Patents

Literature

99results about How to "Precise control of movement speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

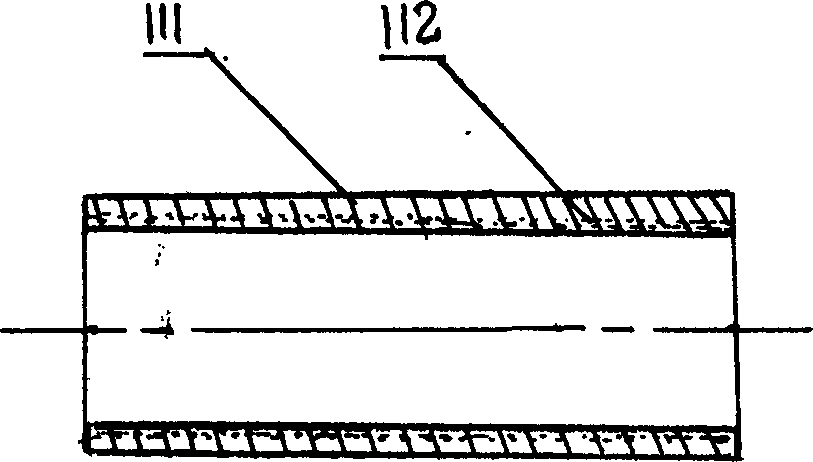

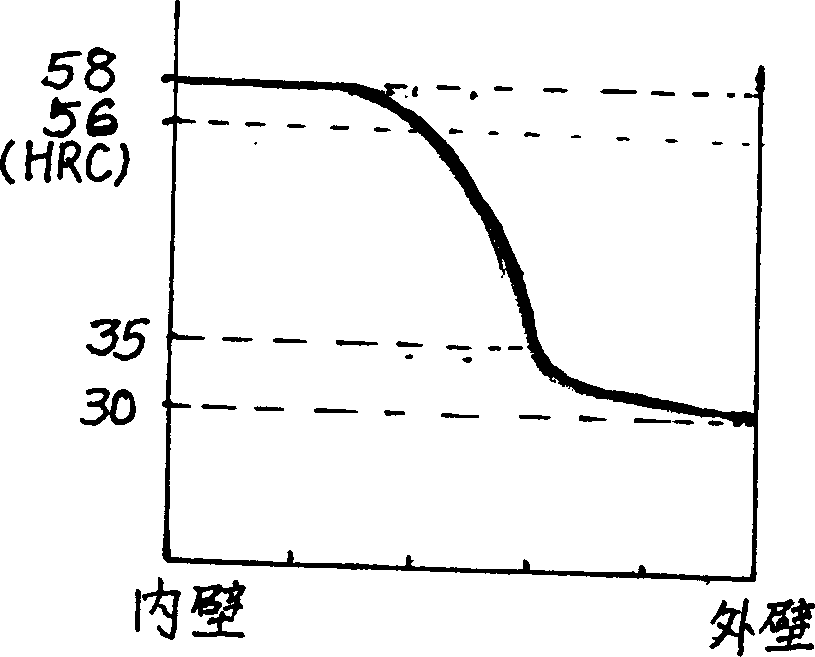

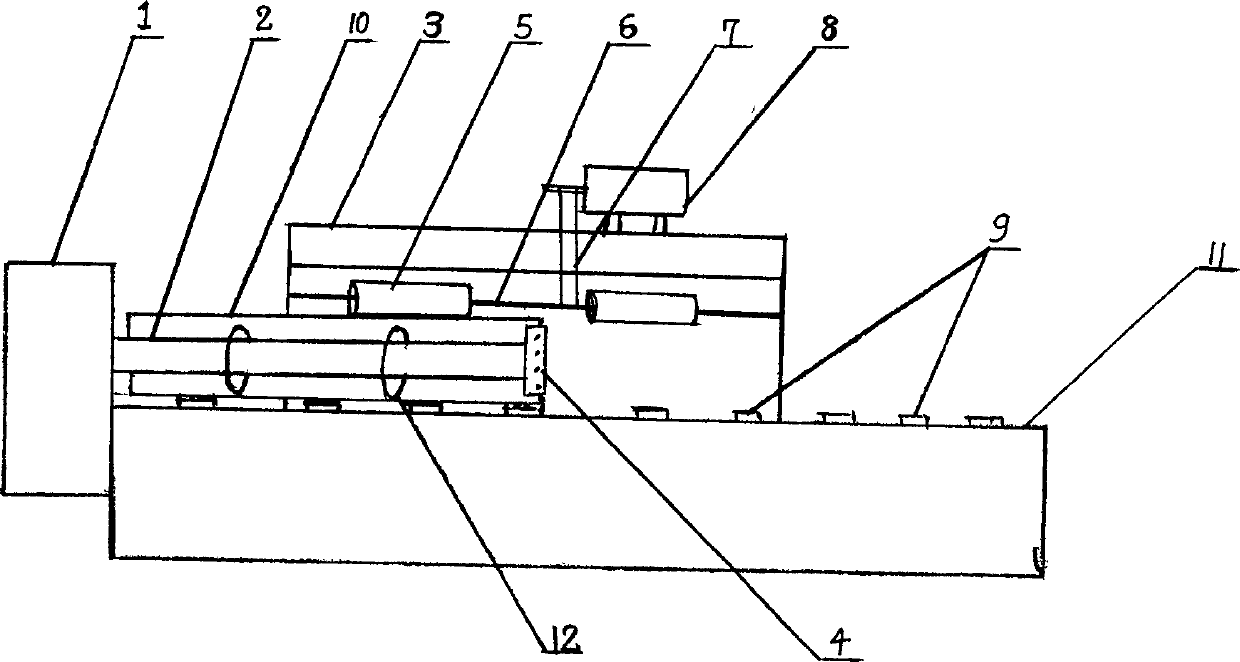

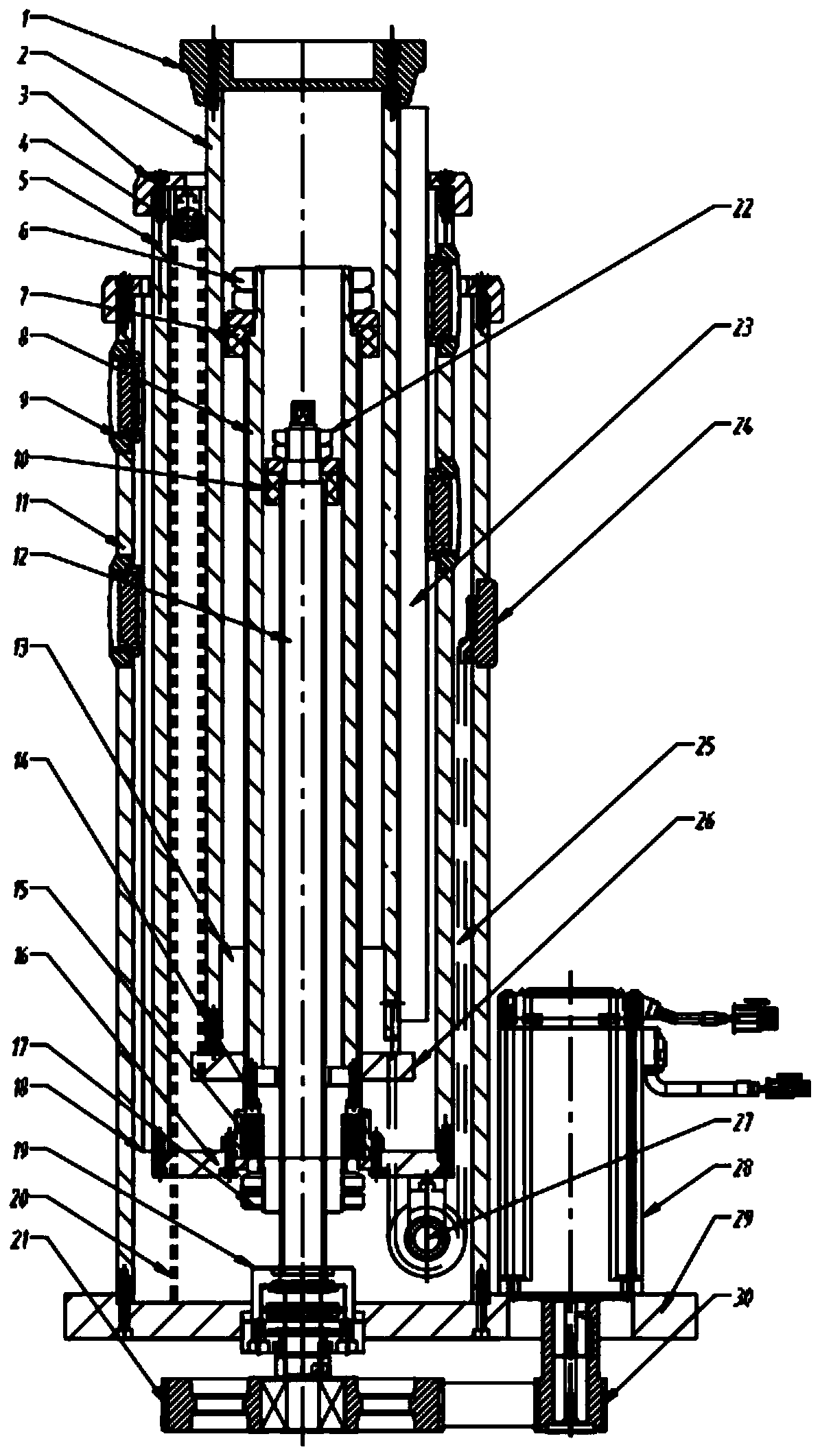

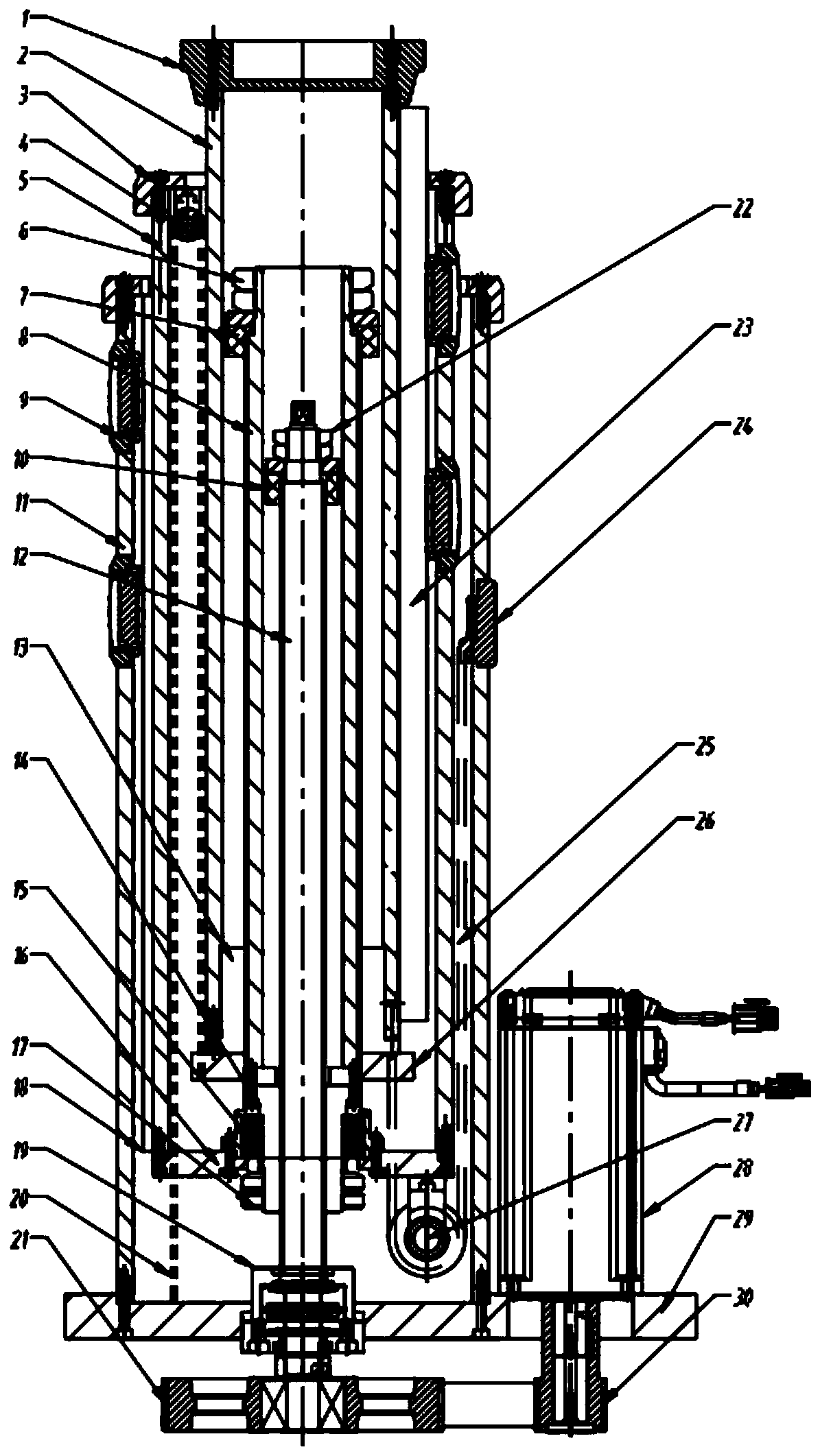

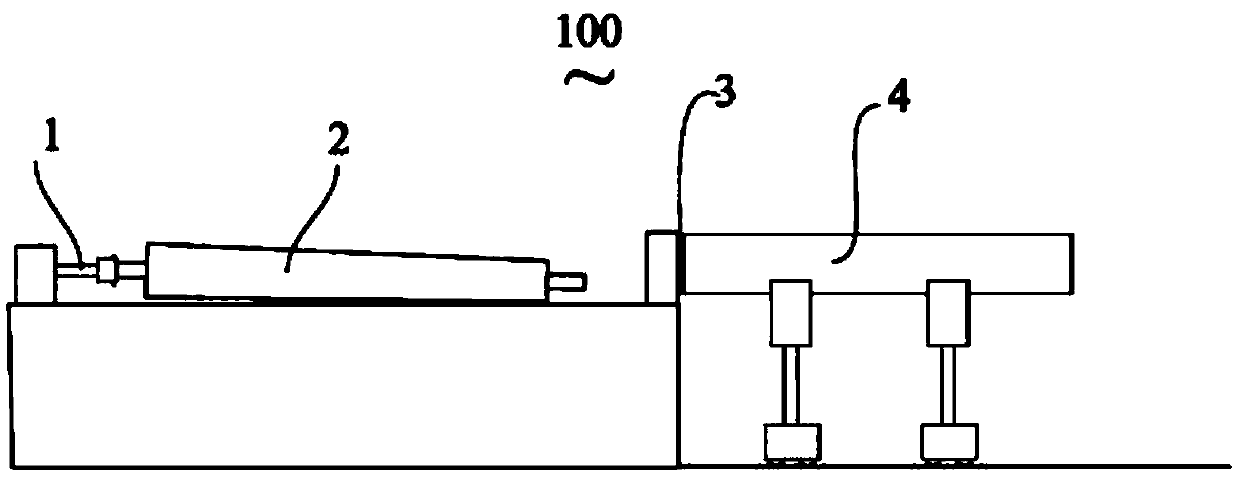

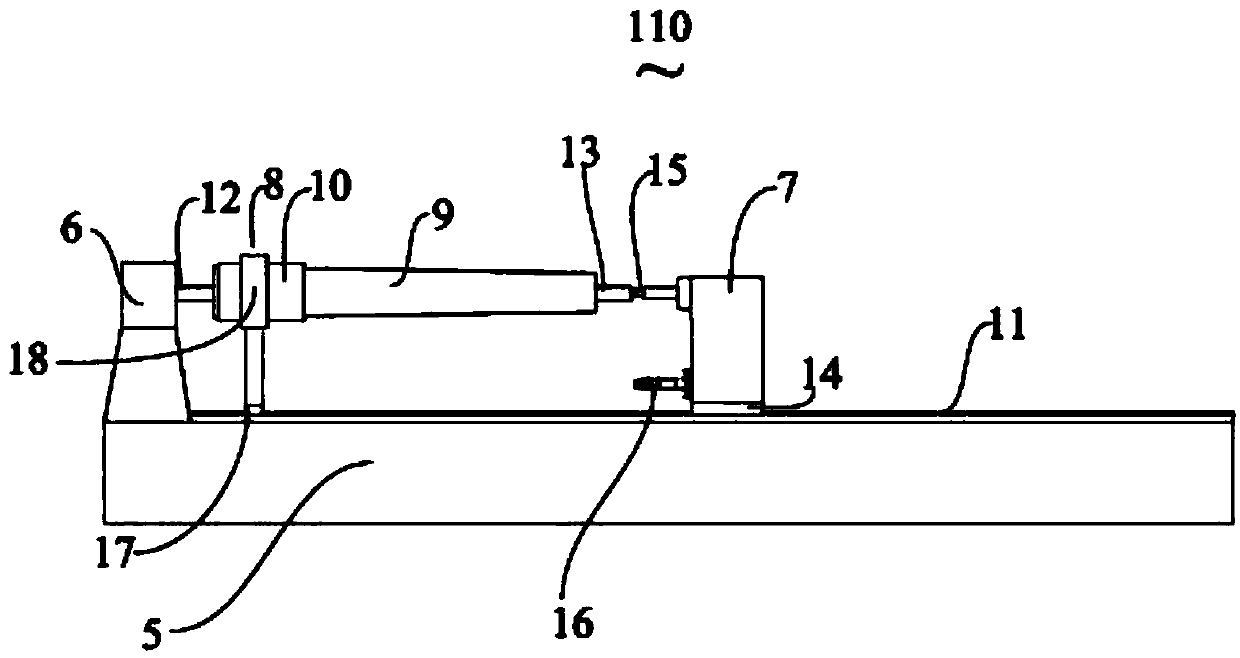

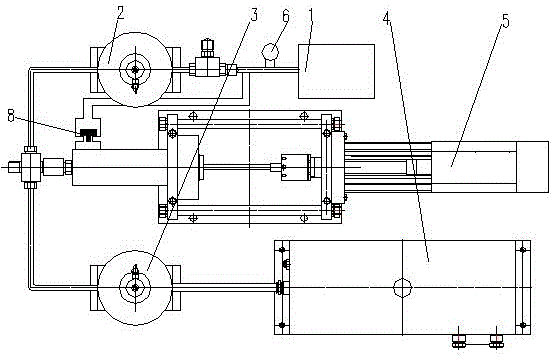

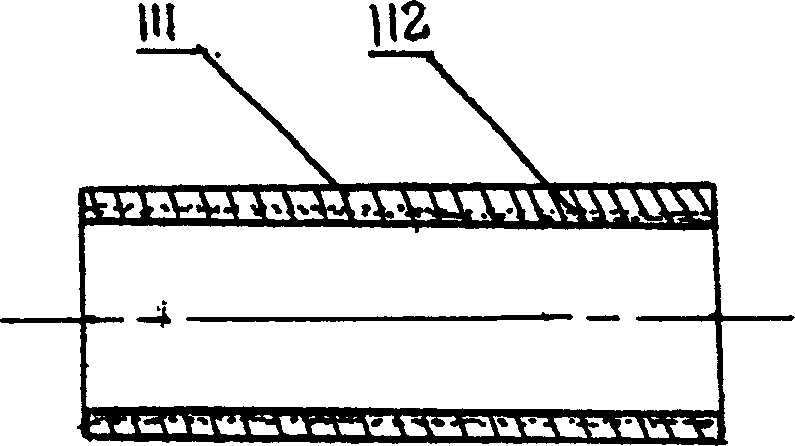

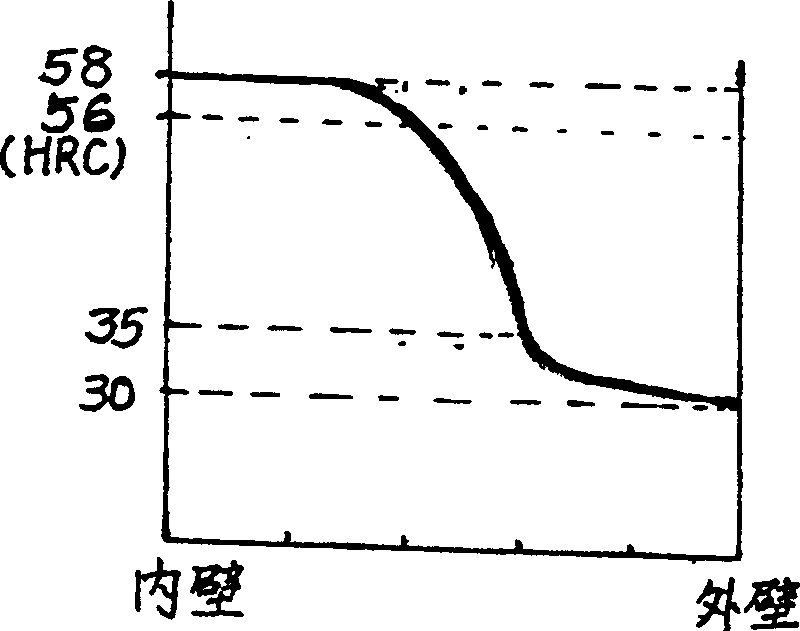

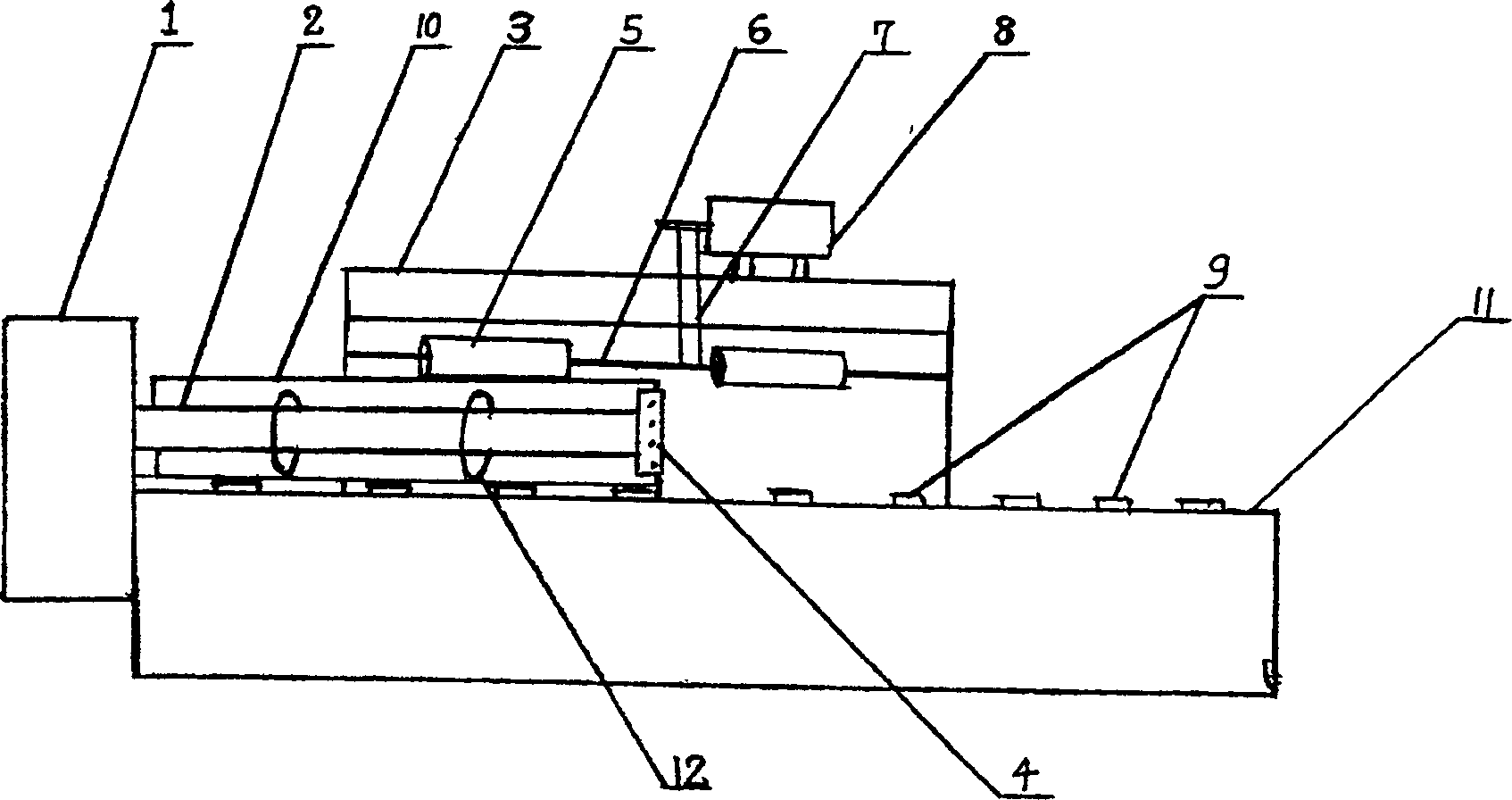

Cylinder shape pipe piece with inner harden layer and production method and equipment

InactiveCN1433942ALarge caliberSave materialIncreasing energy efficiencyFurnace typesFrictional coefficientEngineering

The present invention relates to a cylindrical pipe with internal hardened layer, its production method and special-purpose equipment. Said cylindrical pipe has small wall thickness and long length, its pipe wall has internal layer and external layer with different hardness, the hardness of its internal layer is greater than that of external layer, and said pipe is applicable for conveying material with high frictional coefficient. Its production method adopts the mode utilizing frequency to control pipe movement and proper hardening temp. range, and is special-purpose equipment is simple in structure, stable in operation, and can accurately control hardening temp., pipe moving speed nad depth of hardened layer.

