Patents

Literature

85results about How to "High sealing requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

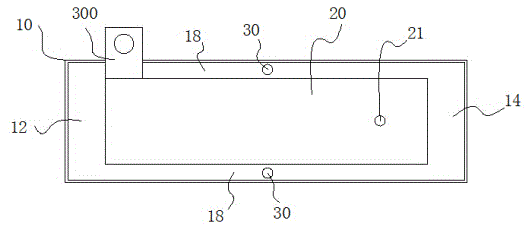

Disinfecting method of disinfection cabinet and disinfection cabinet

ActiveCN101890174AAvoid the problem of easy leakage of ozoneHigh sealing requirementsHeatRadiationThermal energyEngineering

The invention provides a disinfecting method of a disinfection cabinet and the disinfection cabinet. The disinfecting method adopted combined light waves and heat to sterilize and disinfect, wherein the light wave has a wall-broken effect on bacteria. The invention also provides the disinfection cabinet adopting the disinfecting method, which is composed of an outer shell and an inner shell, wherein the outer shell encircles the inner shell to form an interlayer, and the inner shell forms an inner cavity provided with a device for producing light waves having a wall-broken effect on bacteria and a device for producing heat capable of maintaining the disinfection cabinet inner cavity at a certain temperature. By the invention, sterilization and disinfection can be realized by combing light waves and heat, thus greatly shortening the disinfecting time.

Owner:HAIER GRP CORP +1

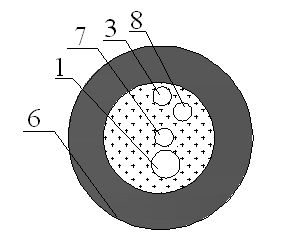

Sealing method of high sealing quasi-horizontal drilling hole

Disclosed is a sealing method of a high sealing quasi-horizontal drilling hole, which is particularly applied to the operation of mechanical grunting and sealing of a quasi-horizontal drilling hole in underground coal mines. The sealing method of the invention adopts a way of two-stage grunting to seal a quasi-horizontal drilling hole. For a gas drainage hole, the steps are: first plugging the front end and the rear end of a gas drainage pipe by using a bagged double composite sealing material, then starting a grunting pump and pumping seriflux of the sealing material into the gas drainage hole through a first time grunting pipe; waiting until the seriflux grunted at the first time is solidified and an interspace emerges on the upper portion of the gas drainage hole because of the self contractility of the grunted seriflux; and pumping the seriflux of the sealing material a second time into the interspace on the upper portion of the gas drainage hole and the fractured coal body adjacent to the hole through a second time grunting pipe. The sealing method provided by the invention enables the grunted seriflux to effectively seal the inner space of a drilling hole and the fractured coal body surrounding the hole, realizing the maximization of space and crack sealing and meeting the requirement of high sealing. Besides, the sealing method merits in easy operation and low cost.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

