Double-closed loop speed control captive trajectory simulation (CTS) test method based on time and space transformation

A technology of speed control and space-time transformation, which is applied in aerodynamic tests, machine/structural component tests, and measuring devices, etc., which can solve problems such as low test efficiency, low control test accuracy, and long time, and achieve experimental accuracy Low, low test efficiency, high cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

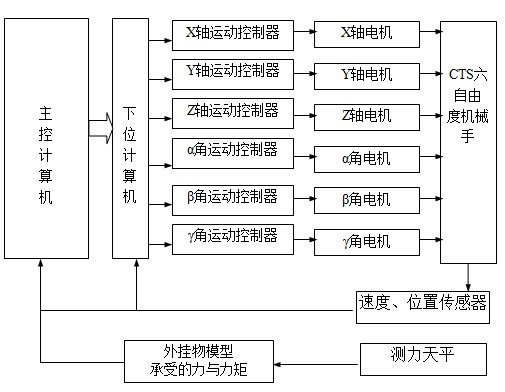

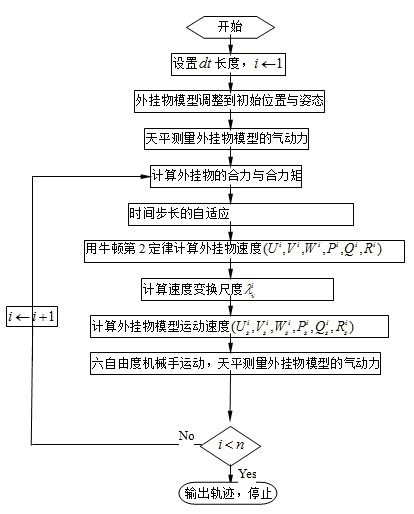

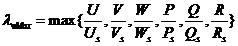

[0022] Such as figure 1 As shown, the double-closed-loop speed control CTS based on space-time transformation is mainly composed of the main control computer, the lower computer and its six-degree-of-freedom motion controller (X-axis, Y-axis, Z-axis, horn, horn, angular motion controller) and motors (X-axis, Y-axis, Z-axis, horn, horn, Angle motor), the motor jointly drives the CTS six-degree-of-freedom model support mechanism (six-degree-of-freedom manipulator), and the position and speed sensor used to detect the position and running speed of the external store model, and is used to measure the force of the load on the external store model Balance; the speed sensor transmits the data to the lower computer to ensure the accuracy of the running speed of the store model, and the position sensor transmits the data to the lower computer to ensure that the position of the store model is within the movement range of the CTS six-degree-of-freedom mechanism; at the same tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com