Owner:王克发 +1

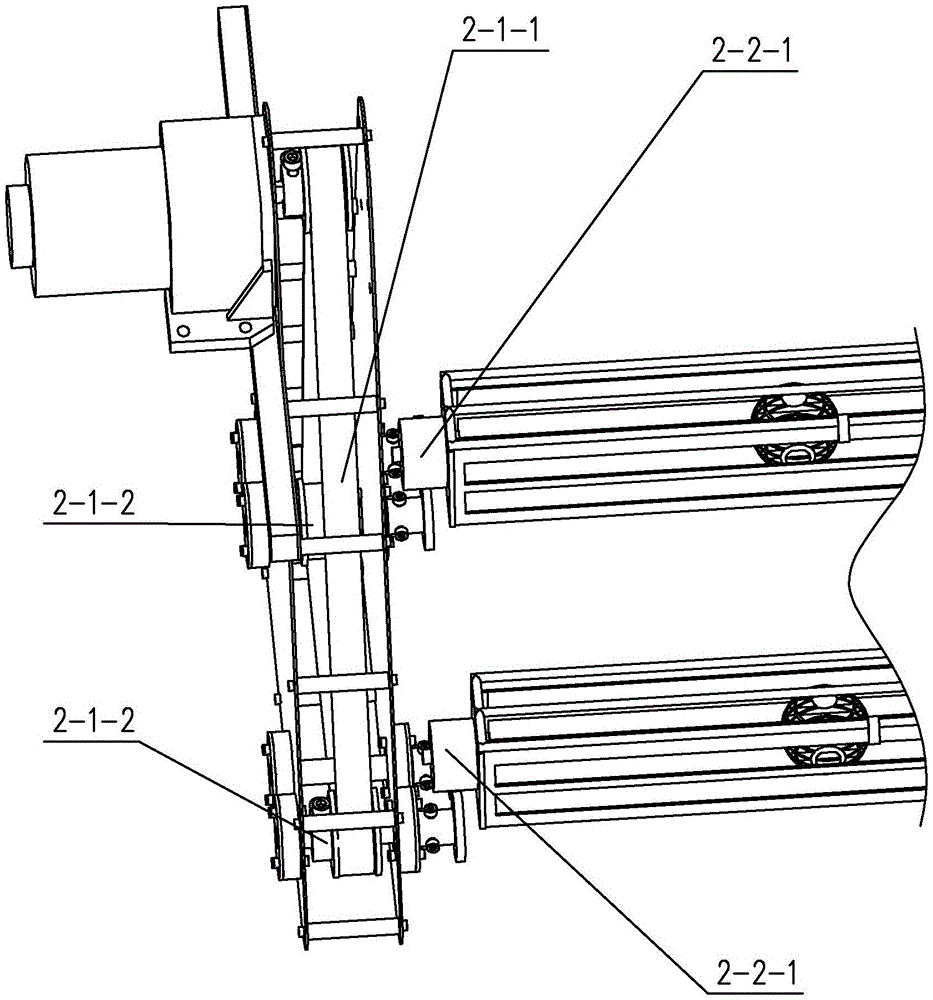

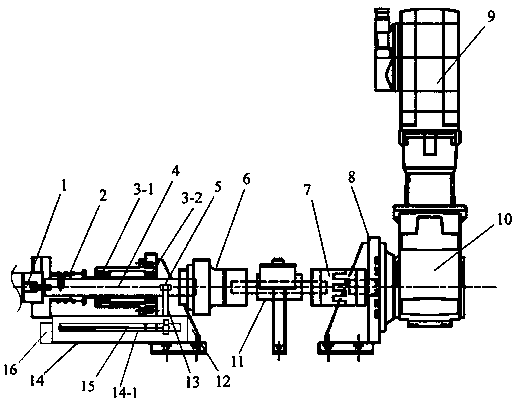

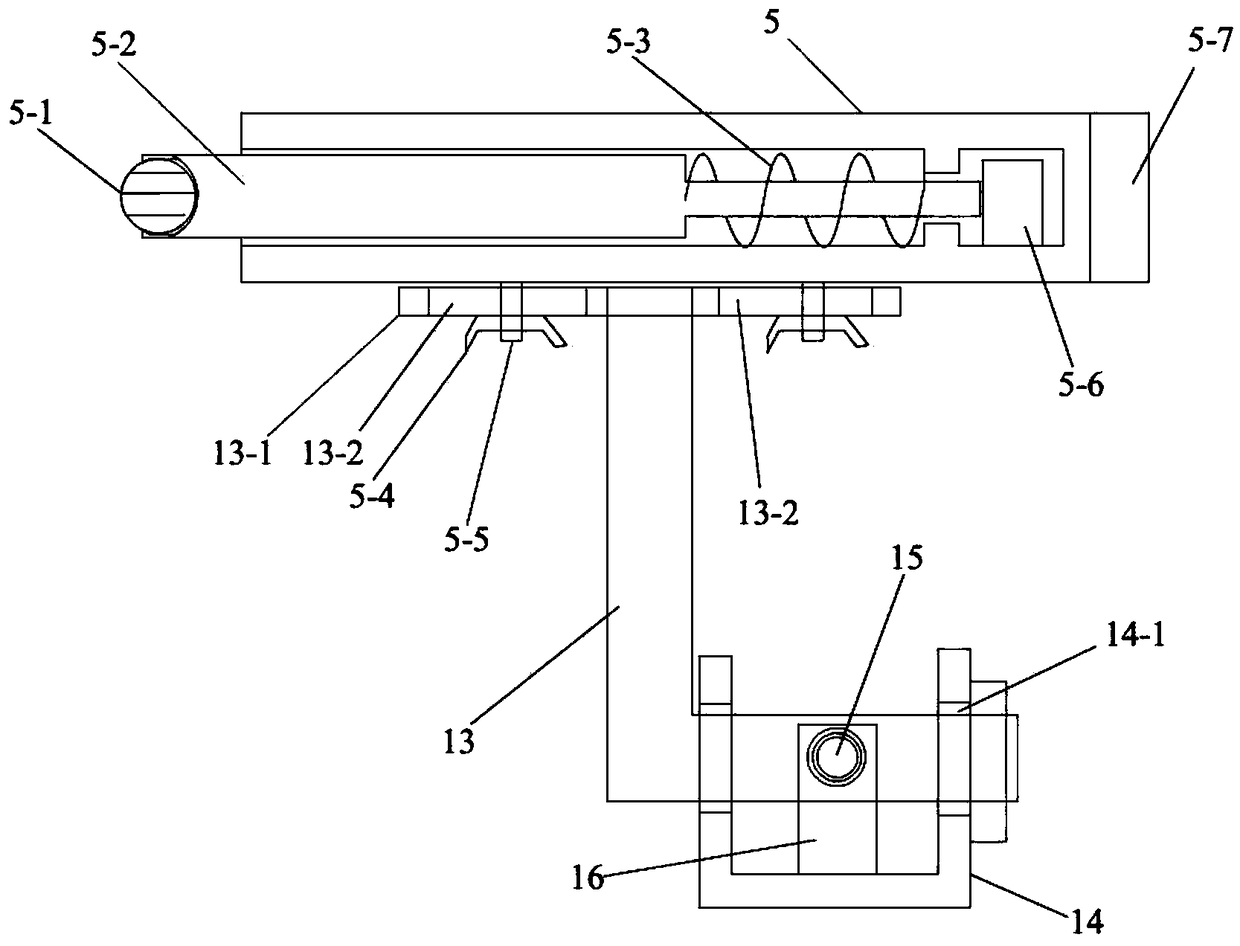

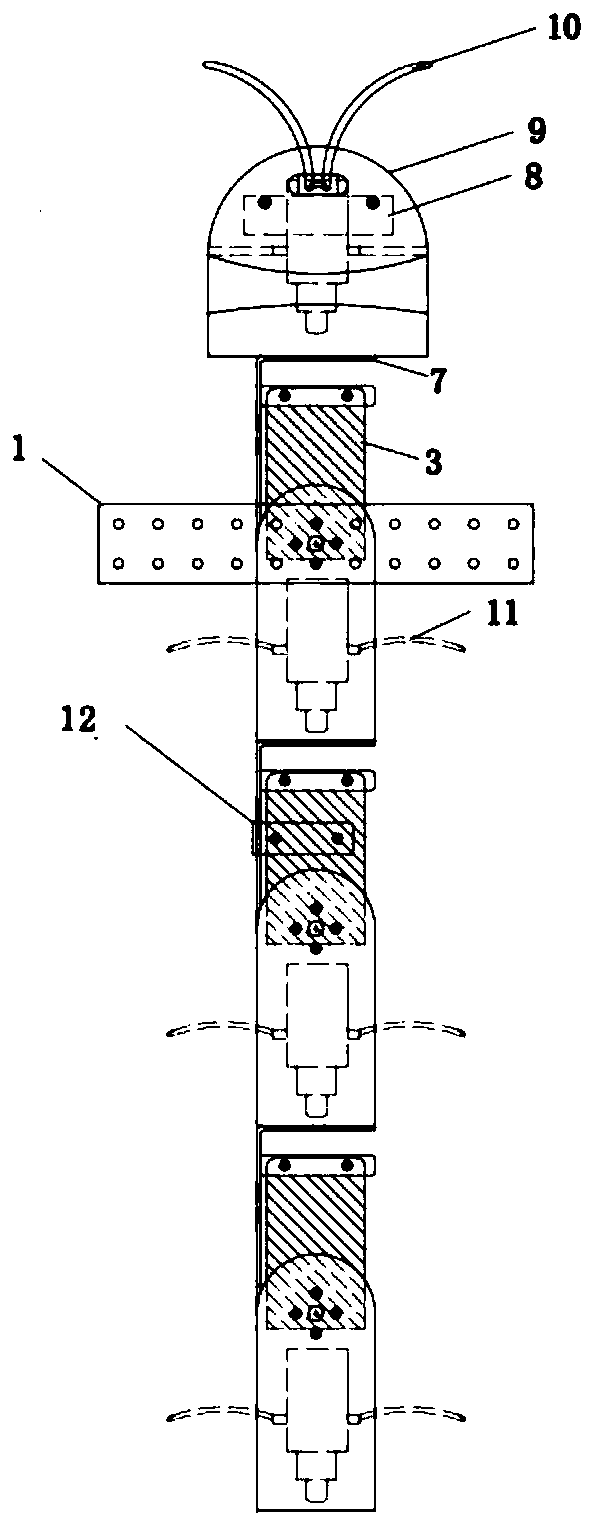

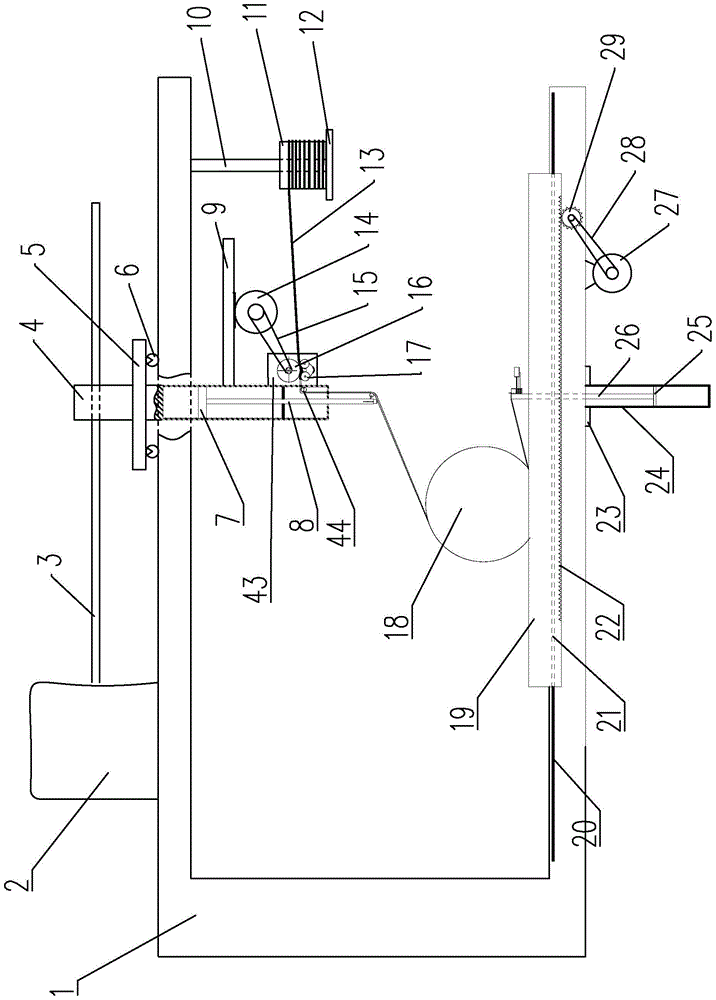

Multi-stage synchronous screw rod push rod mechanism

ActiveCN109915567APrecise Control of DisplacementPrecise control of movement speedGearingMechanical energy handlingBall screw driveEngineering

The invention discloses a multi-stage synchronous screw rod push rod mechanism. The multi-stage synchronous screw rod push rod mechanism comprises a transmission mechanism, a stretching mechanism, a fixing mechanism and a guide mechanism. A servo motor of the transmission mechanism drives a first-stage ball screw of a first-stage transmission mechanism to rotate through a motor synchronous pulleyand a ball screw synchronous pulley sequentially, the first-stage ball screw drives a first-stage ball nut and a first-stage guide mechanism to move so as to drive the other-stage hollow ball screws to rotate separately, thereby driving the ball nuts and guide mechanisms corresponding to the hollow ball screws at the same stage to move through the stretching mechanism. The multi-stage synchronousscrew rod pushing rod mechanism is small in size and capable of realizing large-stroke transmission, high-precision expansion about n times of the length of the mechanism is realized, and a pluralityof sections can be expanded and retracted simultaneously. The multi-stage ball screw push rod mechanism can achieve synchronous expansion and retraction of the multi-stage ball screws at the same speed, and has the characteristics of being high in transmission precision, small in occupied space, high in transmission efficiency, low in noise and the like.

Owner:NANJING UNIV OF SCI & TECH +1

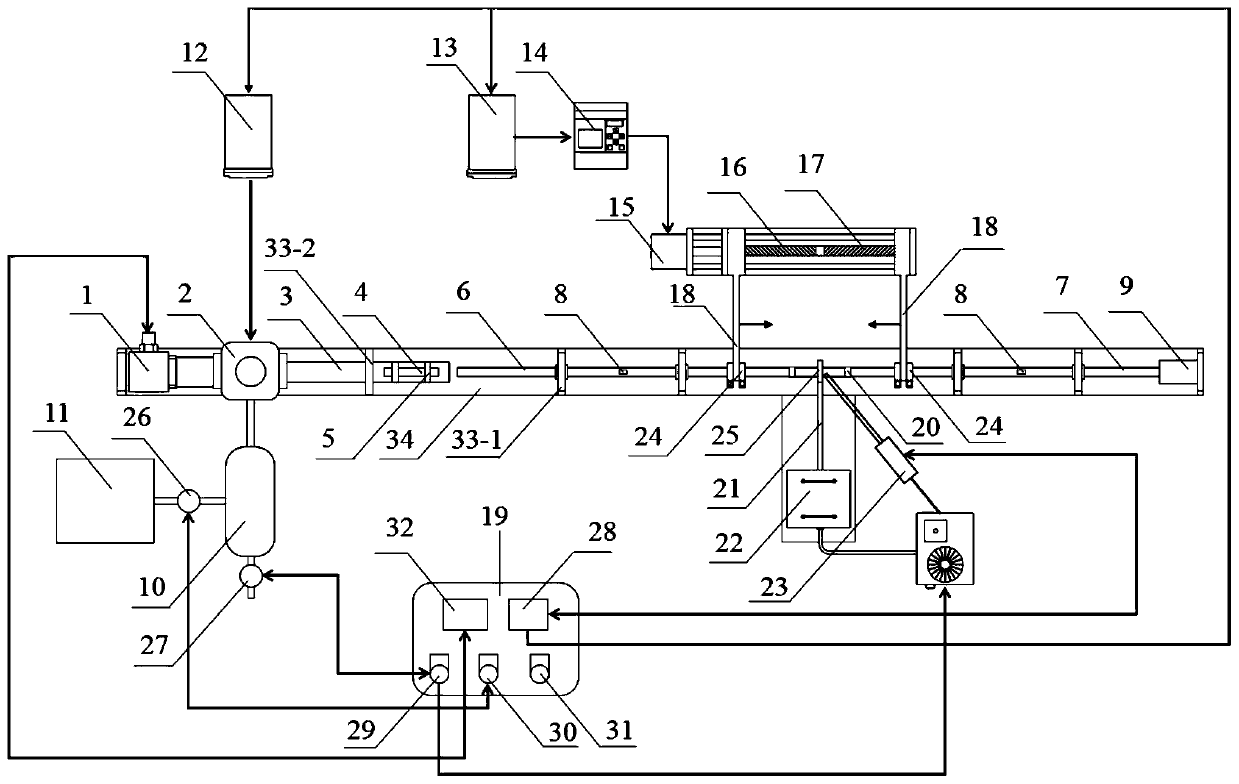

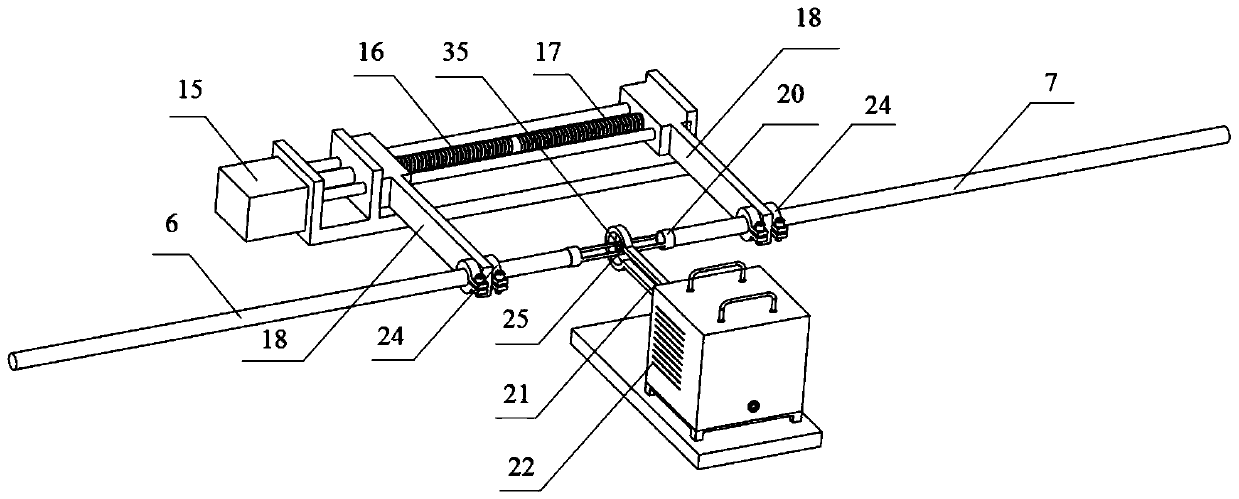

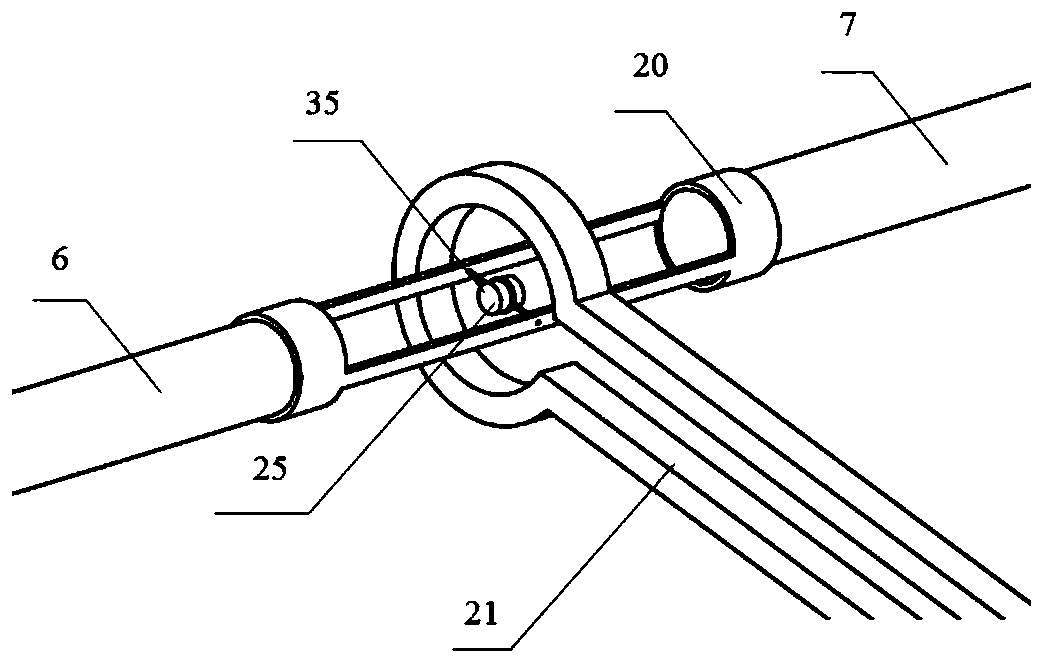

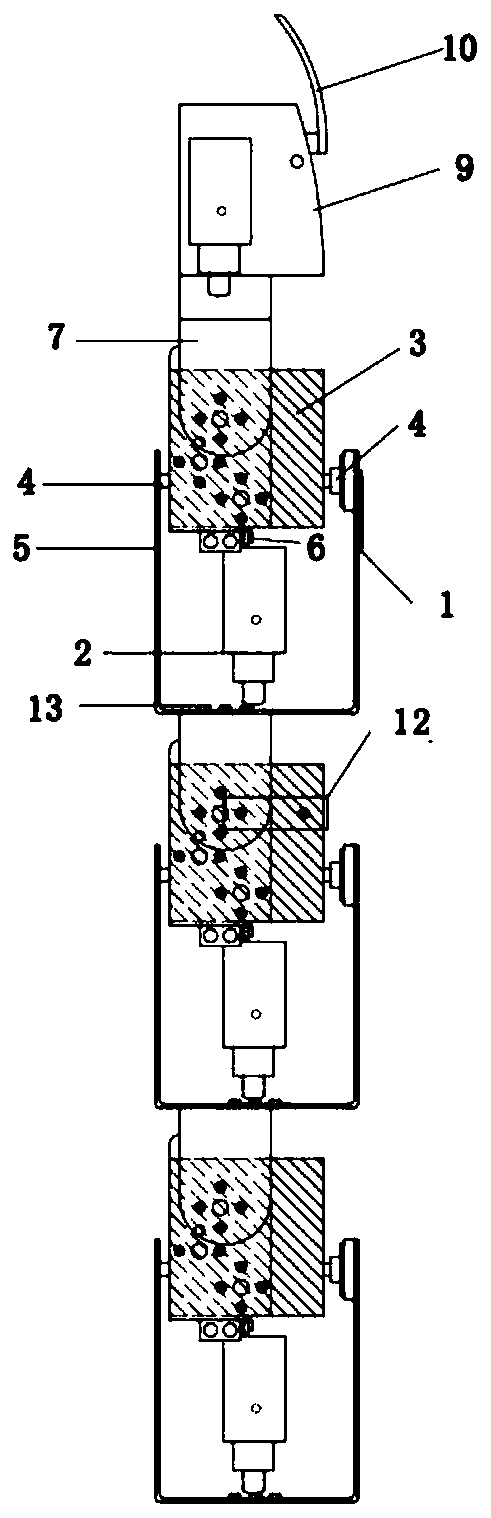

High-temperature Hopkinson tensile bar test system by using two-way electromagnetically-driven synchronous assembly and method

ActiveCN110196199APrecise dynamic compression mechanical propertiesPrecise control of hot and cold contact timeMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesPilot systemDirect test

The invention relates to a high-temperature Hopkinson tensile bar test system by using two-way electromagnetically-driven synchronous assembly and method. A high-temperature Hopkinson tensile bar system and a high-temperature compression test method which use an accurate electromagnetically-driven two-way synchronous sliding assembly system and a high-frequency electromagnetic induction rapid heating method are built. According to the device in the invention, a set of electromagnetic control device, a set of electromagnetically-driven two-way synchronous assembly device and two high-precisiondelay devices are additionally arranged on the conventional Hopkinson tensile bar, the starting and ending time of each process including an impact process, a heating process and a loading rod synchronous assembly process during the high-temperature dynamic compression test can be accurately controlled, and the cold and hot contact time during the whole test process can be further accurately controlled. A control component is designed in an integrated module mode, the test accuracy is improved, and the dynamic compression mechanical properties of the material at a high temperature can be accurately and directly tested.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