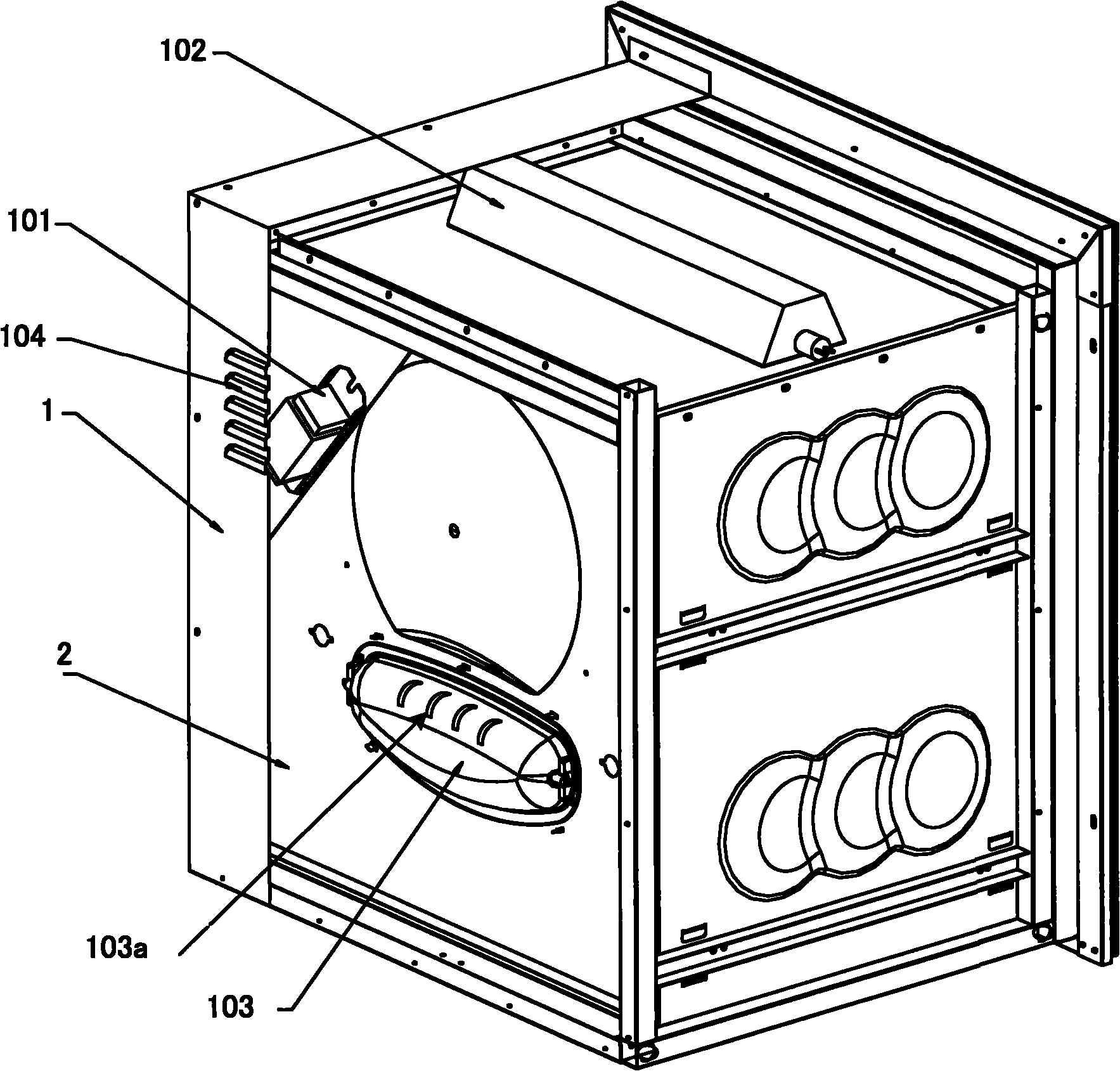

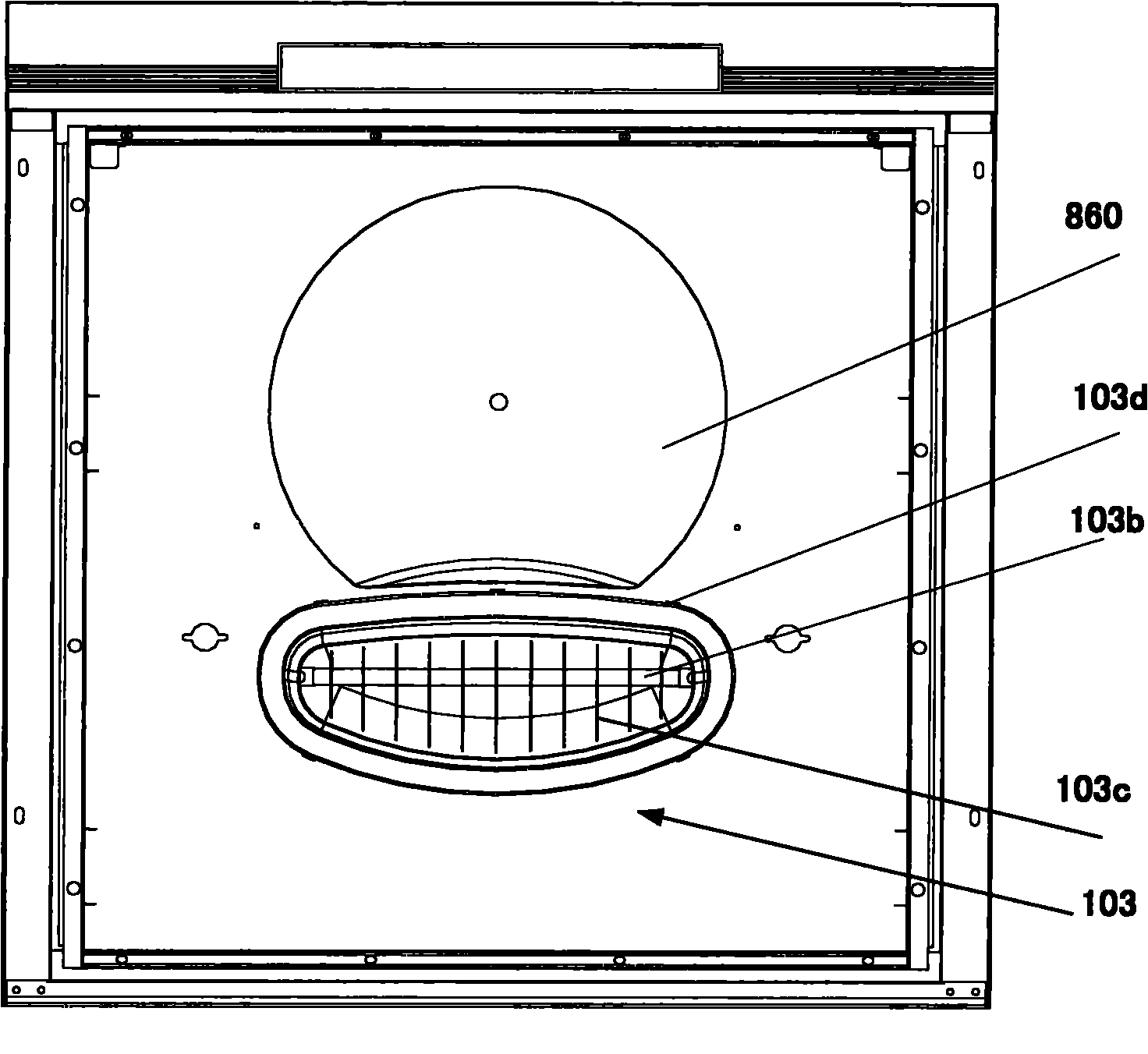

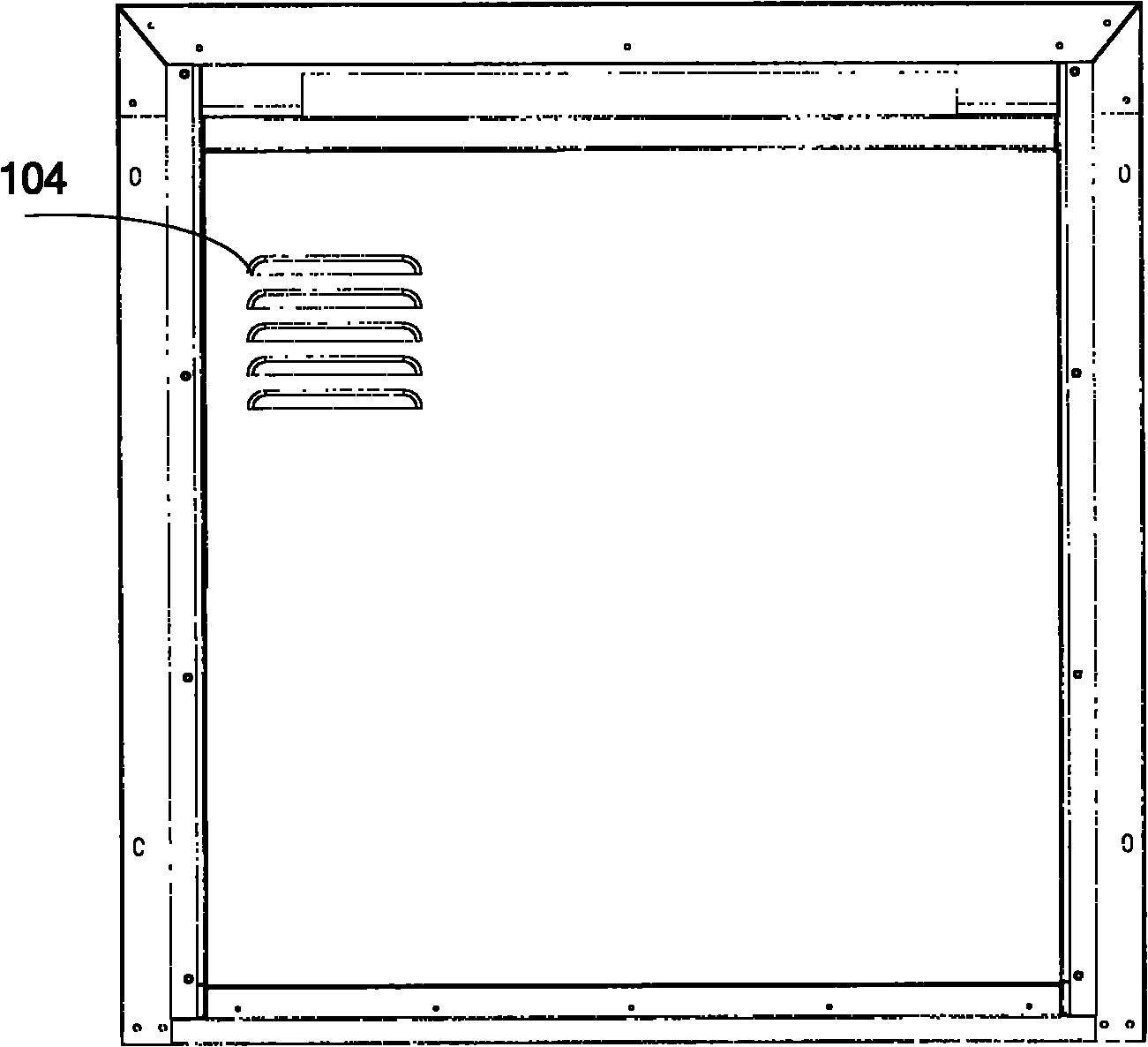

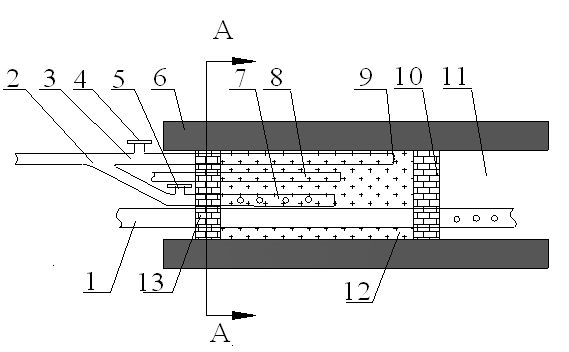

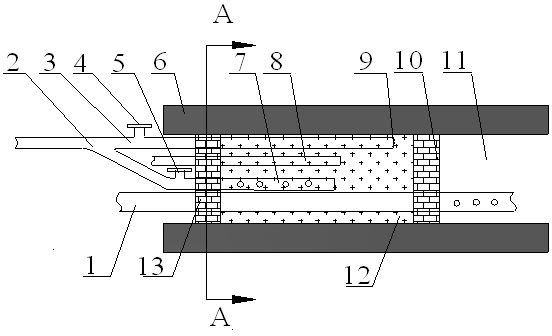

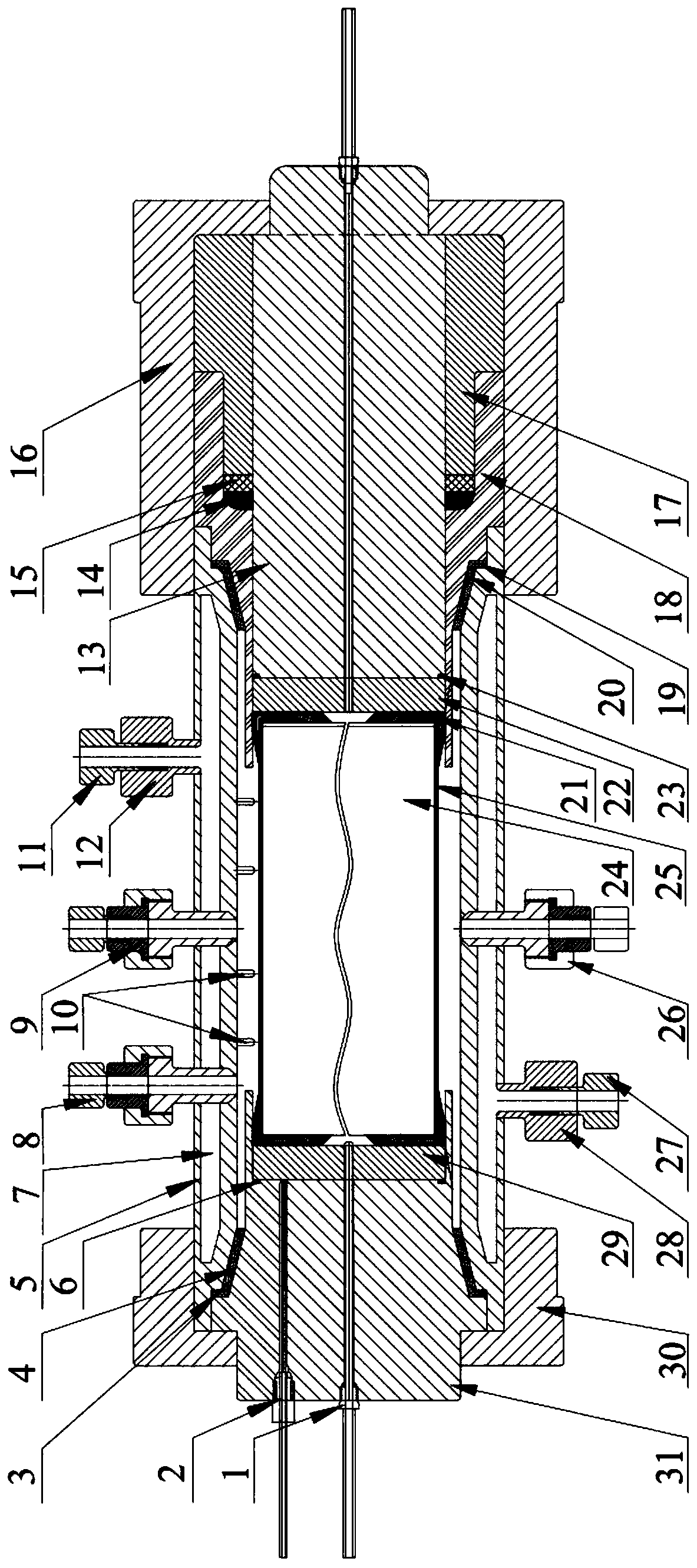

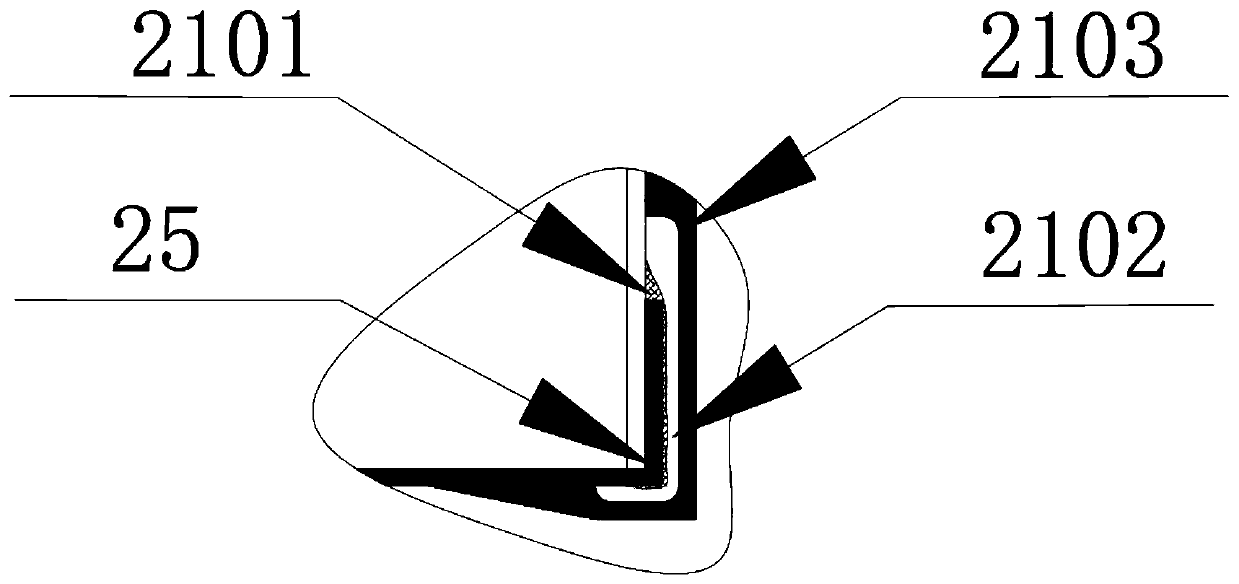

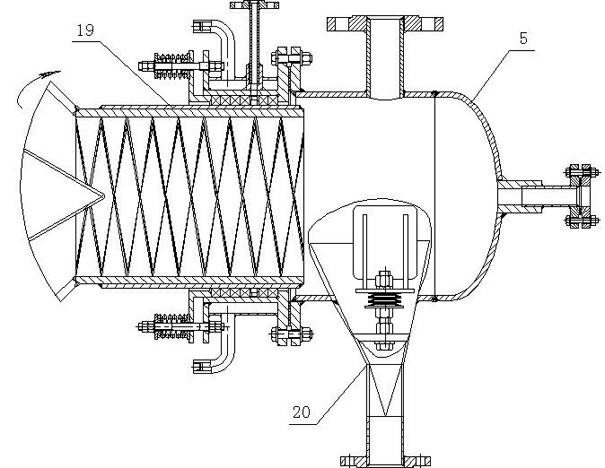

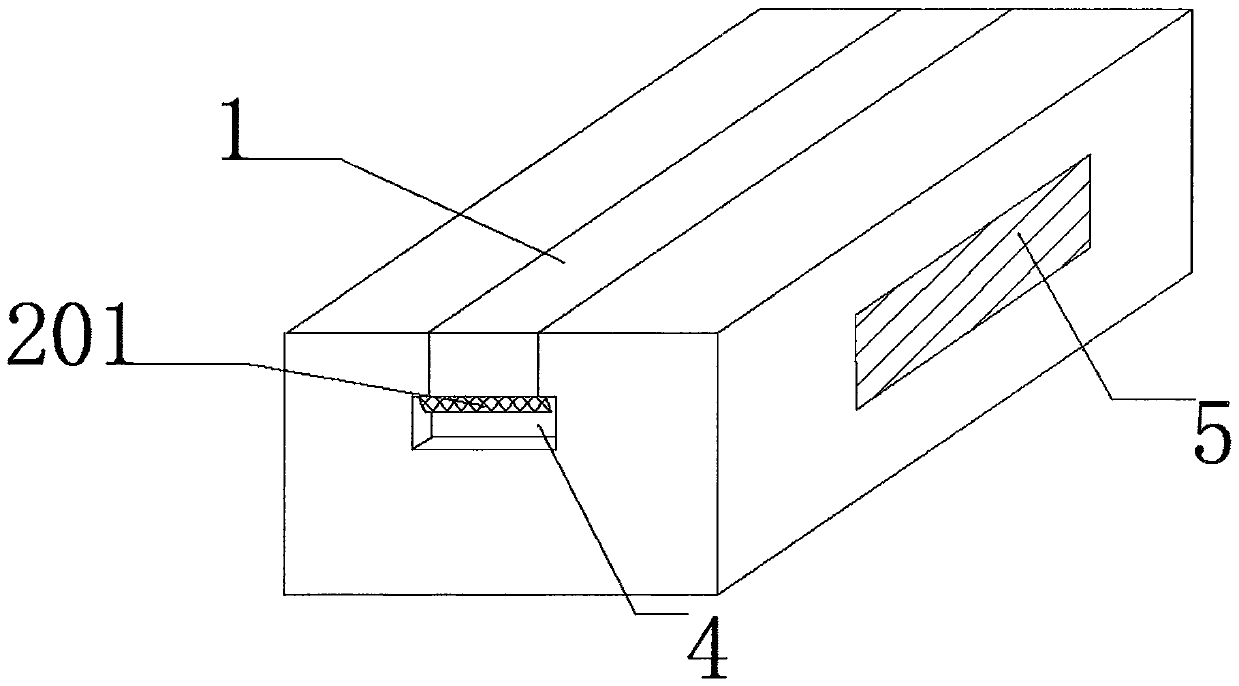

High-temperature high-pressure glass micro model gripper used for heavy oil thermal recovery

The invention discloses a high-temperature high-pressure glass micro model gripper used for heavy oil thermal recovery. The high-temperature high-pressure glass micro model gripper comprises a high-temperature high-pressure bin and high-pressure glass visual windows and further comprises a drawer type micro model support, upper pressing plates and lower pressing plates. The high-temperature high-pressure bin is a square-cylinder-shaped bin body. The upper portion and the lower portion of the inner wall of the bin body are each provided with an annular step. One high-pressure glass visual window is fixed to each annular step. The upper pressing plates and the lower pressing plates are arranged on the outsides of the high-pressure glass visual windows correspondingly. The high-temperature high-pressure bin is provided with a heater leading to an inner cavity of the bin body. The side face of the bin body is further provided with a model support inlet. The drawer type micro model support is pushed into the bin body from the model support inlet. Through the drawer type high-temperature high-pressure gripper, operation is simple, fast and convenient, and the problem of the unreliability of the leakproofness of the bin body due to repeated disassembly and assembly of the visual windows is avoided. A plurality of injection openings and control valves, bull plugs and back-pressure valves of the injection openings are adopted, so that noninterference between injection fluid is achieved, and meanwhile, the continuity of the injection fluid and pressure is ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

