Novel LED light source

A LED light source, a new type of technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problem of single color temperature, etc., and achieve the effects of convenient preparation, high driving precision, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

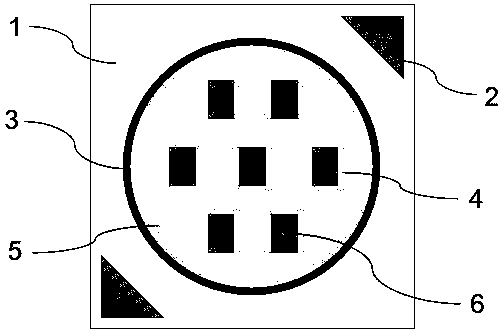

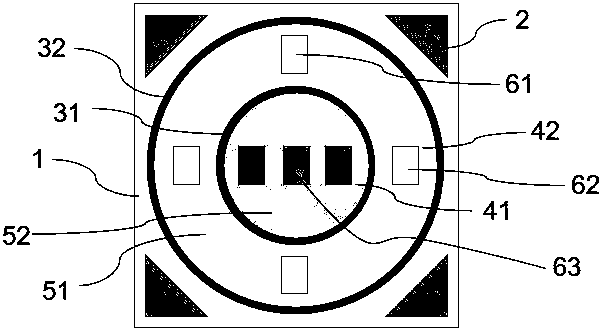

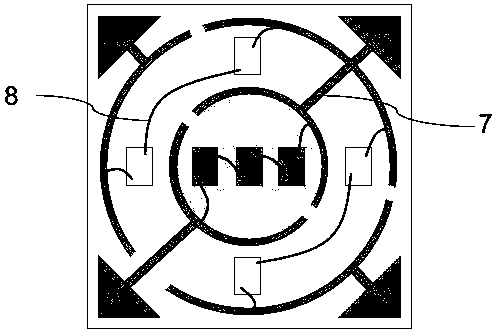

Embodiment 1

[0034] Such as figure 2 As shown, the LED light source is a COB common anode structure. The COB substrate 1 includes four electrode soldering pins 2, one of which is connected to the positive pole and three of which are connected to the negative pole. The substrate 1 is also provided with an inner pad 41 and an outer pad 42. The electrodes Welding wires 7 are arranged around the pads and communicate with the electrode soldering pins 2 respectively. Multiple groups of LED blue light chips 63 are fixed on the pads 41 through crystal bonding glue, and multiple groups of LED red and green chips are fixed on the pads 42. Above, the positive and negative poles of the LED chip are conducted through the conductive lead wire 8 or the conductive material and the electrode welding leg wire 7. The specific connection method is as follows: image 3 As shown, the positive poles of the LED R, G, and B chips are all connected to the common positive pole of the welding pin, and the negative p...

Embodiment 2

[0037] Such as Figure 4 As shown, and with reference to Embodiment 1, the structure of the LED light source is changed from square to hexagonal, and the number of electrode welding feet is increased to six. In addition, the difference from Embodiment 1 lies in that the LED chips of the same type are each positive, The negative electrode is respectively connected to the positive and negative electrodes of one of the welding legs, and the others are the same.

Embodiment 3

[0039] Such as Figure 5 As shown, and with reference to Embodiment 1, the difference from Embodiment 1 is that multiple groups of LED blue light chips 63 are fixed on the pad 42 by die-bonding glue, and multiple groups of LED red light and green light chips are fixed on the pad 41 Above; glue 51 is dispensed and packaged at the inner dam 31, and glue 52 is packaged between the dams 31 and 32, and the others are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com