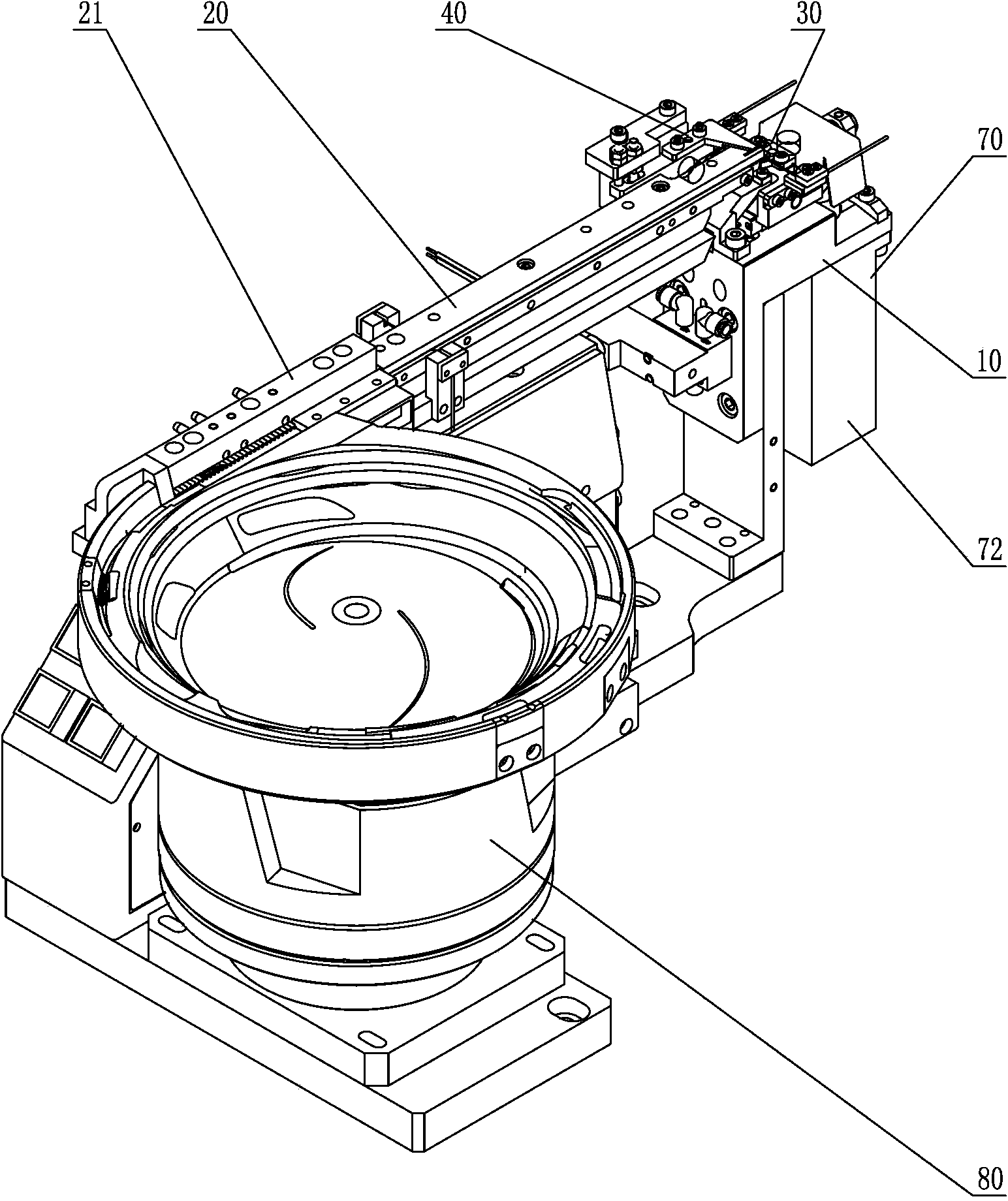

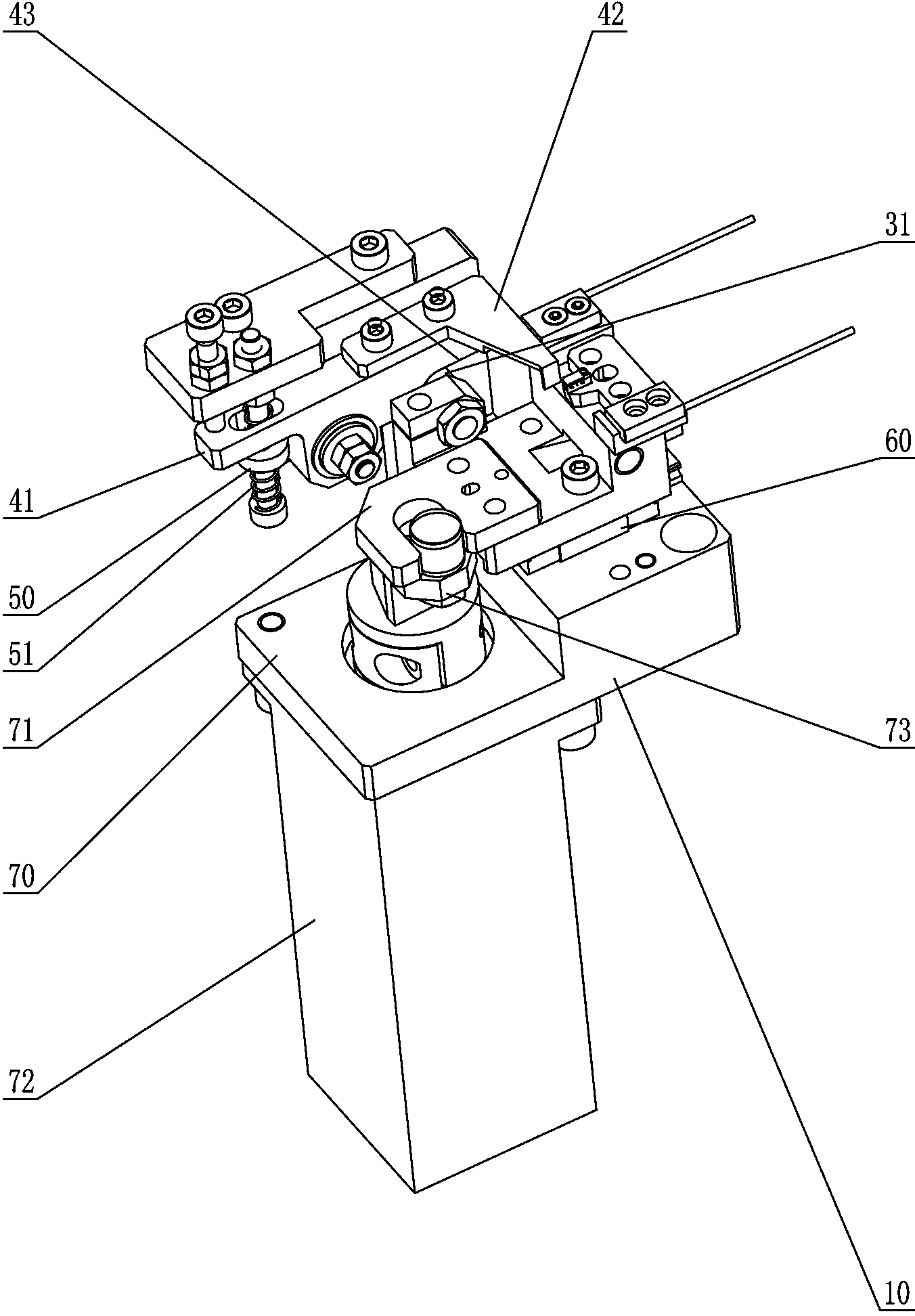

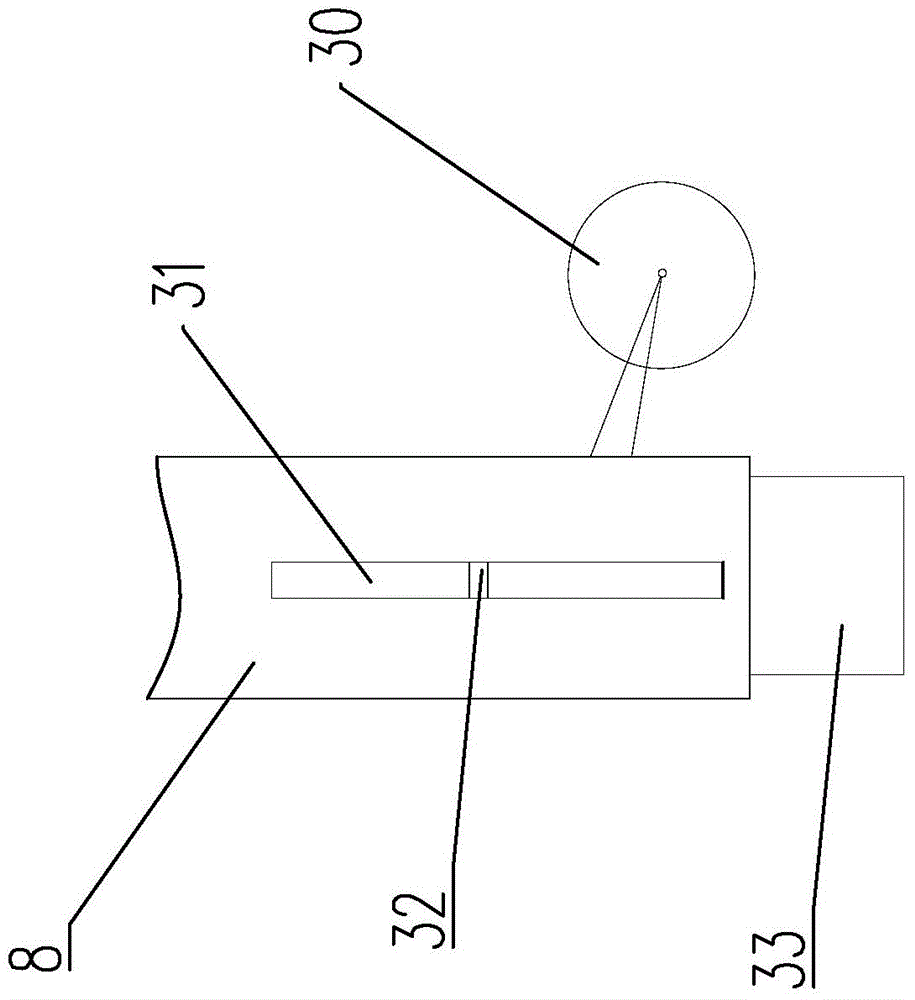

Feeding apparatus

ActiveCN104114015ASolve the bottleneck problem of production and processing efficiencyImprove feeding efficiencyElectrical componentsEngineeringMagnet

The invention discloses a feeding apparatus. The feeding apparatus comprises a pedestal, a channel connected with the pedestal, a material fixing mechanism which is arranged at one end of the channel and can horizontally move relative to the channel, and a material blocking mechanism which is used for blocking materials in the channel. The material blocking mechanism comprises a swing block and a blocking sheet connected with the swing block. The swing block comprises a guide surface. The material fixing mechanism further comprises a roller which is contacted with and cooperates with the guide surface. The feeding apparatus further comprises a vibration disc arranged at the other side of the channel. One side, which is close to the vibration disc, of the channel is provided with a magnet. The feeding apparatus with such a structure can rapidly separate the multiple materials which are tidily arranged in the channel and are closely attached and send the materials to a next processing station.

Owner:深圳市复德科技有限公司

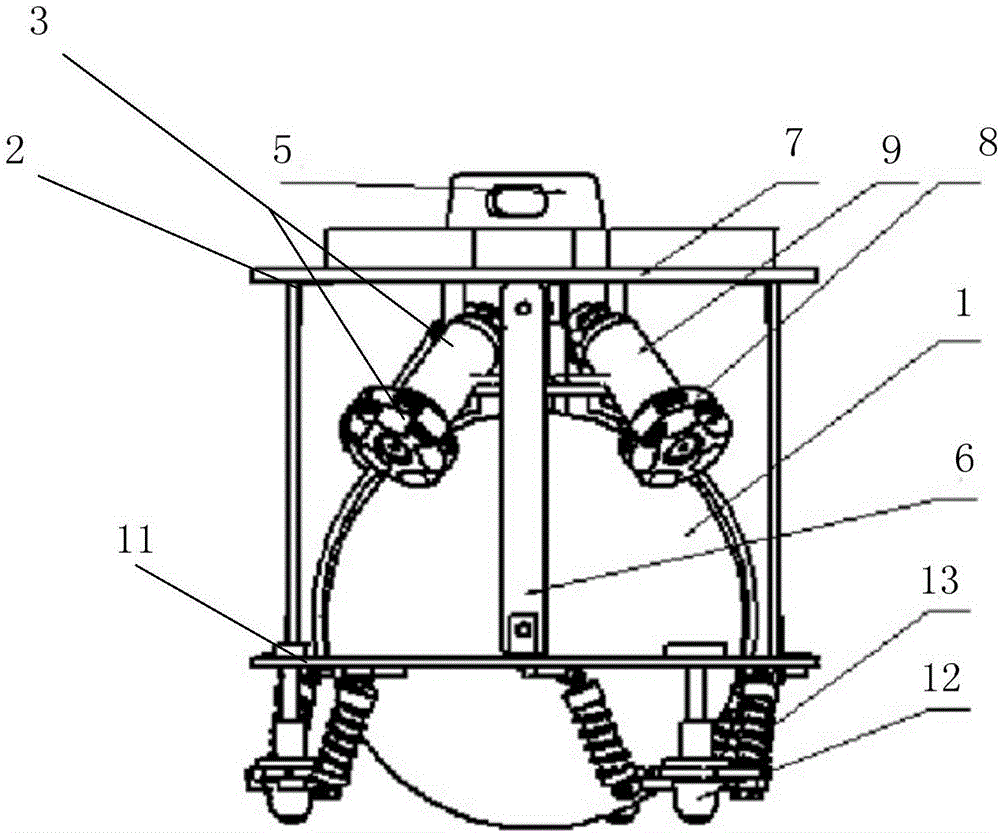

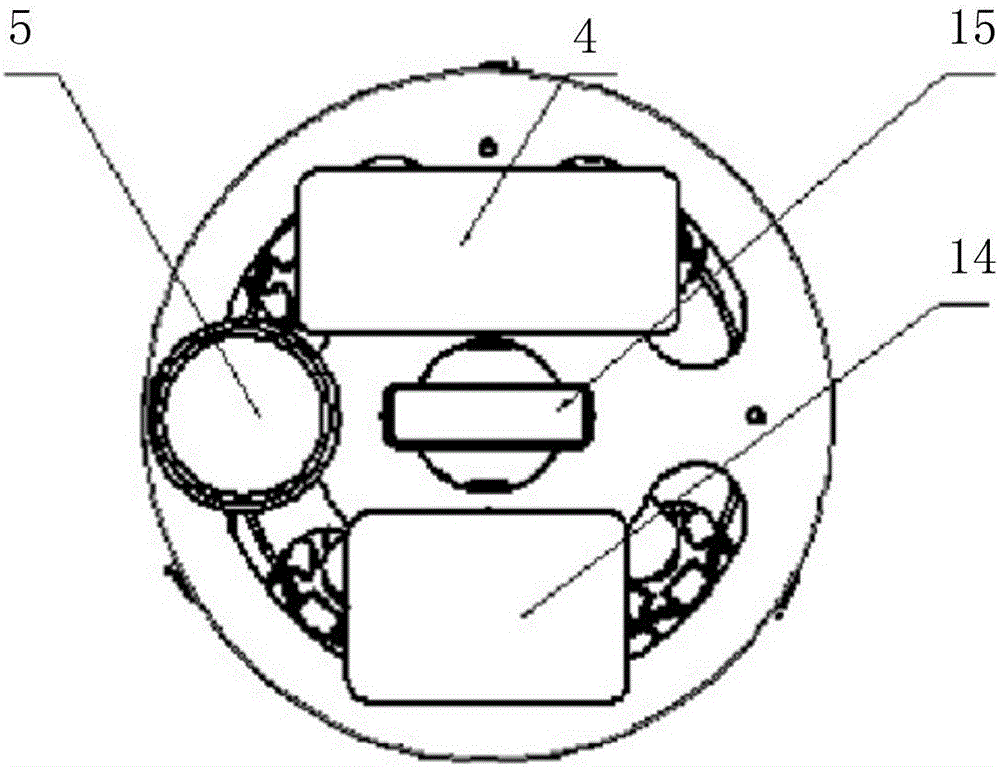

Autonomous navigation robot based on global wheel

InactiveCN106695744AImprove mobile flexibilityEliminate distracting factorsProgramme-controlled manipulatorDrive motorPID controller

The invention provides an autonomous navigation robot based on a global wheel. The autonomous navigation robot based on the global wheel comprises a distance detector, a main controller, a rechargeable lithium battery, a microcomputer, a control platform, a drive motor, an omnidirectional wheel, a spherical tyre, a tyre support, a buffer mechanism, a bullseye wheel, a robot support and a tyre drive mechanism. The robot support comprises the tyre support and the control platform; the tyre support is arranged on the outer side of the spherical tyre in a sleeving manner; the control platform is arranged above the tyre support; the tyre drive mechanism comprises at least three groups of drive wheels and drive motors; the drive wheels are respectively connected with the corresponding drive motors; the drive motors are connected with the main controller; the distance detector is connected with the main controller; the main controller and the distance detector are arranged on the control platform; the at least three groups of drive wheels are arranged on the surface of the spherical tyre and are rotatably connected with the surface of the spherical tyre.