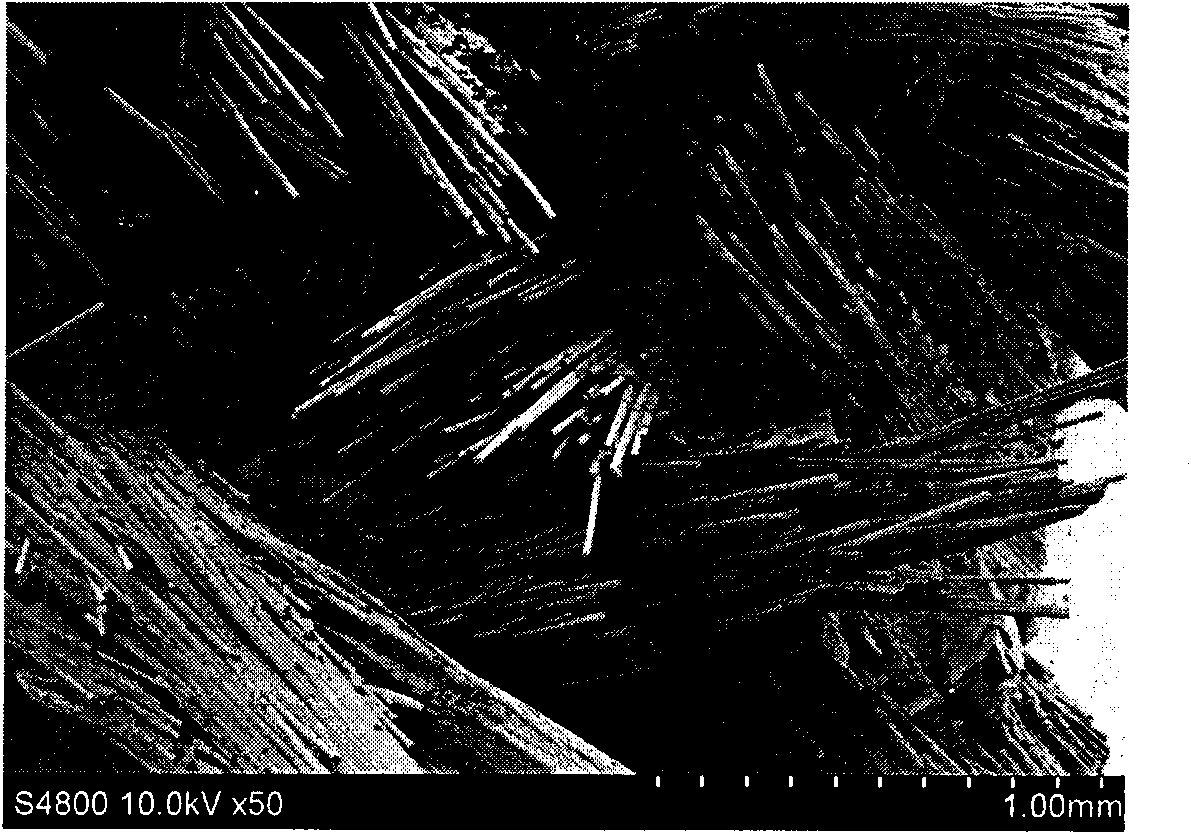

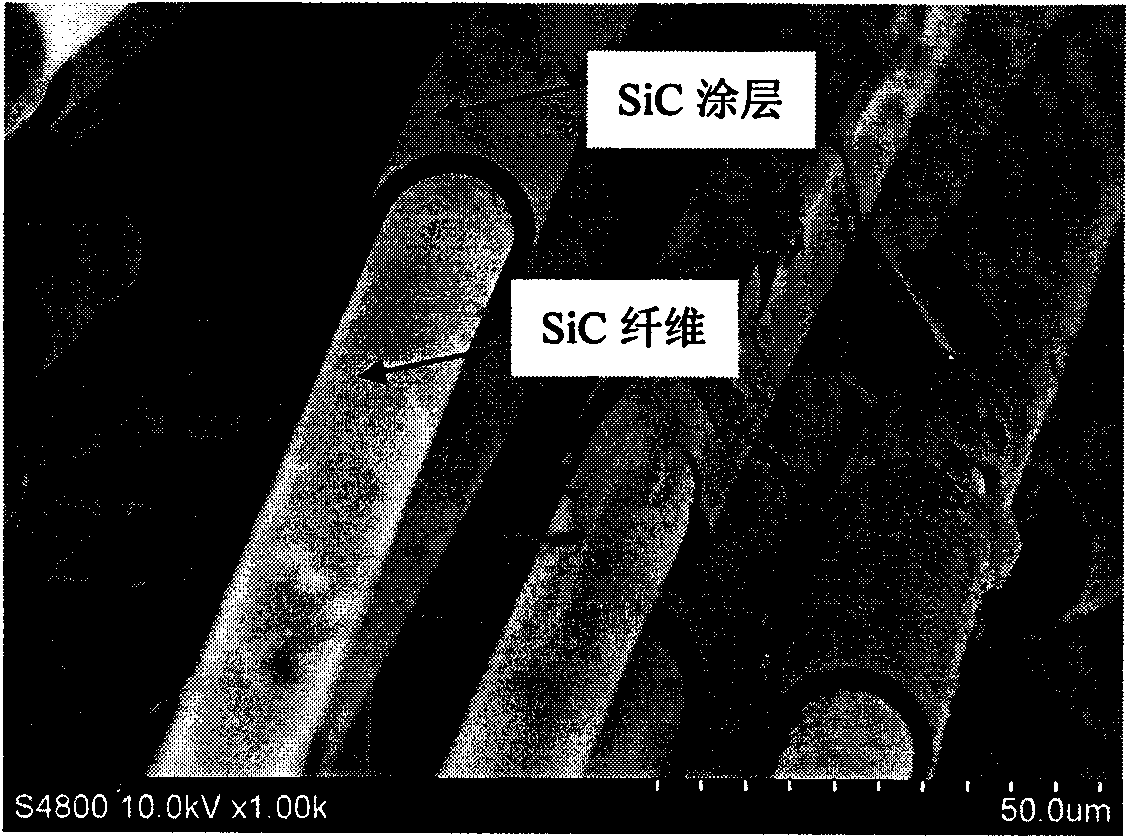

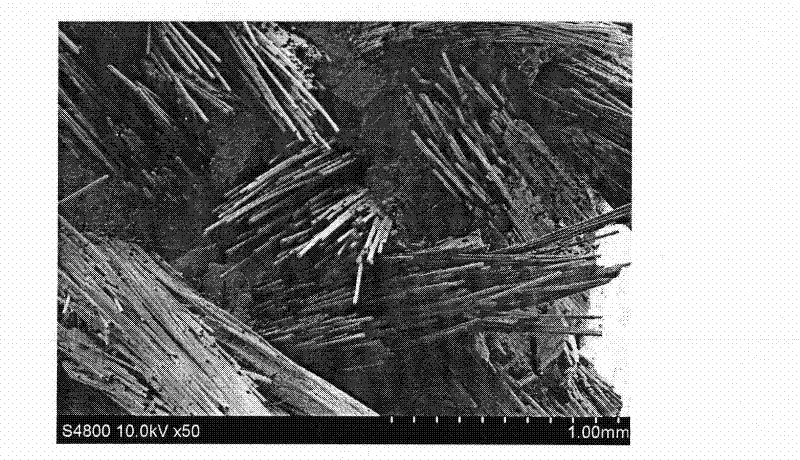

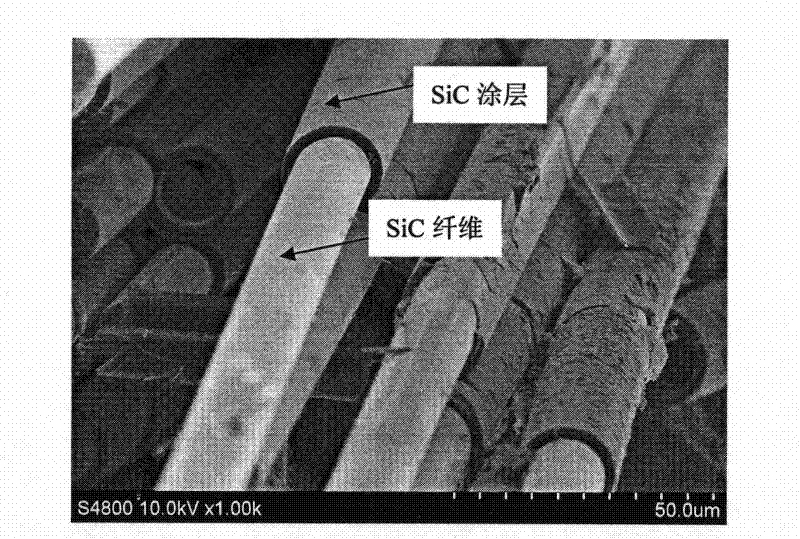

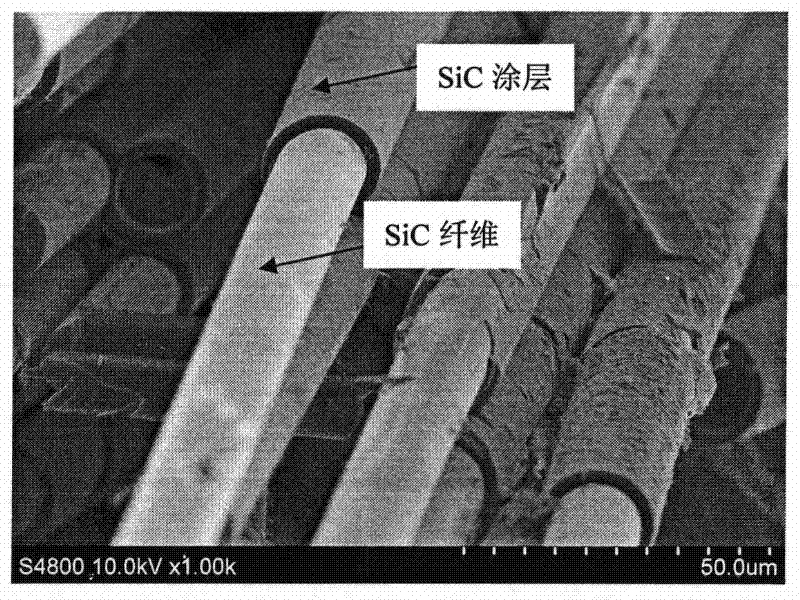

Method for preparing SiCf/SiC compound material by combination of chemical vapor carbon deposition process and gas phase siliconizing process

The invention discloses a method for preparing SiCf / SiC compound material by combination of a chemical vapor carbon deposition process and a gas phase siliconizing process, comprising the following steps: taking SiC fiber as a raw material, adopting three dimensional weaving technology to prepare SiC fibre-woven pieces; taking trichloromethyl silane as a deposition material and carrying out a primary chemical vapor deposition on the SiC fibre-woven pieces with thickness of deposited SiC coating being 0.1-70 mum; then taking methane or propylene gas as a raw material and carrying out carbon deposition on SiC fibre-woven pieces by a secondary chemical vapor deposition, thus obtaining SiCf / C midbody; finally, taking simple substance silicon as a raw material and carrying out siliconizing on the SiCf / C midbody by the gas phase siliconizing process, thus obtaining the SiCf / SiC compound material. The method of the invention has the advantages of short preparation cycle and low cost, thus being capable of preparing SiCf / SiC composite material featuring high compactness, high mechanical property and thermal conduction.

Owner:NAT UNIV OF DEFENSE TECH

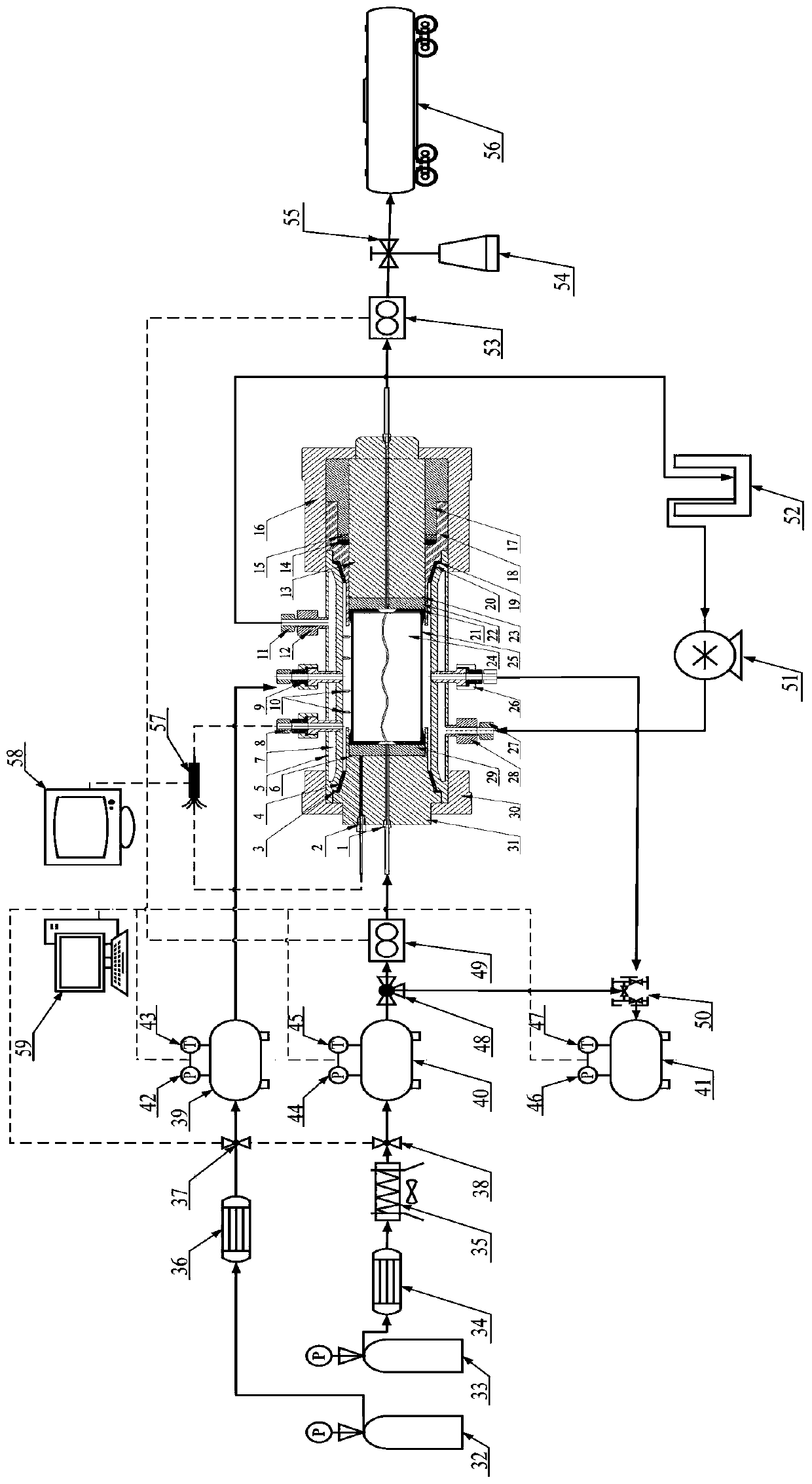

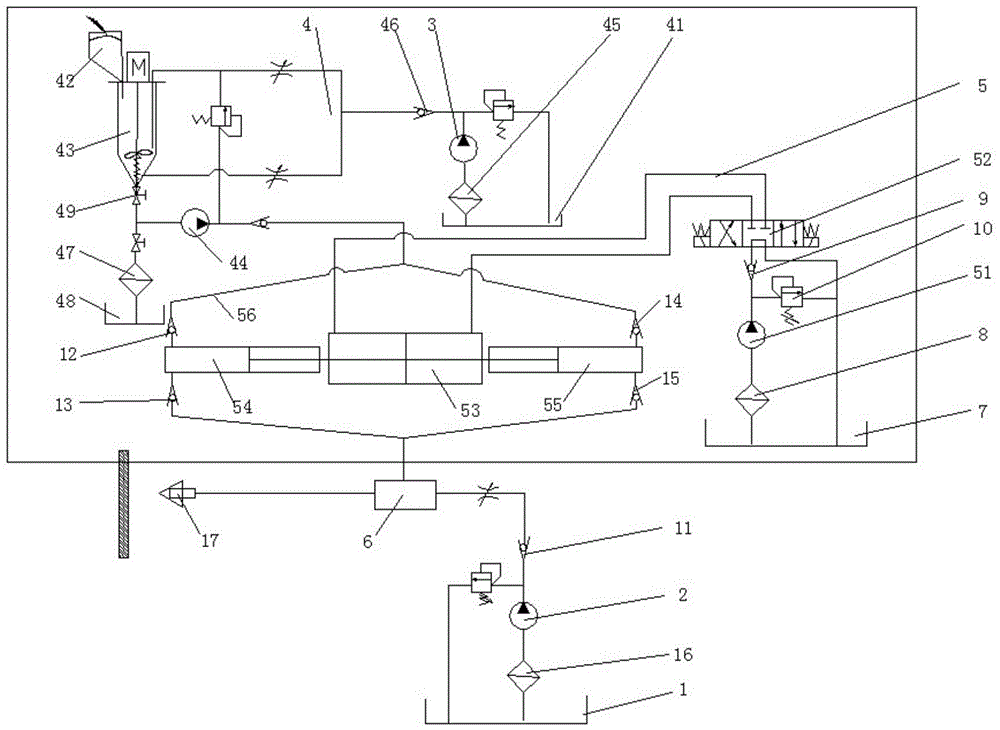

In-situ exploitation flow-heat transfer experiment device for compact oil shale

PendingCN111119877AContinuous and stable outputHigh sealing requirementsFluid removalRock coreMeasuring instrument

The invention relates to an in-situ exploitation flow-heat transfer experiment device for compact oil shale, and belongs to the technical field of experiment measuring instruments. The device comprises a flow-heat transfer core holding unit, an axial-confining pressure injection system, an axial-radial pressure stabilizing system, a temperature-strain monitoring system, a liquid cooling circulating system, a safety backflow preventing system, a flow monitoring system, a gas collection-recovery system and a control and data recording system cooperating with each other. According to the device,a thermal fluid medium with pressure is injected into a core with a fracture in the flow-heat transfer core holding unit, and axial and radial strains are observed to determine a critical temperaturepoint that the fracture in the core closes up under the condition of heat injection and critical pressure that the fracture is opened again under the pressurizing condition of the thermal fluid mediumin the later period, and thereby, closure critical parameters of the fracture during in-situ exploitation are obtained; and the permeability variation situation of the core with the rock mass fracture can be evaluated through the conditions of flow before changes and flow after changes, and thereby, reservoir fractures effectively communicate for a long term by regulating site construction parameters to facilitate heat injection and oil and gas migration in the later period.

Owner:JILIN UNIV

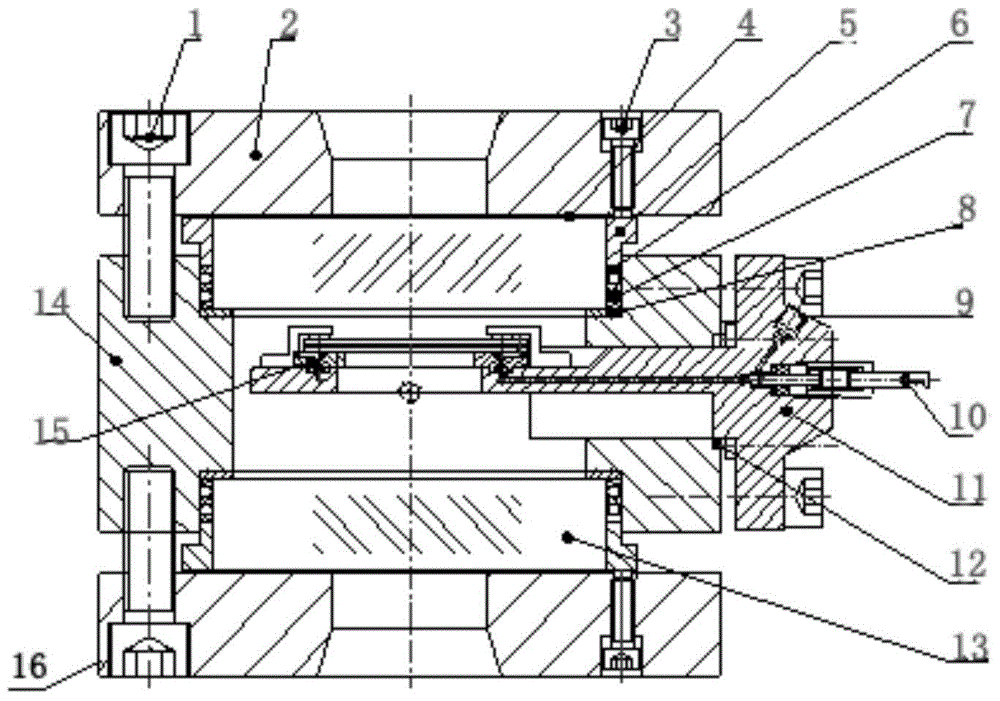

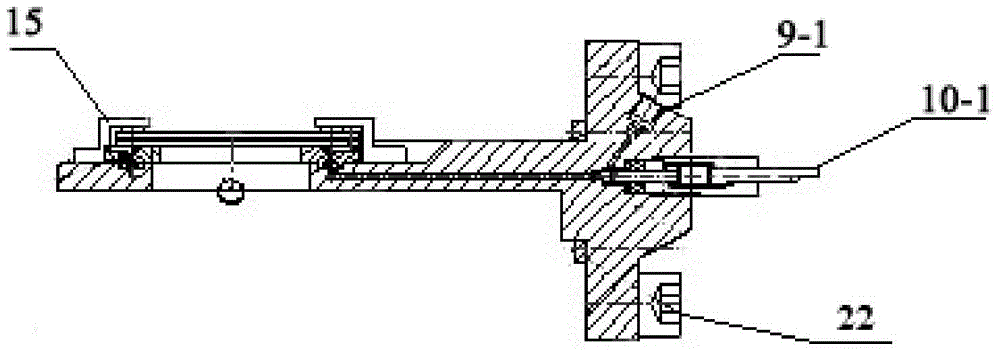

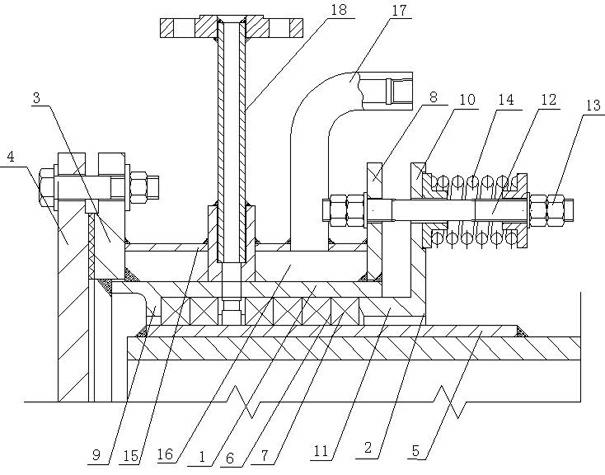

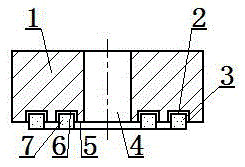

Front mixing grinding material jet-flow continuous feeding system

ActiveCN104552027AImprove work efficiency and work qualityLow priceAbrasive feedersJet flowHigh pressure

The invention discloses a front mixing grinding material jet-flow continuous feeding system. The front mixing grinding material jet-flow continuous feeding system comprises a main water tank, a high pressure pump, a low pressure pump, a continuous feeding system, and a mixing chamber, wherein one end of the main water tank is communicated with the high pressure pump; an outlet of the high pressure pump is connected with an inlet of the mixing chamber; an inlet of the low pressure pump is connected with the inlet of the mixing chamber through the continuous feeding system; the continuous feeding system comprises a feeding system and a pressurization system; the feeding system is communicated with the pressurization system; an outlet of the mixing chamber is communicated with a nozzle. The front mixing grinding material jet-flow continuous feeding system realizes the truly significant continuous feeding, overcomes the phenomena that the continuous working time is short and the grinding material is short of supply in the working process, can greatly improve the working efficiency and the work quality of the system, and facilitates industrialized popularization of the front mixing grinding material jet flow technology; secondly, the difference between the piston areas on the two sides of a piston rod can play the pressurization effect.

