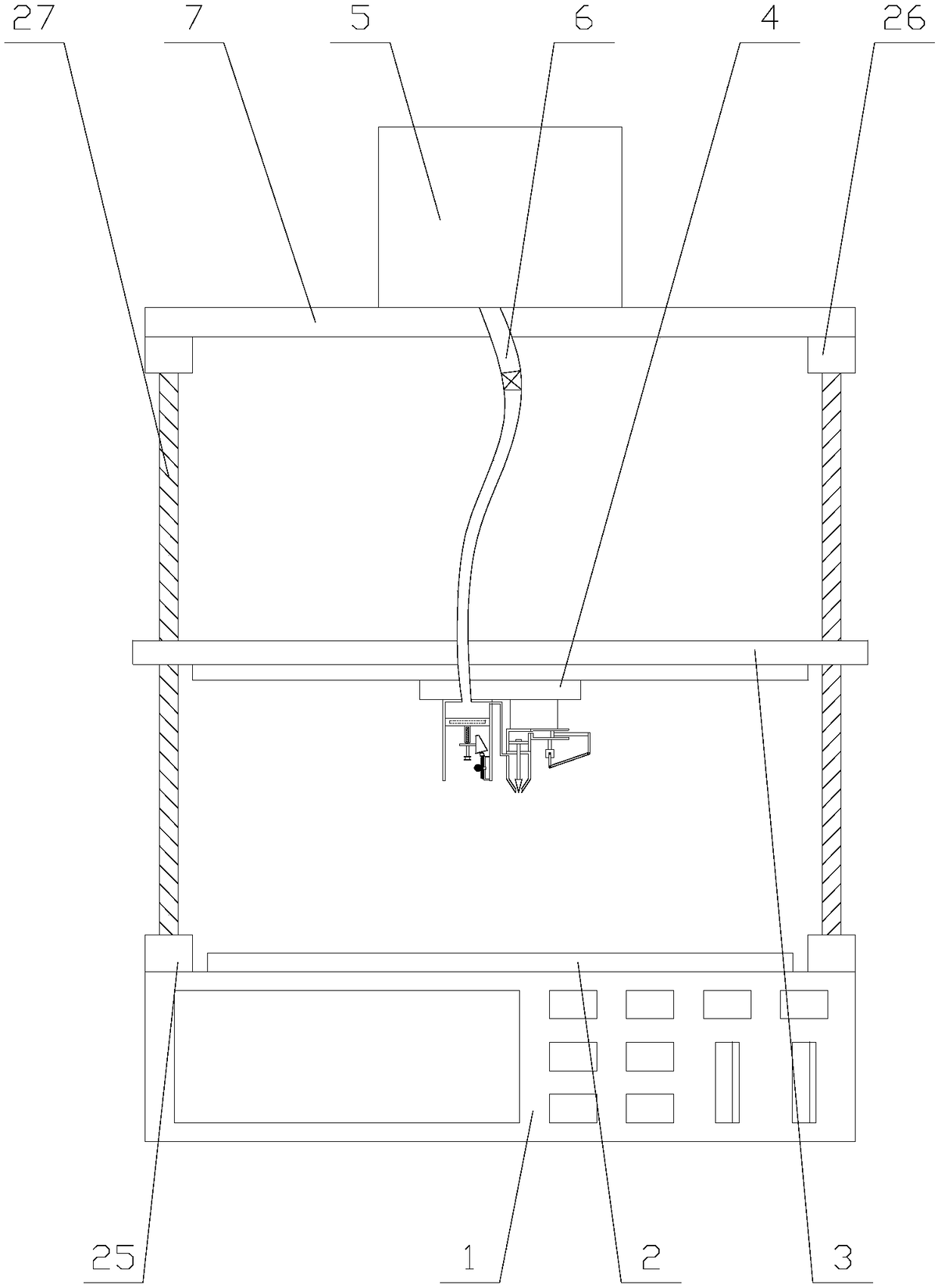

Three-dimensional printer and printing method thereof

PendingCN107127967AImprove driving precisionImprove printing accuracyAdditive manufacturing apparatus3D object support structuresComputer printing3 dimensional printing

The invention provides a three-dimensional printer and a printing method thereof. The three-dimensional printer comprises a frame; the frame comprises an upper support base and a lower support base oppositely arranged, and three sets of driving devices; and the three sets of driving devices are uniformly arranged between the upper support base and the lower support base in the peripheral direction of the upper support base. The three-dimensional printer further comprises a printing platform and a first printing head; the first printing head is fixedly mounted on the upper support base; each set of driving devices comprises a guide rail, a connecting block, a support arm and a driving module; the guide rail is connected between the upper support base and the lower support base; the connecting block is slidingly connected with the guide rail in the extension direction of the guide rail; two ends of the support arm are respectively hinged with the printing platform and the connecting block; and the driving module drives the connecting block to move back and forth along the guide rail. The invention further discloses a printing method of the three-dimensional printer. The three-dimensional printer and the printing method thereof can prevent touch and interference with a power supply wire and a signal wire connected with the printing head and a printed three-dimensional solid during printing.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