Owner:ZHENGZHOU UNIV

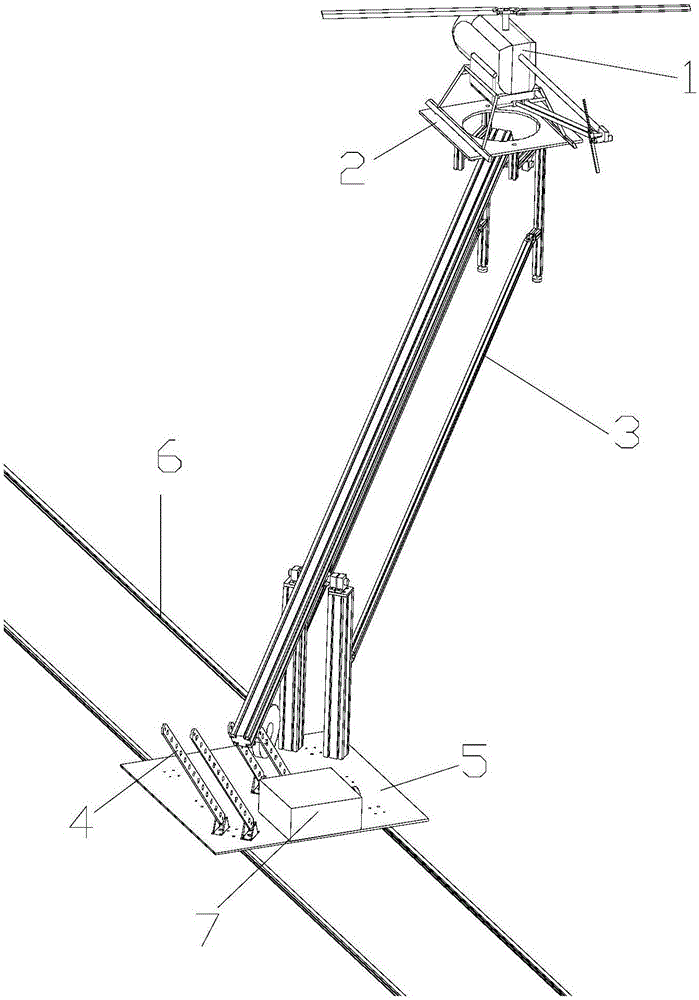

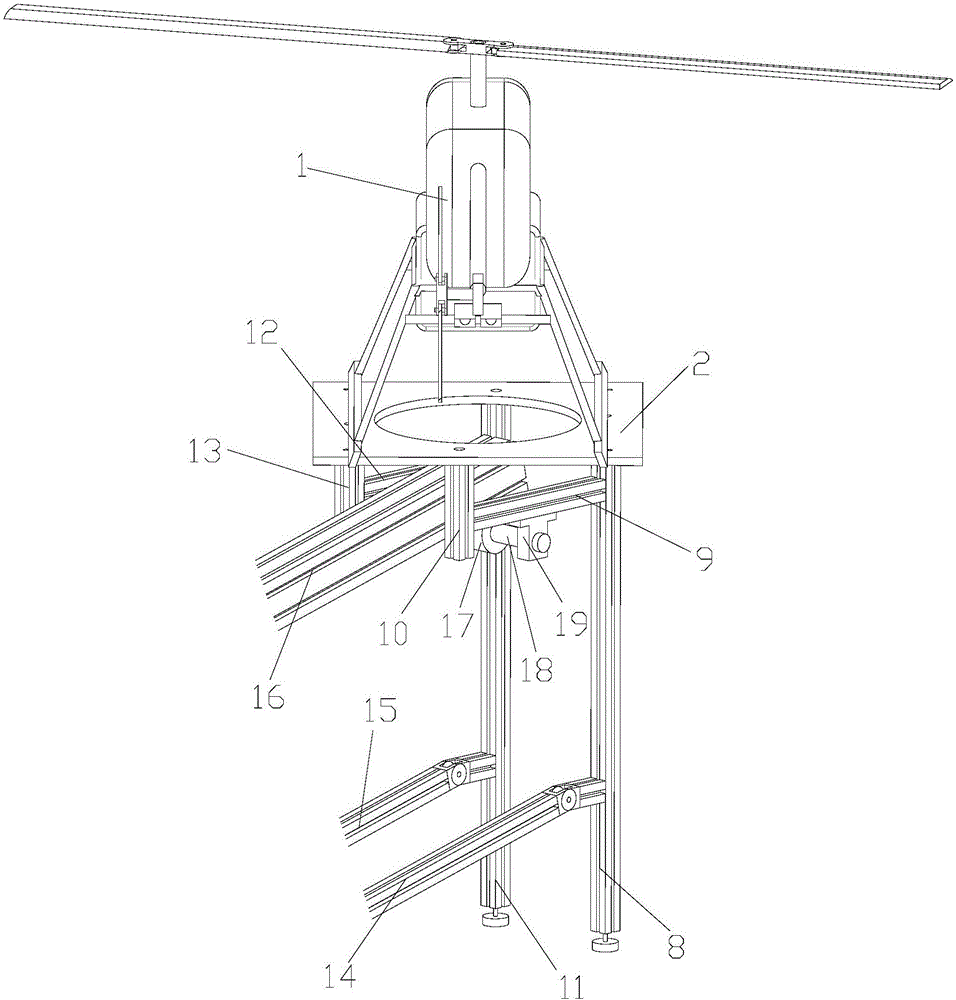

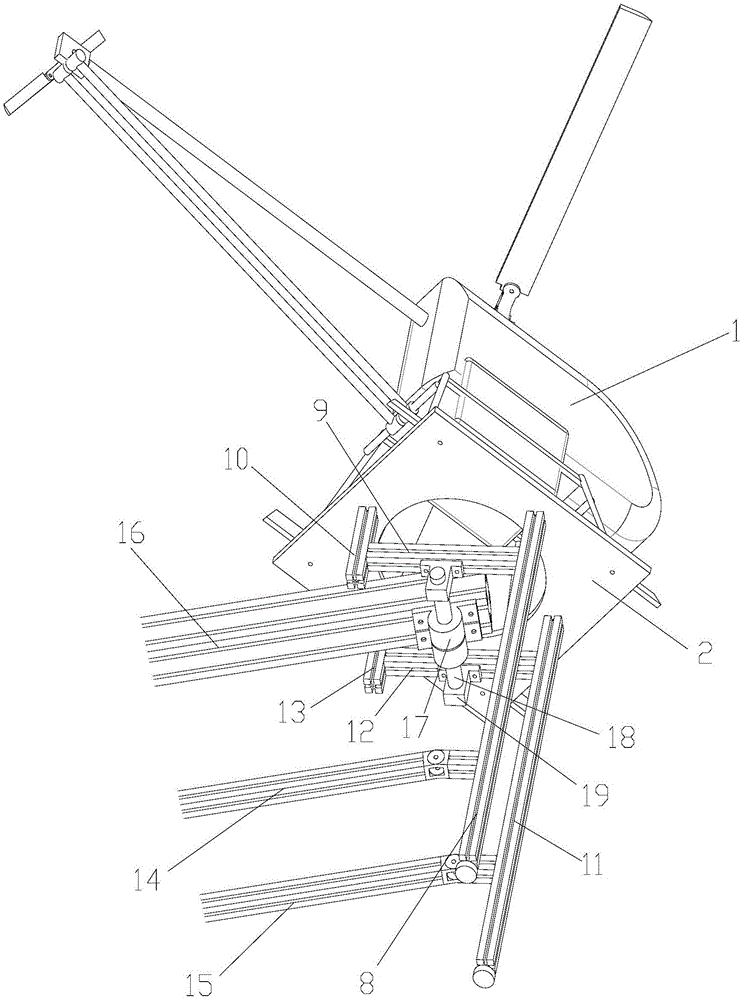

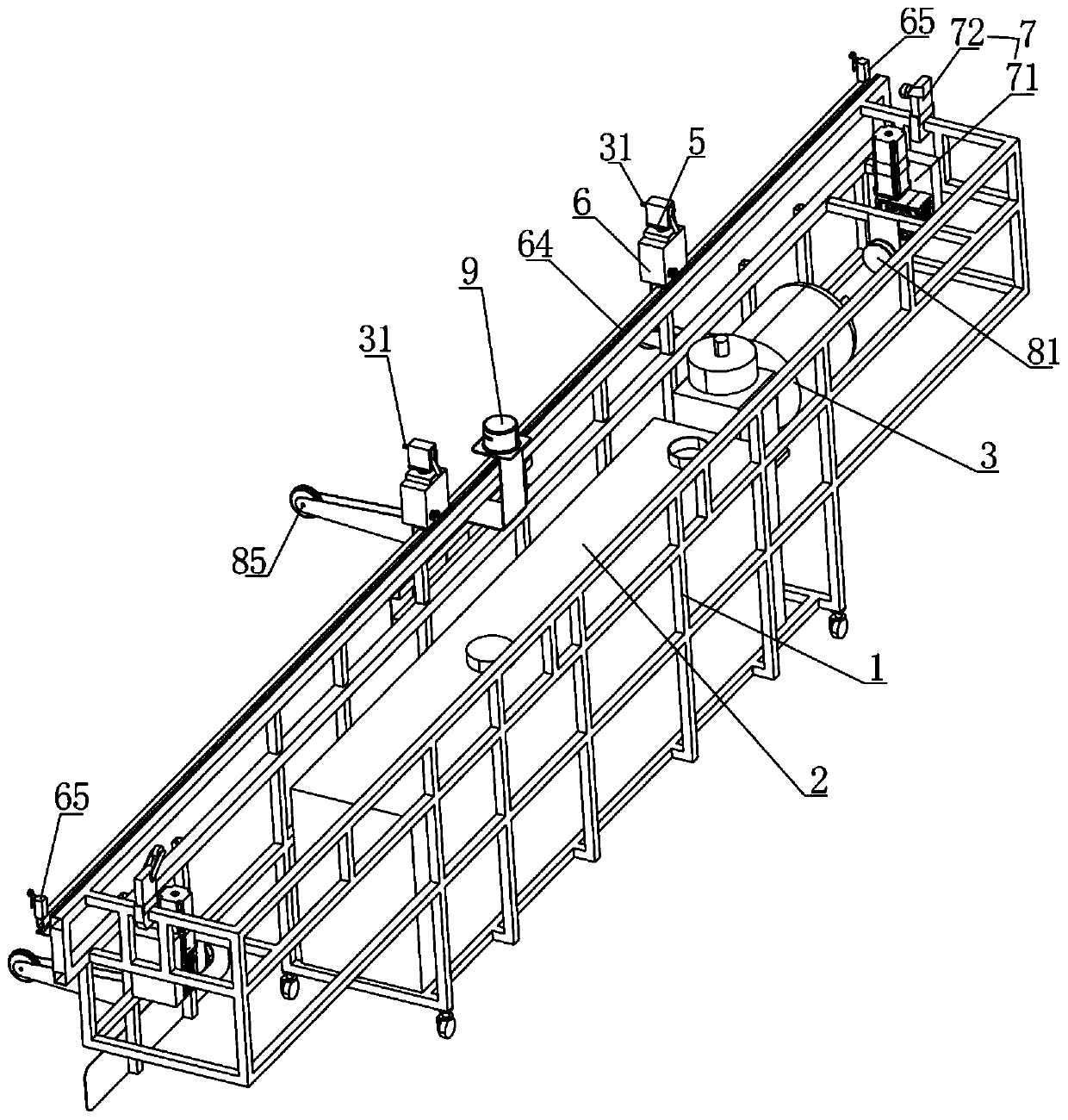

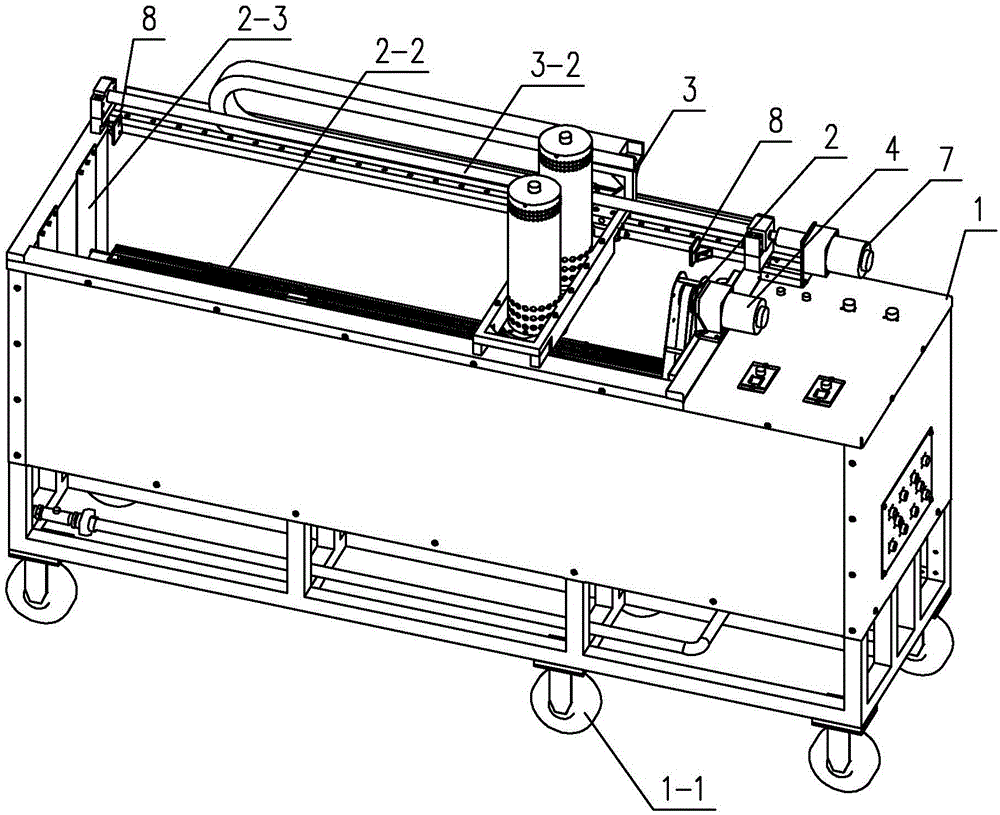

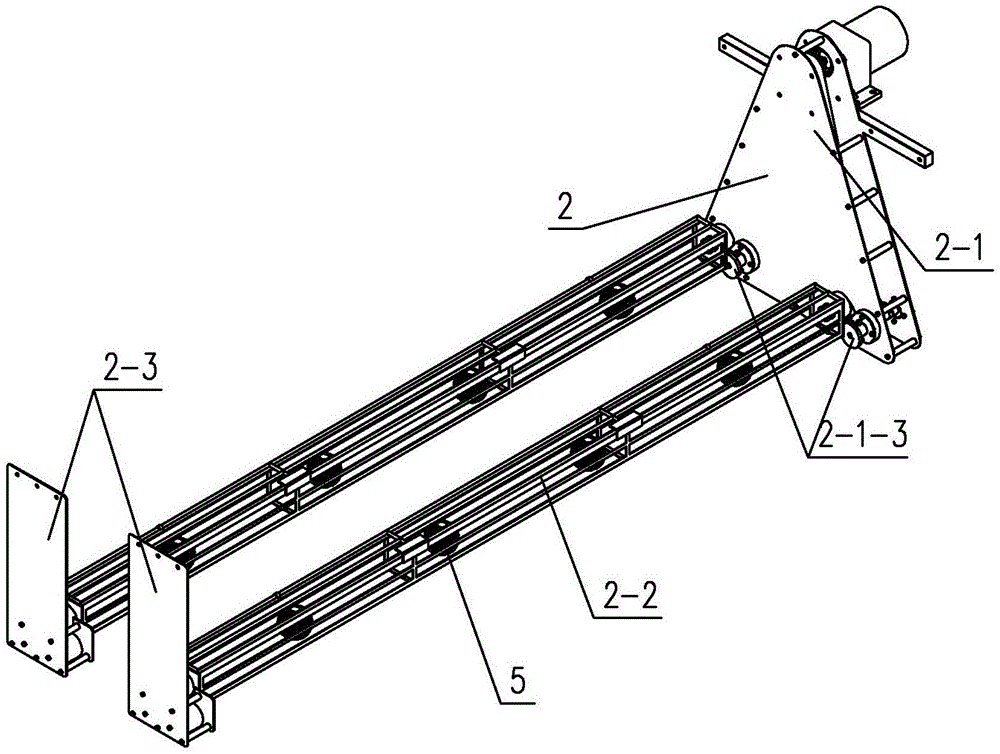

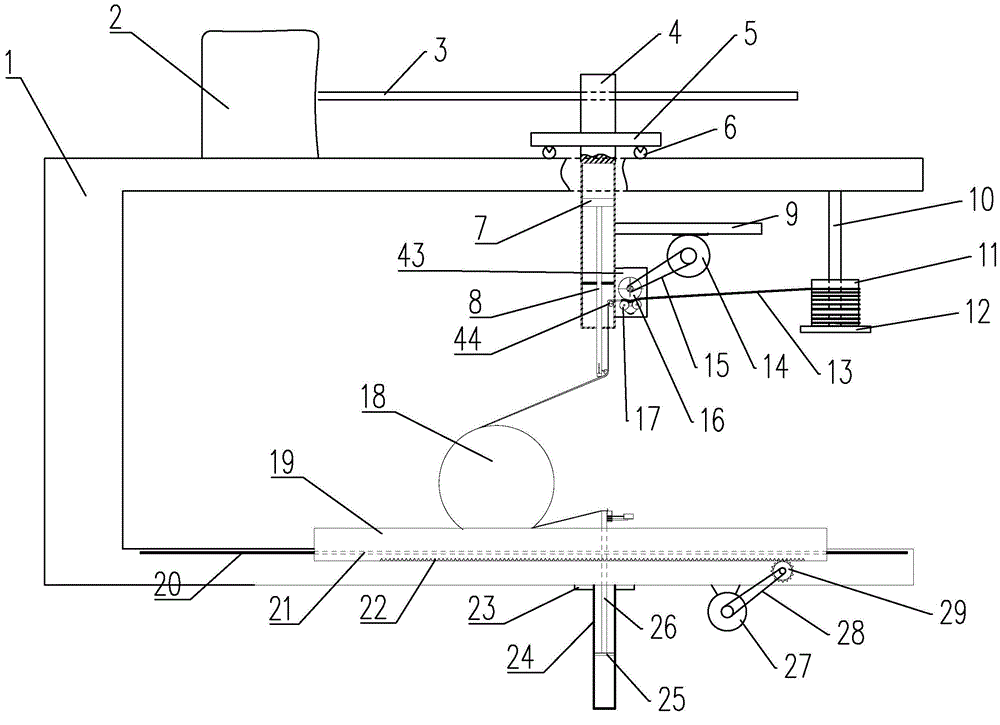

Indoor agricultural unmanned aerial vehicle test platform

ActiveCN106628245AIsolate interferenceAdjust and lock height accuracyAircraft components testingAviationAgricultural engineering

The invention relates to an indoor agricultural unmanned aerial vehicle test platform. The indoor agricultural unmanned aerial vehicle test platform comprises an unmanned aerial vehicle, a parallel four-bar linkage, a movable trolley, a guide rail and a load-bearing platform; the unmanned aerial vehicle which flies horizontally is installed on the load-bearing platform; the load-bearing platform is installed on the parallel four-bar linkage; the parallel four-bar linkage is installed on the movable trolley; and the movable trolley is movably installed on the guide rail. The parallel four-bar linkage comprises an upper rotating rod, a lower rotating rod, a vertical fixed rod and a vertical lifting rod; the upper rotating rod is rotationally installed on the fixed rod and the lifting rod; one end of the lower rotating rod is rotationally installed on the fixed rod, and the other end of the lower rotating rod is rotationally installed on the lifting rod; and the fixed rod is installed on the movable trolley. The indoor agricultural unmanned aerial vehicle test platform can reliably and precisely test the unmanned aerial vehicle and belongs to the technical field of agricultural aviation.

Owner:SOUTH CHINA AGRI UNIV

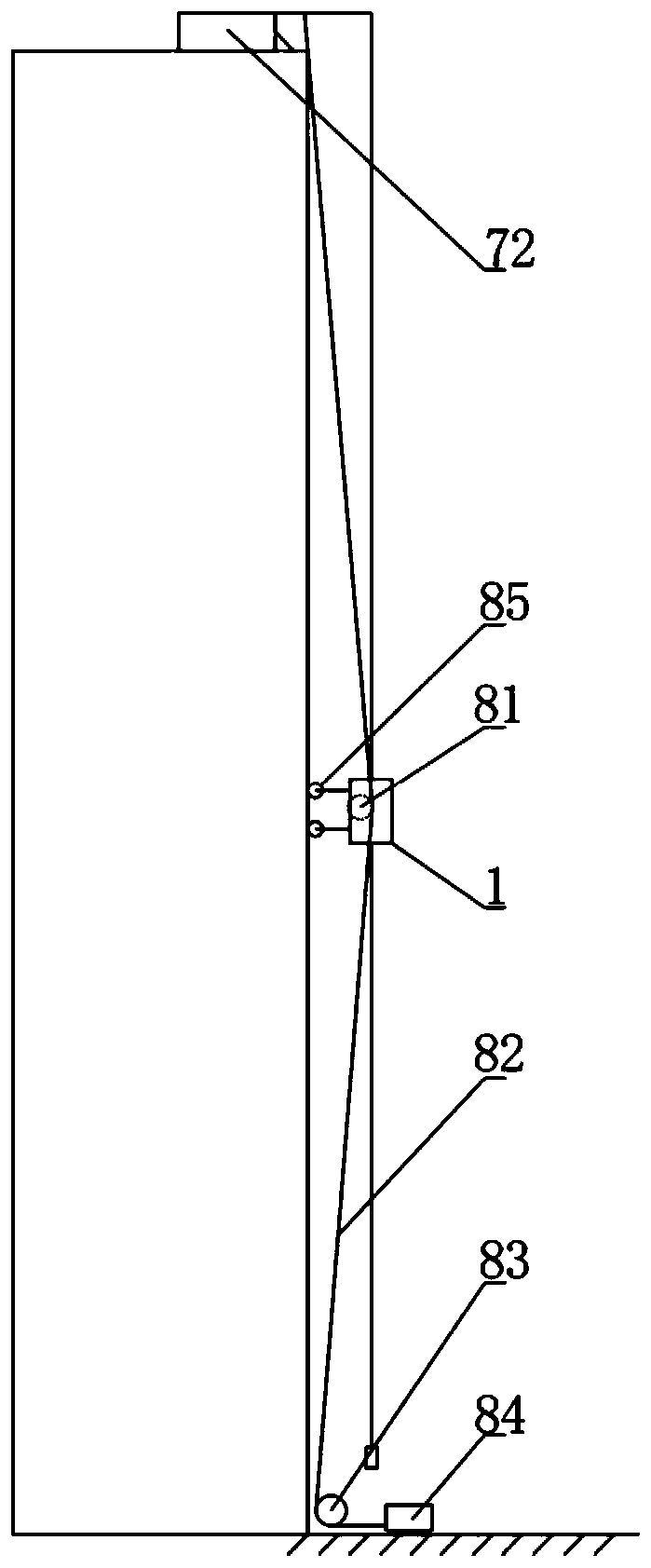

Building outer wall spraying robot and control method thereof

ActiveCN110370296AImprove spray qualityGuarantee personal safetyBuilding constructionsManipulatorControl engineeringStructural engineering

The invention provides a building outer wall spraying robot and a control method thereof, and relates to the technical field of building robots. The building outer wall spraying robot comprises a machine frame, a material storage box and a spraying machine, wherein the material storage box and the spraying machine are arranged on the machine frame, a spraying gun of the spraying machine is provided with a rotating mechanism capable of changing a spraying direction, and the spraying gun is fixed on a horizontal moving device capable of sliding in the horizontal direction of the machine frame; and the machine frame is provided with a lifting mechanism for enabling the machine frame to move in the direction of a plumb bob, and a stability maintaining mechanism for adjusting the movement stability of the machine frame, an outer wall recognition device for identifying a spraying region is further arranged on the machine frame, and the outer wall recognition device, the rotating mechanism, the horizontal moving device and the lifting mechanism are electrically connected to a controller. According to the robot and the method, the problems that in the prior art, manual building outer wallspraying is dangerous, the efficiency is low, and the spraying quality is not stable are solved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Ultrasonic damage-free descaling machine used for cleaning oilfield equipment unit

InactiveCN105080899AReduce workloadImprove work efficiencyCleaning using liquidsElectric machineryTransducer

The invention relates to a scaleplate device, in particular to an ultrasonic damage-free descaling machine used for cleaning an oilfield equipment unit. The ultrasonic damage-free descaling machine aims at solving the problems that an exiting cleaning device is low in work efficiency, and manual turning cleaning is needed. The ultrasonic damage-free descaling machine used for cleaning the oilfield equipment unit comprises an ultrasonic cleaning tank, a rotating mechanism and a movable energy collecting transducer mechanism. The rotating mechanism is arranged in the ultrasonic cleaning tank. The movable energy collecting transducer mechanism is hung at the upper end of the notch of the ultrasonic cleaning tank through a transducer support. The rotating mechanism comprises a driving assembly, a net box support and a plurality of net boxes. The other end of each net box is connected with the driving assembly. The front end of the driving assembly is connected with a speed regulating motor. The movable energy collecting transducer mechanism comprises a lead screw, a lead screw nut and a plurality of energy collecting transducers, and the energy collecting transducers are arranged at the upper end of the transducer support. The ultrasonic damage-free descaling machine is used for cleaning the oilfield equipment unit.

Owner:杭州瑞利声电技术有限公司 +1

Convenient and fast yarn winding roller mounting frame

The invention discloses a convenient and fast yarn winding roller mounting frame. The frame comprises a base, two supporting rods vertically and fixedly arranged on the surface of the base, a windingroller installed between the two supporting rods, a first motor arranged at one end of the winding roller and used for driving the winding roller to rotate, a first component, a second component and amoving seat which is used for driving the second component to move to realize clamping or separation of the first component and the second component. The frame is simple in structure and convenient to operate, by arranging the first component, the second component, the moving seat and a driving mechanism which are matched with one another for use, and a mortise and a tenon are adopted to performfixing between the first component and the second component through clamping, so that the first component and the second component can be locked and fixed without the aid of other auxiliary fixing components, the winding roller can be conveniently disassembled or installed, and the frame can be suitable for winding rollers of different sizes.

Owner:宿迁至诚纺织品股份有限公司

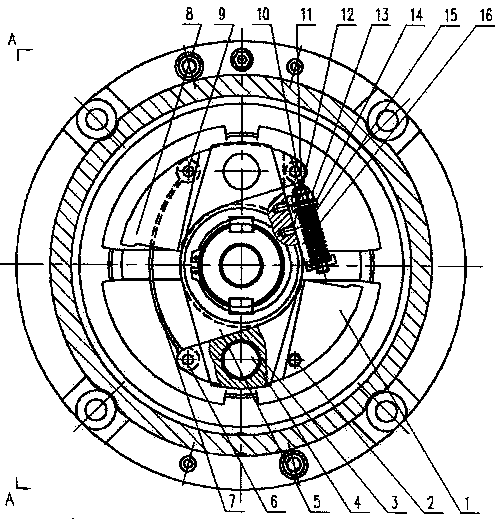

Low-speed anti-falling safety device

The invention relates to a low-speed anti-falling safety device. According to the low-speed anti-falling safety device, a brake gear is supported by an end cover and a brake drum through a big bearing and a small bearing, and a support is installed on the brake gear; a first centrifugal block and a second centrifugal block are installed on the support through bearings and rest pins, and the two centrifugal blocks are in central symmetry about the rotation center of the safety device; a connecting rod is connected with the tail portion of the first centrifugal block and a pin hole formed in the front portion of the second centrifugal block through hinge pins or bolts, and therefore it is guaranteed that the work positions of the two centrifugal blocks are synchronous; the tail portion of the second centrifugal block is provided with a thrust bolt through a third hinge pin, the thrust bolt is provided with a governing spring in a penetrating mode, and the thrust of the governing spring enables the first centrifugal block to be tightly pressed on the support; a belleville spring and a pressing nut are arranged on a threaded rod located at the end of the outer side of the brake drum, and the pressure of the belleville spring is transmitted to the brake drum through the pressing nut. According to the low-speed anti-falling safety device, through a speed limiting mechanism of the safety device, whether the speed of an operation component of a protected target exceeds a preset value under the low-speed condition can be detected, the safety device can automatically brake the operation component, and therefore low-speed operation of the safety device is achieved.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD +1

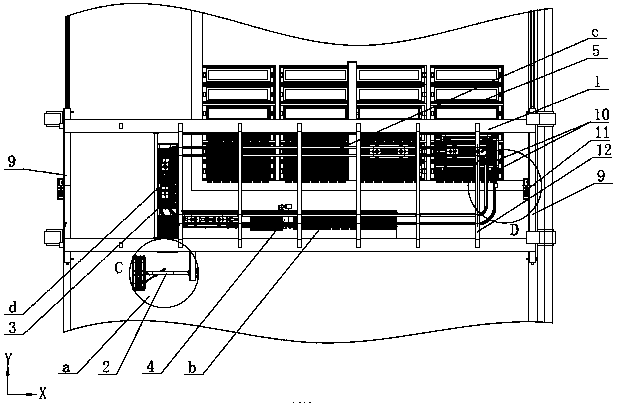

Tank entering and exiting system and method

PendingCN109457271AImprove work efficiencyShort slot timePhotography auxillary processesElectrolysis componentsCartArm moving

The invention discloses a tank entering and exiting system. A cart girder which can be shifted is arranged above electrolytic tanks arranged to form an array, and a circular track is arranged on the cart girder. The circular track is movably provided with a plurality of liftable mechanical arms, and a feeding and discharging area a, a tank area b to be entered, a tank entering and exiting workingarea c and a discharging passivation area d are arranged on the circular track and on the side of the circular track. The mechanical arms move along the circular track to work, N electrolytic tanks are arranged in a row, and the whole system is provided with N+1 mechanical arms and a positioning device. The first mechanical arm entering the system is only responsible for removing a negative plate,the last mechanical arm is only responsible for inserting the negative plate, and all the mechanical arms in the middle complete two jobs of the insertion of a tank position negative plate and the extraction of the next tank position negative plate, namely all the mechanical arms working twice in one working period. Compared with the previous process that each mechanical arm only works once in one working period, the working efficiency is significantly improved.

Owner:江苏晨力环保科技有限公司

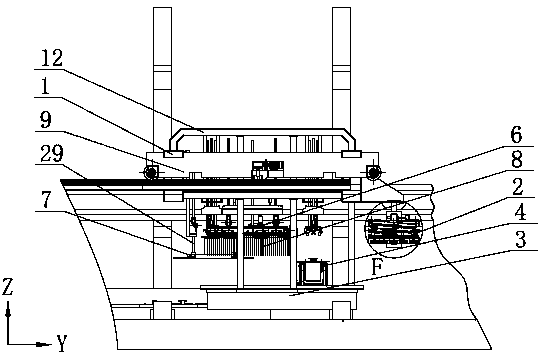

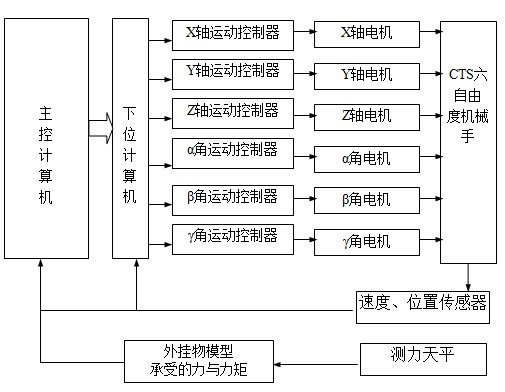

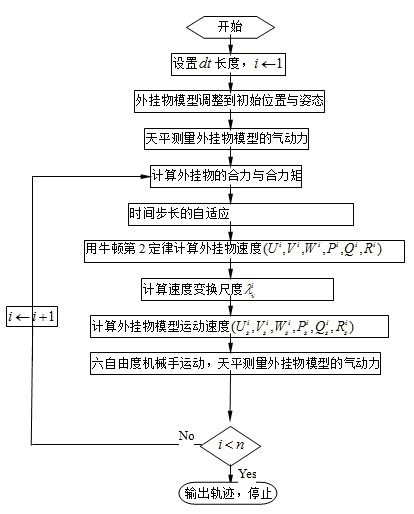

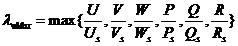

Double-closed loop speed control captive trajectory simulation (CTS) test method based on time and space transformation

The invention discloses a double closed loop speed control captive trajectory simulation (CTS)CTS test method based on time and space transformation. On the one hand, an error model of CTS speed control is established by a load discreet value calculation method based on speed second order interpolation polynomials, the self adaption of time step length of the movement of external models is realized, and the optimal time and space transformation scale is dynamically produced by combining dynamic response parameters of CTS hardware and errors of trajectory control; and on the other hand, the movement speed of a support mechanism for a six-freedom degree model is precisely controlled in a conventional speed closed loop control mode formed by a lower computer and a speed sensor, signal measurement and data calculation can be performed without suspension, the center of gravity of the model is ensured to be continuously kept on a real movement track, false collision of the external models and a master is avoided, and the CTS time is shorten and the test cost is reduced possibly under the condition of ensuring test precision.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

