Feeding apparatus

A feeding device and material technology, applied in electrical components, electrical components and other directions, can solve the problems of low efficiency, unstable and reliable operation, low efficiency, etc., and achieve the effect of improving the efficiency of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

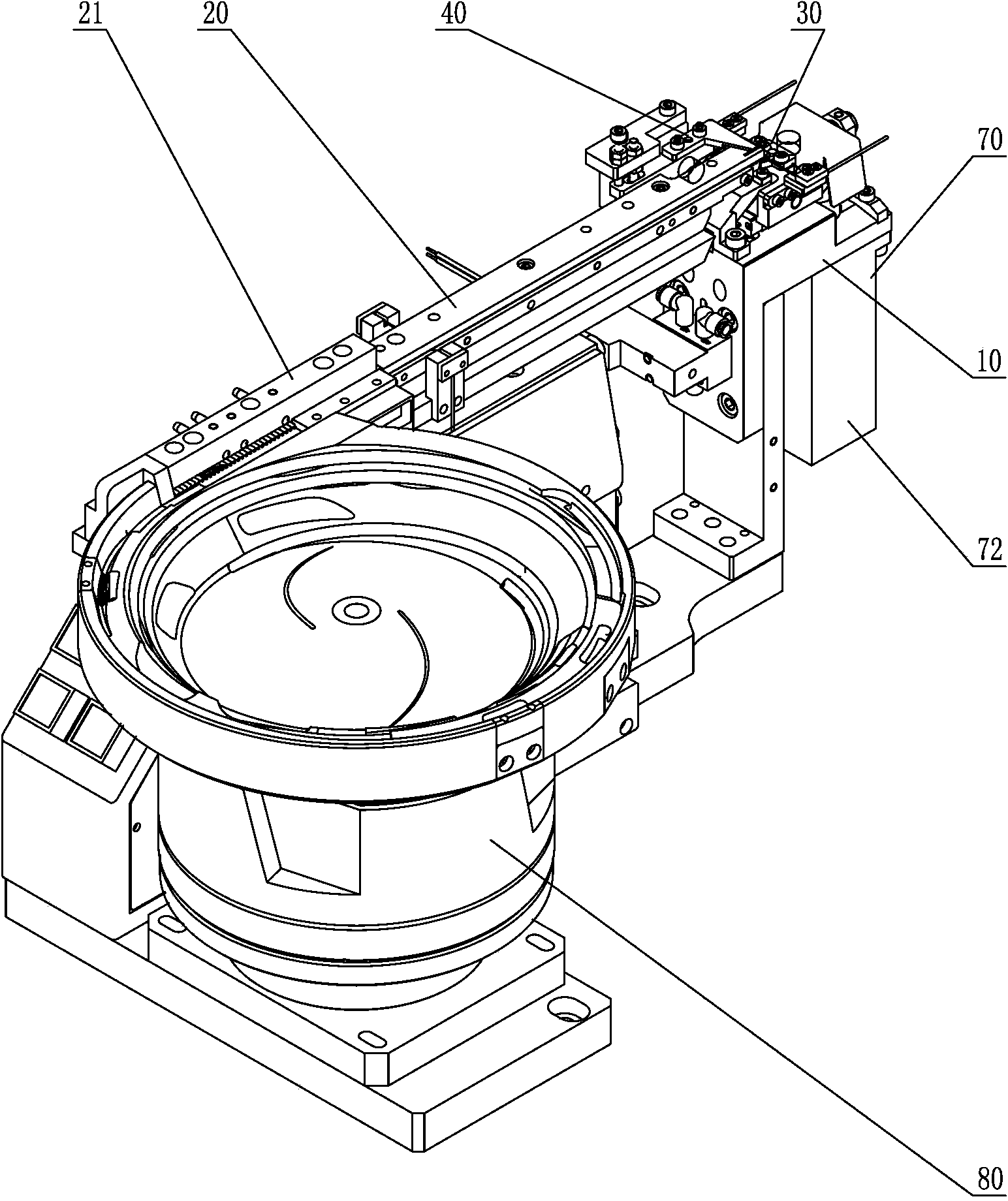

[0017] like figure 1 As shown, a feeding device includes a base 10, a flow channel 20 connected to the base 10, a material fixing mechanism 30 that is arranged at one end of the flow channel 20 and can move horizontally relative to the flow channel 20, and A stopper mechanism 40 for blocking the material in the flow channel 20 .