Owner:苏州峰启科教设备有限公司

Special sealing device for cylinder body of high-temperature rotary kiln

The invention discloses a special sealing device for a cylinder body of a high-temperature rotary kiln. The special sealing device comprises a first gland fixedly connected with a discharging box, a second gland connected with one end of the first gland far away from the discharging box, and sealing fillers, wherein the sealing fillers are filled in a sealed space between the inner wall of the first gland and the cylinder body of the rotary kiln and are clamped by the first gland and the second gland; one end of the first gland close to the second gland is provided with a first flange extending outwards; one end of the first gland close to the discharging box is provided with a first protrusion part extending inwards; the second gland is provided with a second flange extending outwards and a second protrusion part extending to the sealed space; and the first flange and the second flange are connected through a filler clamping mechanism, and when the filler clamping mechanism is screwed down, the second gland can move axially along the surface of the cylinder body of the rotary kiln. The special sealing device disclosed by the invention has the advantages of being good in sealing effect, reducing the temperature on a sealed surface, and prolonging the replacement cycle of the fillers, and the sealing fillers are easy to maintain.

Owner:NANJING TIANHUA CHEM ENG

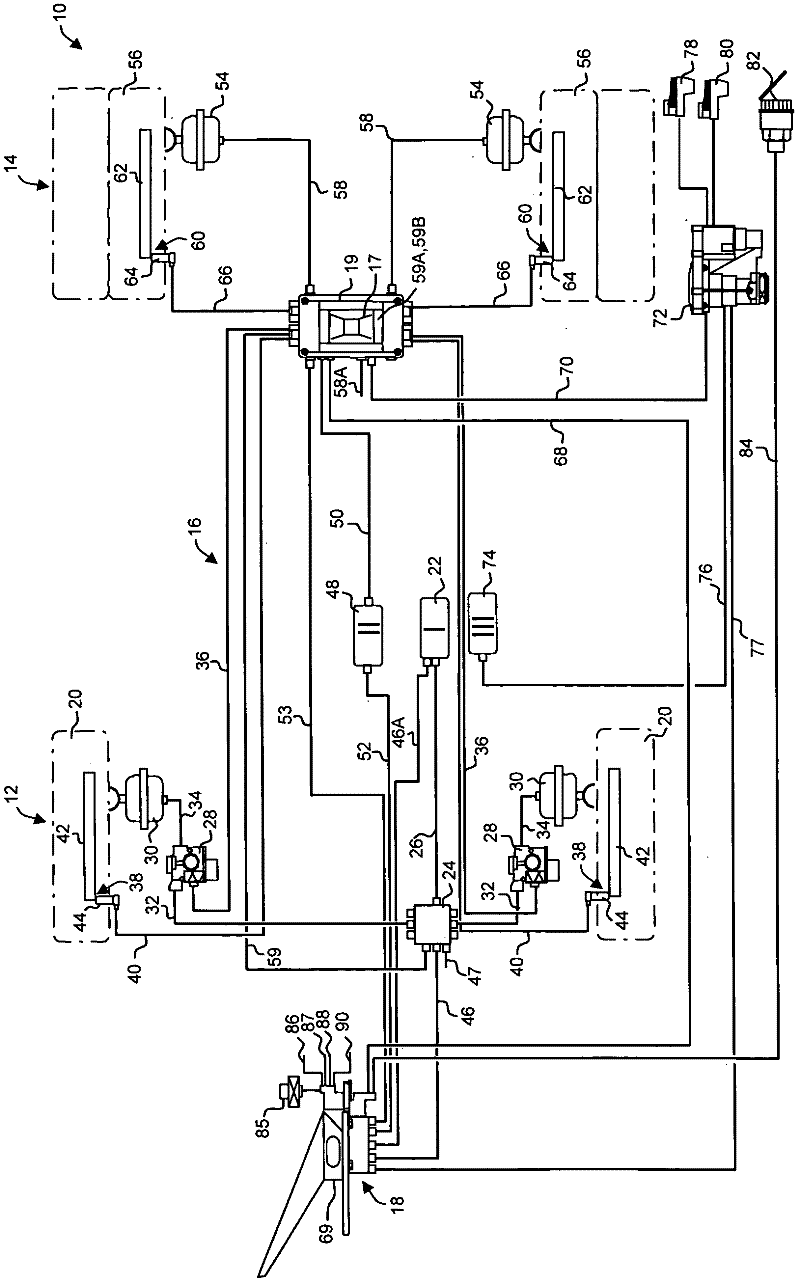

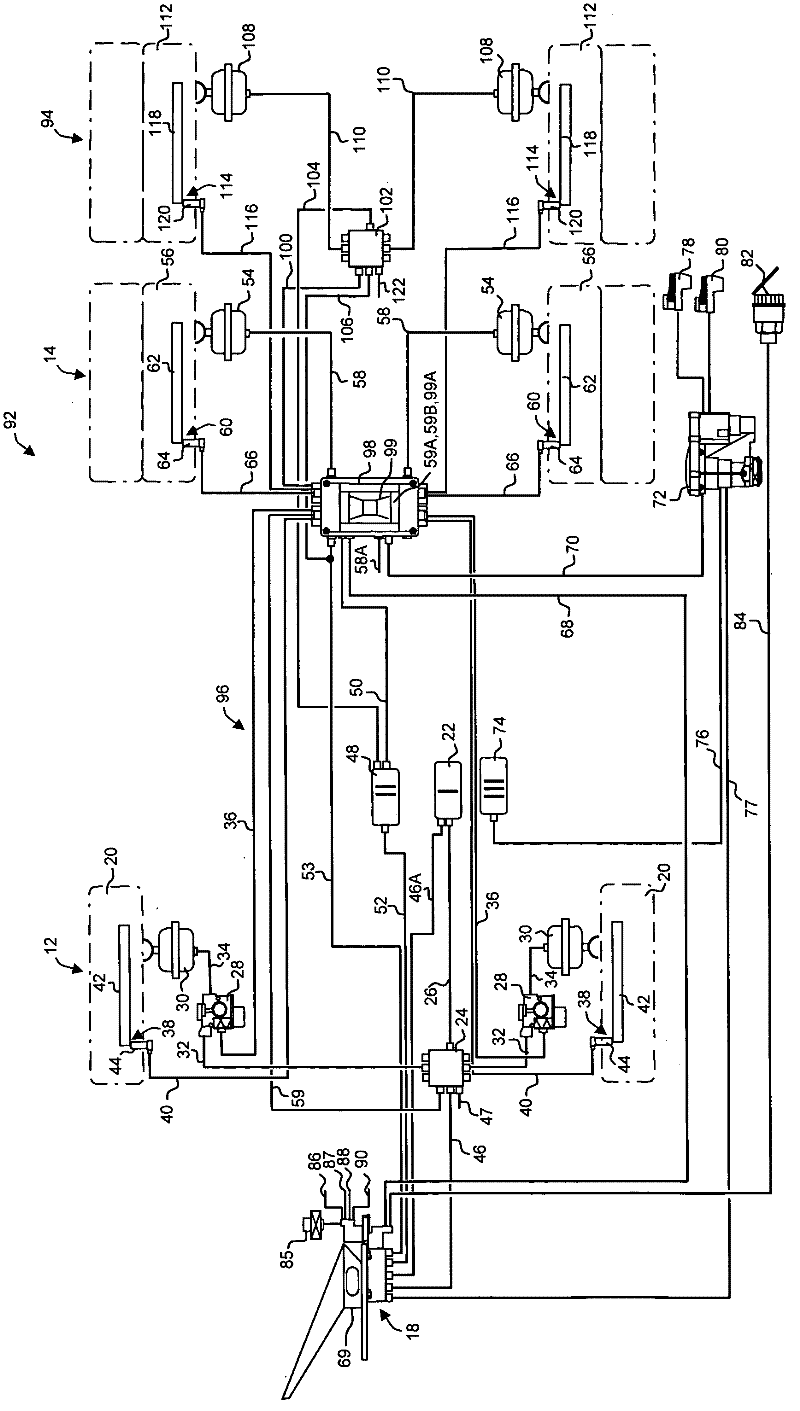

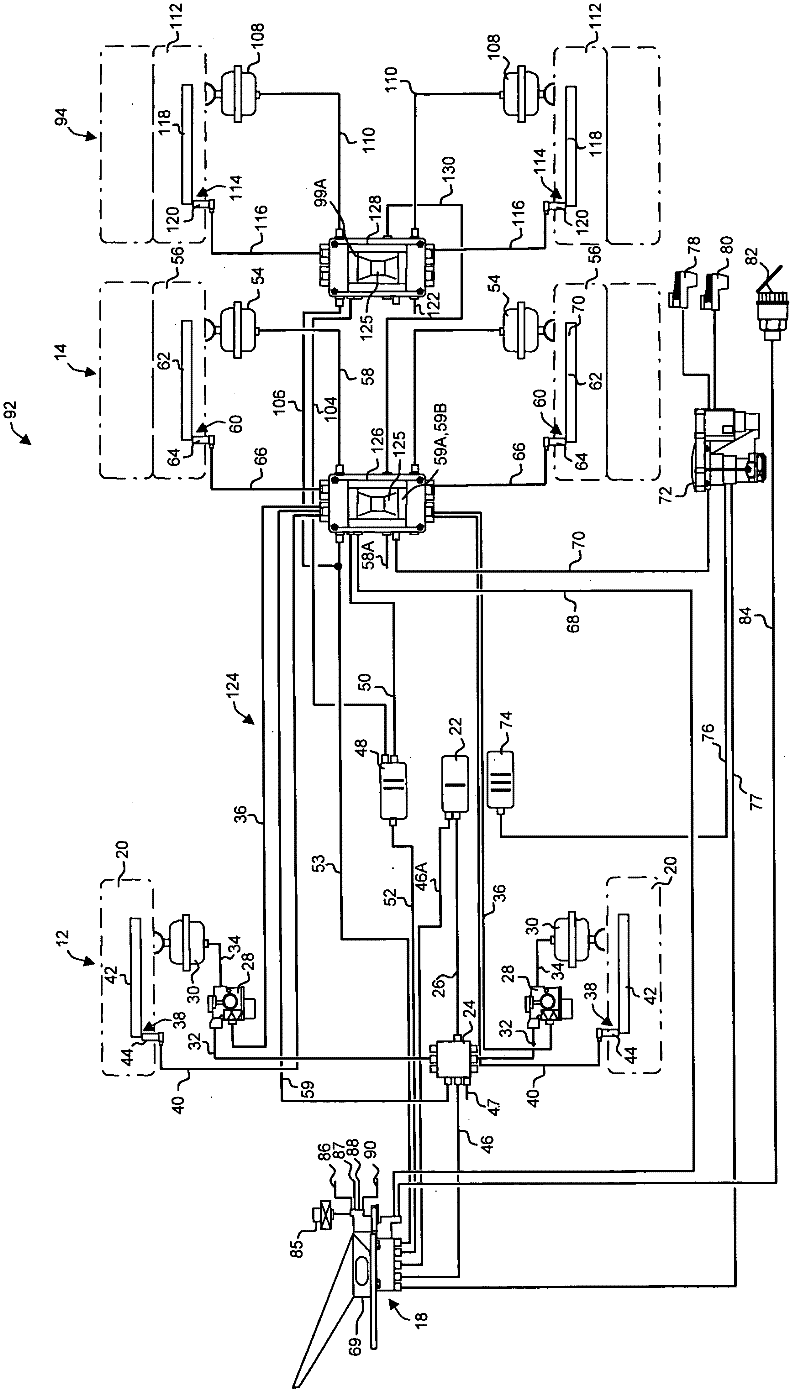

Control device for the brake system of a vehicle

ActiveCN102470848AReduce in quantityImprove sealingBraking action transmissionAntenna adaptation in movable bodiesAir springBraking system

The invention relates to a control device for a brake system of a vehicle (10; 92; 132; 238), said vehicle (10; 92; 132; 238) having a supporting structure (222; 240) and a cabin (224; 242) that is supported by the supporting structure (222; 240) and has at least one driver's seat (226). The control device is located outside the cabin (224; 242) on the supporting structure (222; 240) and the control device has additional functionality for controlling an electronic air spring system.

Owner:ZF CV SYST EURO BV

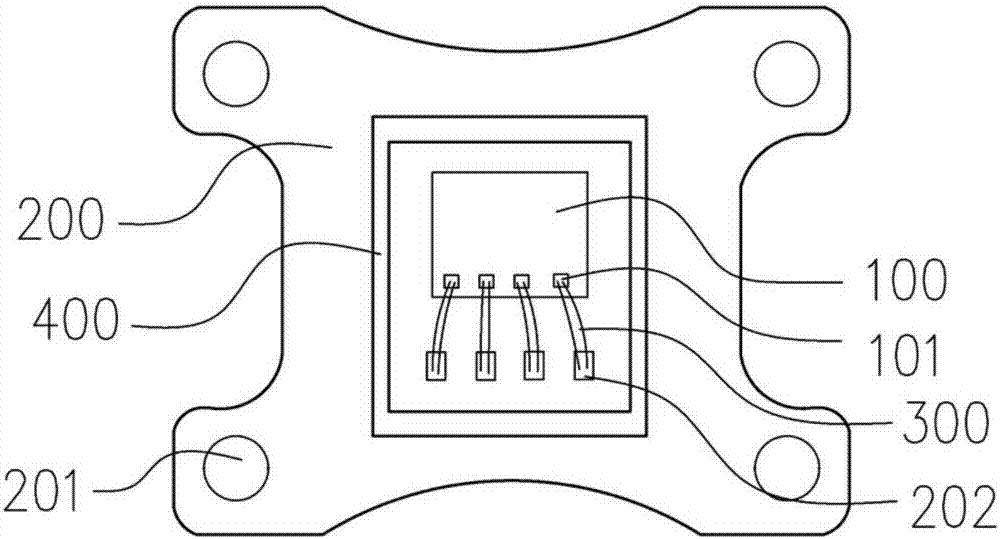

Pressure transducer and preparation method thereof

InactiveCN106946213AAchieve Oxidation ProtectionAvoid pollutionDecorative surface effectsFluid pressure measurementTransducerEngineering

The invention discloses a pressure transducer and a preparation method thereof. The pressure transducer comprises a circuit board, a chip, a shell and a gel. The side of the circuit board is provided with an inward concave curved sides and a circuit board bonding pad and a location hole. The chip is arranged on the lower part of the circuit board. The shell is provided with a first mounting groove, and the chip is arranged in a second mounting groove which is arranged in the bottom of the first mounting groove. An air hole is arranged in the bottom of the second mounting groove. The circuit board is arranged in the first mounting groove; steps are arranged around the notch of the second mounting groove; a groove is arranged on the periphery of the steps and is filled with silica gel. A registration mast is adapted with the location hole of the circuit board. A contact pin bonding pad is arranged at the shell. The contact pin bonding pad is bonded with the circuit board through aluminium wire bonding wire. The first mounting groove is filled with the gel. The transducer has the advantages of good anti-corrosive properties, good long term stability and high overload capability.