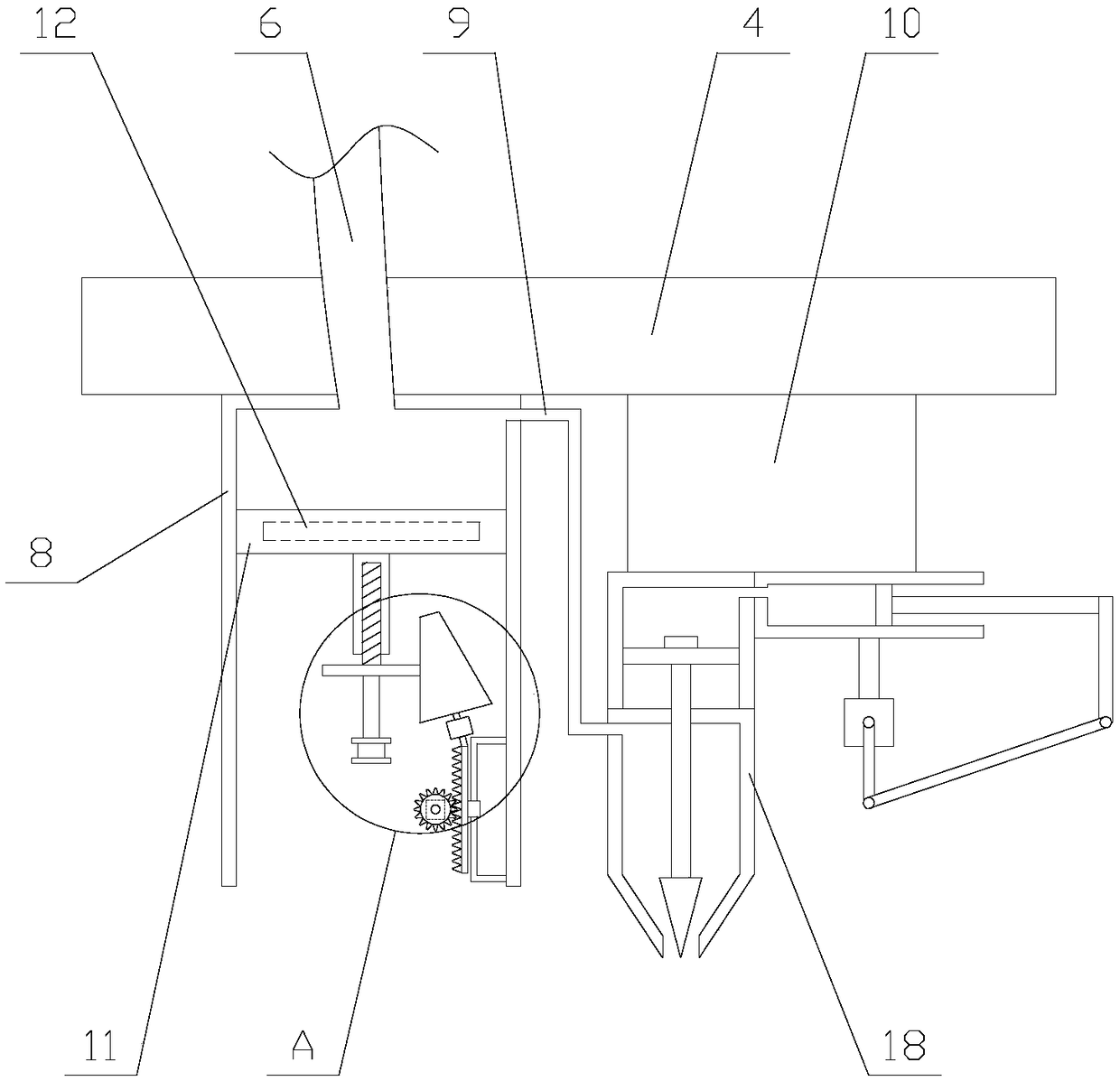

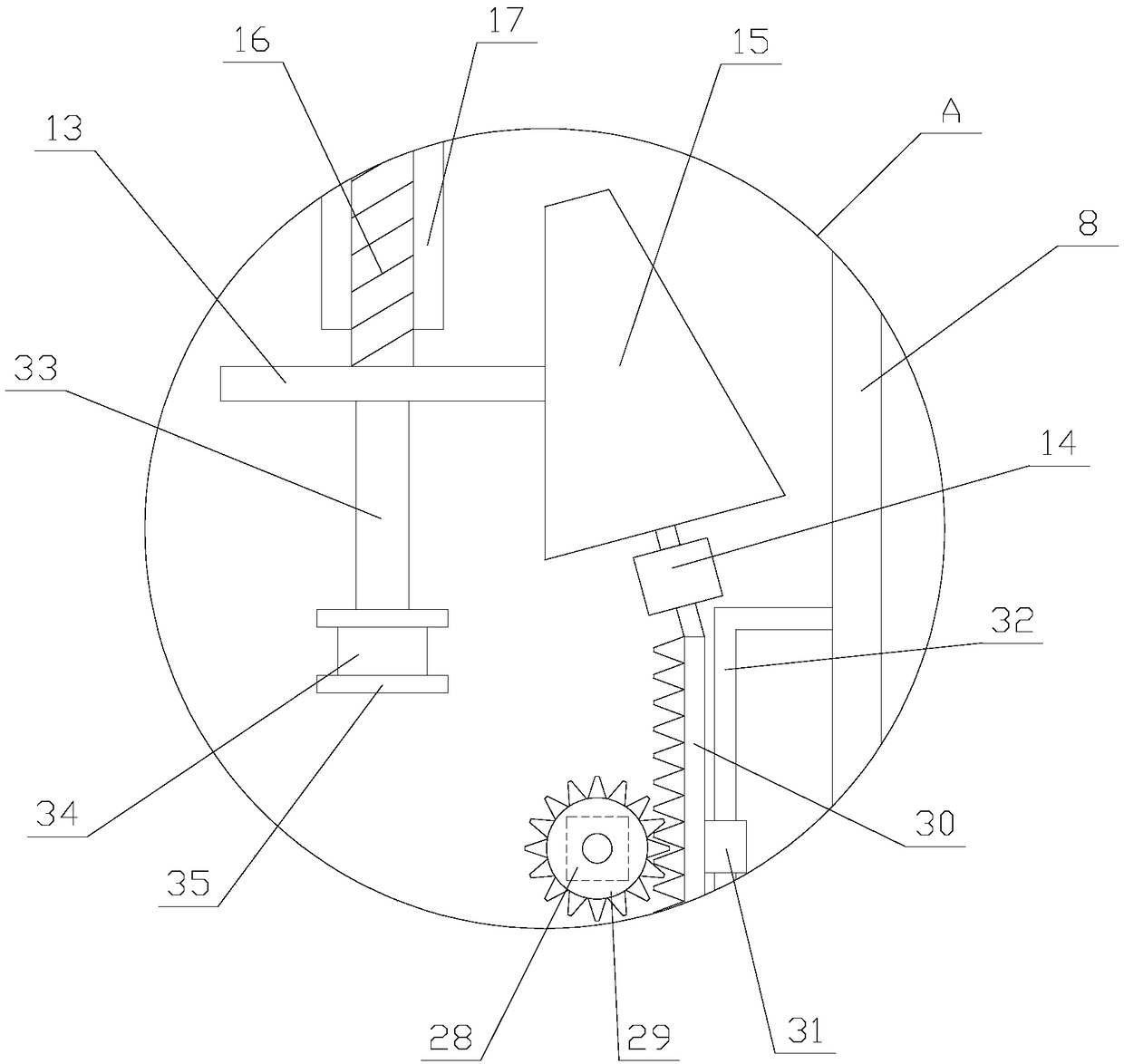

3D printer with adjusting function

ActiveCN109177157AGuaranteed uptimePrecise control of movement speedManufacturing heating elementsAdditive manufacturing with liquidsSprayerEngineering

The invention relates to a 3D printer with an adjusting function. The 3D printer comprises a host, a printing platform, a lifting plate, a planer moving device, a translation plate, a discharging device, a material box, a material pipe, a top plate and four lifting mechanisms; the discharging device comprises a heating pipe, a connecting pipe, a connecting block and a discharging mechanism; a heating plate and a speed regulating mechanism are arranged in the heating pipe; the speed regulating mechanism comprises a turntable, a support component, a first motor, a driving block, a speed regulating assembly, a rotating shaft and a sleeve; the discharging mechanism comprises a sprayer, a first cylinder, a second cylinder and a translation component; an adjusting block and a vertical rod are arranged in the sprayer. The 3D printer with the adjusting function is capable of accurately controlling the moving speed of the heating plate by the speed governing device according to the accuracy requirement of print positions, so that the printing efficiency can be guaranteed and the printing precision can be promoted. Meanwhile, the size of the gap of the opening of the sprayer can be adjustedby the discharging mechanism, so that the discharging speed can be adjusted according to the printing requirement and the practicality of the device is improved.