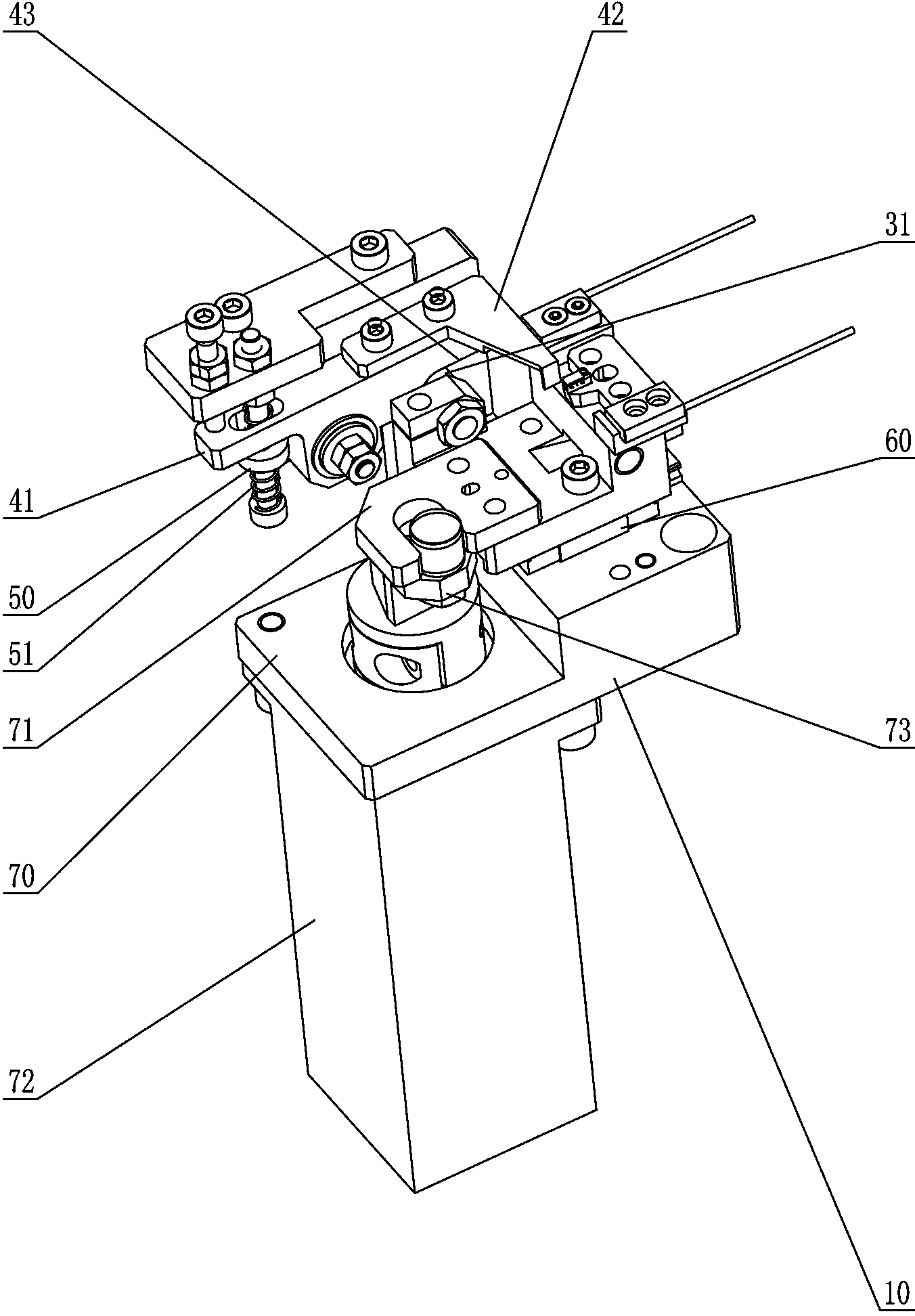

[0018] like figure 1 , 2 As shown, the material blocking mechanism 40 includes a swing block 41 and a blocking piece 42 connected with the swing block 41, the swing block 41 includes a guide surface 43, and the material fixing mechanism 30 includes a Cooperating rollers 31 . The guide surface 43 can be a certain inner surface of the guide channel provided on the swing block 41, or it can be a certain outer surface of the swing block 41, and the guide surface 43 can be a slope, a curved surface, or a slope and a slope. A combination of surfaces. In this embodiment, the guide surface 43 is an outer surface of the swing block 41 , and the guide sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com