Owner:芜湖恒铭电子科技有限公司

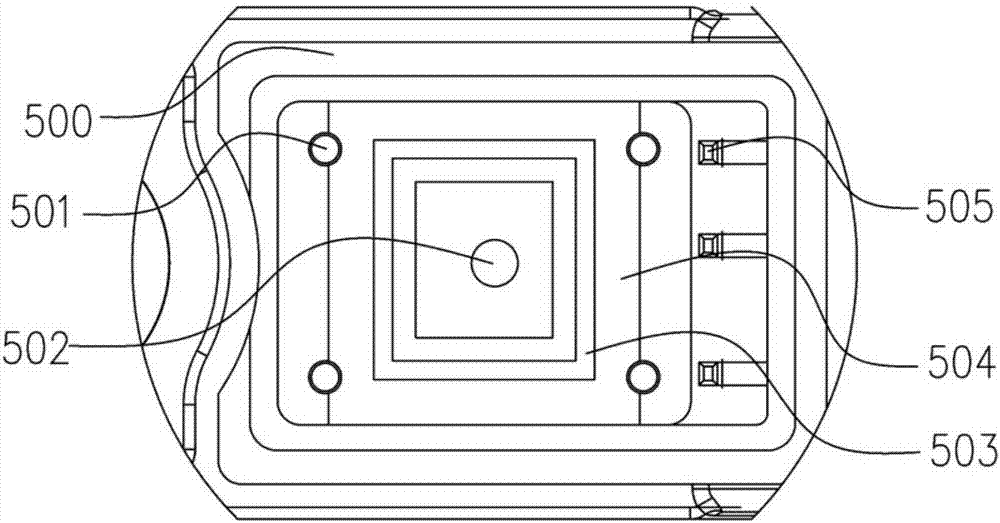

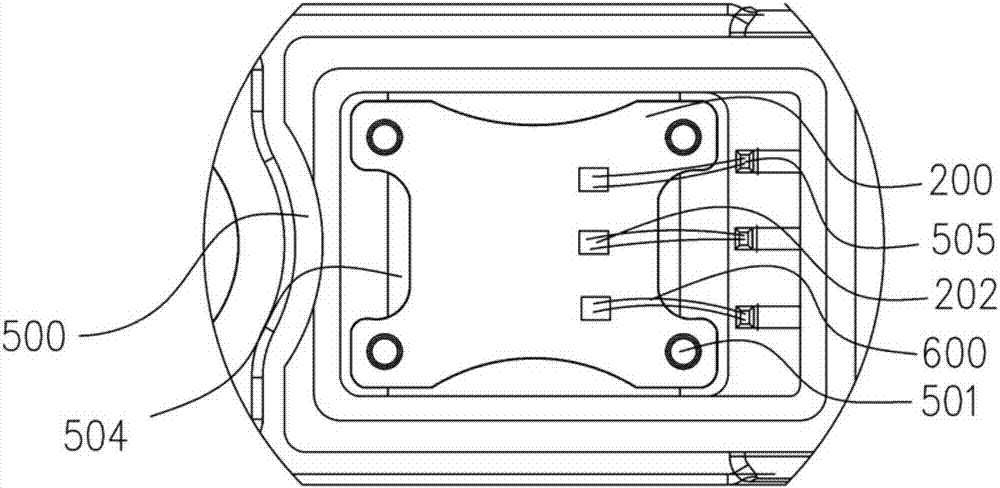

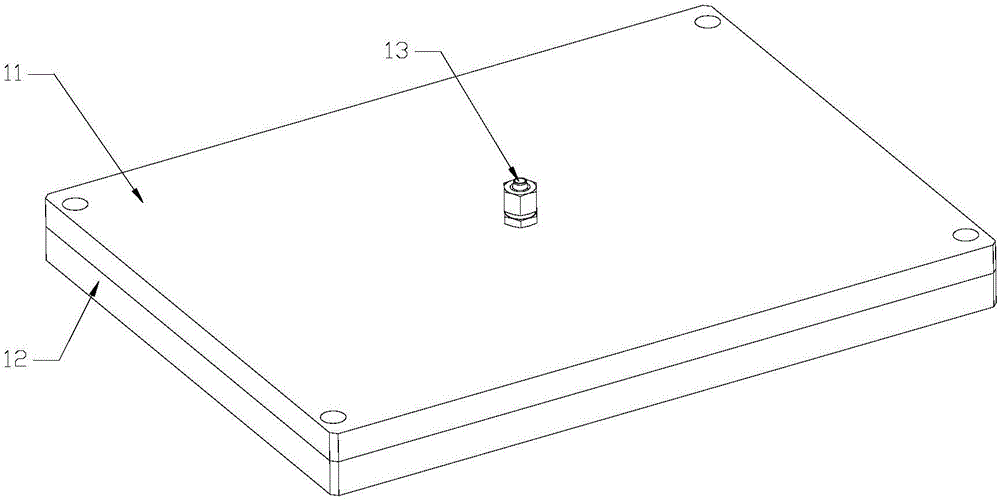

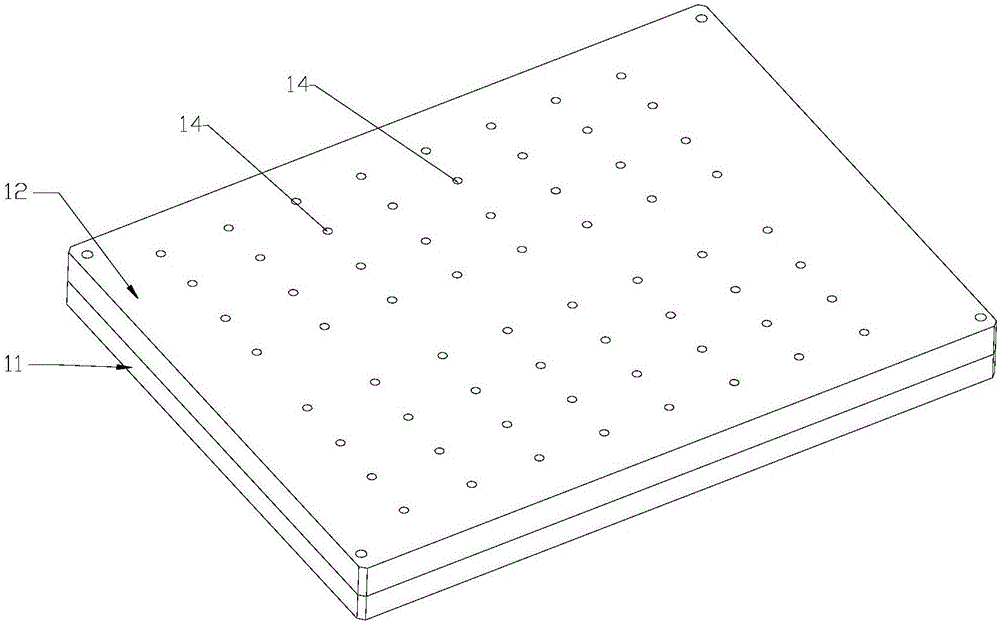

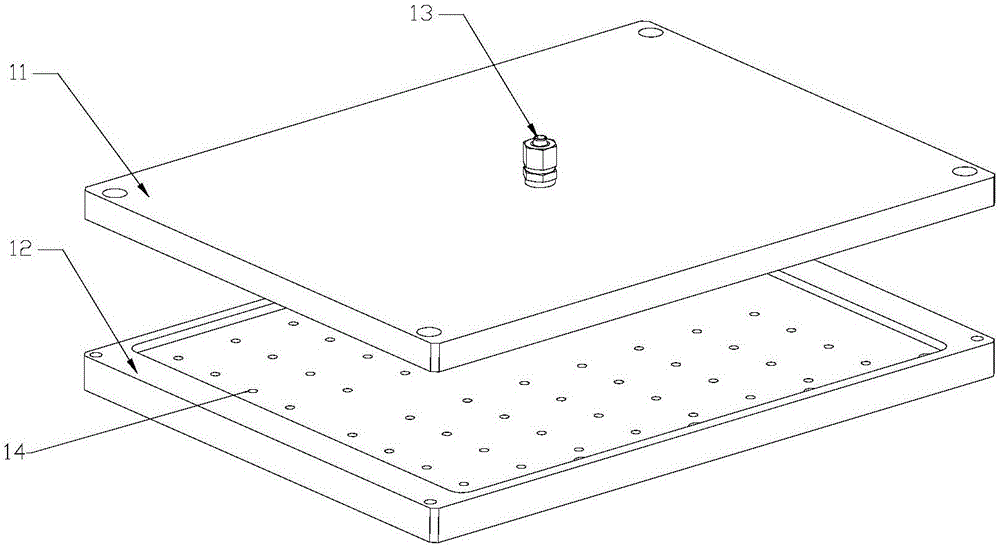

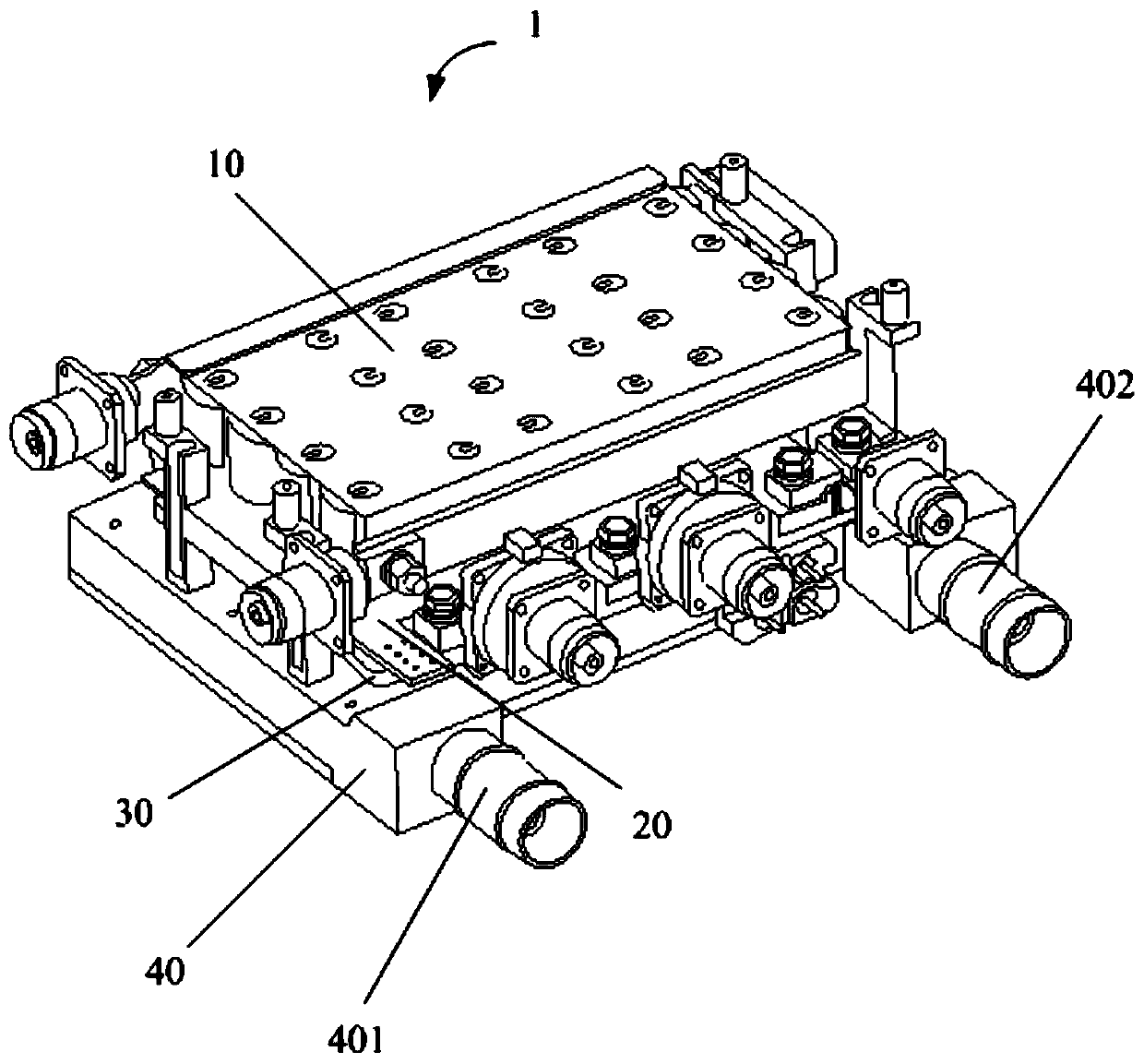

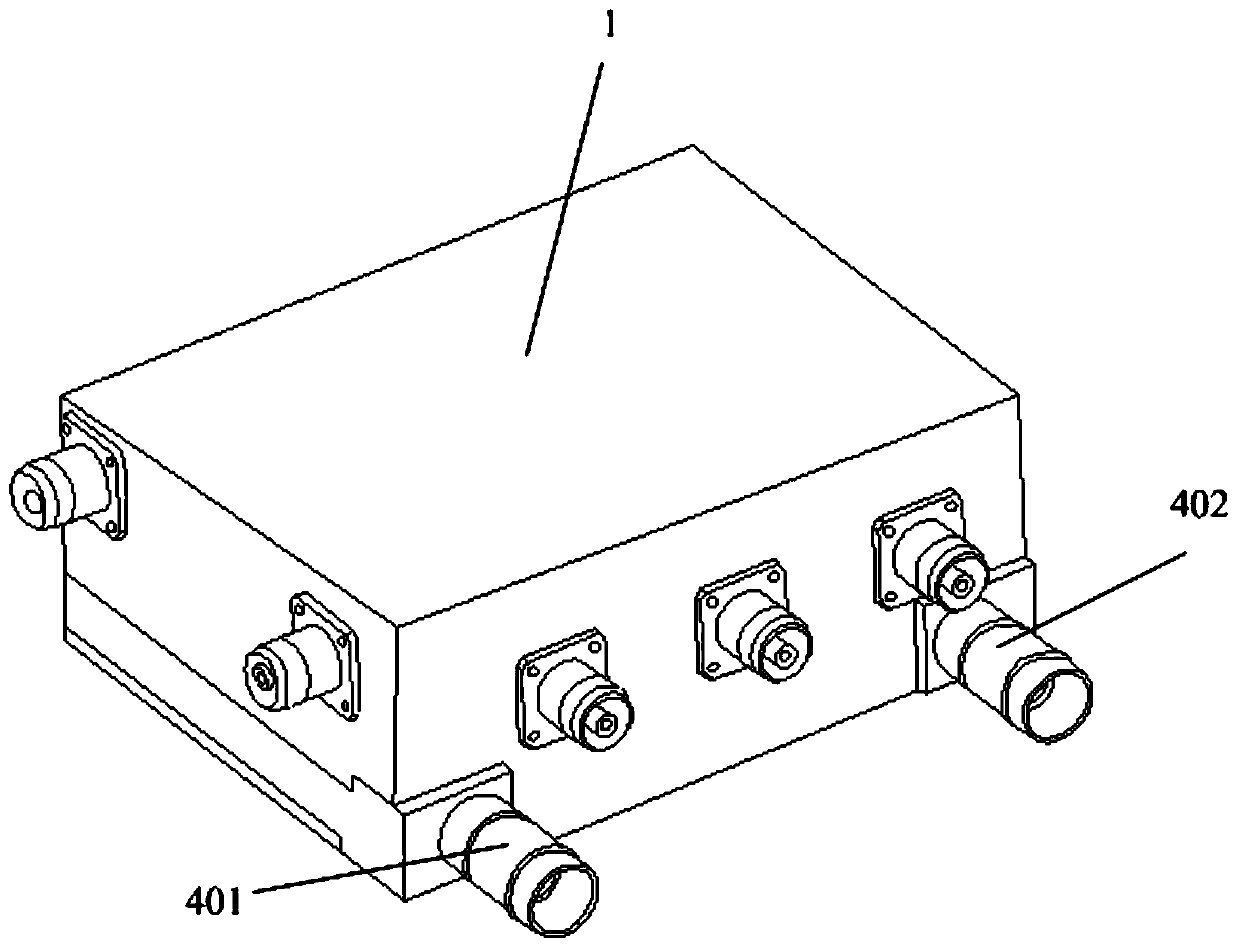

Gas sensor testing device and testing method

ActiveCN106645572AHigh sealing requirementsReduce test efficiencyGas analyser construction detailsWhole bodyProcess engineering