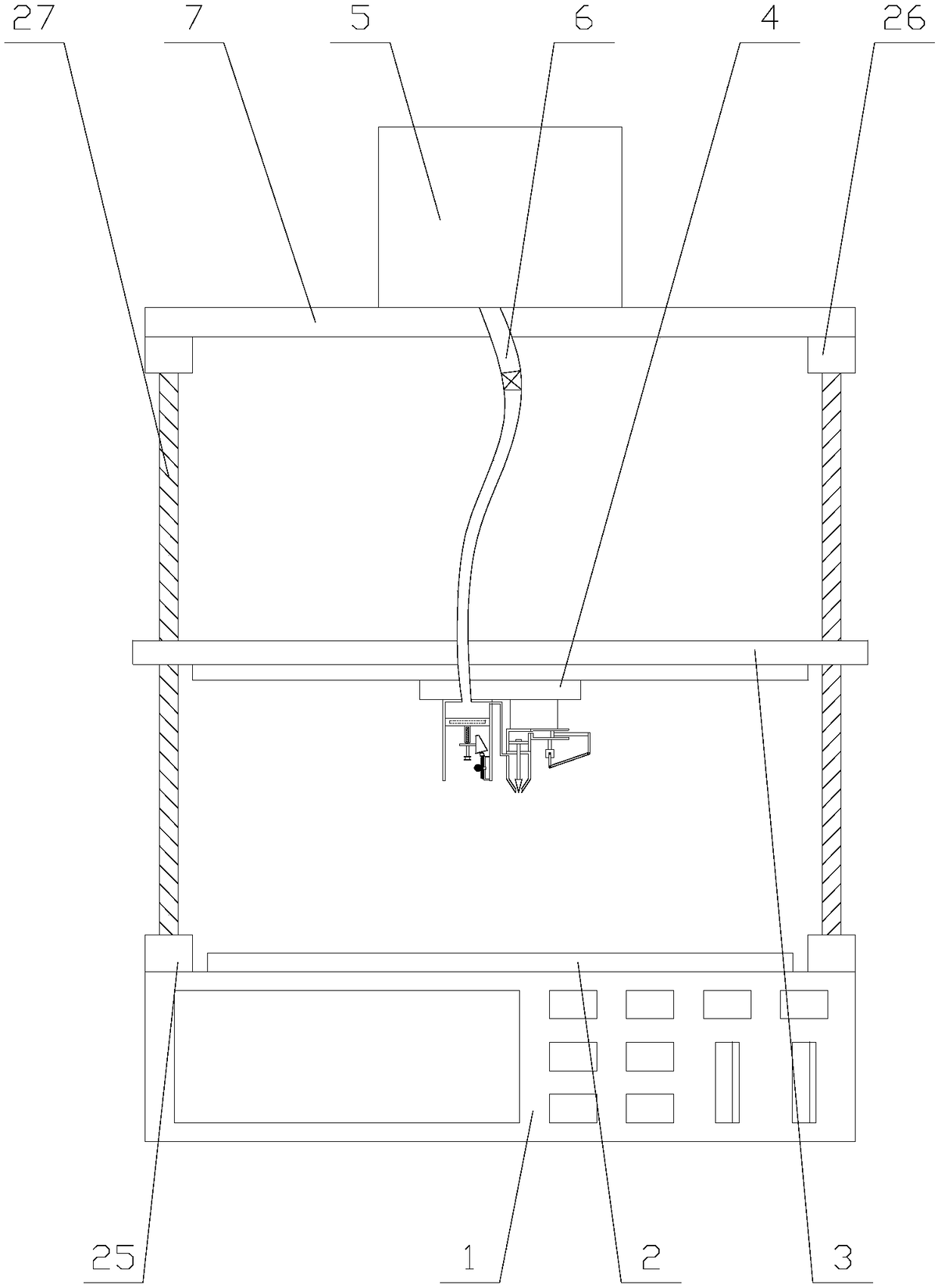

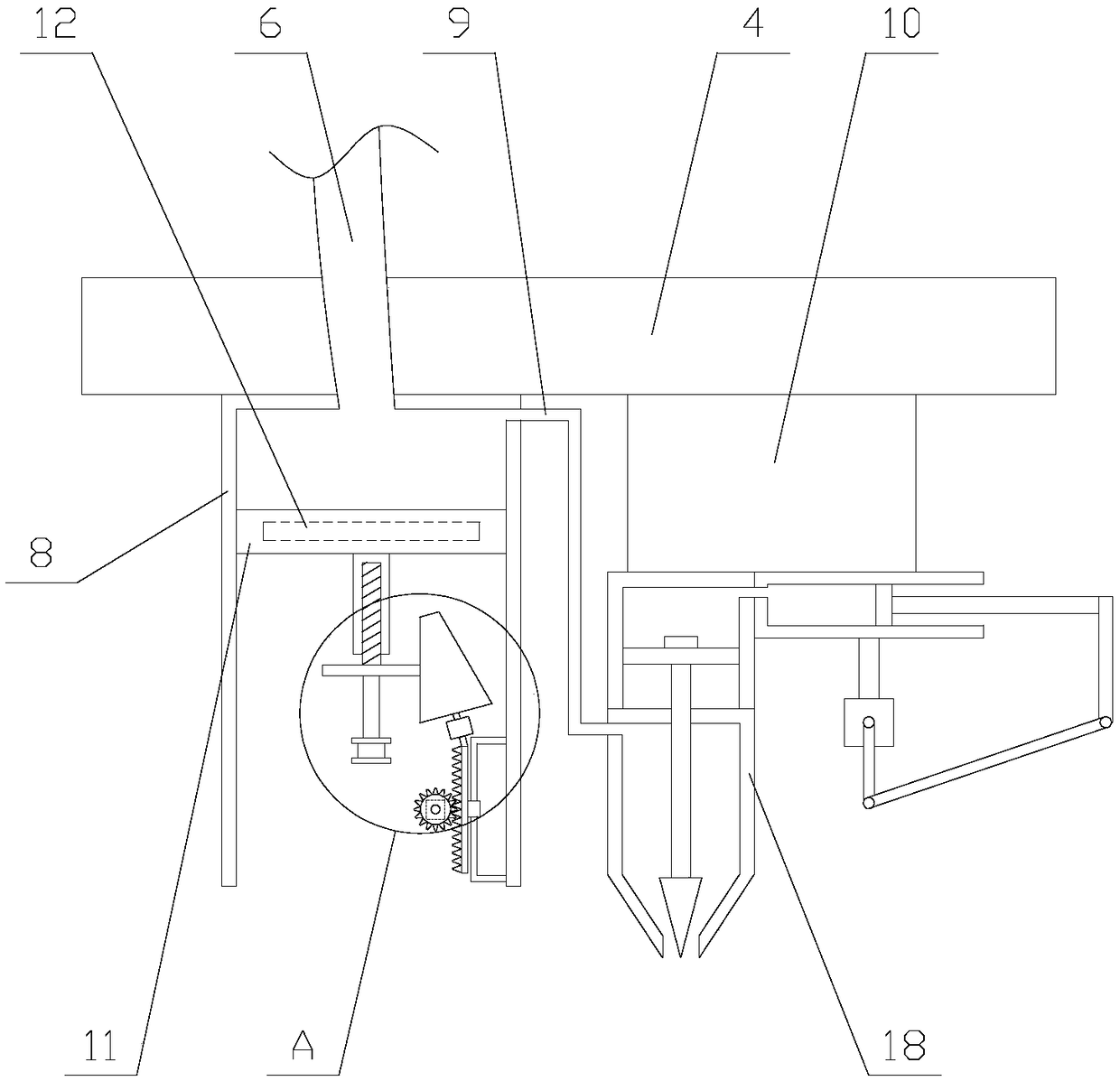

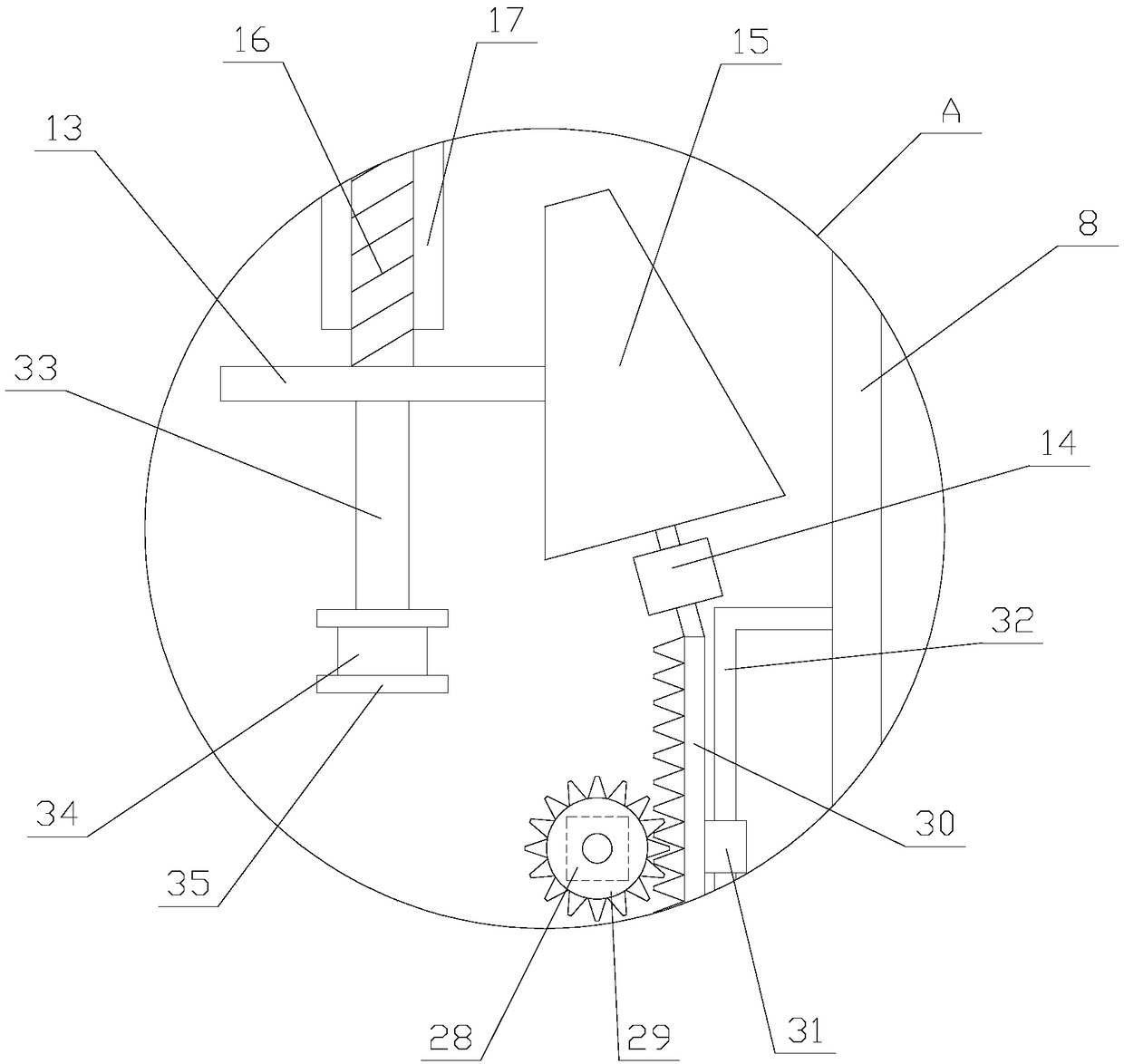

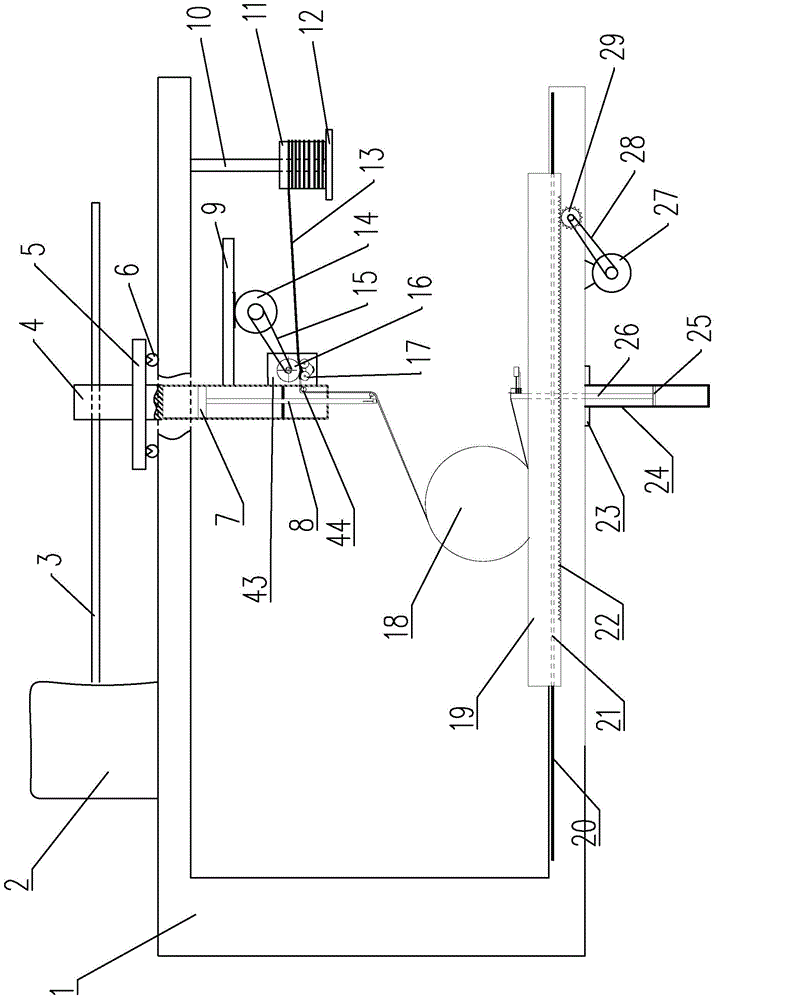

3D printer with adjusting function

ActiveCN109177157AGuaranteed uptimePrecise control of movement speedManufacturing heating elementsAdditive manufacturing with liquidsSprayerEngineering

The invention relates to a 3D printer with an adjusting function. The 3D printer comprises a host, a printing platform, a lifting plate, a planer moving device, a translation plate, a discharging device, a material box, a material pipe, a top plate and four lifting mechanisms; the discharging device comprises a heating pipe, a connecting pipe, a connecting block and a discharging mechanism; a heating plate and a speed regulating mechanism are arranged in the heating pipe; the speed regulating mechanism comprises a turntable, a support component, a first motor, a driving block, a speed regulating assembly, a rotating shaft and a sleeve; the discharging mechanism comprises a sprayer, a first cylinder, a second cylinder and a translation component; an adjusting block and a vertical rod are arranged in the sprayer. The 3D printer with the adjusting function is capable of accurately controlling the moving speed of the heating plate by the speed governing device according to the accuracy requirement of print positions, so that the printing efficiency can be guaranteed and the printing precision can be promoted. Meanwhile, the size of the gap of the opening of the sprayer can be adjustedby the discharging mechanism, so that the discharging speed can be adjusted according to the printing requirement and the practicality of the device is improved.

Owner:永康市普方铝业有限公司

Working method of rodlike section bar bundling robot

ActiveCN104554858AGood flexibilityEasy clampingBinding material applicationBundling machine detailsEngineeringMechanical engineering

The invention relates to a working method of a rodlike section bar bundling robot. The robot adopts the structure that a frame is provided with an upper arm and a lower arm; an air cylinder I is arranged on the upper arm and is suitable for moving left and right relative to the upper arm; a piston rod I and a connecting rod I in the air cylinder I are suitable for moving vertically; a flexible nail box is arranged at the bottom end of the connecting rod I; a table-board for placing a steel bundle is in sliding fit with the lower arm in a left-and-right manner; an air cylinder II is fixedly arranged at the bottom of the lower arm; a piston II and a connecting rod II at the top of the piston II are arranged in the air cylinder II; a pair of grooves are formed in the top of the connecting rod II; when the connecting rod I and the connecting rod II are aligned and compressed, a nail can penetrate and clench a rubber strip for bundling the steel bundle; a compressing block which is suitable for moving relative to the connecting rod II for clamping the end part of the rubber strip is arranged on the right side of the connecting rod II. The rodlike section bar bundling robot provided by the invention is free of false wires in the bundling process and the rolled steel bundled is prevented from being loosened due to shift.

Owner:HAIMEN CANGYUN MACHINERY CO LTD

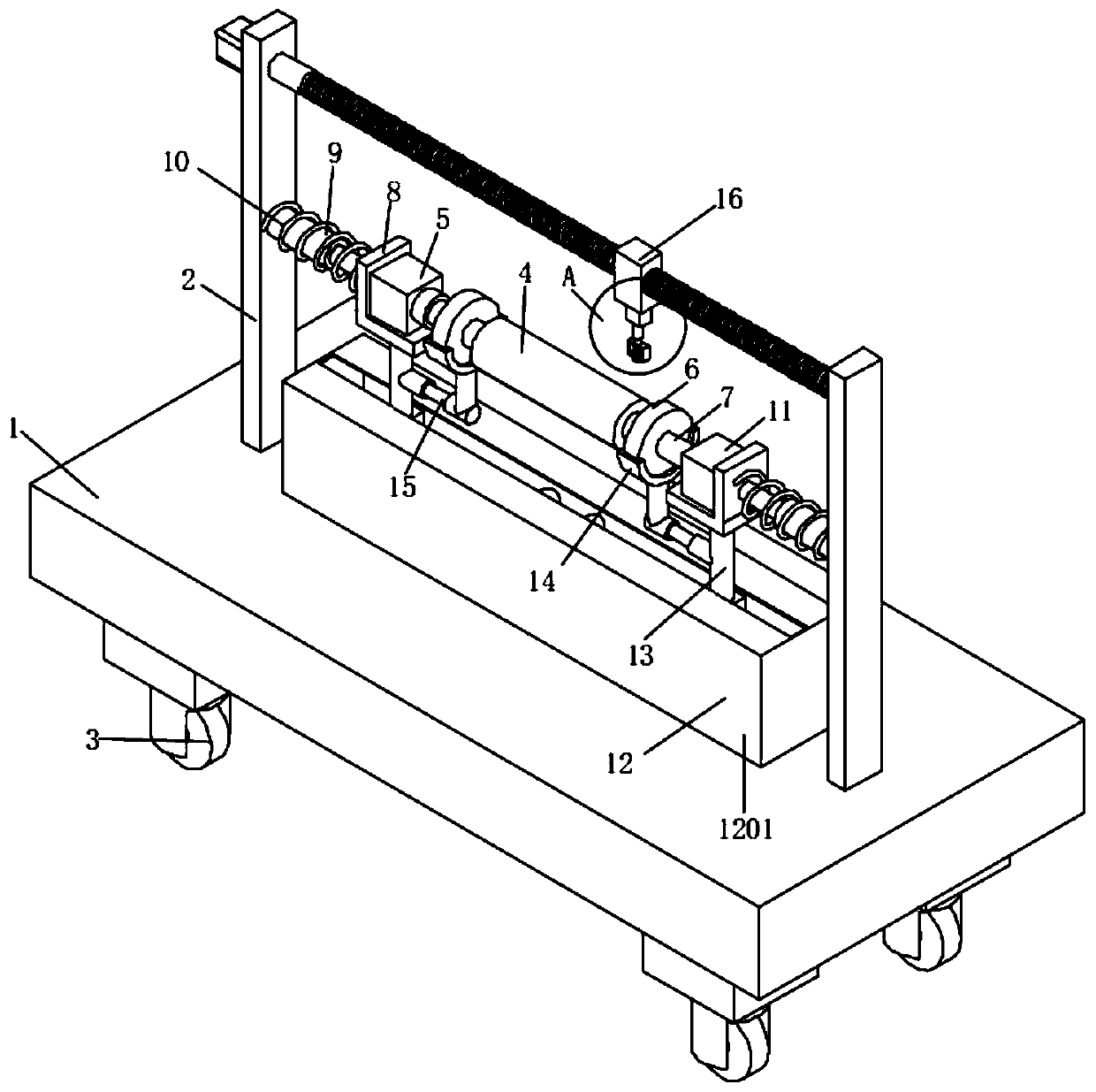

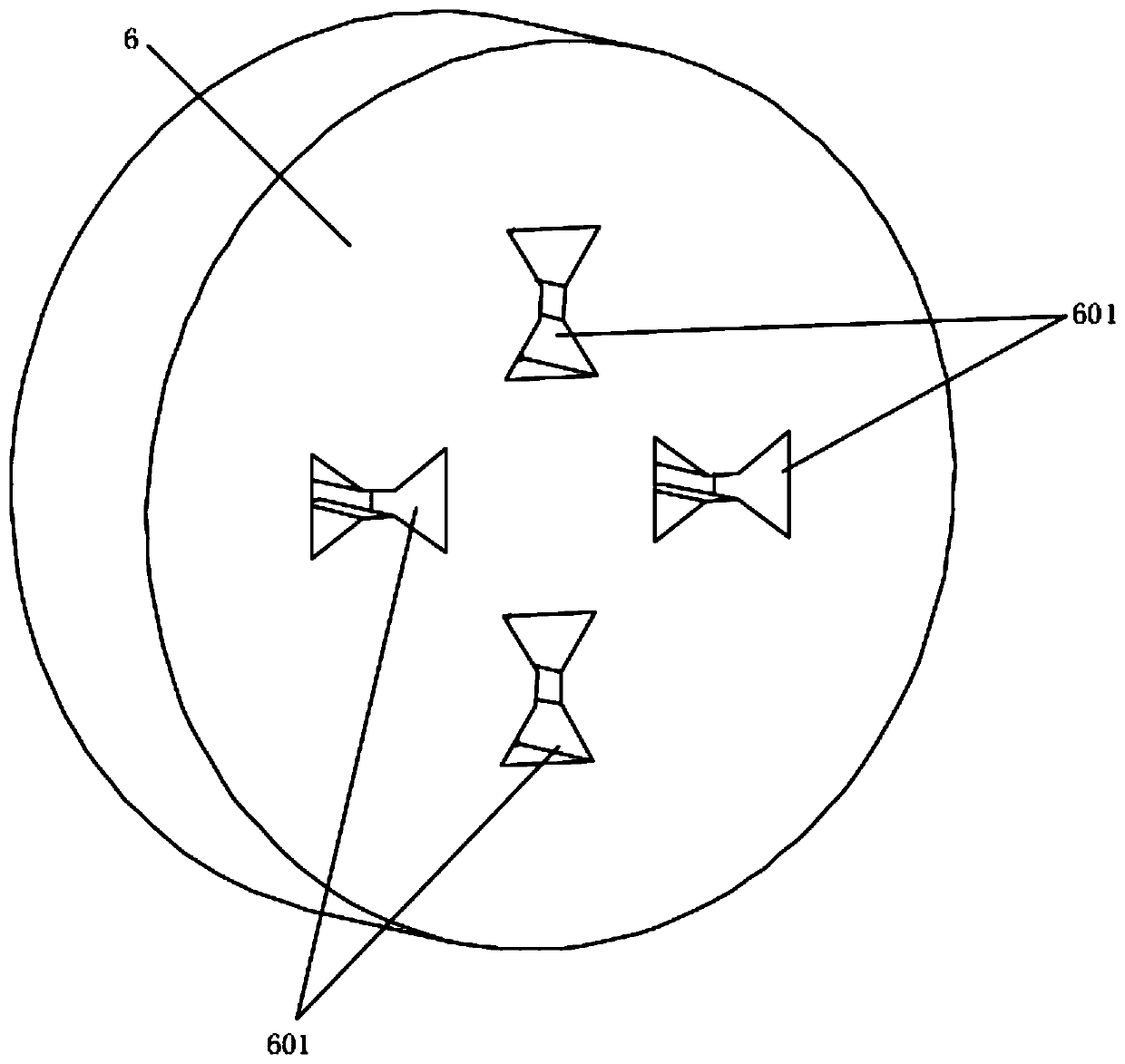

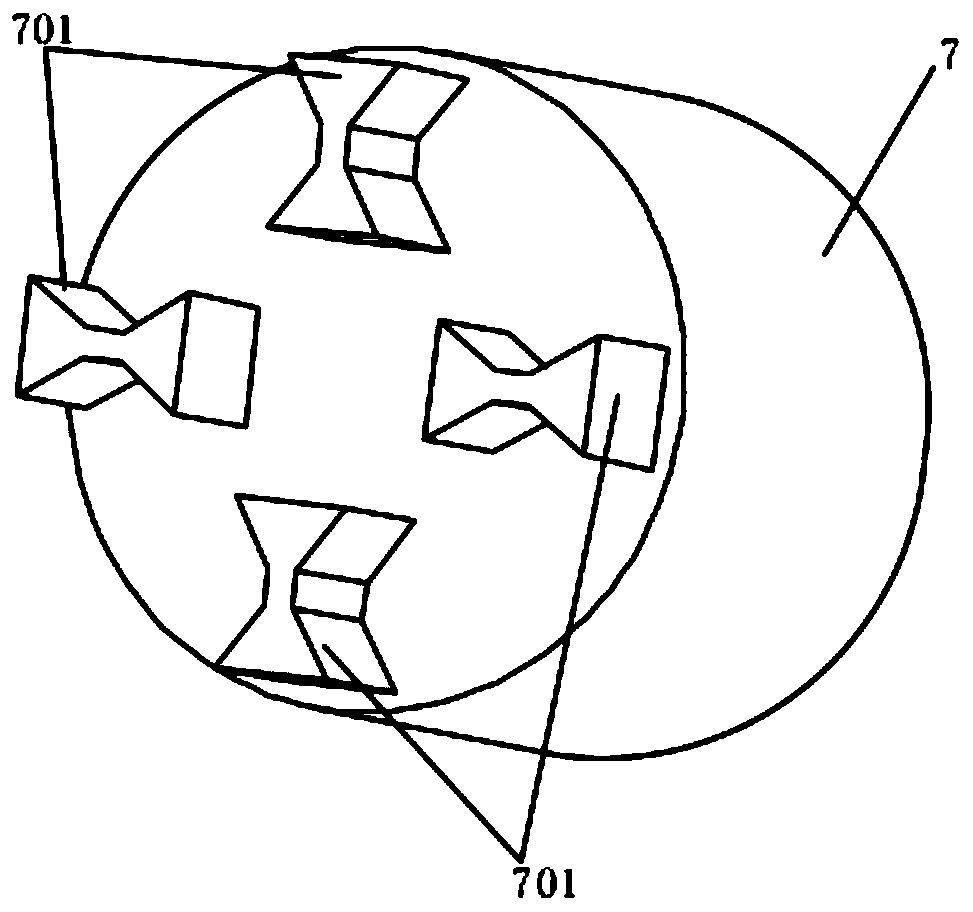

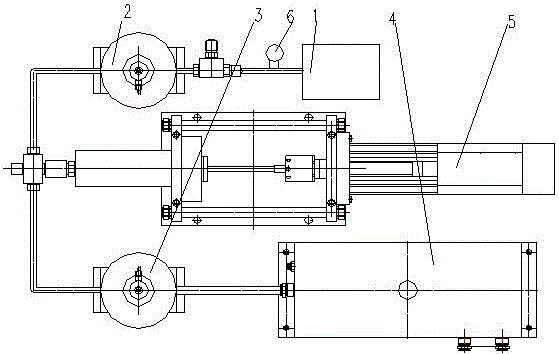

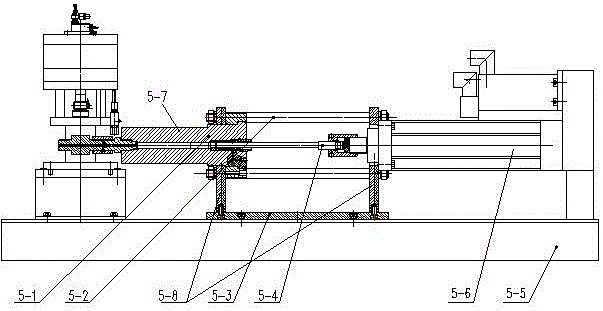

Automatic measuring device for gyroscopic moment of crankshaft and roundness of rotation shaft in engine

PendingCN109307497AImplement binding detection functionGuaranteed stabilityMeasurement devicesGyroscopic momentDrive motor

The invention discloses an automatic measuring device for a gyroscopic moment of a crankshaft and a roundness of a rotation shaft in an engine. The automatic measuring device comprises a driving motor, a gearbox, a gearbox support, a rotation shaft connector, a torque sensor, rolling bearings, a rolling bearing support, the rotation shaft, a connecting sleeve, and a roundness detection assembly. The roundness detection assembly comprises a detection support, a detection rod, a detection rod spring, a varistor, and a pressure display recorder. The detection support is distributed around the periphery of the rotation shaft. According to the automatic measuring device for the gyroscopic moment of the crankshaft and the roundness of the rotation shaft in the engine, the gyroscopic moment of the crankshaft and the roundness of the rotation shaft are accurately detected, and the using effect is good.