Owner:永康市普方铝业有限公司

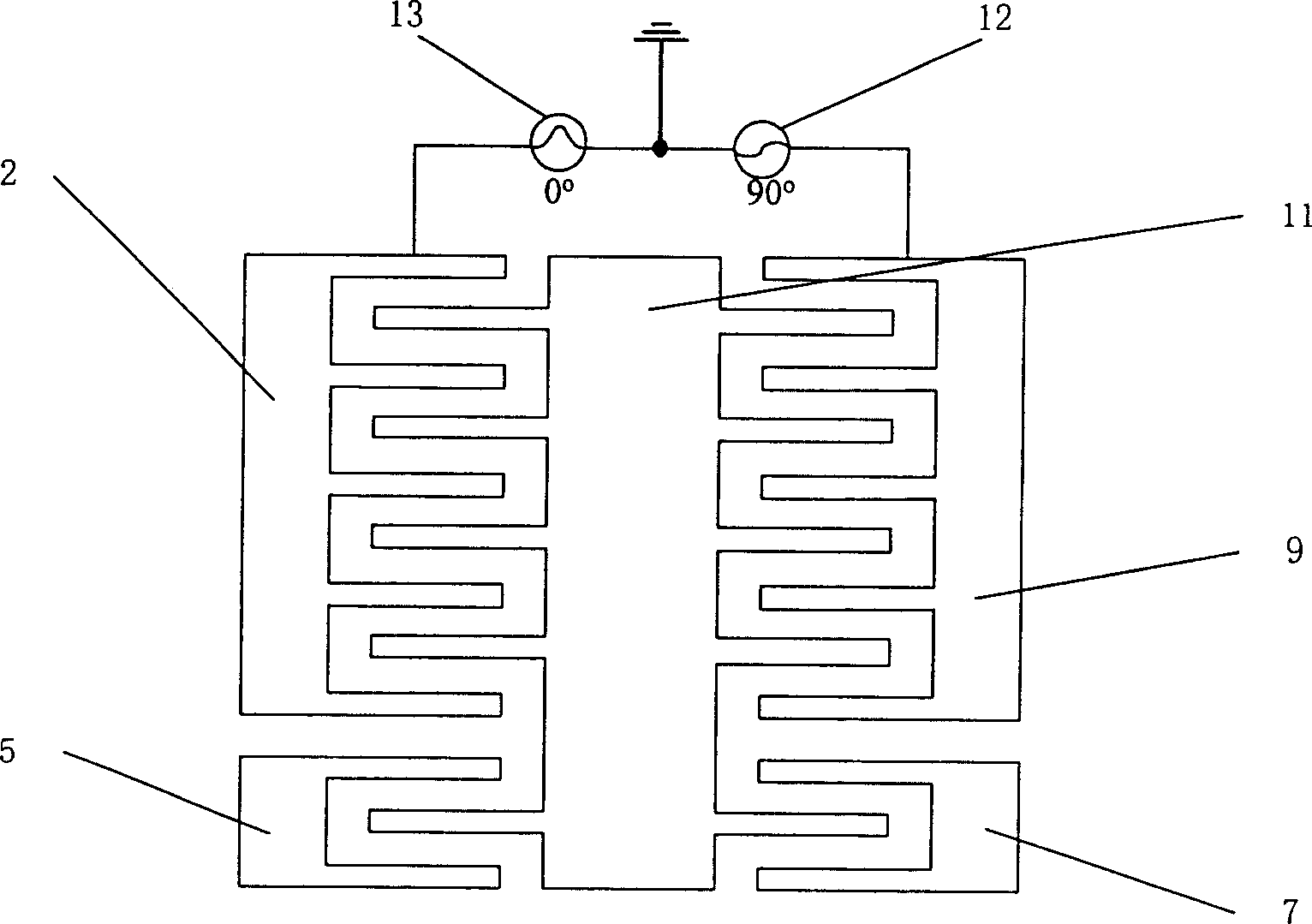

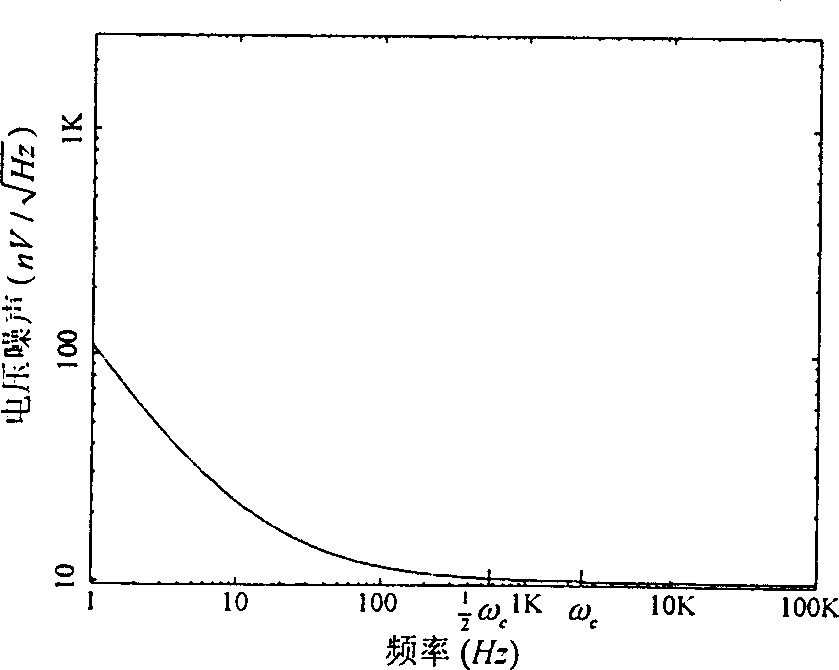

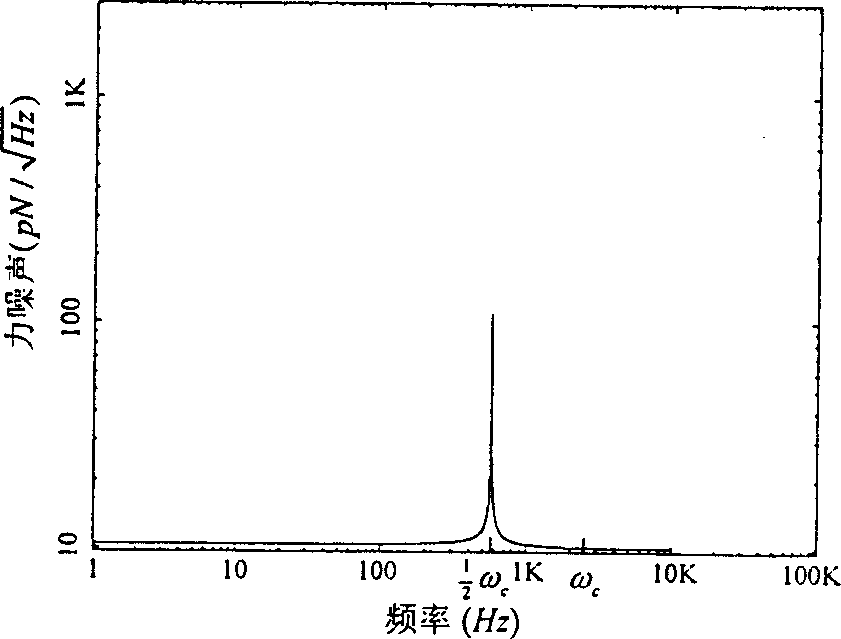

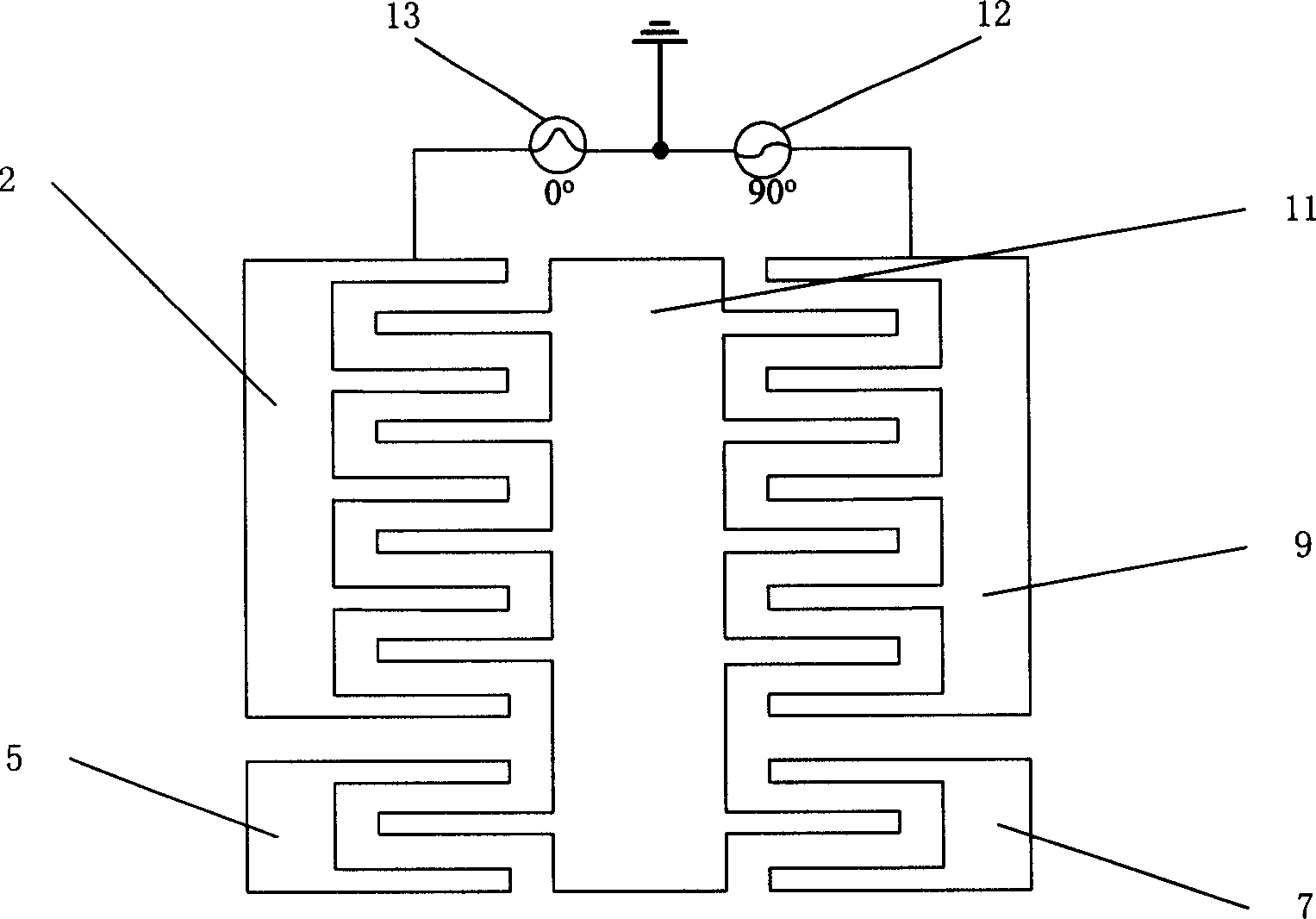

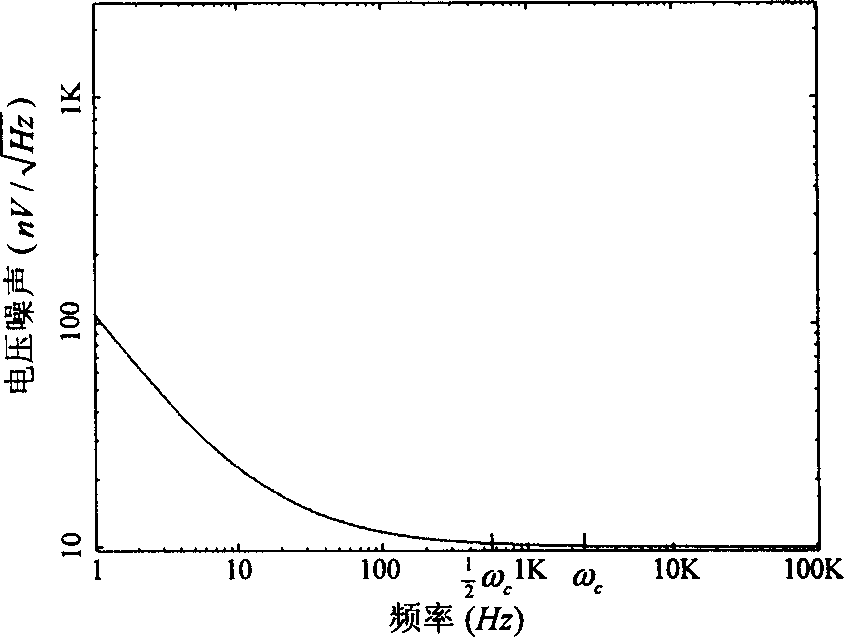

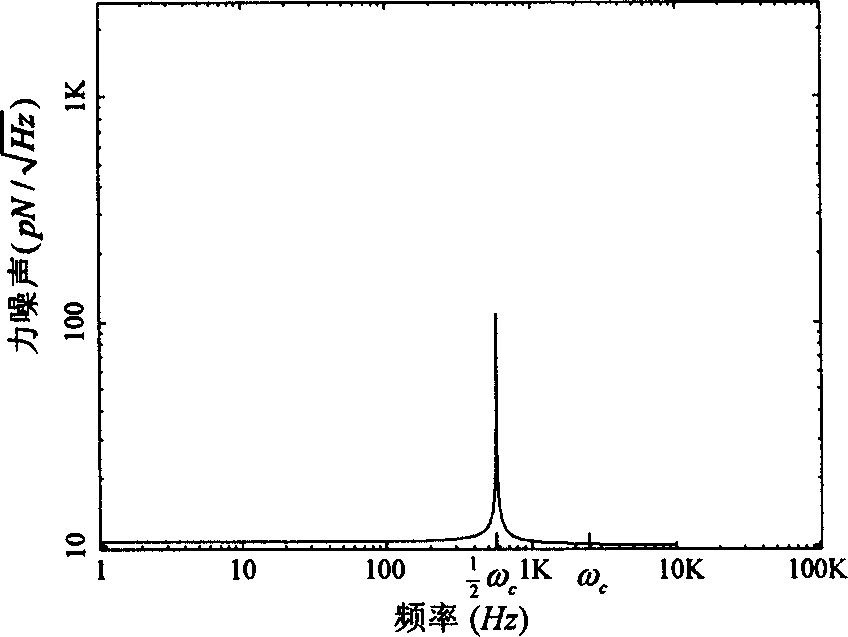

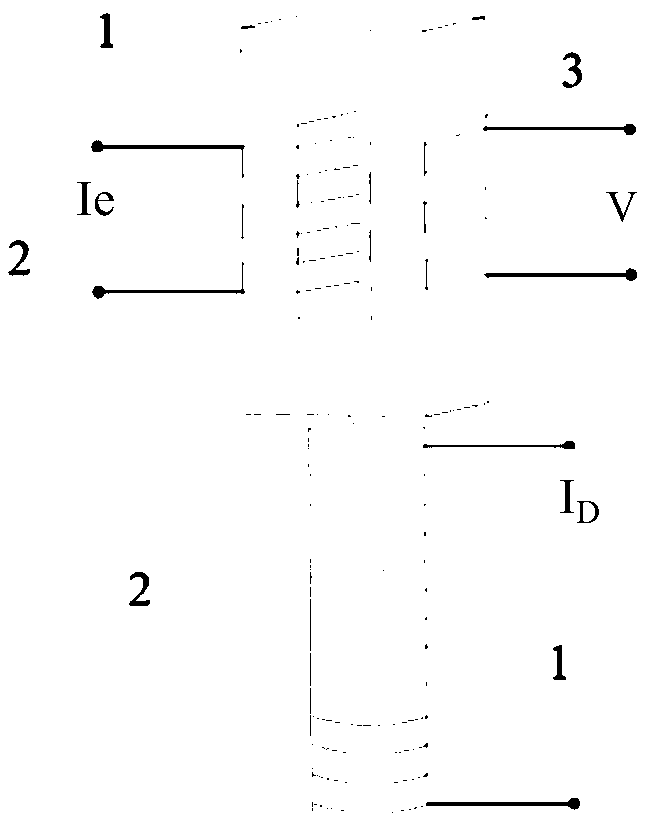

Semi-frequency driving and loop closing method for micro mechanic sensor

InactiveCN1299427CImprove driving precisionReduce noiseElectrostatic generators/motorsElectricityLoop control

The half-band driving and closed loop method for micro mechanism sensor. For overcoming the effects of electrical coupling and 1 / f noise, this invention opens the half-band driving method for micro mechanism sensor, the feature is: at the two drive pole of static differential diver, adds two way pure alternating voltage to dive it, and the above statement two way voltage have 90 degree discrepancy, its frequency is the half of the mover vibration frequency. This method can eliminate the electrical coupling from the driving voltage to the sensor, can reduce effects of 1 / f noise introduce from driving voltage, and for this method utilizes approximate way in small scale to eliminate the effects of non-linear from voltage to electrical static force, implements closed loop control.