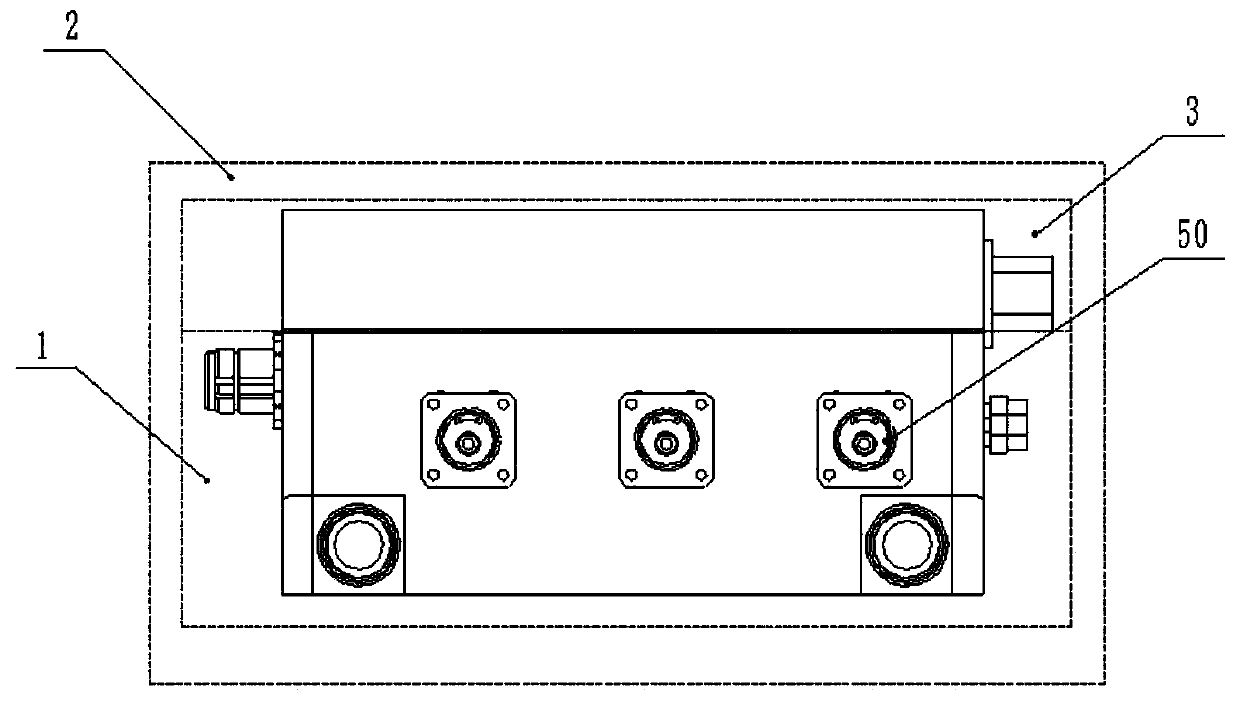

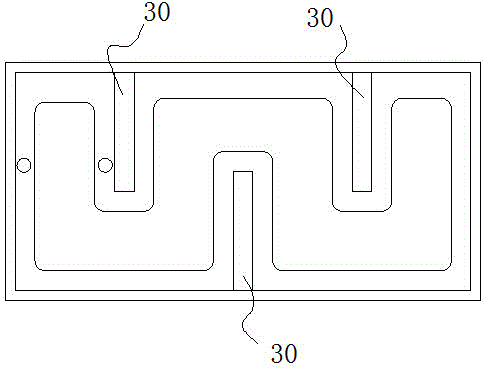

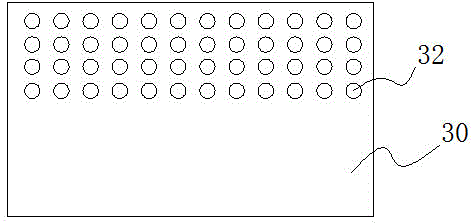

The invention discloses a gas sensor testing device and a testing method. The testing device comprises a gas distributing device, a gas supply device and a signal collection device, wherein the gas distributing device is used for distributing and providing gas for testing; the gas supply device is used for distributing tested gas and comprises a gas inlet plate and a gas outlet plate; the gas inlet plate and the gas outlet plate are connected into a whole body in a sealed way, so that a cavity is formed in the interior between the gas inlet plate and the gas outlet plate; the gas inlet plate is provided with a gas inlet used for being communicated with the cavity and the air distributing device; the gas outlet plate is provided with a plurality of gas outlets used for being communicated the cavity and an inlet of a gas sensor; the signal collection device is used for collecting inductive signals of the gas sensor. The testing device can realize rapid testing and batch detecting of the gas sensor, and saves the gas for testing.

Owner:WEIFANG GOERTEK MICROELECTRONICS CO LTD

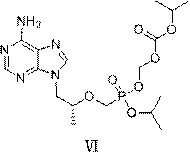

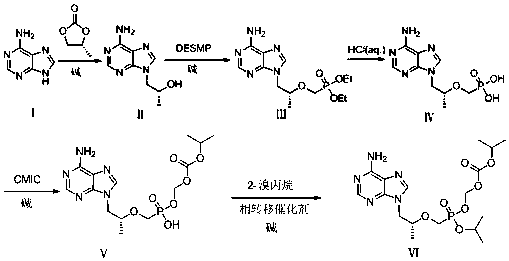

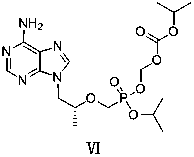

Tenofovir disoproxil fumarate analog preparation method

ActiveCN109384813AHigh purityThe synthesis process is simpleGroup 5/15 element organic compoundsPropylene carbonateSubstitution reaction

The present invention discloses a tenofovir disoproxil fumarate analog preparation method, which comprises: carrying out a substitution reaction on adenine as a raw material and (R)-propylene carbonate in the presence of an alkali, carrying out a substitution reaction with (diethoxyphosphoryl)methyl-4-methylbenzenesulfonate, hydrolyzing with a concentrated hydrochloric acid solution, crystallizingto obtain anhydrous tenofovir, carrying out a reaction on the anhydrous tenofovir and chloromethyl isopropyl carbonate to obtain tenofovir monoester, and carrying out a reaction with 2-bromopropane to obtain the target compound. According to the present invention, the selected starting raw materials are inexpensive and easy to obtain, the process is simple, and the material utilization rate and total yield are improved; and the intermediate of the method is purified by re-crystallization, such that the yield is high, and the purity is high.

Owner:GUANGZHOU BAIYUNSHAN PHARMA HLDG CO LTD BAIYUNSHAN PHARMA GENERAL FACTORY

Power module of SIC electric automobile

PendingCN110034664AReduce installation clearancePart insulation gap is smallSpeed controllerElectric devicesMOSFETBusbar

The invention provides a power module of a SIC electric automobile. The power module comprises a SIC MOSFET device, a radiator, a low-inductance busbar, a capacitor core group, a driver, a sensor anda hydroelectric terminal; the power module is sequentially provided with the radiator, the SIC MOSFET device, the driver and the capacitor core group from bottom to top; the capacitor core group is electrically connected with the SIC MOSFET device and is arranged above the SIC MOSFET device; the driver is installed and fixed on an auxiliary terminal of the SIC MOSFET device through welding; and each component of the power module is formed by integrally packaging and filling through an epoxy resin three-layer filling and sealing technology, and a metal shell is not needed. According to the power module, a motor control unit (MCU) is detached and separated, and the motor control unit and the power module can be installed together to serve as a complete automobile controller according to therequirements of a vehicle factory in an application, and the function of the motor control unit can be integrated into a vehicle control unit (VCU) by the vehicle factory and the power module is onlyused as an execution part for use by the vehicle factory.

Owner:SHENZHEN HOVERBIRD ELECTRONICS TECH CO LTD

Pre-mixed abrasive jet continuous feeding system

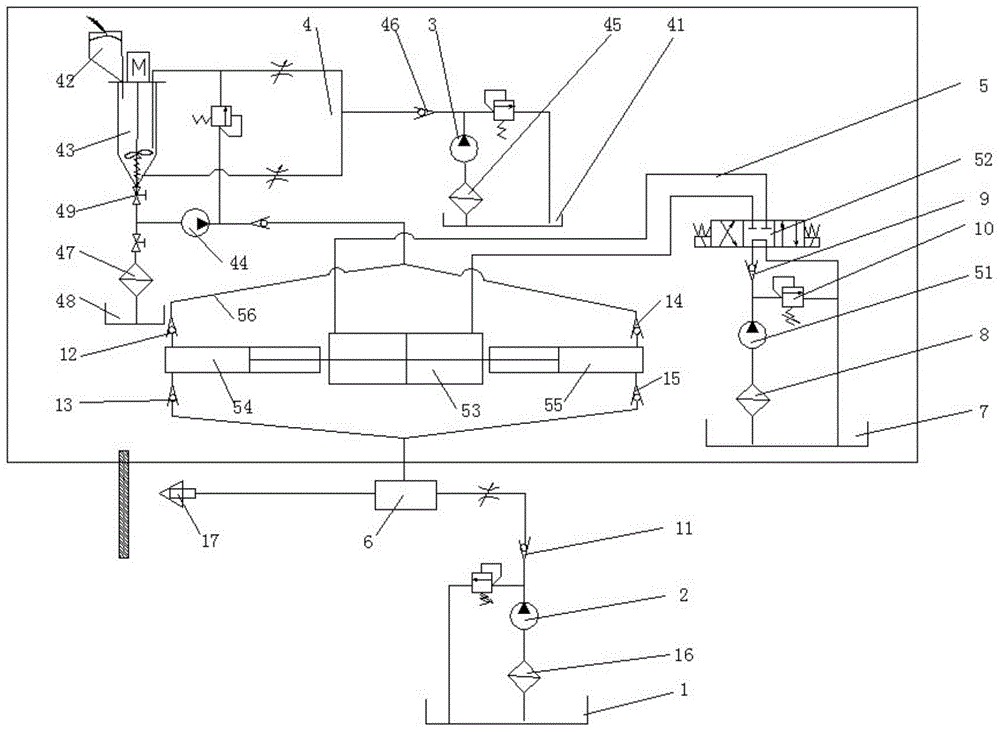

ActiveCN104552027BOvercoming abrasive outagesImprove work efficiencyAbrasive feedersJet flowSpray nozzle

The invention discloses a front mixing grinding material jet-flow continuous feeding system. The front mixing grinding material jet-flow continuous feeding system comprises a main water tank, a high pressure pump, a low pressure pump, a continuous feeding system, and a mixing chamber, wherein one end of the main water tank is communicated with the high pressure pump; an outlet of the high pressure pump is connected with an inlet of the mixing chamber; an inlet of the low pressure pump is connected with the inlet of the mixing chamber through the continuous feeding system; the continuous feeding system comprises a feeding system and a pressurization system; the feeding system is communicated with the pressurization system; an outlet of the mixing chamber is communicated with a nozzle. The front mixing grinding material jet-flow continuous feeding system realizes the truly significant continuous feeding, overcomes the phenomena that the continuous working time is short and the grinding material is short of supply in the working process, can greatly improve the working efficiency and the work quality of the system, and facilitates industrialized popularization of the front mixing grinding material jet flow technology; secondly, the difference between the piston areas on the two sides of a piston rod can play the pressurization effect.

Owner:苏州峰启科教设备有限公司

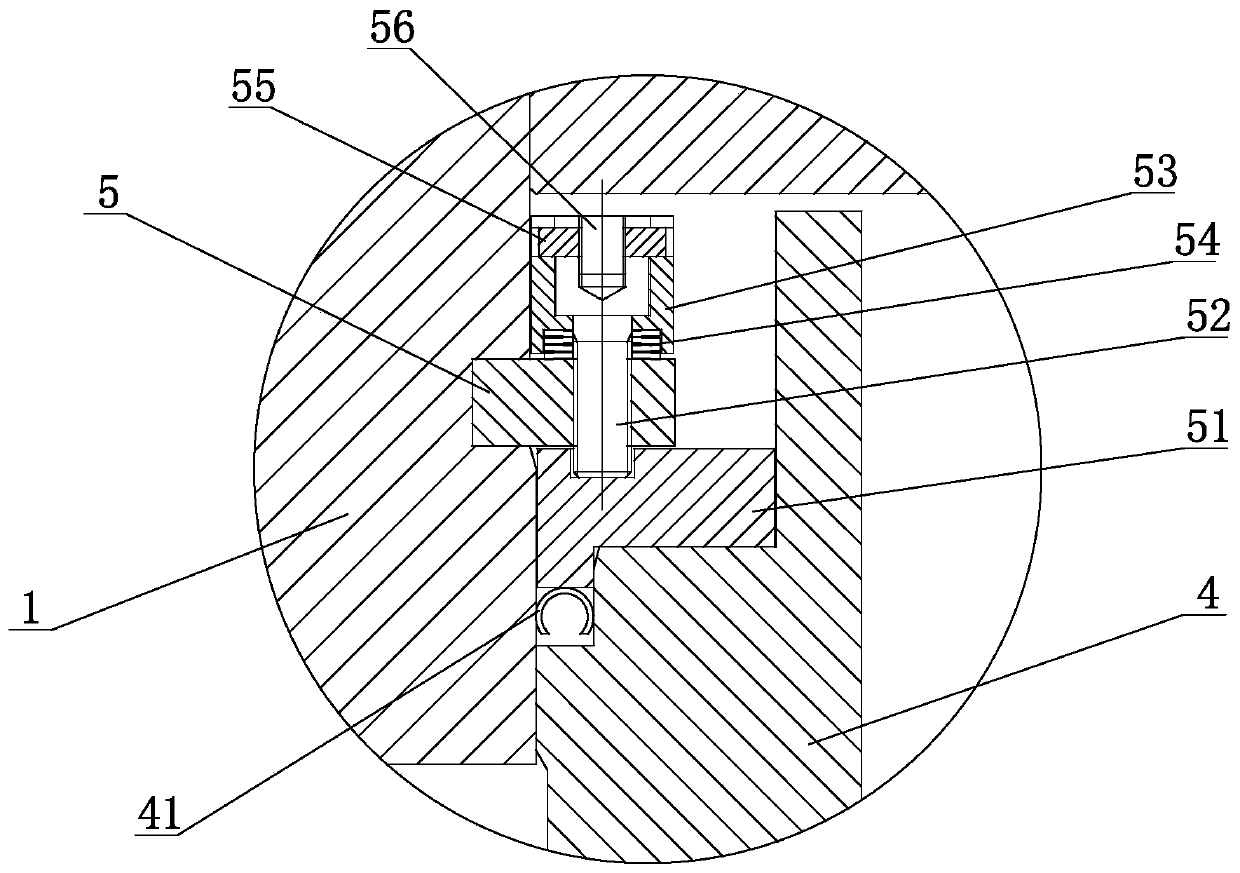

Large-caliber ultrahigh-pressure differential steam emptying valve

PendingCN110345264AEasy and efficient maintenanceOvercome prone to surgeSpindle sealingsValve members for absorbing fluid energyUltra high pressureSplit ring

The invention relates to a large-caliber ultrahigh-pressure differential steam emptying valve. The large-caliber ultrahigh-pressure differential steam emptying valve comprises a valve body, wherein aself-sealing valve seat is arranged in the valve body, a maze sleeve and a pressing ring are sequentially connected to the self-sealing valve seat, and the pressing ring, the maze sleeve and the self-sealing valve seat are pressed in the valve body through a pressing four-split ring; the upper end of the valve body is connected to a valve cover pressing plate, a self-sealing valve cover is arranged in the valve cover pressing plate in a penetrating mode, the sealing end of the self-sealing valve cover is connected to the valve cover pressing plate through a valve cover adjusting bolt and a valve cover nut, and a valve cover self-sealing ring is arranged between the sealing end and the valve body; and a valve cover four-split ring which is located on the upper side of the sealing end of theself-sealing valve cover is arranged in the valve body, a stepped valve element is arranged in the pressing ring, the maze sleeve and the self-sealing valve seat, a valve element sealing mechanism isarranged on the outer side of the stepped valve element, the upper end of the stepped valve element is connected to a valve rod, the valve rod penetrates through the self-sealing valve cover to extend to the outside, and the valve rod and the self-sealing valve cover are sealed through a valve rod sealing mechanism. According to the large-caliber ultrahigh-pressure differential steam emptying valve, the valve seat is detachable, mounting and maintaining are convenient, operation is stable, and sealing is firm.