Owner:GUANGXI YUCHAI MASCH CO LTD

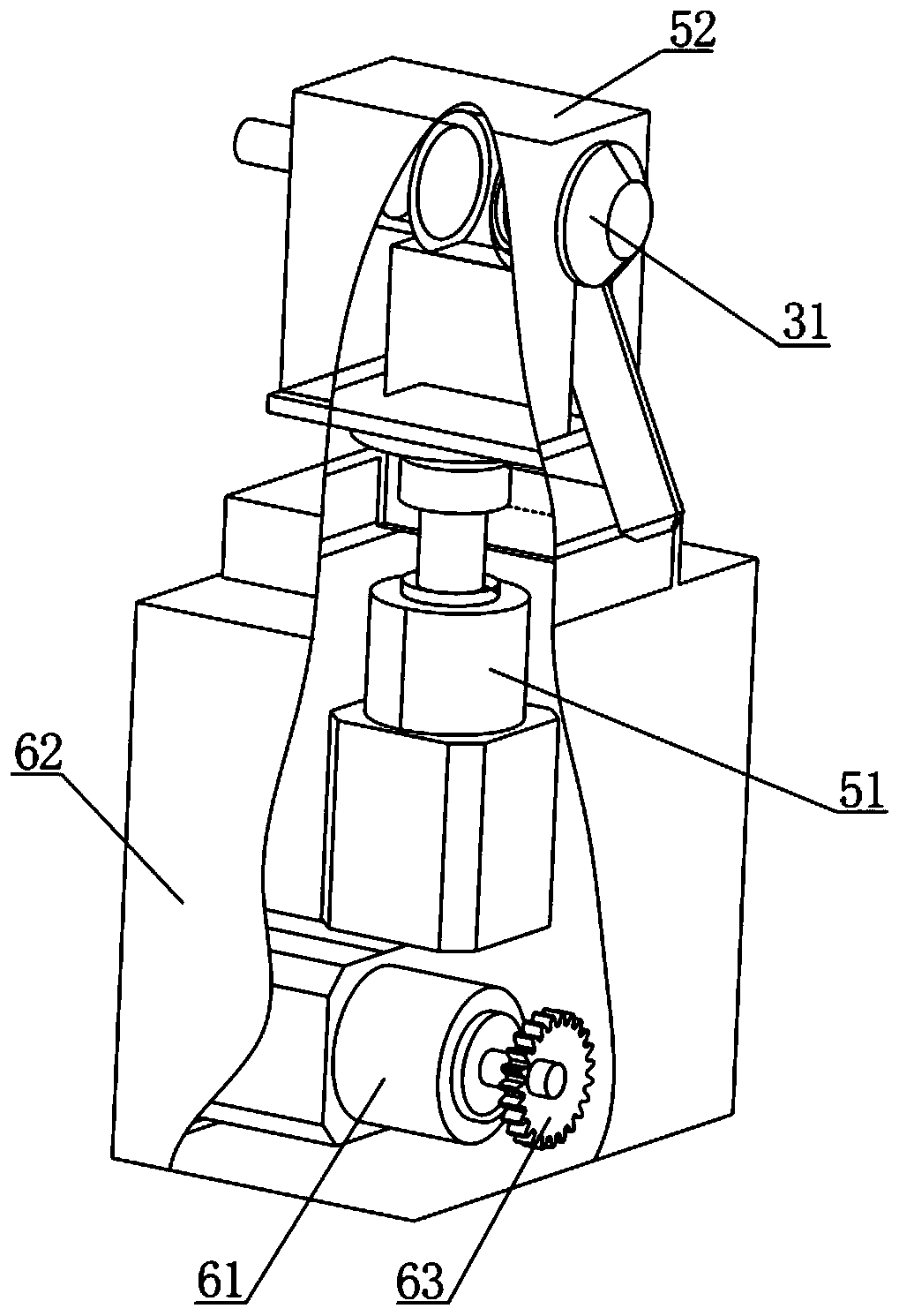

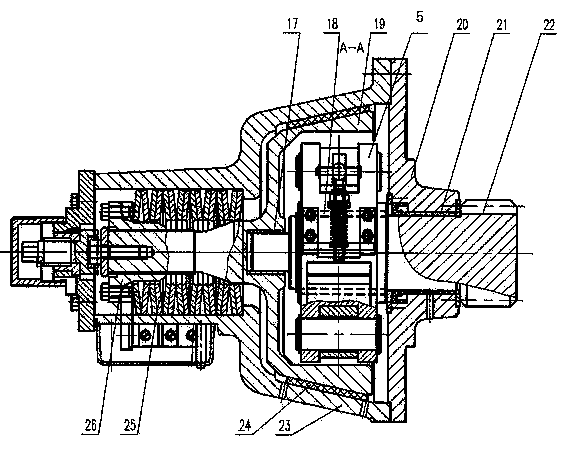

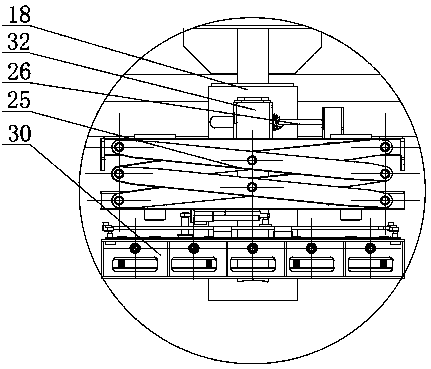

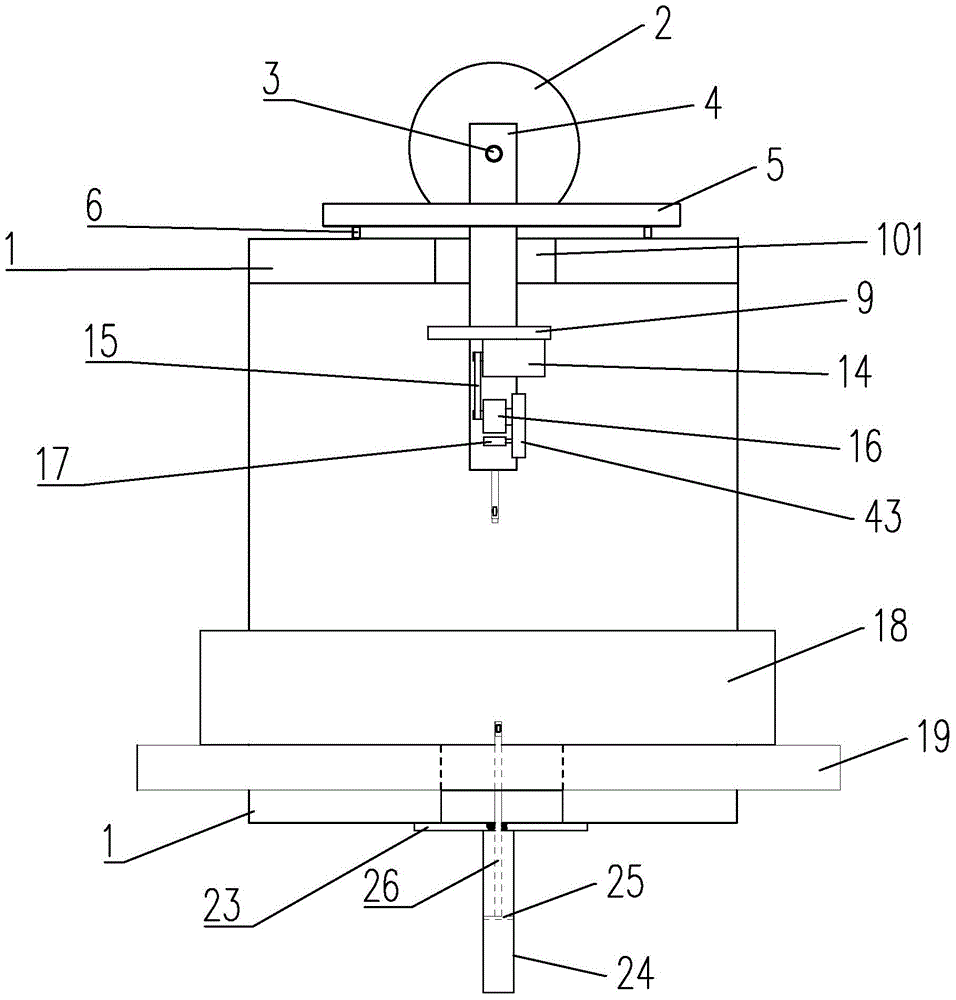

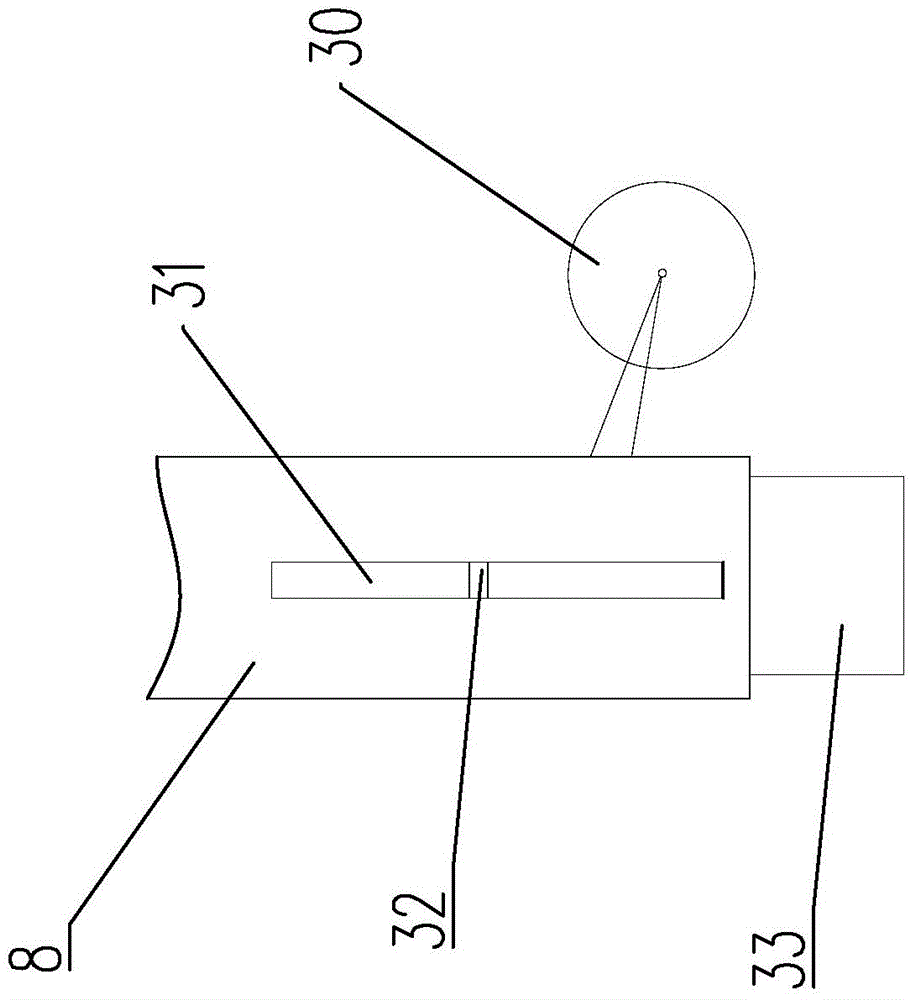

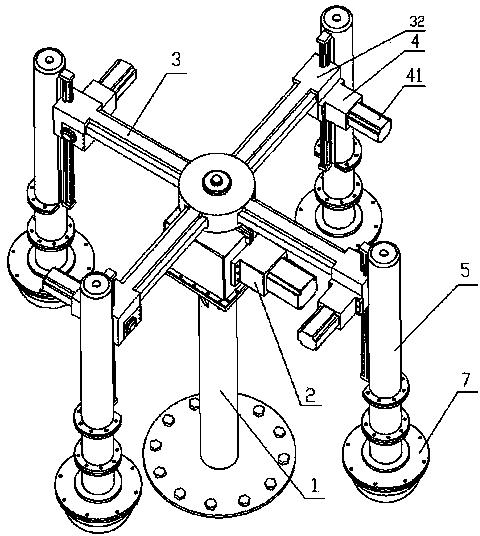

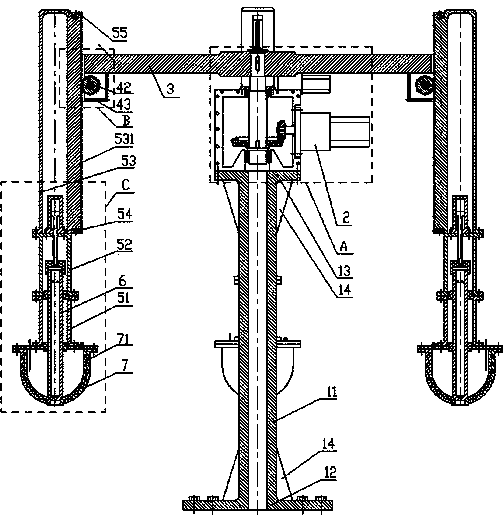

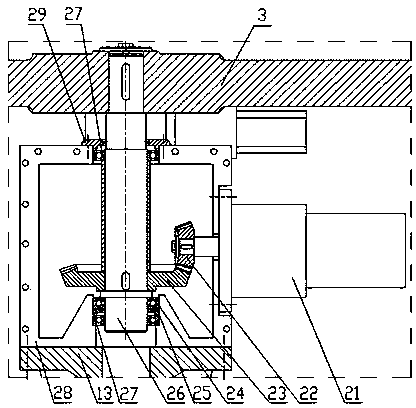

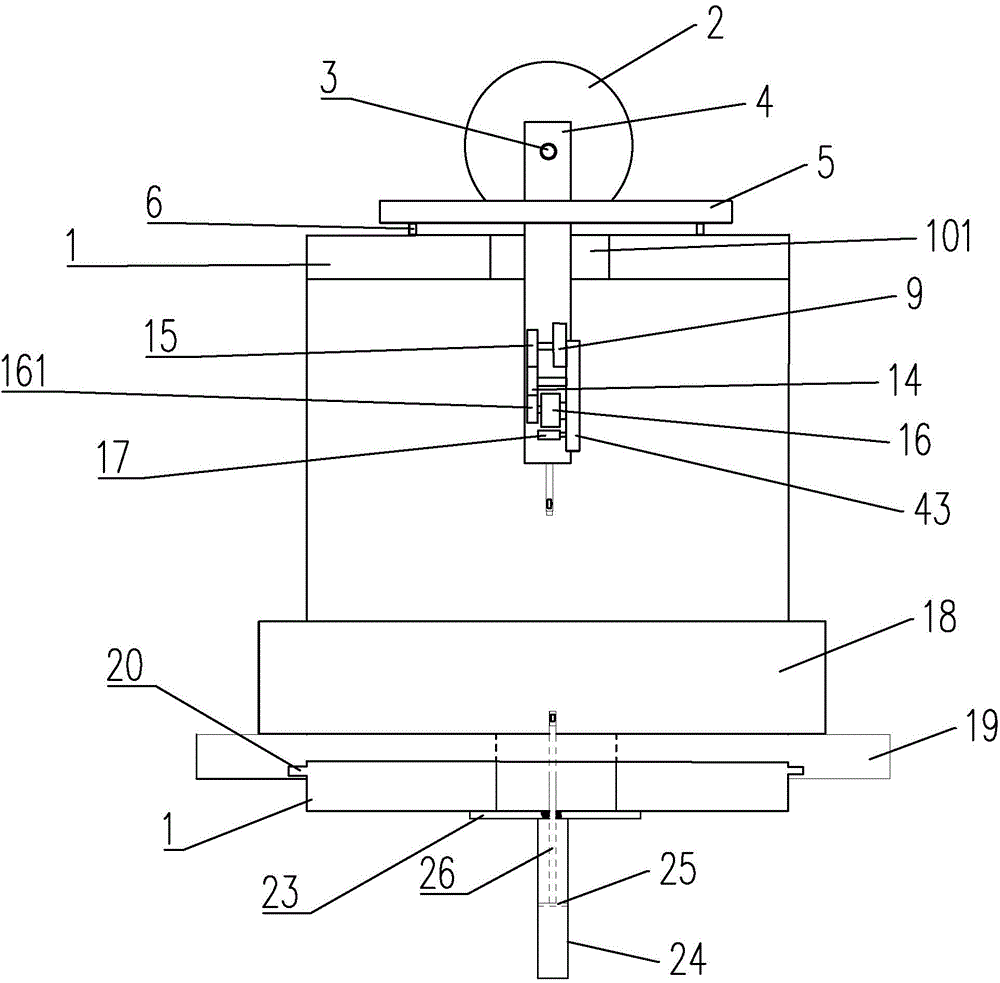

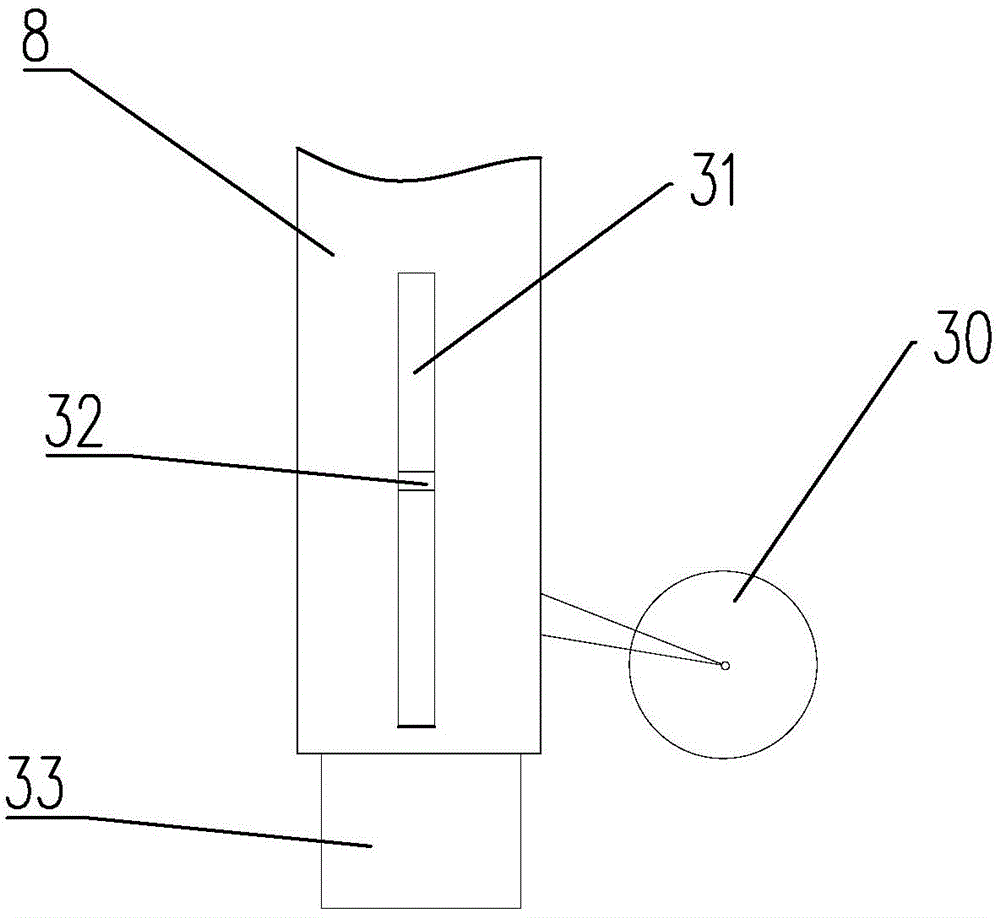

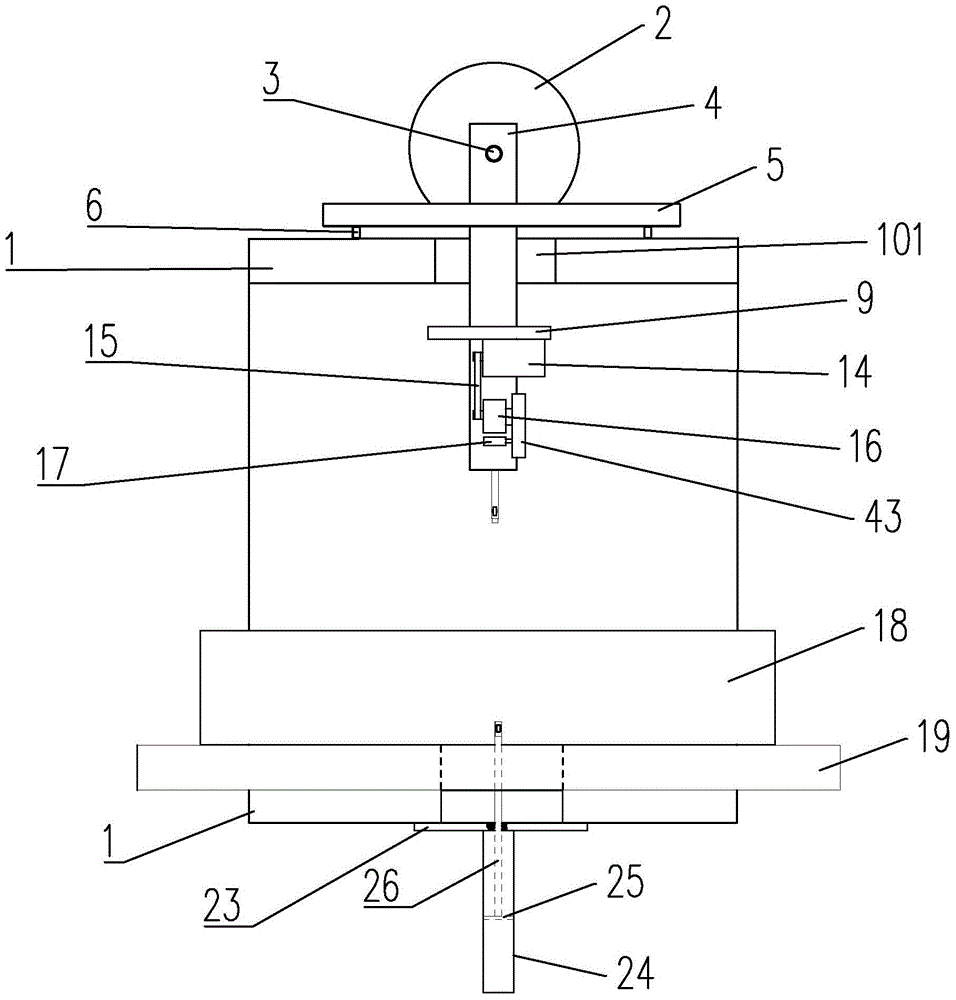

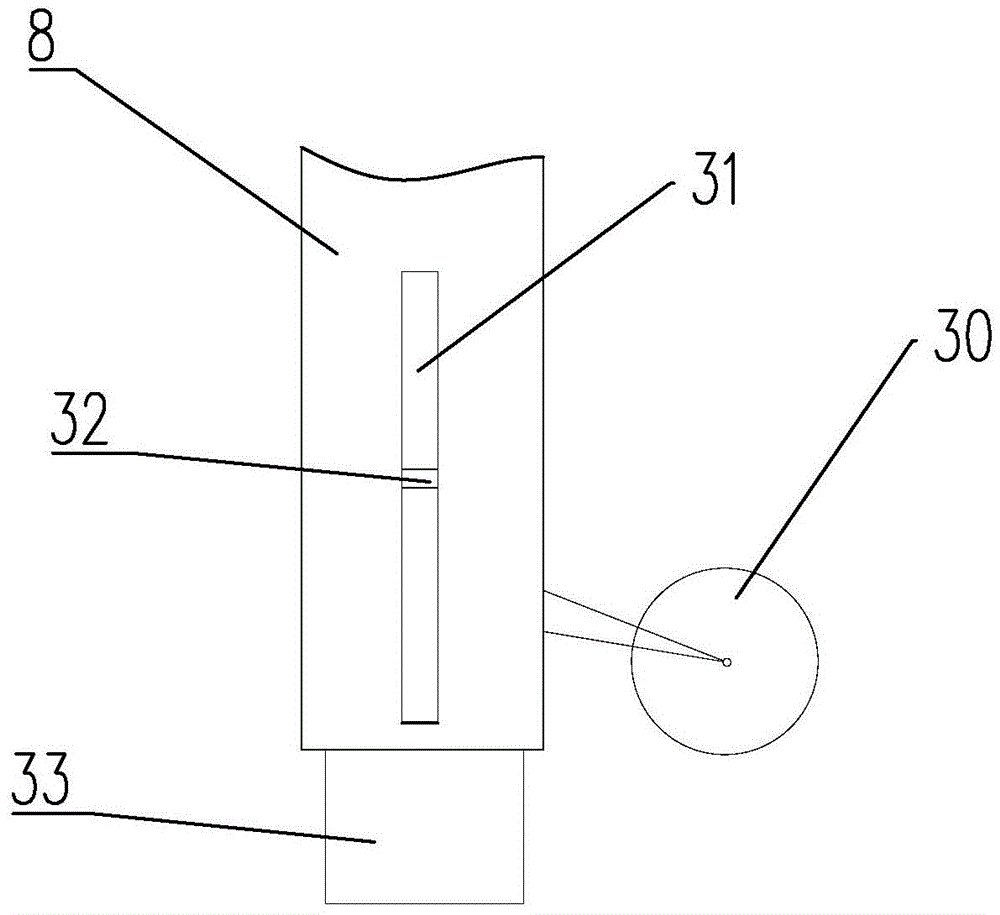

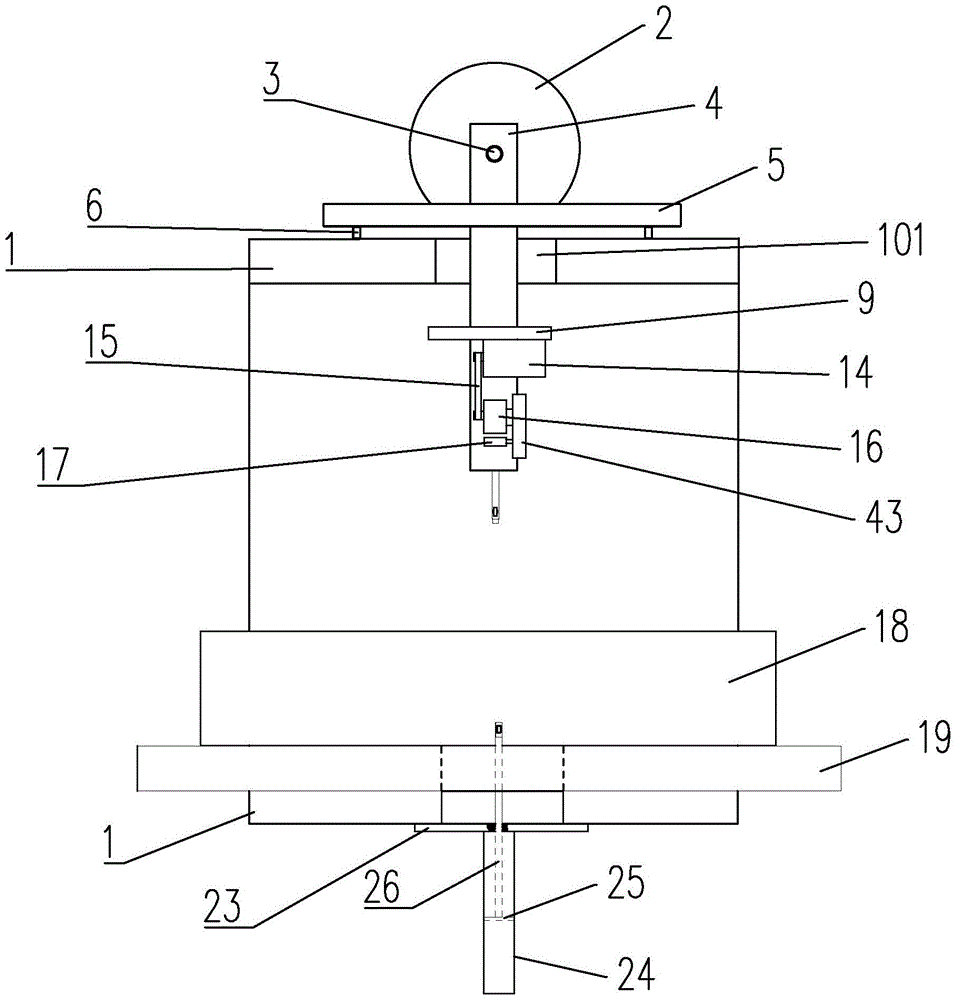

Rotary four-position machine capable of taking and injecting slurry cleanly

InactiveCN103521734AContinuous and uninterrupted high-efficiency advanced semi-solid processing operationsPrecise position controlMetal machiningSemi solid

The invention provides a rotary four-position machine capable of taking and injecting slurry cleanly. The rotary four-position machine capable of taking and injecting the slurry cleanly is characterized by comprising a rack (1), a rotation power assembly (2), a rotation support (3) and four lifting material-taking mechanisms identical in structure. The rotation power assembly (2) is fixed at the top end of the rack (1). The rotation support (3) is arranged on an output shaft (26) of the rotation power assembly (2). The four lifting material-taking mechanisms are mounted on four fixed mounting blocks (32) of the rotation support (3) respectively. The rotary four-position machine can be used for taking and injecting semi-solid state slurry continuously, efficiently and cleanly, thereby effectively improving the work efficiency of semi-solid state metal processing and guaranteeing the quality of the slurry in the taking and injecting process.

Owner:NANCHANG UNIV +1

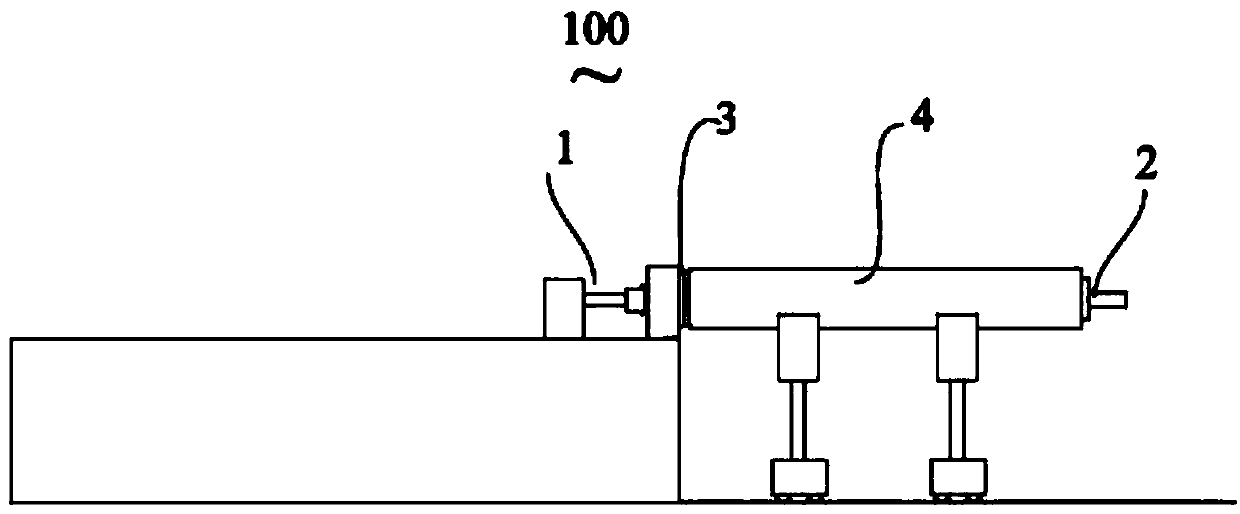

Mold release machine

The invention discloses a mold release machine used for releasing a mold in a tubular product. The mold release machine comprises a machine frame, a fixing device, a movable mold release device and adriving device. The fixing device and the movable mold release device are arranged on the machine frame. The fixing device fixes the core mold in the tubular product, the fixing device comprises a main fixing device and an auxiliary fixing device, the movable mold release device is detachably connected with the outer wall of the tubular product, the driving device pulls the movable mold release device, and the movable mold release device drives the tubular product to move in the axial direction of the tubular product. In the mold release process, the problem that one end of the core mold presses on the tubular product due to gravity is avoided, in other words, no extrusion is formed between the core mold and the tubular product, resistance in the mold release process is reduced, mold release is easier, and damage to the tubular product is avoided.

Owner:JIANGYIN CHENG YUN MACHINERY CO LTD

Ultrahigh pressure testing system and control method thereof

ActiveCN106094913AUnder high pressurePrecise position controlMaterial strength using tensile/compressive forcesFluid pressure control using electric meansPressure riseAutomatic control

The invention discloses an ultrahigh pressure testing system and a control method thereof. The ultrahigh pressure testing system comprises a liquid box, a first control valve and a servo supercharger. The liquid box is connected with the first control valve and the servo supercharger in sequence. The servo supercharger is connected with a pressure testing device. A second control valve is connected between the servo supercharger and the pressure testing device. A first pressure detection module is arranged between the first control valve and the second control valve. A second pressure detection module is arranged between the pressure testing device and the second control valve or in the pressure testing device. The technical purpose of the invention is to provide the ultrahigh pressure testing system which uses the servo supercharger as a power source to ensure high precision and high pressure of medium pressurization and intelligently control the pressure rising / reducing rate, and provide the control method of the ultrahigh pressure testing system to realize automatic control in the pressure testing process.