Owner:TSINGHUA UNIV

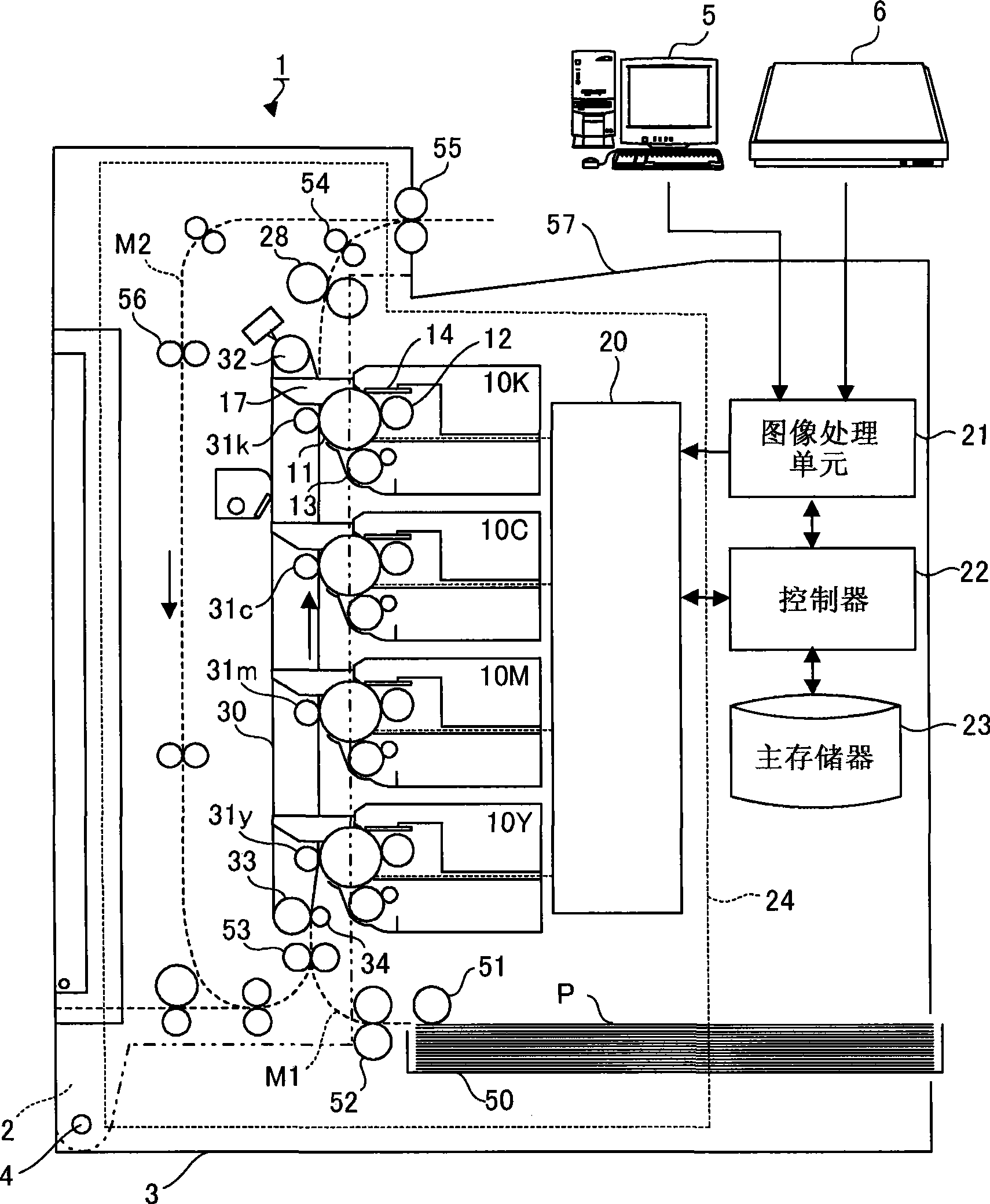

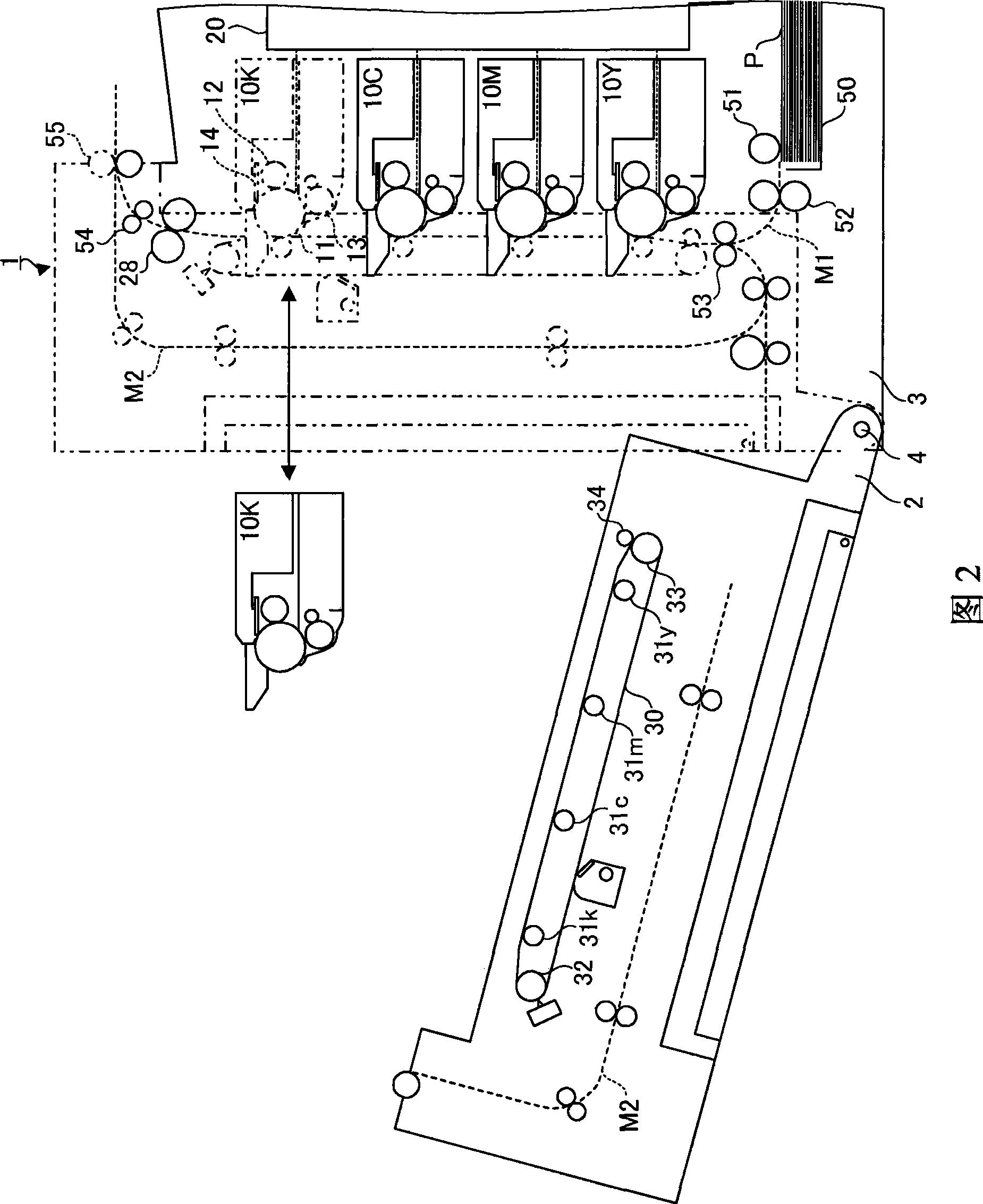

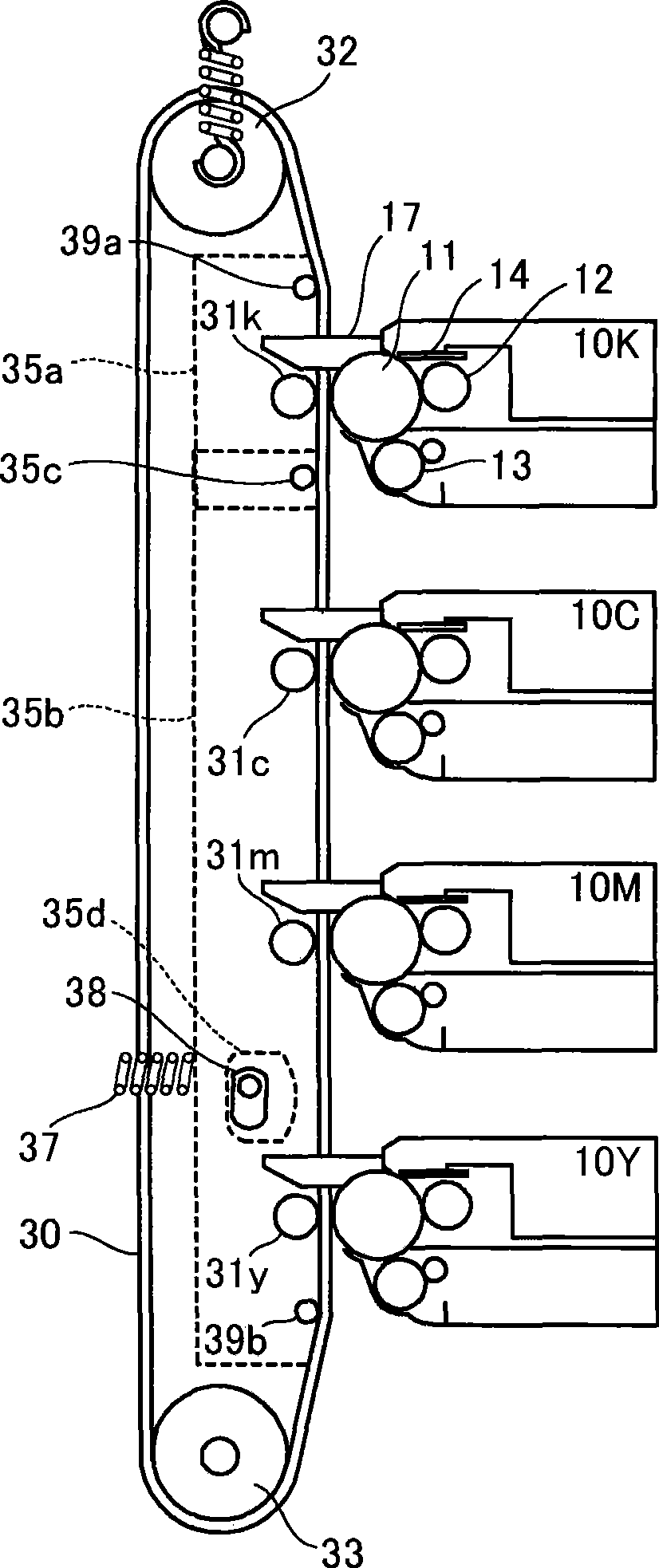

Image forming apparatus and drive converting method

ActiveCN101369115AImprove driving precisionEasy to change jobsElectrographic process apparatusEngineeringImage formation

The image forming apparatus is provided with: plural rotating members that are arranged rotatably; plural rotation side coupling members that are provided corresponding to the respective rotating members and transmit drive force to the respective rotating members; plural drive side coupling members that are connected to the respective rotation side coupling members and rotate and drive the respective rotating members via the rotation side coupling members; and an interconnecting unit that connects a predetermined number of the drive side coupling members among the plural drive side coupling members to the corresponding rotation side coupling members.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Semi-frequency driving and loop closing method for micro mechanic sensor

InactiveCN1490926AImprove driving precisionReduce noiseElectrostatic generators/motorsElectricityLoop closing

The half-band driving and closed loop method for micro mechanism sensor. For overcoming the effects of electrical coupling and 1 / f noise, this invention opens the half-band driving method for micro mechanism sensor, the feature is: at the two drive pole of static differential diver, adds two way pure alternating voltage to dive it, and the above statement two way voltage have 90íÒdiscrepancy, its frequency is the half of the mover vibration frequency. This method can eliminate the electrical coupling from the driving voltage to the sensor, can reduce effects of 1 / f noise introduce from driving voltage, and for this method utilizes approximate way in small scale to eliminate the effects of non-linear from voltage to electrical static force, implements closed loop control.