Owner:WUXI YADI FLUID CONTROL TECH CO LTD +1

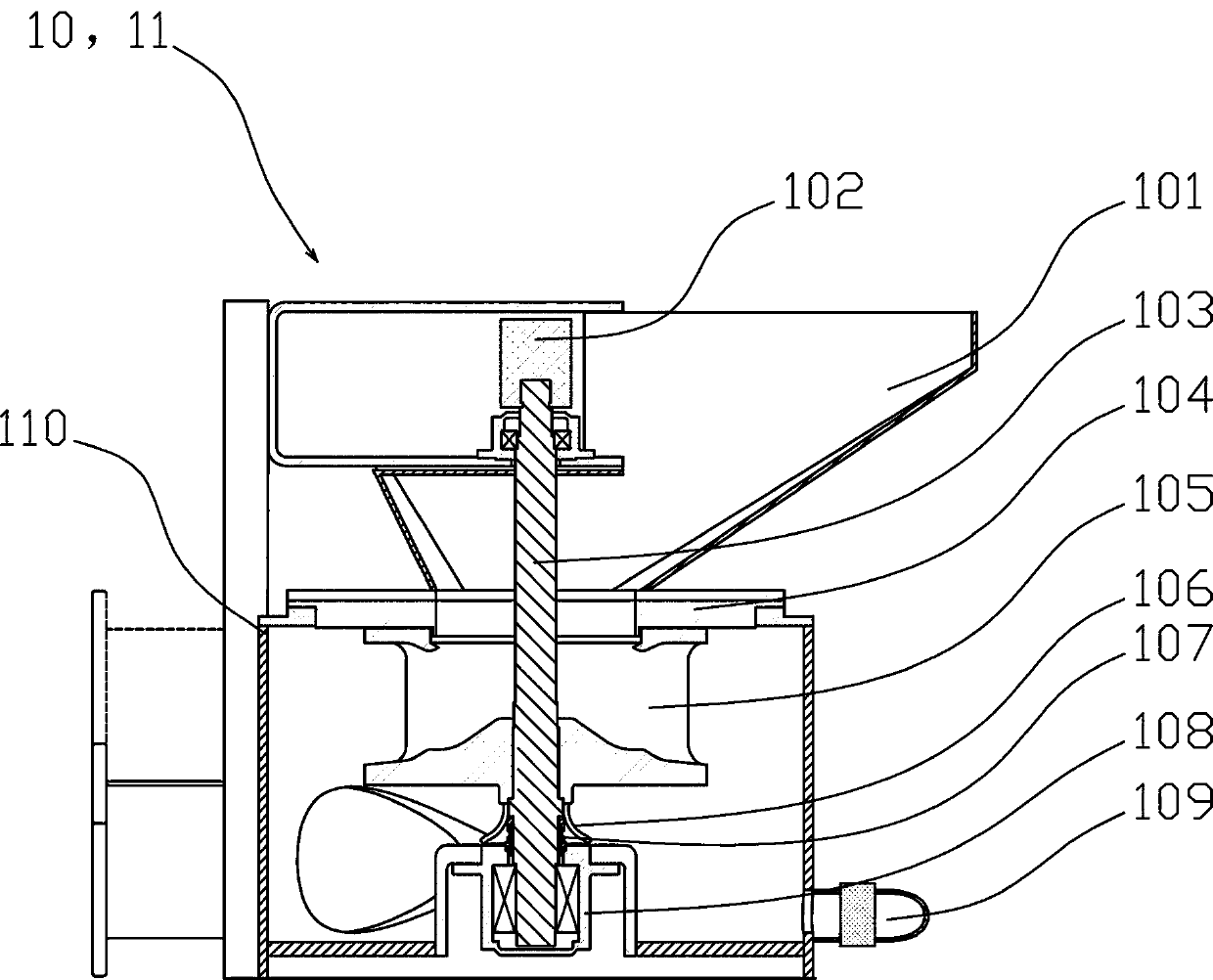

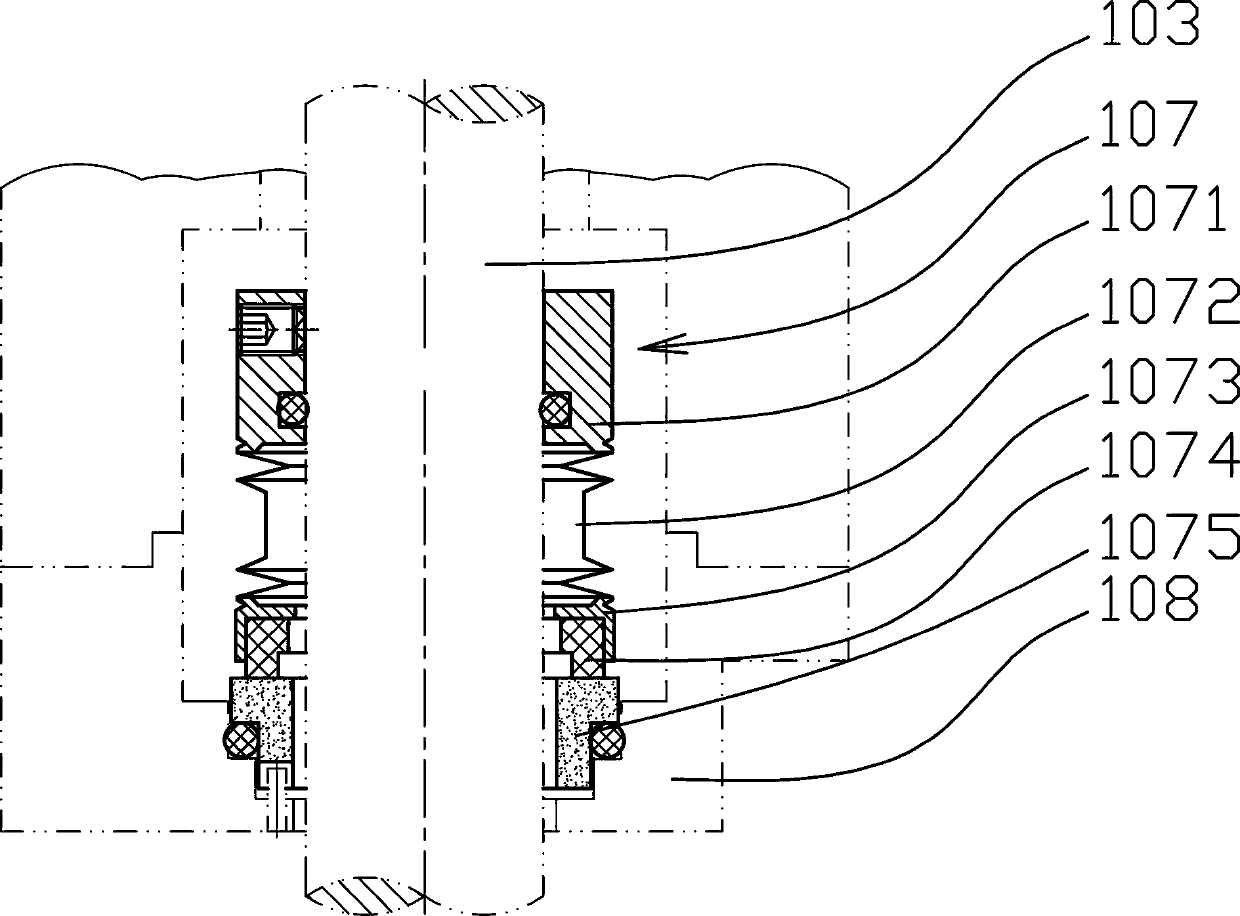

Sand conveying and mixed discharging system and control method

ActiveCN111005710AStable output pressureRelieve pressureTransportation and packagingFluid removalImpellerStructural engineering

The invention provides a sand conveying and mixed discharging system and a control method. The sand conveying and mixed discharging system comprises a mixed discharging device, the structure of the mixed discharging device is characterized in that a feeding hopper is arranged at the top of a tank body, a main shaft is vertically arranged in the tank body by penetrating the feeding hopper, the mainshaft is connected with a driving device driving the main shaft to rotate, a booster impeller is arranged below the feeding hopper, the booster impeller is fixedly connected with the main shaft and rotates along with the main shaft, a top opening is formed in the middle of the top of the booster impeller, the bottom of the feeding hopper communicates with the top opening, a side wall opening is formed in the side wall of the booster impeller, the top opening communicates with the side wall opening, a bearing seat is arranged at the bottom of the main shaft, and a sealing device is arranged between the main shaft and the end part of the bearing seat. According to the system, through the arrangement of the structure of the booster impeller, the centrifugal force can be utilized to maintainthe pressure in the tank body, so that an additional pressurized feed tank is not arranged, the equipment structure is greatly simplified, the installation space of the equipment is reduced, and the equipment volume is reduced.

Owner:中石化四机石油机械有限公司 +2

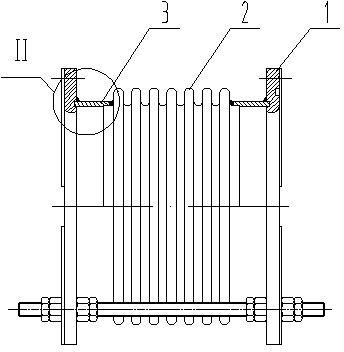

Corrugated expansion joint

InactiveCN104251361AReduce weld penetration defectsImprove welding reliabilityPipeline expansion-compensationEngineeringSilica gel

The invention discloses a corrugated expansion joint, which comprises flanges and a corrugated pipe; each flange is connected with the corrugated pipe through a connecting pipe; each connecting pipe is hermetically connected with the end face of the corresponding flange. The further improvement is that a groove is formed in the end face of each flange; each connecting pipe is embedded into the corresponding groove; a rabbet is formed in the connecting end hole of each connecting pipe and the corrugated pipe; the corrugated pipe is hermetically connected with the interiors of the rabbets; silica gel fills an axial gap between the end part of each connecting pipe and the corrugated pipe. According to the corrugated expansion joint disclosed by the invention, the welding reliability is obviously improved, the sealing effect is effectively ensured, and the service life is obviously prolonged.

Owner:TAIZHOU LISHAN MACHINERY

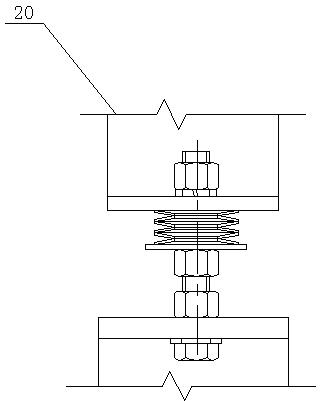

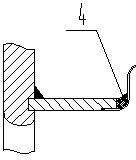

Hexagonal nut with seal rings

InactiveCN105605072APrevent misalignment and deformationInhibit sheddingWashersNutsSoft magnetArchitectural engineering

The invention discloses a hexagonal nut with seal rings. A nut end face outside a screw hole is provided with an inner circular groove and an outer circular groove, the inner circular groove and the outer circular groove are axially identical, an inner seal ring and an outer seal ring are arranged in the inner circular groove and the outer circular groove respectively, and heights of the inner seal ring and the outer seal ring are equal and larger than depths of the bottoms of the inner circular groove and the outer circular groove. A nut body is made from a magnet attracting iron material, the inner seal ring and the outer seal ring are rubber soft magnets, and magnetic surfaces of the inner seal ring and the outer seal ring are positioned upwards to enable the inner seal ring and the outer seal ring to be attracted in the inner circular groove and the outer circular groove respectively under the magnetic action. The hexagonal nut with the seal rings has the advantages that excellent sealing effects are achieved since deflection and deformation of the seal rings are prevented, and the seal rings are protected from being lost resulted from shedding from a screw rod.

Owner:罗福仲

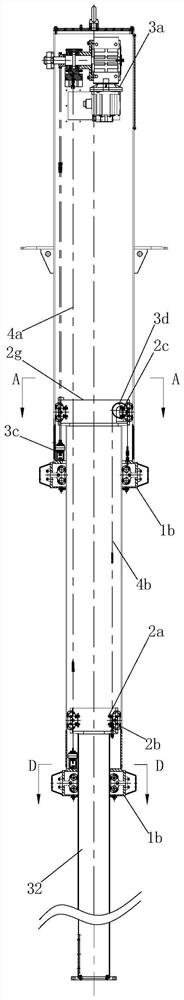

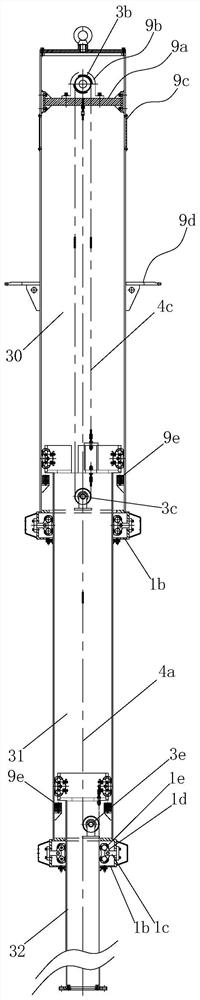

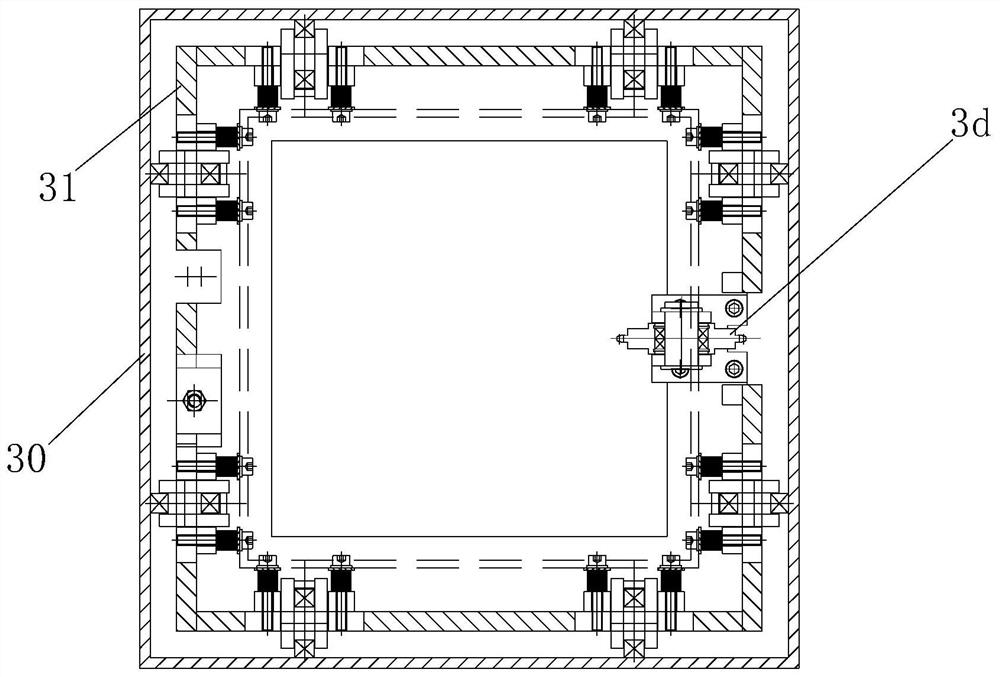

Chain type driving telescopic arm

The invention belongs to the technical field of mechanical arms and driving structure design thereof, and particularly relates to a chain type driving telescopic arm. The chain type driving telescopic arm comprises a fixed arm, a telescopic arm, a tail end arm and a servo driving assembly; the fixed arm comprises a fixed arm body and a fixed arm supporting sleeve piece; the telescopic arm comprises a telescopic arm body, a telescopic arm guide assembly and a telescopic arm supporting sleeve piece; the tail end arm comprises a tail end arm body and a tail end arm guide assembly; and the servo driving assembly comprises a servo motor set and a driving gear. The chain type driving telescopic arm is simple and compact in overall structure, the cost is effectively reduced, meanwhile, the number and the length of needed gears and chains are reduced, and the probability of occurrence of the problems of jamming, dislocation, sliding and the like is effectively reduced; and according to the chain type driving telescopic arm, the independence and the sealing performance of a telescopic arm driving system are guaranteed, so that the telescopic arm can be used in various production operation occasions with high sealing requirements and high anti-pollution requirements on mechanical arms, such as shot blasting and paint spraying.