Owner:四川杰特机器有限公司

Multi-legged robot based on Arduino Bluetooth wireless download

The invention provides a multi-legged robot based on Arduino Bluetooth wireless download and belongs to the field of robot structures. The multi-legged robot based on Arduino Bluetooth wireless download comprises a head part and a body part connected with the head part; an obstacle avoidance device is arranged in the head part; the body part comprises a plurality of body sections which are hingedwith each other in sequence; each body section comprises one or two pairs of feet, a first driving device and a second driving device, wherein the feet are symmetrically arranged on the two sides of the body section, the first driving device drives each foot to move, and the second driving device is used for driving the body section to move; the multi-legged robot based on Arduino Bluetooth wireless download further comprises a control board used for controlling the first driving devices and the second driving devices; and the body part is also provided with a power supply module for providingpower supply for a main control board, the first driving devices and the second driving device. The multi-legged robot based on Arduino Bluetooth wireless download has the beneficial effect that a realistic model is provided for bionic research on multi-legged creatures such as centipedes.

Owner:GUANGXI RADIO & TV UNIV +1

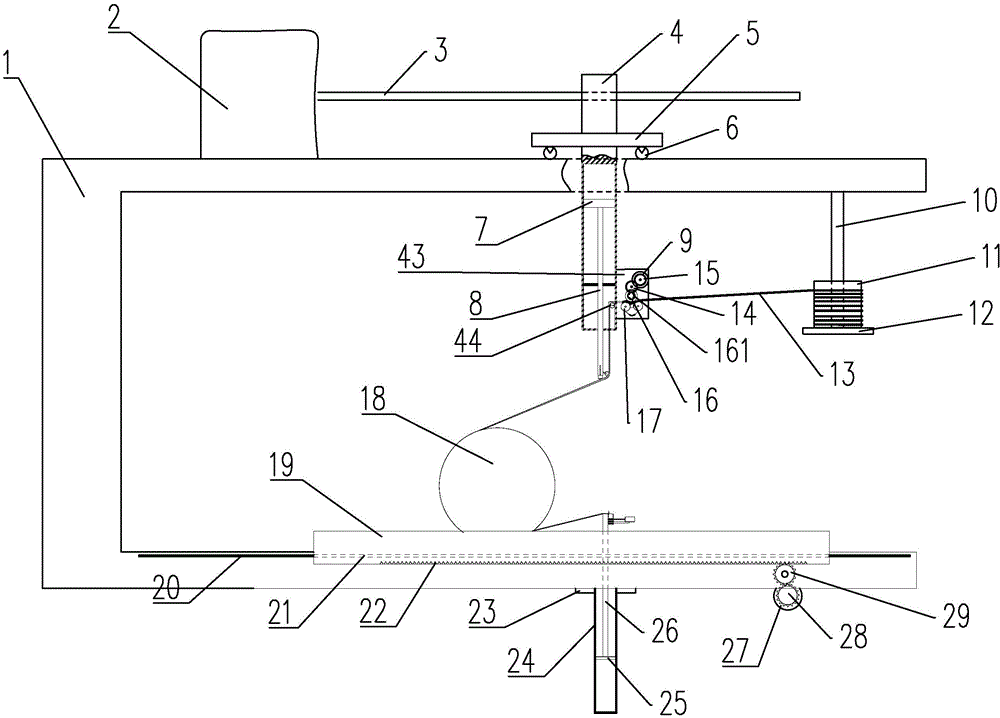

Cylinder shape pipe piece with inner harden layer and its production method and equipment

InactiveCN1190617CStable jobUniform speed regulationIncreasing energy efficiencyFurnace typesFrictional coefficientPipe fitting

The present invention relates to a cylindrical pipe with internal hardened layer, its production method and special-purpose equipment. Said cylindrical pipe has small wall thickness and long length, its pipe wall has internal layer and external layer with different hardness, the hardness of its internal layer is greater than that of external layer, and said pipe is applicable for conveying material with high frictional coefficient. Its production method adopts the mode utilizing frequency to control pipe movement and proper hardening temp. range, and is special-purpose equipment is simple in structure, stable in operation, and can accurately control hardening temp., pipe moving speed nad depth of hardened layer.

Owner:王克发 +1

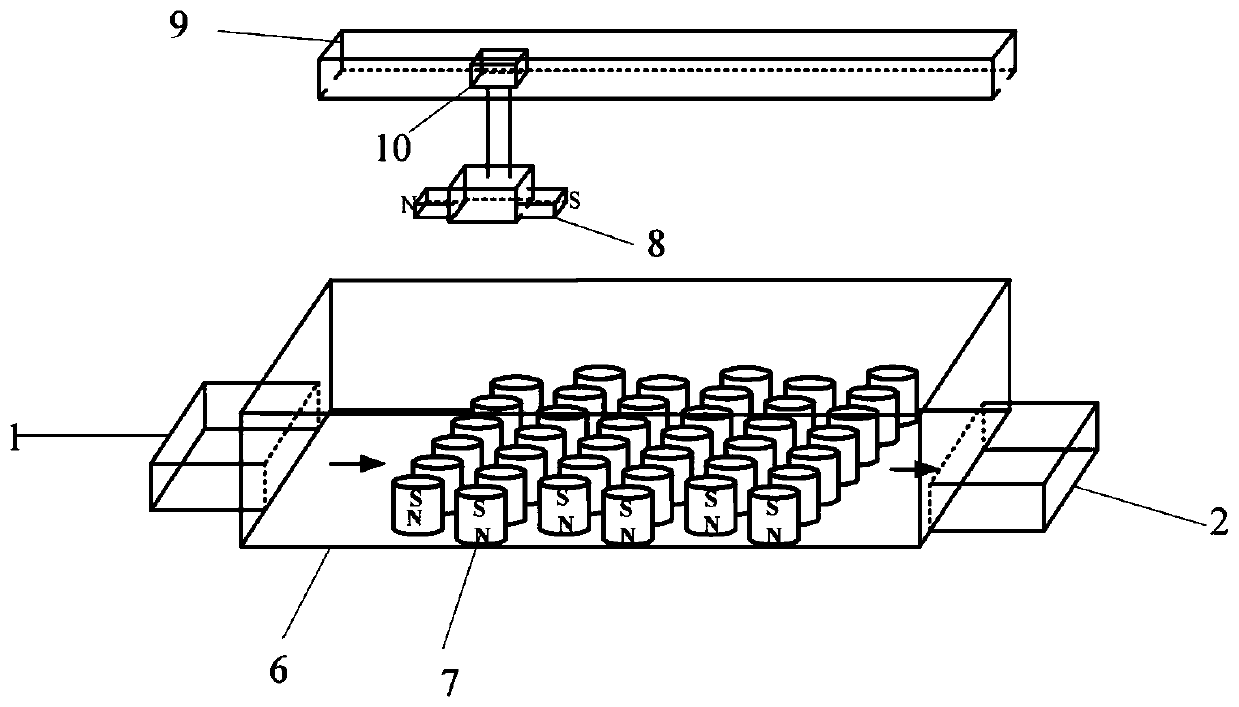

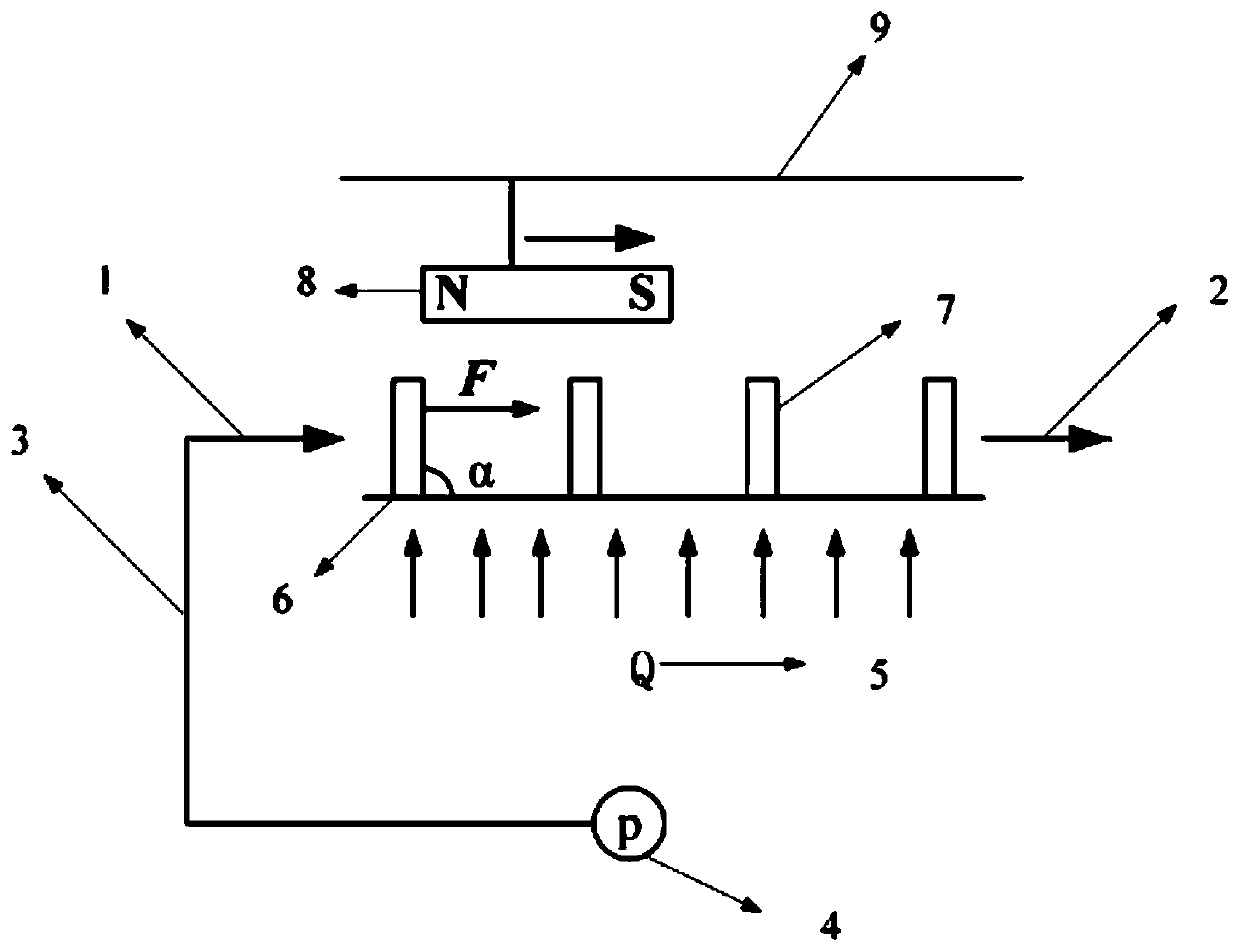

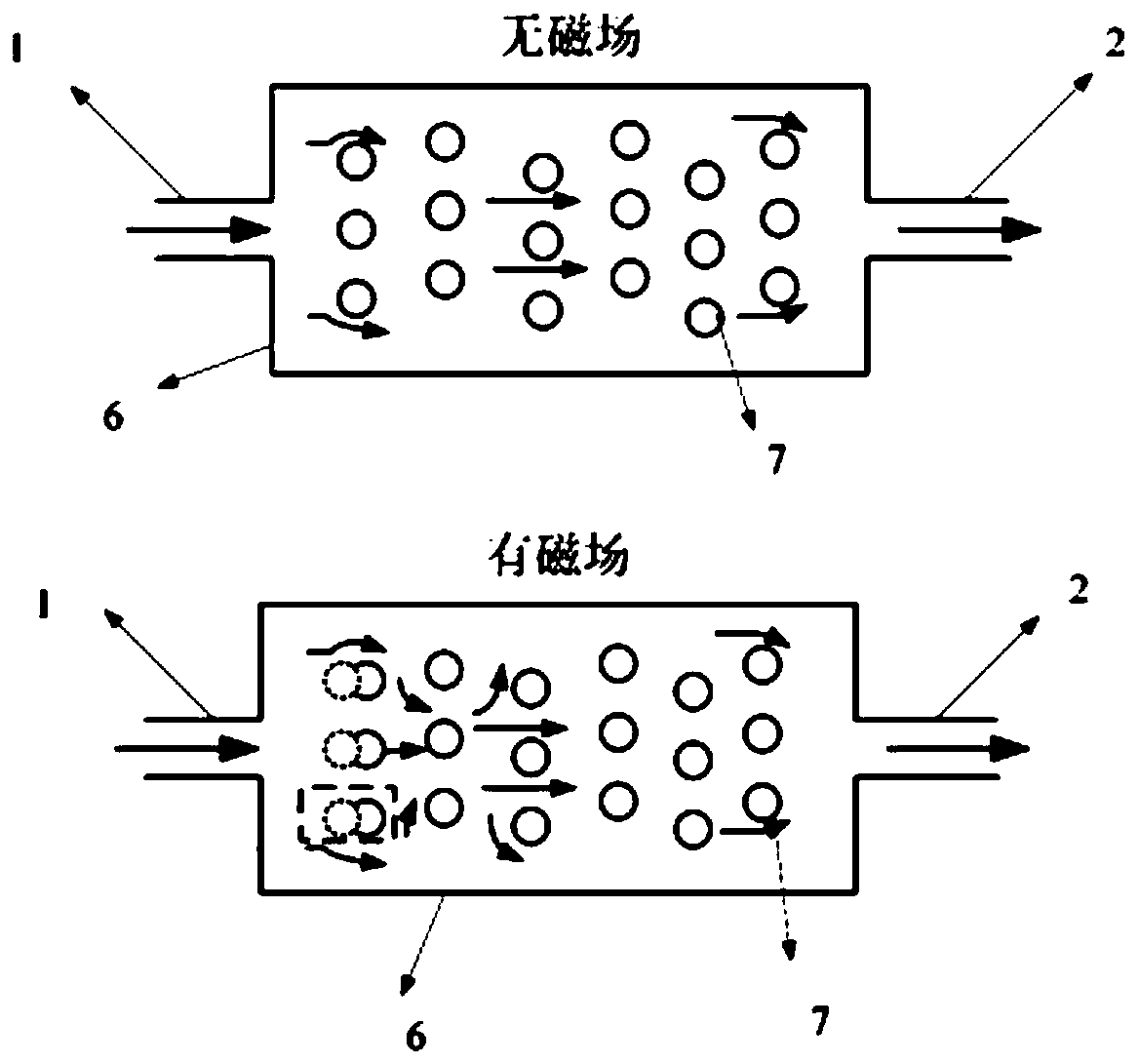

Magnetism-based microchannel apparatus and method with intensified convective heat exchange

ActiveCN110505793AEnhanced convective heat transferReduce heat transfer areaModifications using liquid coolingEngineeringMagnet

The present invention relates to a magnetism-based microchannel apparatus and method with intensified convective heat exchange, and belongs to the field of microchannel technologies. The apparatus comprises a heat exchange box body, wherein several rows of heat exchange microcolumns are fixedly arranged on a heat exchange baseboard of the heat exchange box body along a working medium flow direction, the heat exchange microcolumns form a microchannel, a single heat exchange microcolumn in the Nth row is on a central axis of two adjacent heat exchange microcolumns in the (N-1)th row, wherein N is >= 2; a sliding chute is opened on a top wall of the heat exchange box body along a central axis of the working medium flow direction, a sliding block is disposed inside the sliding chute, a permanent magnet is fixedly arranged on the bottom of the sliding block, and the permanent magnet is right above the microchannel; and the heat exchange box body is disposed above a heat source. According tothe microchannel apparatus and method, when a working medium to be heat exchanged passes through intricately arranged heat exchange microcolumns of a heating box, convective heat exchange is enhanced.

Owner:KUNMING UNIV OF SCI & TECH

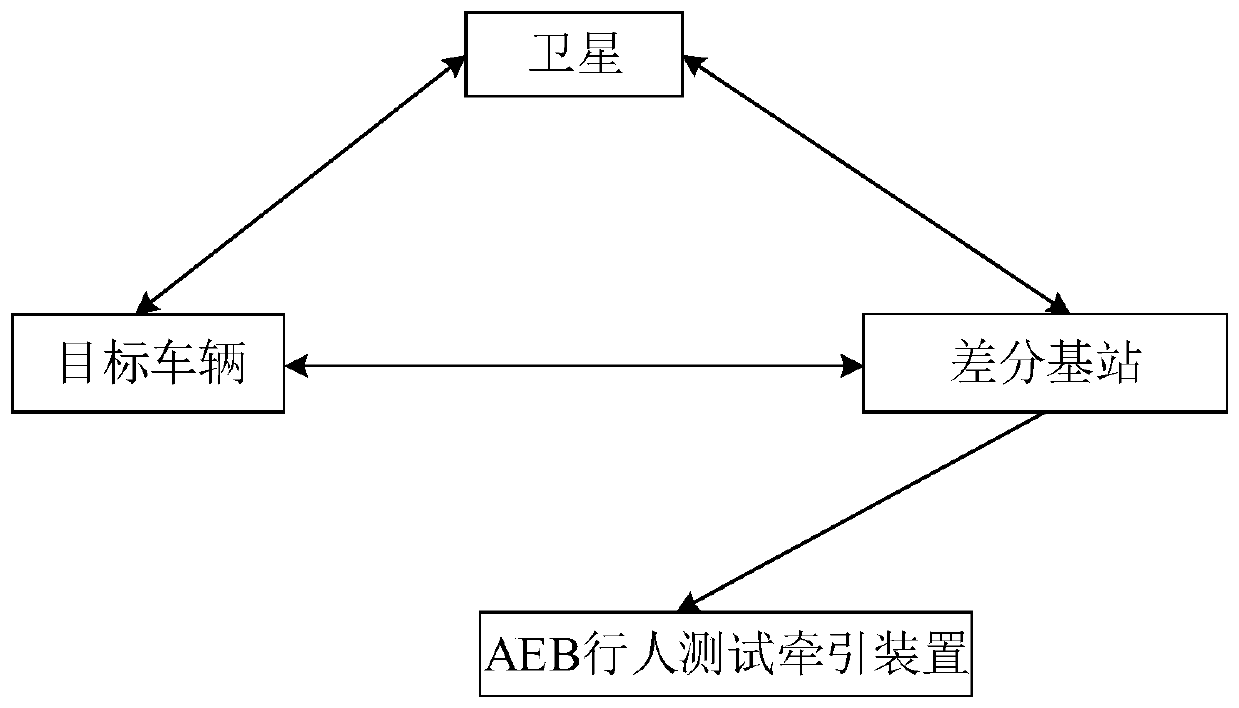

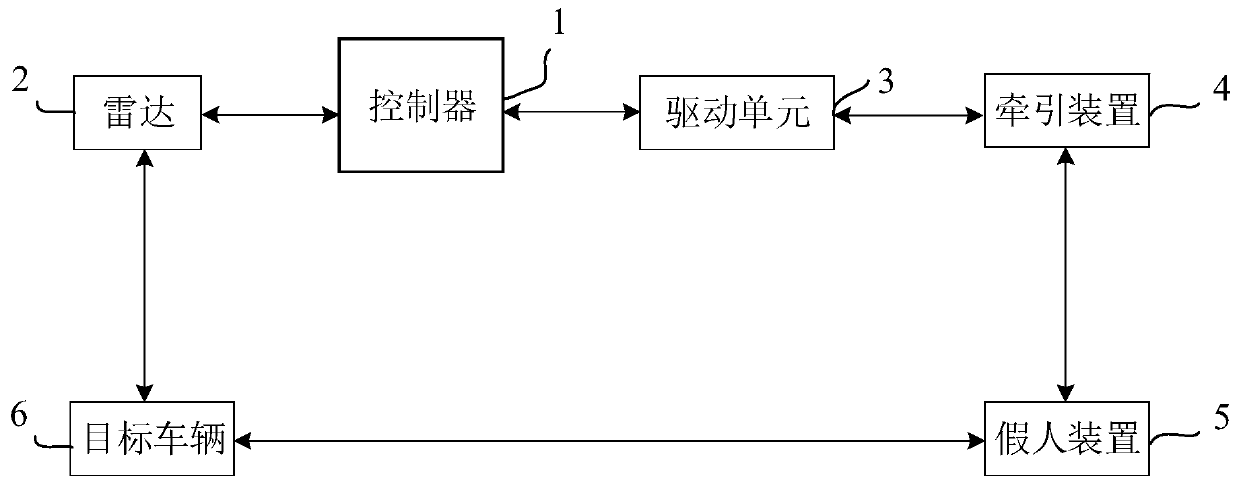

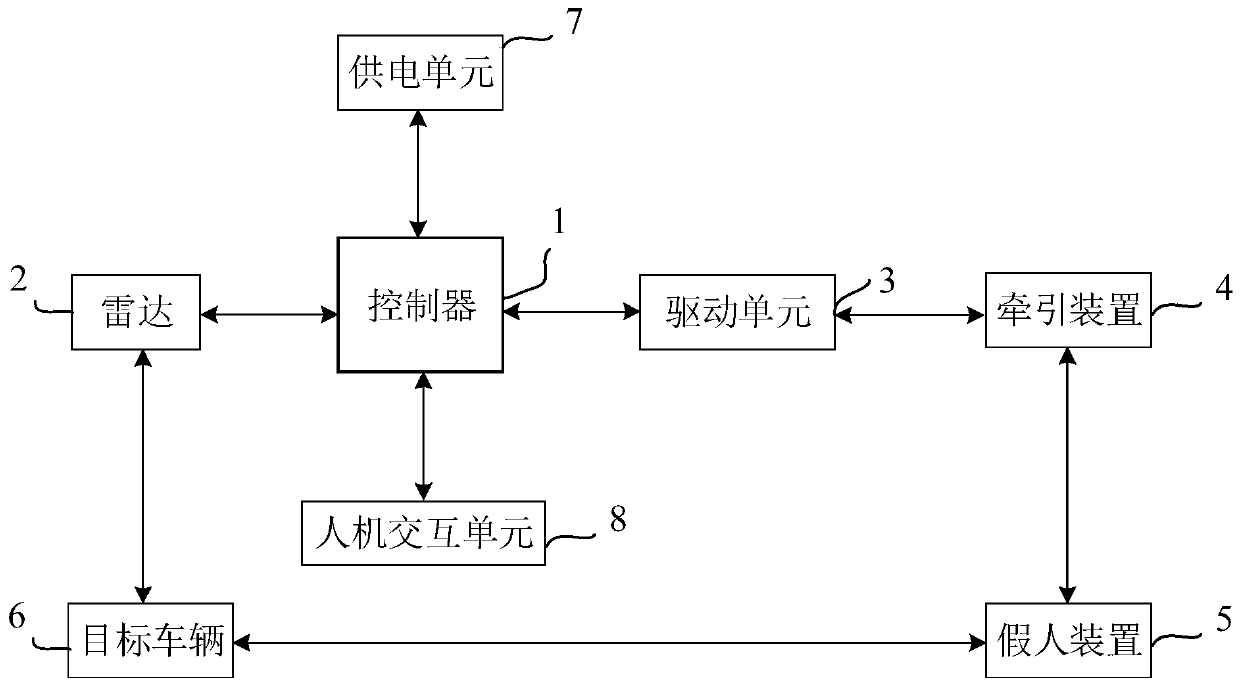

VRU motion triggering system and method in automobile AEB test

PendingCN110488235AImplement power managementPrecise control of movement speedWave based measurement systemsRadarEngineering

The invention discloses a VRU motion triggering system and a VRU motion triggering method in an automobile AEB test, which belong to the field of driving assistance systems. The VRU motion triggeringsystem comprises a controller, a radar, a driving unit, a traction device and a dummy device, wherein the radar is used for detecting a moving speed of the target vehicle and a distance between the target vehicle and the dummy device VRU; the controller is used for acquiring collision time of the target vehicle and the dummy device VRU according to the moving speed of the target vehicle and the distance between the target vehicle and the dummy device VRU, and sending a driving signal to the driving unit when the collision time is less than or equal to preset time; the driving unit is used forsending a trigger signal to the traction device after receiving the driving signal; and the traction device is used for controlling and pulling the dummy device VRU to move according to a preset speedand a preset direction under the driving action of the driving unit after receiving the trigger signal. The VRU motion triggering system and the VRU motion triggering method are low in implementationcost, and meet the requirements of AEB pedestrian tests simply and efficiently.