Owner:TSINGHUA UNIV

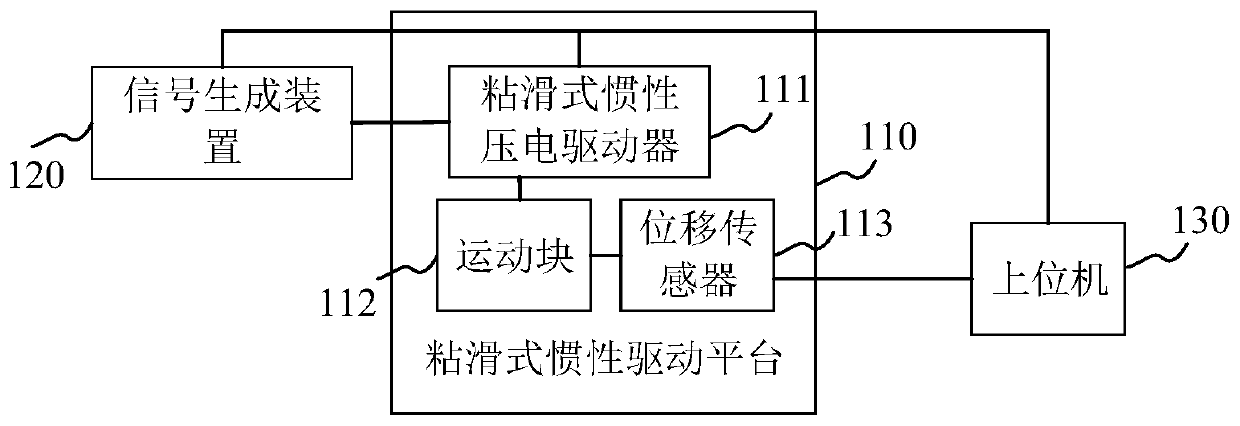

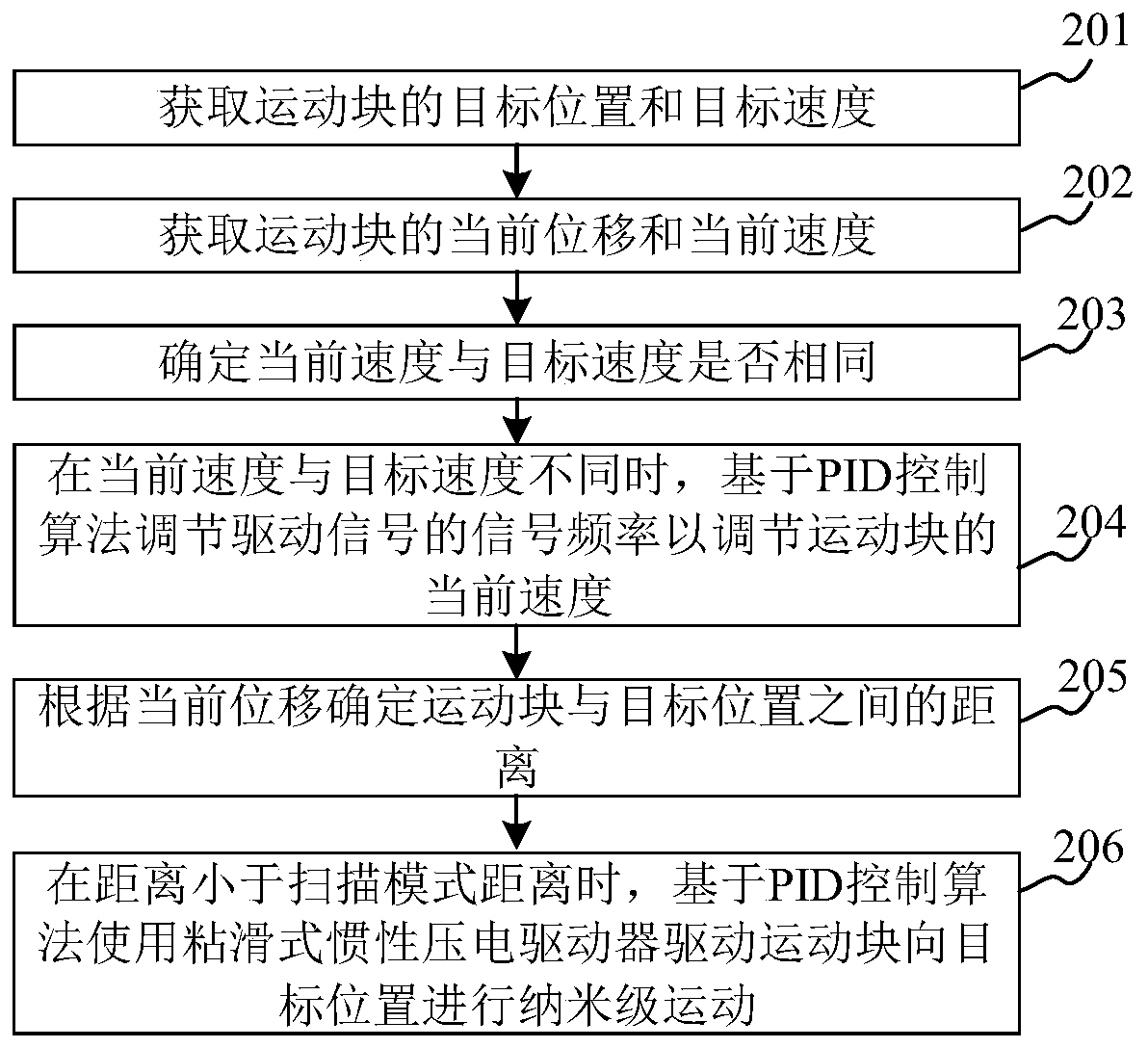

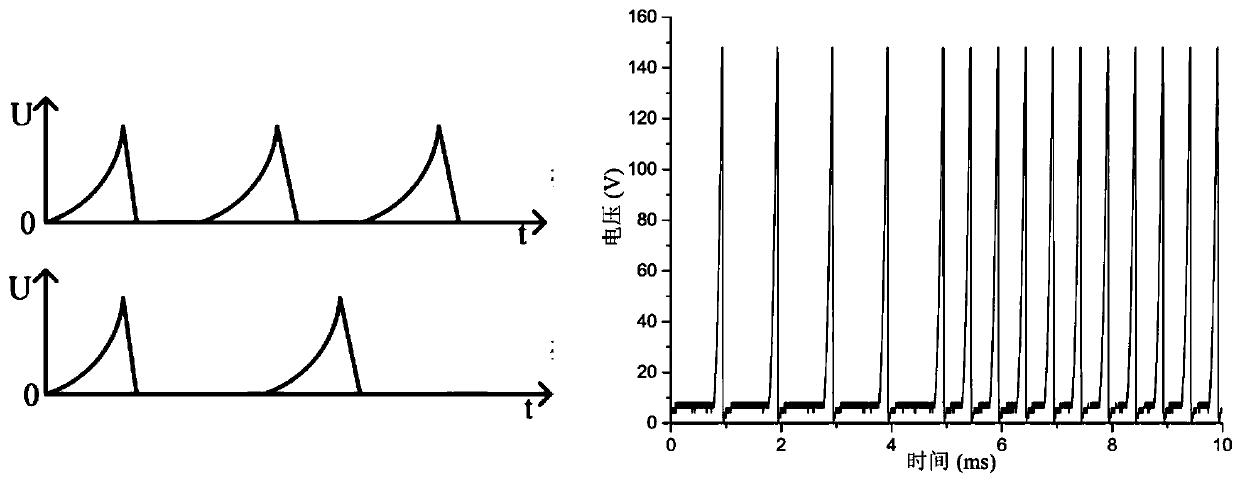

Motion control method and device for stick-slip inertial piezoelectric actuator

ActiveCN109818526AImprove driving precisionPiezoelectric/electrostriction/magnetostriction machinesCurrent velocityElectricity

The invention relates to a motion control method and device for a stick-slip inertial piezoelectric actuator, and belongs to the technical field of driving control. The method comprises the steps: obtaining a target position and a target speed of a moving block; acquiring the current displacement and the current speed of the moving block; determining whether the current speed is the same as the target speed or not; adjusting the signal frequency of the driving signal based on a PID control algorithm to adjust the current speed of the moving block when the current speed is different from the target speed; determining the distance between the moving block and the target position according to the current displacement; driving a moving block to perform nano-scale motion towards a target position based on the PID control algorithm through using a stick-slip inertial piezoelectric driver when the distance is smaller than the scanning mode distance. The method can solve the problem that the movement speed of a moving block cannot be adjusted in the prior art. The method can achieve the adjustment of the position and the speed, and improves the driving precision of the stick-slip type inertial piezoelectric actuator.

Owner:SUZHOU UNIV

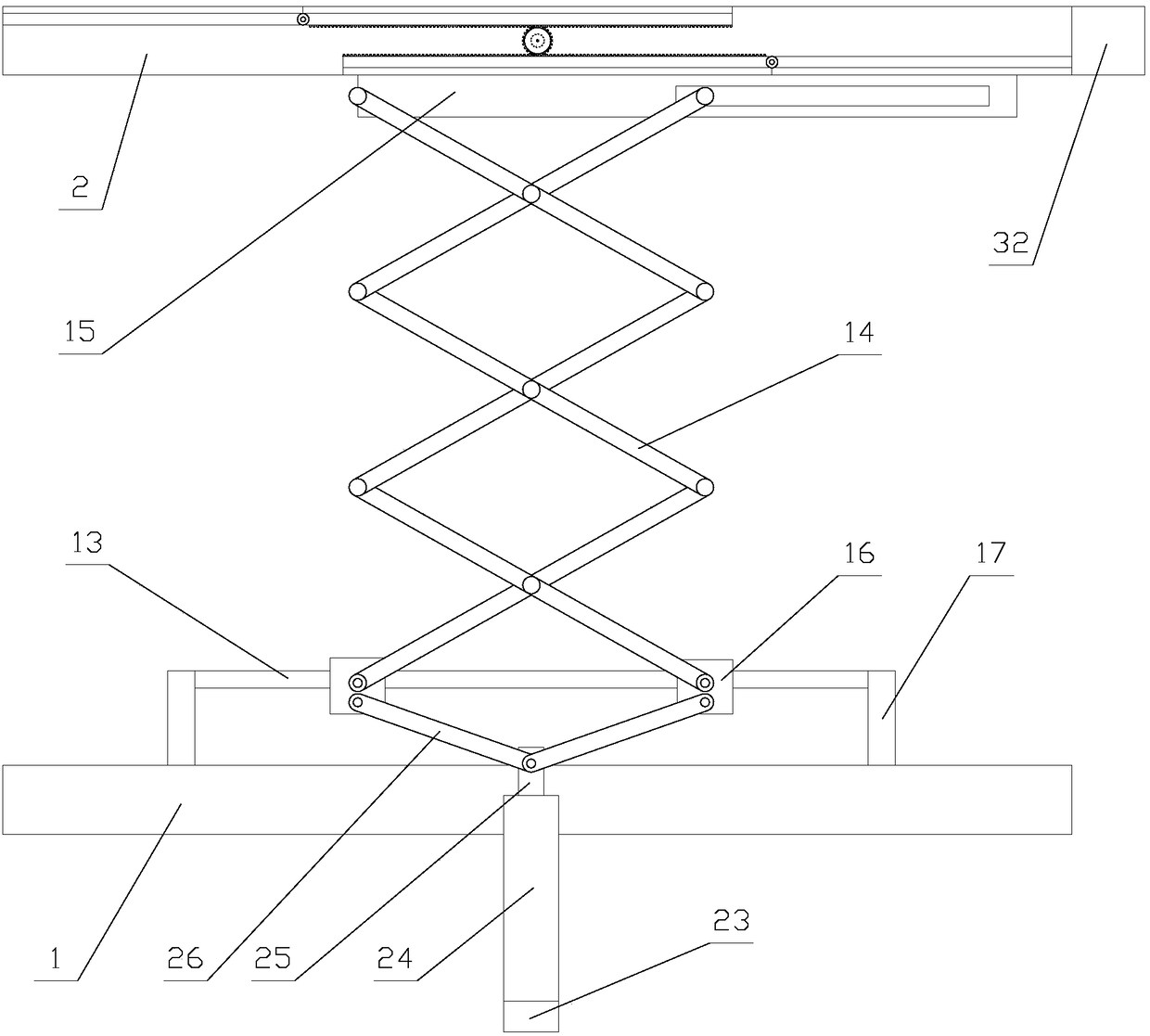

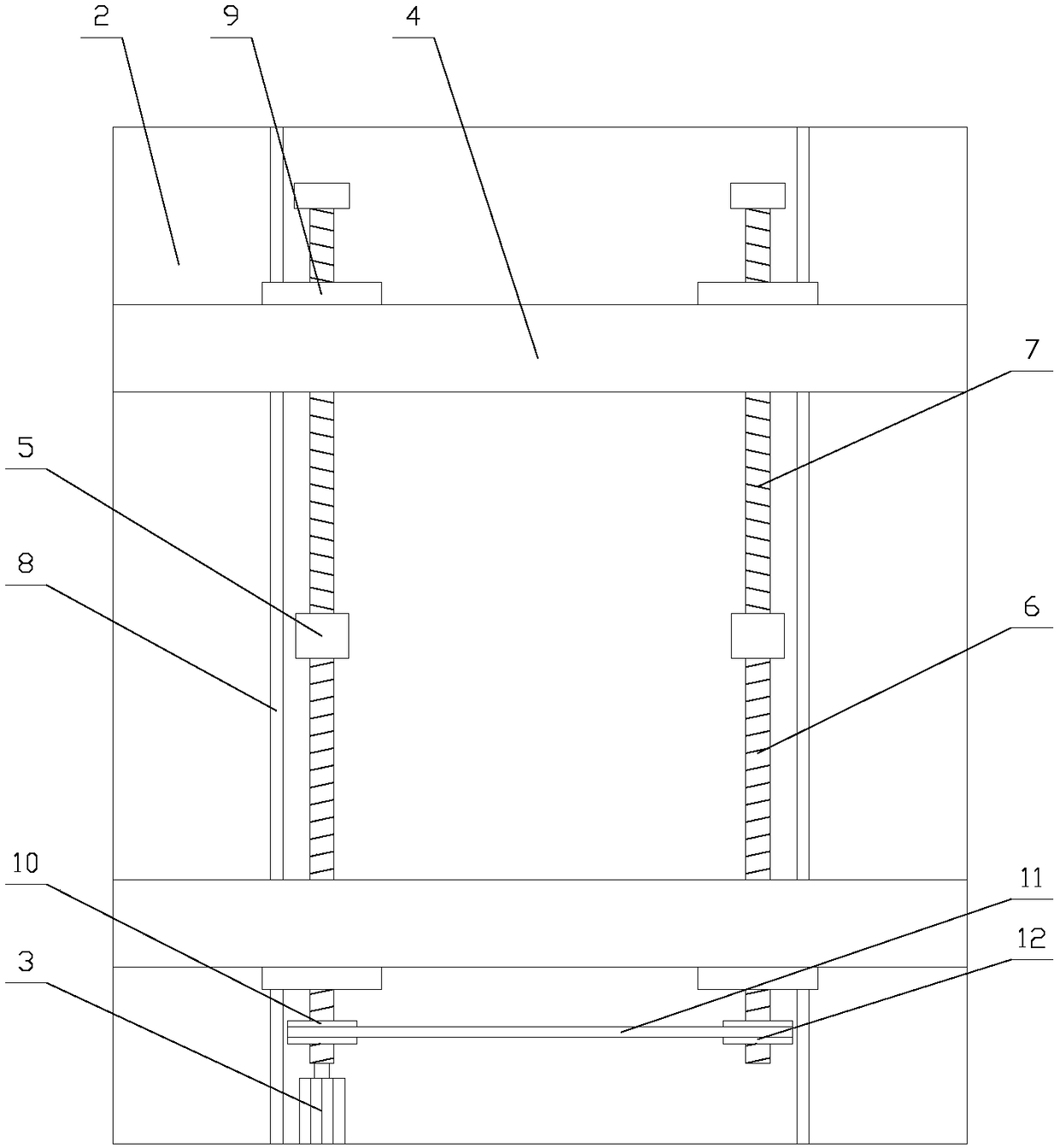

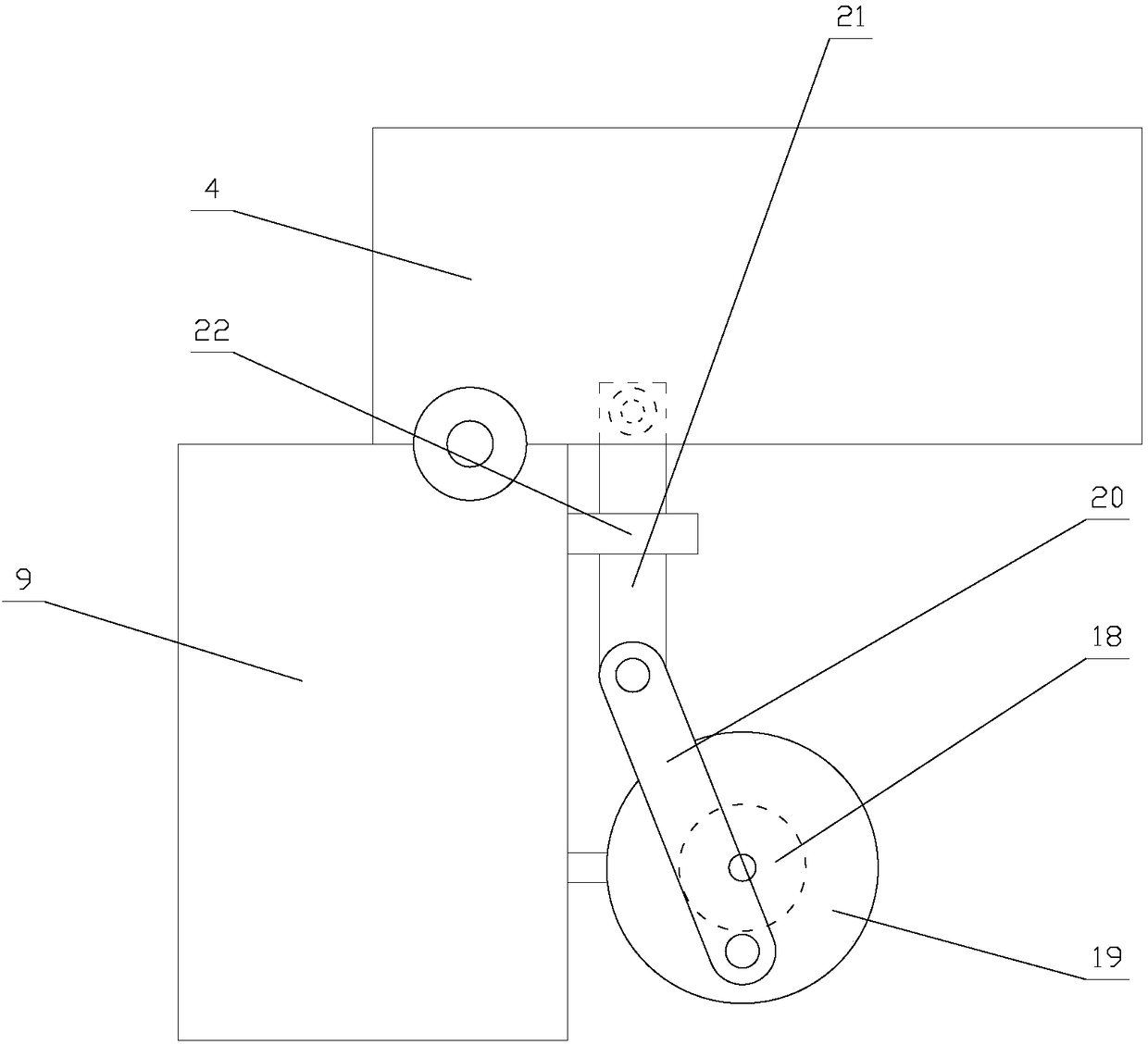

Three-dimensional-type parking equipment with protecting function and good stability