Owner:WUHAN JIMU INTELLIGENT TECH CO LTD +1

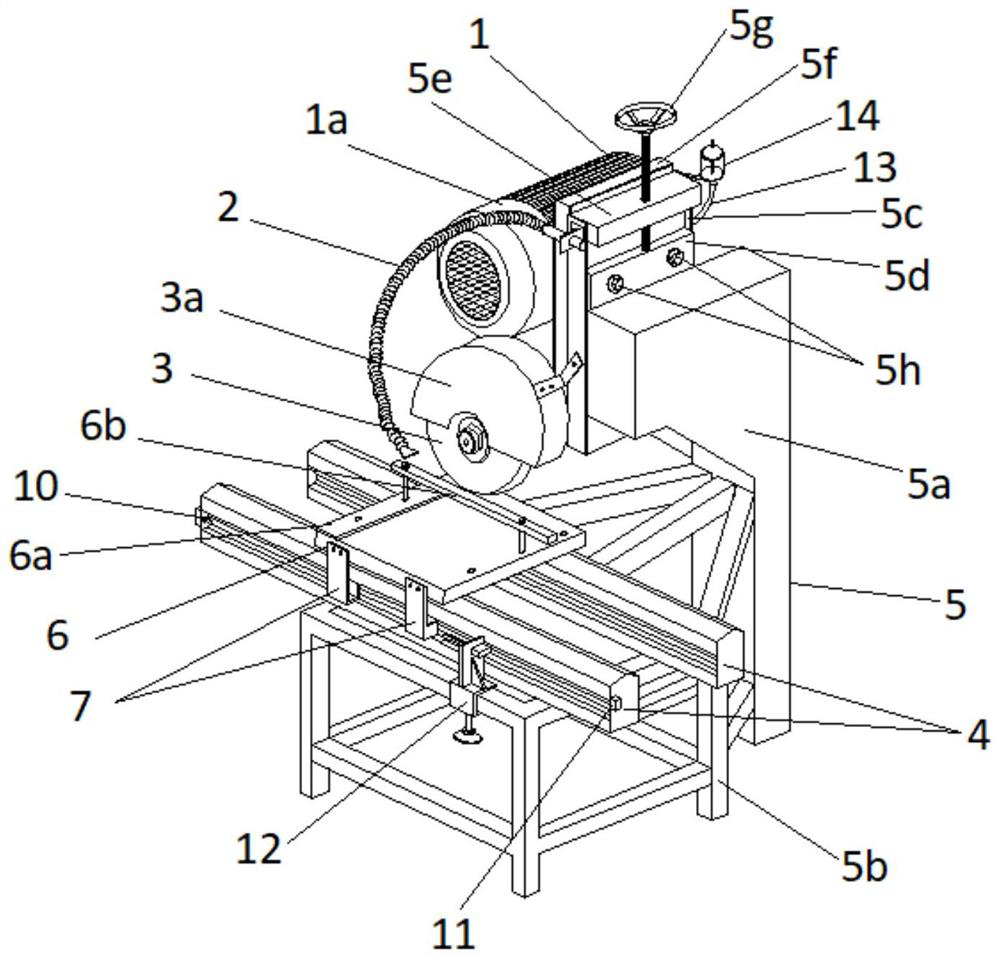

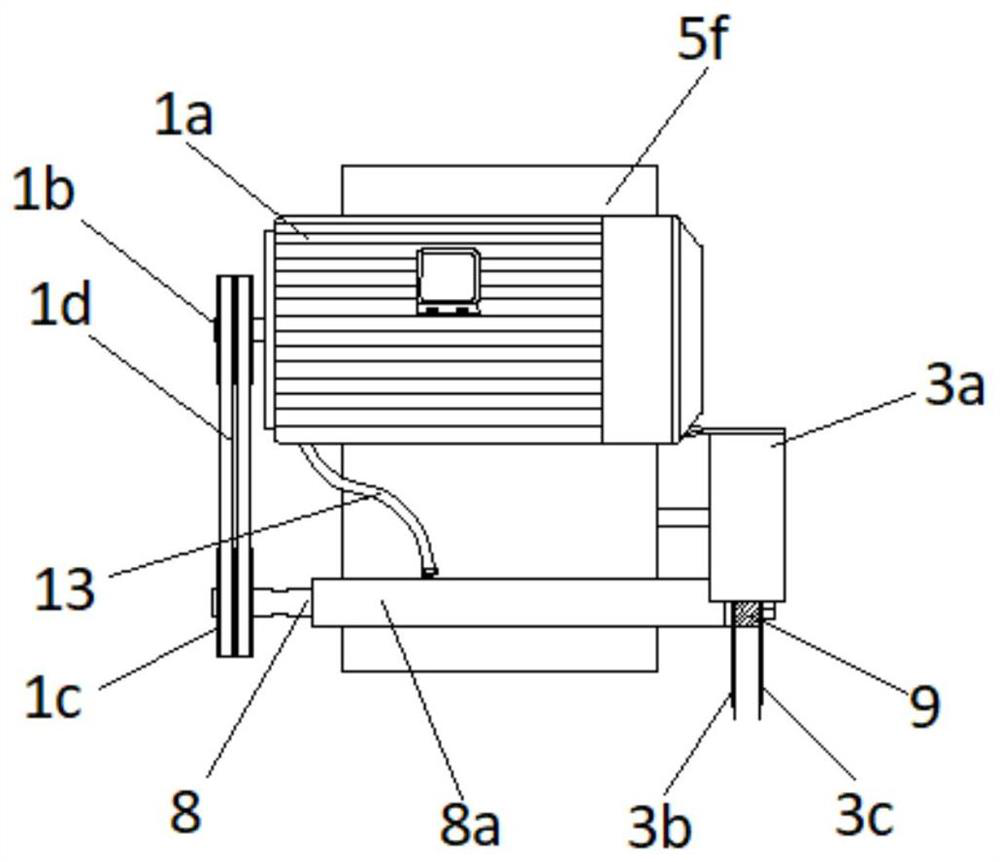

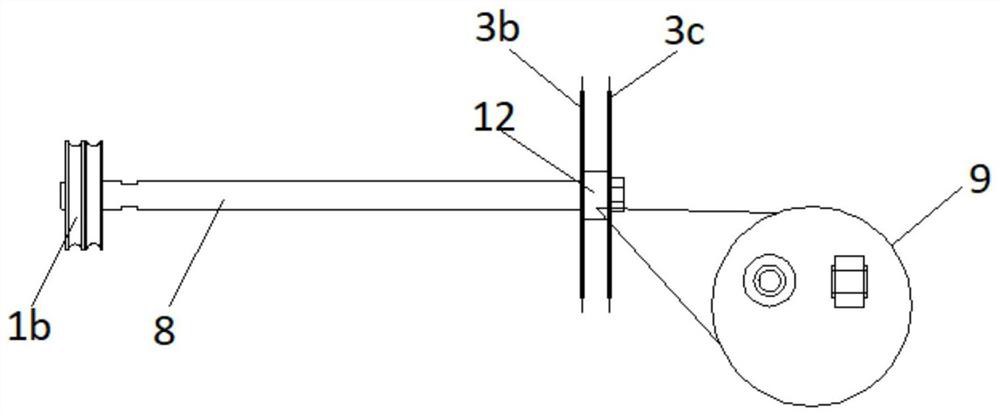

Double-cutter asphalt concrete test piece cutting machine

PendingCN112706307ASimple structureNovel and reasonable designWorking accessoriesStone-like material working toolsSupporting systemControl system

The invention discloses a double-cutter asphalt concrete test piece cutting machine. The double-cutter asphalt concrete test piece cutting machine comprises a supporting system, a cutting system and a control system. The height-adjustable cutting system is arranged on the supporting system and is used for cutting an asphalt concrete test piece. A sample conveying system capable of moving horizontally is further arranged on the supporting system, is positioned below the cutting system and is used for pushing an asphalt concrete sample to be cut to the cutting system. The control system is used for controlling the cutting work of the cutting system to start or stop and controlling the position of the sample conveying system to move or stop. The double-cutter asphalt concrete test piece cutting machine is simple in structure, novel and reasonable in design and convenient to operate, the whole cutting process is high in automation degree, the sample conveying process is uniform in speed, errors are reduced, and the quality of the asphalt concrete test piece is improved; the speed of adjusting the distance between cutter heads is high, and the working efficiency is improved; and various types of asphalt concrete samples can be clamped, the application range is wide, and the double-cutter asphalt concrete test piece cutting machine is suitable for general popularization.

Owner:SINOHYRDO ENG BUREAU 3 CO LTD

Bundling robot

InactiveCN104554863AGood flexibilityElasticBinding material applicationBundling machine detailsEngineeringMechanical engineering

The invention relates to a rod section bar bundling robot. The rod section bar bundling robot comprises a machine frame, wherein an upper arm and a lower arm are arranged on the machine frame; an air cylinder I is arranged on the upper arm and is suitable for moving left and right relative to the upper arm, a piston I and a connecting rod I in the air cylinder I are suitable for vertically moving, and a telescopic nail box is arranged at the bottom end of the connecting rod I; a table board for placing a steel bundle is arranged on the lower arm in a left-right sliding fit manner, an air cylinder II is fixedly arranged at the bottom of the lower arm, a piston II and a connecting rod II at the top of the piston II are arranged in the air cylinder II, a pair of grooves is formed in the top surface of the connecting rod II, and the grooves are suitable for allowing nails to penetrate through and tightly grasp a rubber tape for bundling the steel bundle when the connecting rod I and the connecting rod II are aligned and pressed; a pressing block which is suitable for moving relative to the connecting rod II and is used for clamping ends of the rubber tape is arranged on the right side of the connecting rod II. For the rod section bar bundling robot, during the process of bundling, a virtual-wire phenomenon cannot occur, and once bundling is finished, the steel bundle is not easy to loosen due to displacement of steel wires.

Owner:DONGGUAN UNIV OF TECH

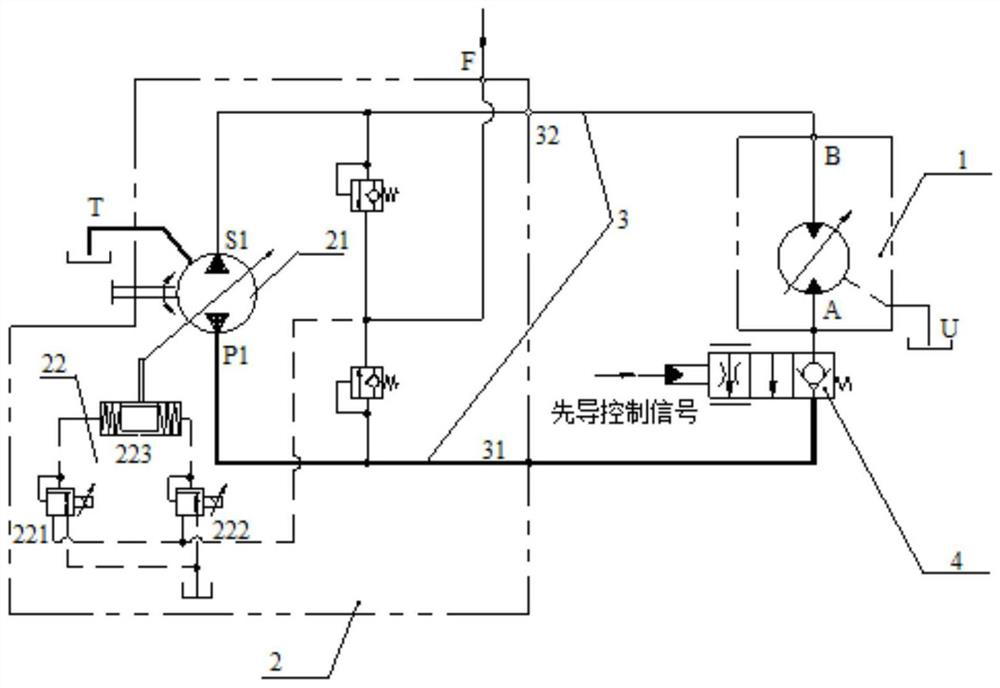

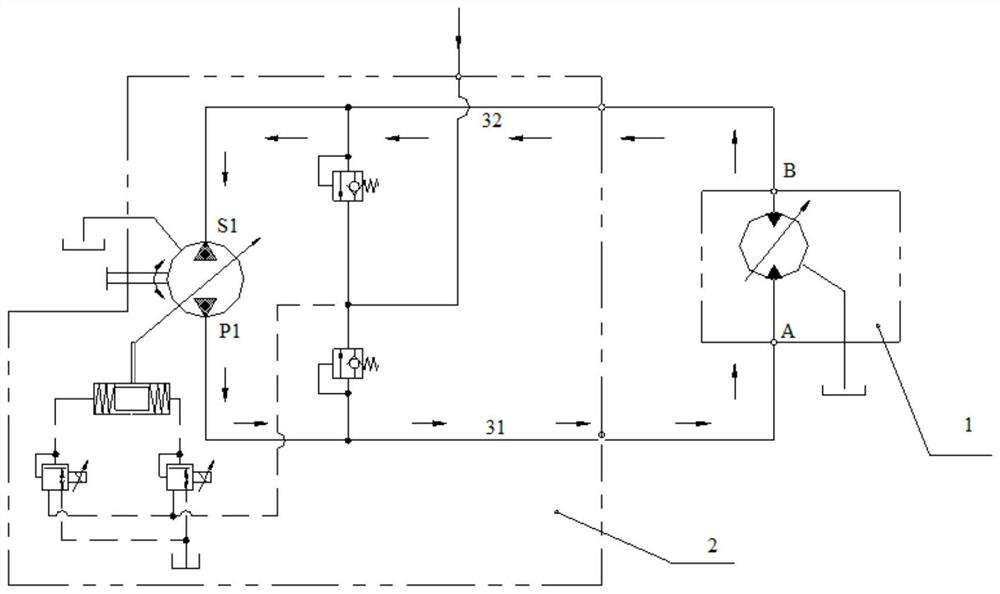

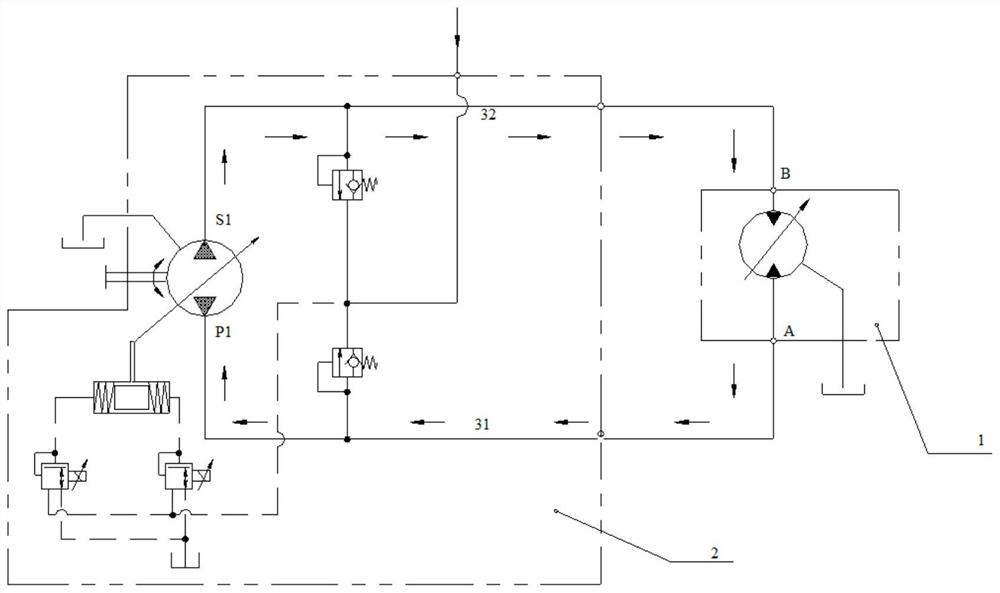

Closed system, hoisting equipment and crawler-type travelling equipment

ActiveCN113928980AImprove securityPrevent reversalServomotor componentsServomotorsMechanical equipmentDrive motor

The embodiment of the invention discloses a closed system, hoisting equipment and crawler-type travelling equipment. The closed system comprises a motor used for driving a hoisting mechanism or a travelling mechanism of mechanical equipment to work, a closed pump connected with the motor by means of a working pipeline and used for driving the motor, and an inching control valve arranged on the working pipeline or an oil port of the motor and used for conducting inching control when the mechanical equipment descends and / or preventing the motor from rotating reversely when the mechanical equipment ascends. The closed system is simple in structure, a speed of the mechanical equipment can be slightly increased from zero, a movement speed of the mechanical equipment is accurately controlled, controllability of the mechanical equipment is improved, opening impact is reduced, and therefore safety of the closed system is improved.

Owner:ZOOMLION HEAVY IND CO LTD

Bundling device

ActiveCN104554861AGood flexibilityElasticFlexible elementsBinding material applicationEngineeringMachine

The invention relates to a rod section bar bundling device for bundling steel wires by rubber tapes. The rod section bar bundling device comprises a machine frame, wherein an upper arm and a lower arm are arranged on the machine frame; an air cylinder I is arranged on the upper arm and is suitable for moving left and right relative to the upper arm, a piston I and a connecting rod I in the air cylinder I are suitable for vertically moving, and a telescopic nail box is arranged at the bottom end of the connecting rod I; a table board for placing a steel bundle is arranged on the lower arm in a left-right sliding fit manner, an air cylinder II is fixedly arranged at the bottom of the lower arm, a piston II and a connecting rod II at the top of the piston II are arranged in the air cylinder II, a pair of grooves is formed in the top surface of the connecting rod II, and the grooves are suitable for allowing nails to penetrate through and tightly grasp a rubber tape for bundling the steel bundle when the connecting rod I and the connecting rod II are aligned and pressed; a pressing block which is suitable for moving relative to the connecting rod II and is used for clamping ends of the rubber tape is arranged on the right side of the connecting rod II. For the rod section bar bundling device, during the process of bundling, a virtual-wire phenomenon cannot occur, and once bundling is finished, the steel bundle is not easy to loosen due to displacement of the steel wires.

Owner:威尔机械江苏有限公司

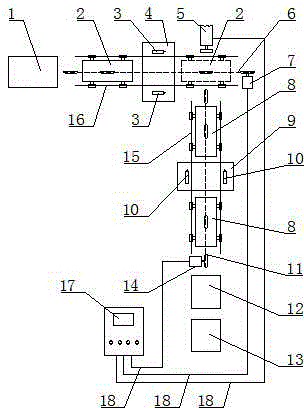

Automatic numerically-controlled final trimming and dust collecting device for PVC sheets

InactiveCN105666572APrecise control of movement speedAvoid pollutionDirt cleaningMetal working apparatusLeft–right symmetryEnvironmentally friendly

The invention discloses an automatic numerically-controlled final trimming and dust collecting device for PVC sheets. The automatic numerically-controlled final trimming and dust collecting device is characterized by comprising a table (1), a transverse rail trolley (2), two transverse cutting hobs (3) arranged in an up-down symmetry mode, a transverse cutting dust-collection hood (4), an electric pushing device (5), a transverse chain wheel transmission mechanism (6), a transverse chain wheel driving servo motor (7), a longitudinal rail trolley (8), a longitudinal cutting dust-collection hood (9), two longitudinal cutting hobs (10) arranged in a left-right symmetry mode, a longitudinal chain wheel transmission mechanism (11), a finished product table (12), an automatic packaging machine (13), a longitudinal chain wheel driving servo motor (14), two parallel longitudinal guide rails (15), two parallel transverse guide rails (16), an electronic control box (17) and wires (18). The automatic numerically-controlled final trimming and dust collecting device for the PVC sheets is novel in structure, high in cutting precision and speed, high in automation degree, capable of remarkably improving production efficiency, safe and environmentally friendly.

Owner:HUANGSHI HUAYI PLASTIC

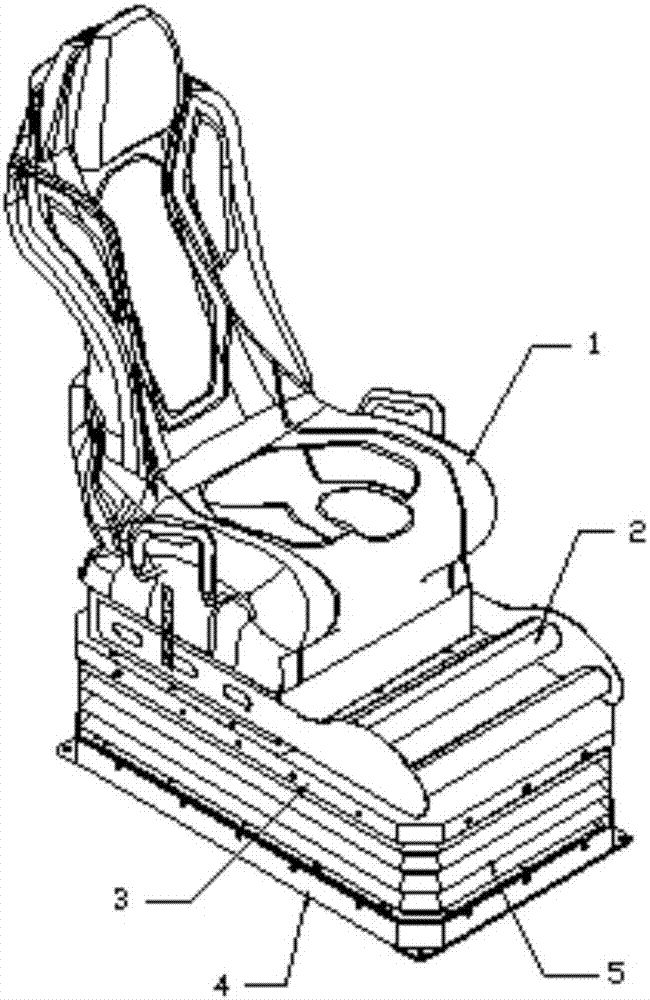

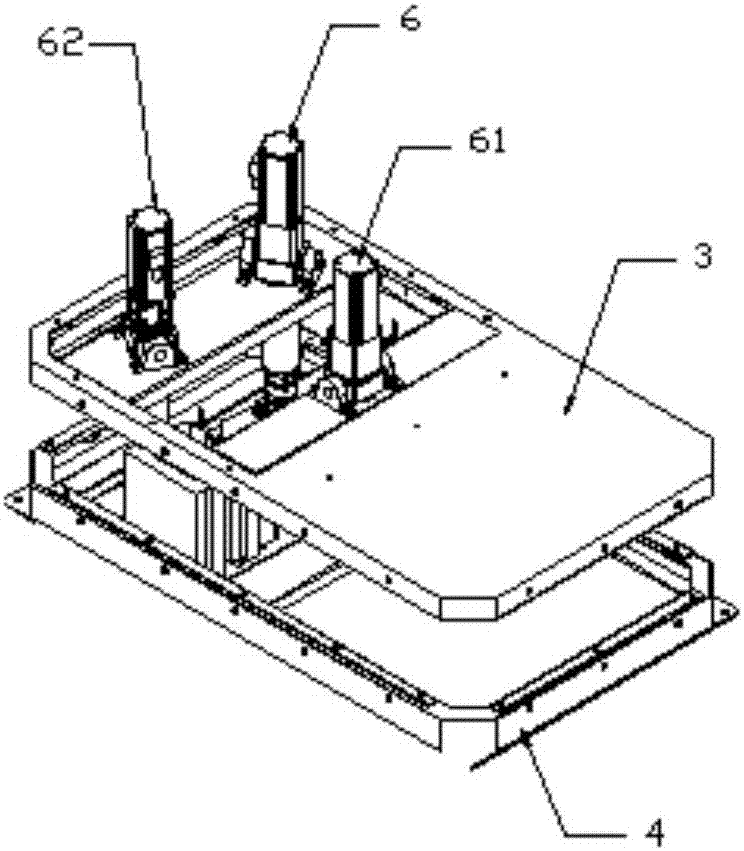

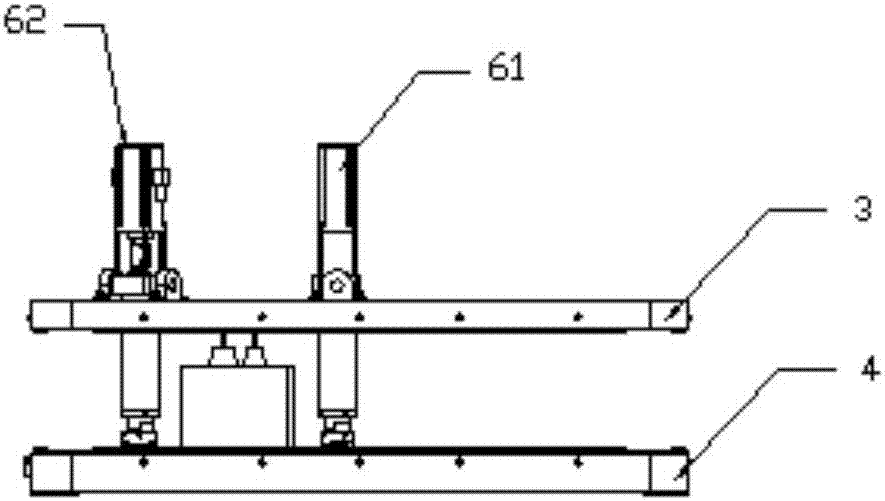

Power control device of single-person dynamic seat

InactiveCN107362557AMeticulous experienceComfort experienceAmusementsCinema apparatusControl systemDynamic motion

The invention discloses a power control device of a single-person dynamic seat. The single-person dynamic seat comprises a fiber glass reinforced plastic seat main body, an upper platform, a lower platform and an electric control system, wherein a first electric cylinder, a second electric cylinder and a third electric cylinder are fixed to the upper platform; the first electric cylinder, the second electric cylinder and the electric cylinder are fixedly connected to the lower platform by virtue of hinges; and the electric control system is fixedly arranged between the upper platform and the lower platform. The single-person dynamic seat provided by the invention is simple in structure, low in construction cost and strong in practicability; the electric control system is a closed-loop control system, so that the first electric cylinder, the second electric cylinder and the third electric cylinder can be independently controlled in motions of lifting, inclining leftwards and rightwards and pitching back and forth; therefore, a loading capacity is enhanced, and a phenomenon of becoming deflected is prevented; movement speeds and movement positions can be precisely controlled, so that a high simulation effect can be achieved; and each electric cylinder is stepless-adjustable in motion, so that delicate dynamic motions can be provided in accordance with movie plots; therefore, an audience can have a delicate and comfortable experience.

Owner:CHANGZHOU JINGANG NETWORK TECH

Working method of steel strapping machine with rubber belt

ActiveCN104554859BEven by forceGood flexibilityBinding material applicationBundling machine detailsEngineeringMechanical engineering

The invention relates to a working method of a steel product binding machine using rubber belts. According to the working method, a frame is provided with an upper arm and a lower arm, an air cylinder I is arranged on the upper arm and suitable for left-right movement relative to the upper arm, a piston I and a connecting bar I which are arranged in the air cylinder I vertically move, a telescopic nail box is arranged at the bottom end of the connecting bar I, a table top for placement of steel bundles is arranged on the lower arm in a left-right sliding fit way, an air cylinder II are fixedly arranged at the bottom part of the lower arm and is internally provided with a piston II and a connecting bar II at the top of the piston II, and a pair of concave grooves are formed in the top face of the connecting bar II, and are used for rendering nails penetrate through and bite rubber belts for binding the steel bundles when the connecting bar I and the connecting bar II are aligned and pressed; a pressing block which moves relative to the connecting bar II and is used for clamping the end part of the rubber belts is arranged on the right side of the connecting bar II. The steel product binding machine has no phenomenon of virtual wires during binding, and the probability of unbinding caused by displacement of steel products after the steel products are bound is low.

Owner:威尔机械江苏有限公司

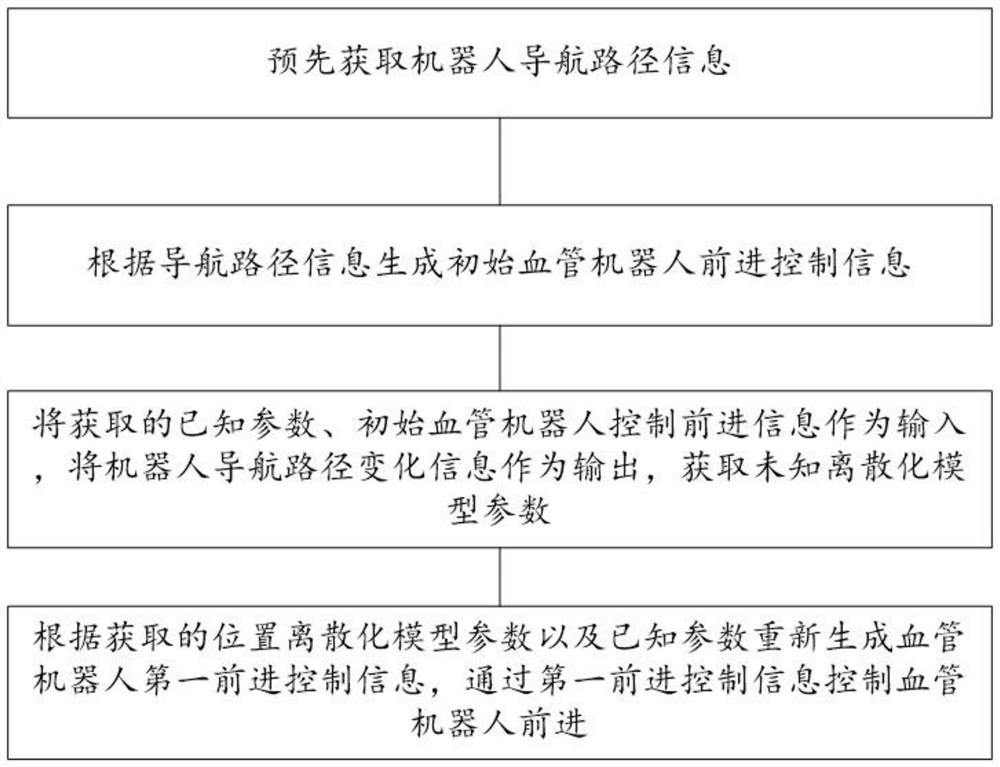

Control method of vascular robot based on bidirectional feedback

ActiveCN111759464APrecise control of movement speedPrecise position controlSurgical navigation systemsComputer-aided planning/modellingInformation controlSimulation

The invention discloses a control method of a vascular robot based on bidirectional feedback. The control method comprises the following steps: acquiring robot navigation path information in advance;generating initial vascular robot advancing control information according to the navigation path information; acquiring unknown discrete model parameters by taking the acquired known parameters and initial vascular robot control advancing information as input and taking robot navigation path change information as output; and regenerating first advancing control information of the vascular robot according to the acquired position discrete model parameters and known parameters, and controlling the vascular robot to advance through the first advancing control information.

Owner:广东省精格医疗技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com