The invention relates to three-dimensional-type parking equipment with a protecting function and good stability. The three-dimensional-type parking equipment comprises a first platform, a second platform, a telescopic mechanism and a positioning mechanism. The positioning mechanism comprises a first motor, a driving assembly, two driven assemblies, two rotating assemblies and two supporting plates. Each driven assembly comprises a fixing block, a first screw rod, a second screw rod, a guiding rod and two moving blocks. Each rotating assembly comprises two rotating units. According to the three-dimensional-type parking equipment with the protecting function and good stability, front-back displacement of a vehicle parked on the second platform is limited through the positioning mechanism, and the phenomenon of sliding of the vehicle due to gravity is avoided, so that safety of the three-dimensional-type parking equipment is improved; and the second platform can be more stable through thetelescopic mechanism, displacement of the vehicle in the lateral direction is avoided, and meanwhile, the second platform can be supported, so that stability of the three-dimensional-type parking equipment is further improved.

Owner:SHENZHEN ANSIKE ELECTRONICS TECH CO LTD

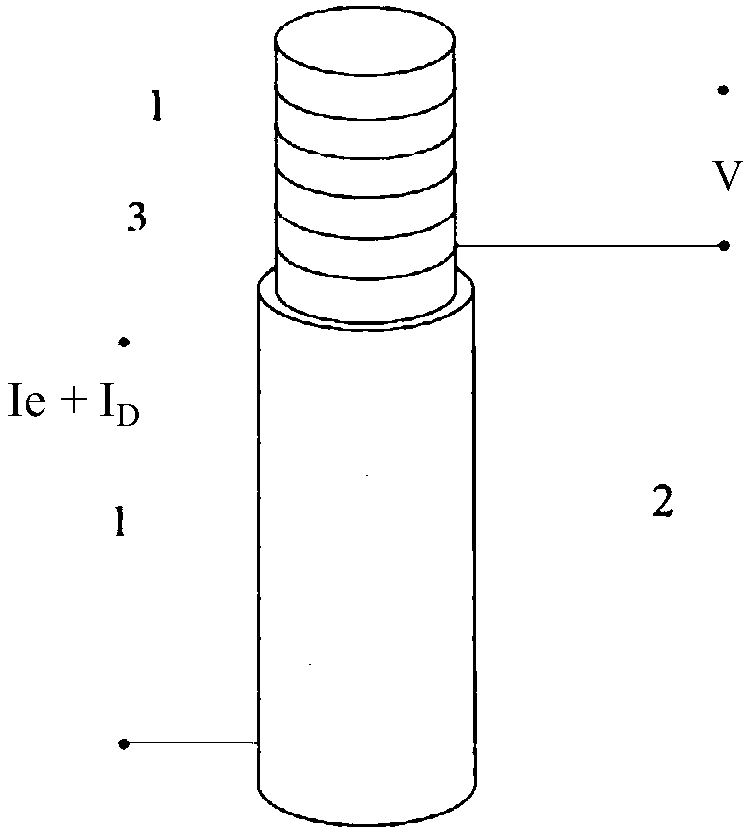

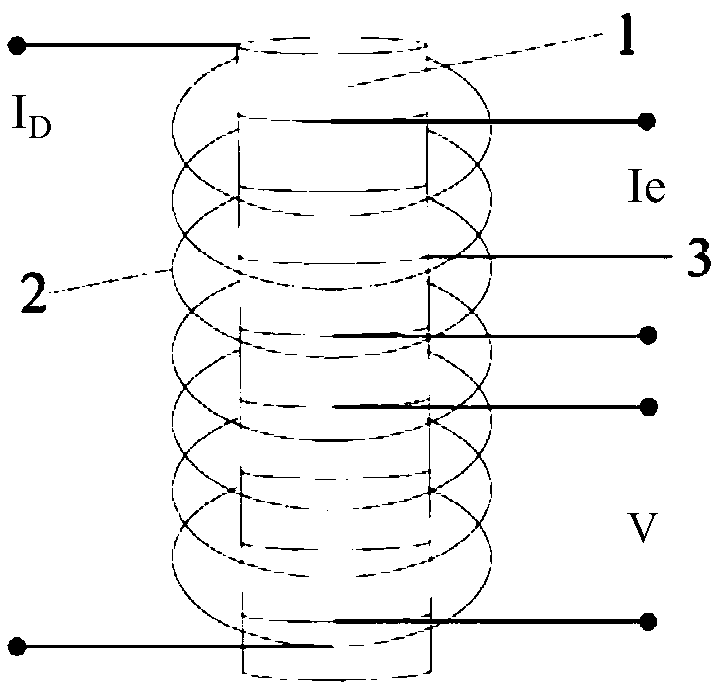

Self-sensing driver based on magnetostrictive material

ActiveCN109495009AImprove compactnessReduce volumePiezoelectric/electrostriction/magnetostriction machinesEngineeringSelf sensing

The invention provides a self-sensing driver based on a magnetostrictive material. The self-sensing driver comprises a driving part and a sensing part. The driving part comprises a driving coil and adriving body. The sensing part comprises an excitation coil, an induction coil and a sensing body. The driving body is mainly made of the magnetostrictive material. The driving body generates a magnetostrictive effect under the action of a driving signal. The driving body is elongated or shortened, so that the driving part outputs displacement and force. The sensing body is mainly made of the magnetostrictive material. The induction coil outputs an induction signal V1 under the action of an excitation signal. After the sensing part is subjected to the impact from the driving part, the magneticfield of the sensing body changes, and the induction signal output by the induction coil of the sensing part is changed to V2. The displacement and force of the driving part are detected by measuringthe signal change V output by the induction coil. According to the invention, the functions of the driver and a sensor can be realized at the same time, and the structure compactness, the driving precision and the sensing efficiency are improved.

Owner:伶机(上海)驱动技术中心(有限合伙)

X-shaped high-precision and high-expansion flexible displacement amplification mechanism

InactiveCN103500794AImprove output displacement accuracyRealize micro-displacement amplification functionPiezoelectric/electrostrictive devicesDevice detailsEngineeringActuator

The invention discloses an X-shaped high-precision and high-expansion flexible displacement amplification mechanism which comprises an outer X-shaped frame, a first actuator adapting push rod, a first intelligent material actuator, an output end flexible hinge, a fixed end flexible hinge, a second intelligent material actuator, an inner X-shaped frame, a second actuator adapting push rod and an inner and outer frame flexible connecting hinge. The upper end of the outer X-shaped frame is connected with the right end of the inner and outer frame flexible connecting hinge, the bottom end of the outer X-shaped frame is connected with the second intelligent material actuator, and the other end of the second intelligent material actuator is connected with the left end of the inner and outer frame flexible connecting hinge through the second actuator adapting push rod. The bottom end of the outer X-shaped frame is further connected with the fixed end flexible hinge. The upper end of the inner X-shaped frame is connected with the left end of the inner and outer frame flexible connecting hinge, the bottom end of the inner X-shaped frame is connected with the first intelligent material actuator, the other end of the first intelligent material actuator is connected with the right end of the inner and outer frame flexible connecting hinge through the first actuator adapting push rod, and the bottom end of the inner X-shaped frame is further connected with the output end flexible hinge.

Owner:BEIHANG UNIV

Novel LED light source

PendingCN111261623ACorrect and compensate color temperatureImprove stabilitySolid-state devicesSemiconductor devicesEngineeringGreen-light

The invention discloses a novel LED light source. The novel LED light source is characterized in that the novel LED light source is of a COB structure and comprises a COB substrate, an LED red light chip, an LED green light chip, an LED blue light chip, two packaging box dams with different sizes, a packaging glue and the like; the COB substrate is provided with an inner side bonding pad, an outerside bonding pad, four or six electrode welding pins, electrode welding pin wires and the like, wherein the inner side bonding pad and the outer side bonding pad are used for placing LED chips; the packaging glue comprises transparent glue and fluorescent powder adding glue; the LED chips are installed on the bonding pads of the COB substrate respectively and are conductively connected to the electrode welding pins; the packaging box dams are filled with the two kinds of packaging glue respectively; and the LED light source is obtained after solidification is performed. According to the novelLED light source of the invention, the LED light source is packaged through the two kinds of glue; the color temperature and the light color of the obtained LED light source can be adjusted at will,so that the problem that the color temperature of an existing LED light source is single is solved, and the multi-application performance of such a light source in different and fixed scene changes isachieved; the LED light source is additionally provided with the LED red chip and the LED green chip, so that the problems of color attenuation and color shift of an existing high-power LED light source in long-term use can be correct and offset.

Owner:轻工业部南京电光源材料科学研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com