Owner:湖北三江航天涂装设备工程有限公司

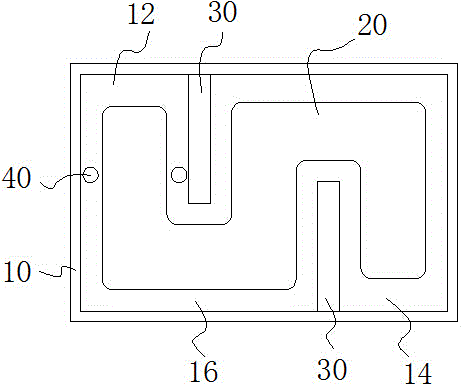

Multifunctional gas storage plate pneumatic stirring and biogas collecting method

InactiveCN104818210AImprove self-circulation fluidityEvenly distributedBioreactor/fermenter combinationsBiological substance pretreatmentsGas cylinderProcess engineering

The invention discloses a multifunction gas storage plate pneumatic stirring and biogas collecting method. According to the method, in the pneumatic stirring process, a plurality of baffles are arranged in a gas storage plate and divide the gas storage plate into a plurality of fermentation regions, and since the distribution of fermentation raw materials, strains and the like in a biogas fermentation system is not uniform, adjacent fermentation regions are different in fermentation efficiency and are not consistent in air pressure and the air pressure difference is used as power; in the biogas collecting process, the top of the gas storage plate of the biogas fermentation system is communicated with a gas inlet of a plus gas collecting system, biogas enters the inner cavity of the system, air pressures at the upper end and the lower end of a gas guide piston connected into a gas cylinder in a sliding way are identical by virtue of a gas channel and the gas guide piston is driven to move when the same air pressure acts on different acting faces.

Owner:陆永柱

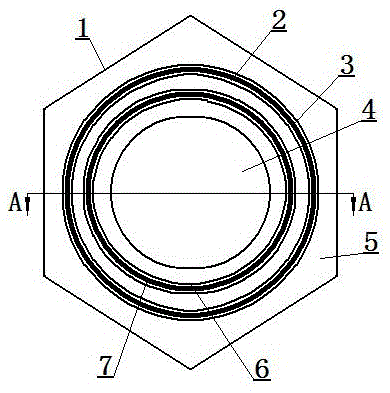

Hexagon bolt with sealing rings

InactiveCN105587729ANo dislocation deformationHigh sealing requirementsEngine sealsScrewsCoaxial lineMagnet

The invention discloses a hexagon bolt with sealing rings. A bolt body comprises a screw and a head portion which are of an integral structure. The lower end face of the head portion is provided with an inner ring-shaped groove and an outer ring-shaped groove which are provided with the same coaxial line as the screw, the inner sealing ring is arranged in the inner ring-shaped groove, the outer sealing ring is arranged in the outer ring-shaped groove, and the heights and the sizes of the inner sealing ring and the outer sealing ring are the same and larger than the depths and sizes of the groove bottom of the inner ring-shaped groove and the groove bottom of the outer ring-shaped groove; the bolt body is made of a magnet material, and both the inner sealing ring and the outer sealing ring are made of rubber soft magnetic strips; and both the magnetic face of the inner sealing ring and the magnetic face of the outer sealing ring are upward, and the inner sealing ring and the outer sealing ring are attracted and attached in the inner ring-shaped groove and the outer ring-shaped groove respectively under the magnetic action. The hexagon bolt with the sealing rings has the beneficial effects that the sealing rings can be prevented from generating movement and deformation, the good sealing effect is achieved, and the sealing rings are prevented from falling off from the screw and being lost as well.

Owner:罗福仲

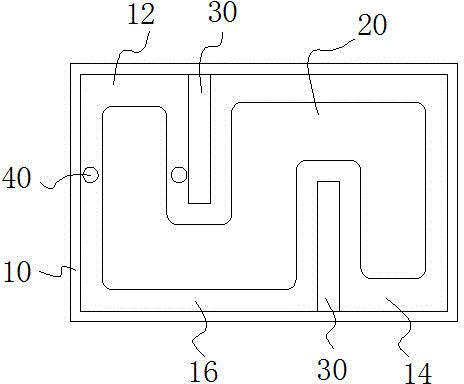

S-type fermentation pool

InactiveCN104804990AReduce the difficulty of productionStable flowBioreactor/fermenter combinationsBiological substance pretreatmentsFermentationRaw material

The invention discloses an S-type fermentation pool, comprising a fermentation pool body, a gas storage plate and partition plates, wherein the partition plates are arranged in the fermentation pool body and are used for partitioning the fermentation pool body into an S-type fermentation chamber; the gas storage plate, which is matched with the fermentation chamber in shape, is fixed in the fermentation pool body; gaps between two ends of the gas storage plate and the fermentation pool body are taken as a feeding port and a discharging port; a gap between the side wall of the gas storage plate and the fermentation pool body as well as gaps between the gas storage plate and the partition plates are taken as a stirring tank; the stirring tank is internally and movably provided with stirring devices. According to the S-type fermentation pool, the fermentation line is long; fermentation raw materials are sufficiently fermented in the fermentation chamber; the uniform distribution of the fermentation raw materials can be enhanced and the fermentation chamber can be dredged by utilization of the stirring action of the stirring devices in the stirring tank, so that the blockage problem is solved.

Owner:张伟伟

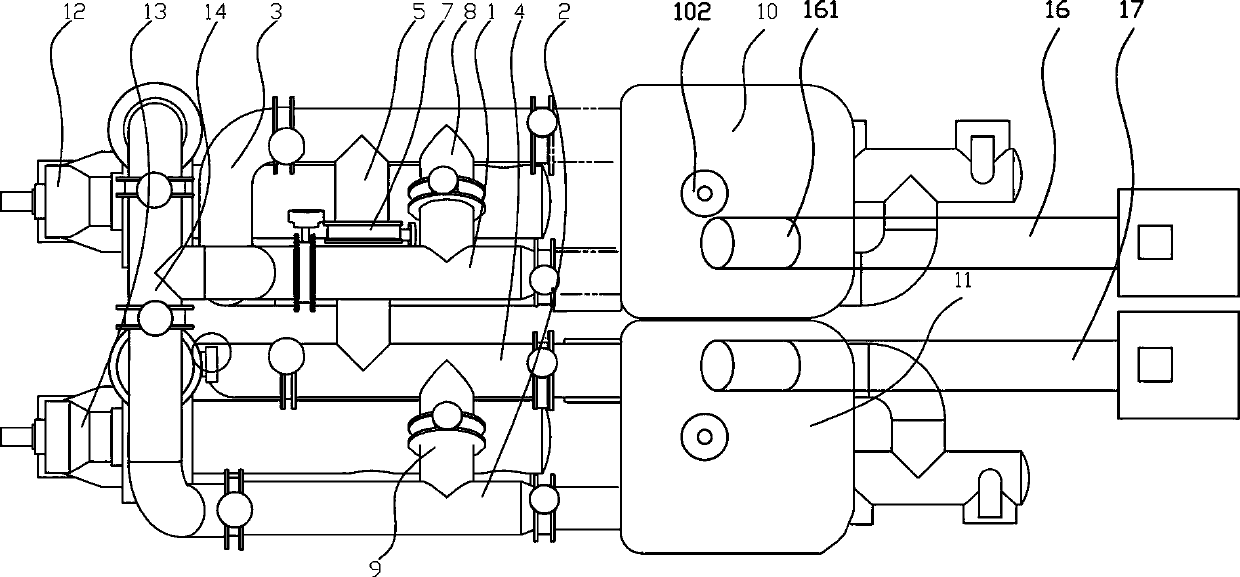

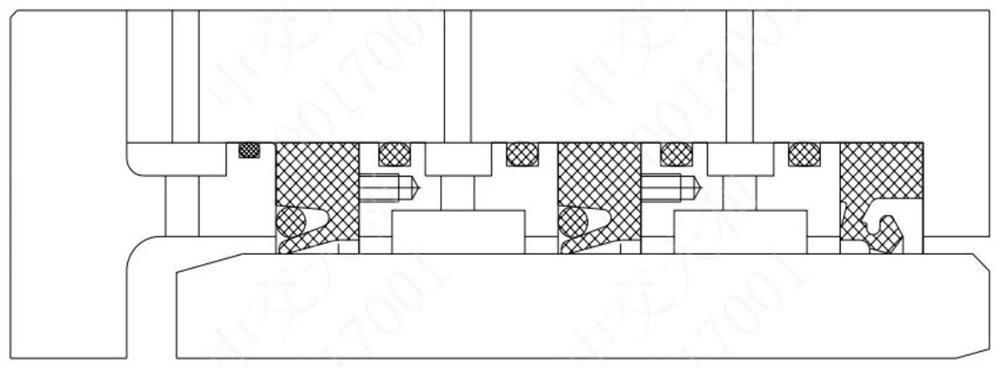

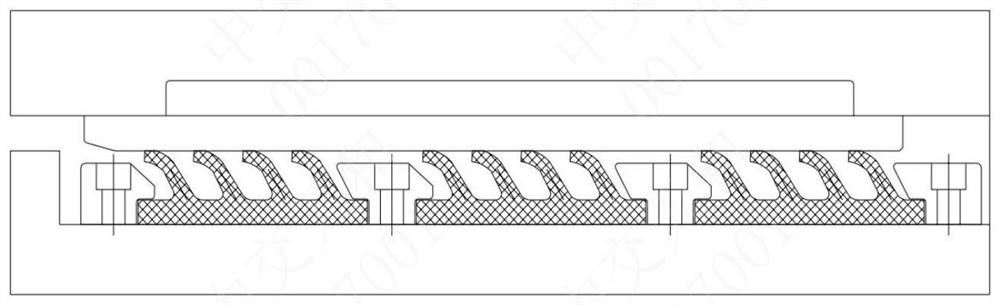

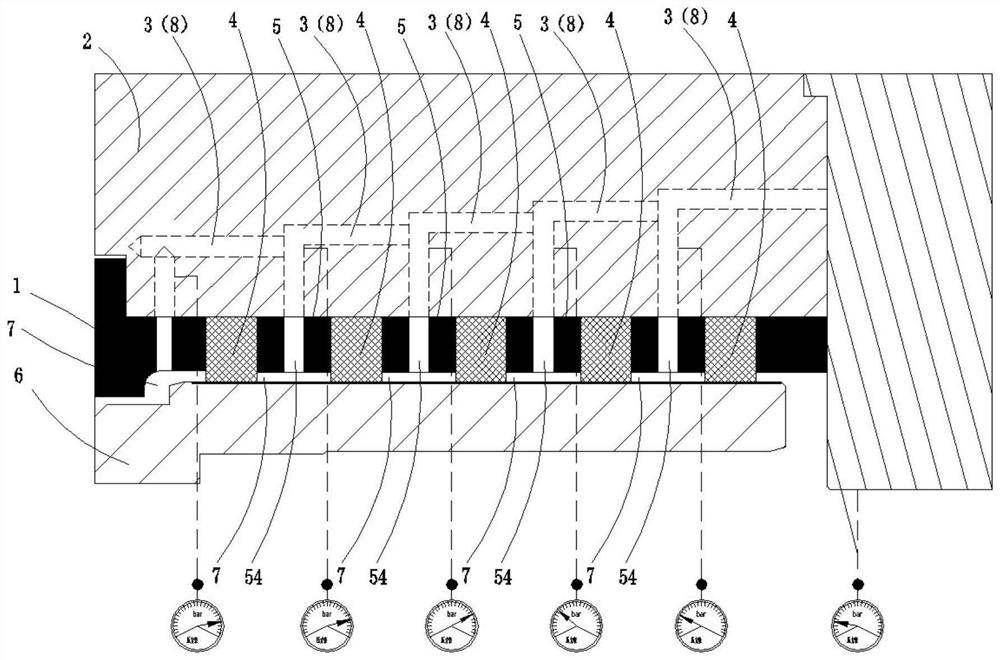

Main drive sealing system and method of shield machine self-adapting to soil bin pressure changes

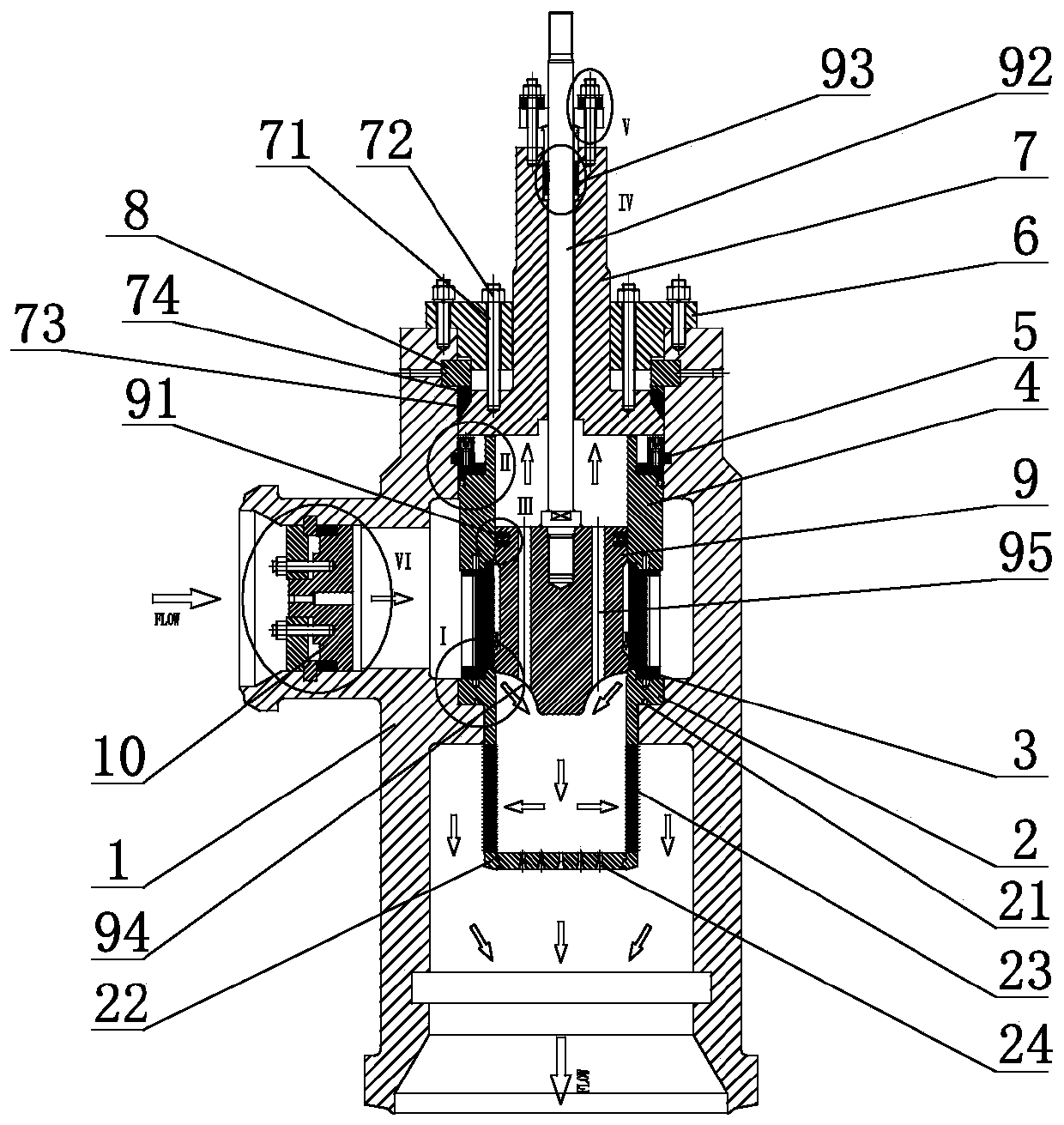

PendingCN111608671AContinuous and automatic collection of pressure changesEasy to useMining devicesTunnelsSoil scienceWorking pressure

The invention discloses a main drive sealing system and method of a shield machine self-adapting to soil bin pressure changes. The system comprises a fluid channel box, a friction ring, a sealing medium and a plurality of sealing rings. The fluid channel box sleeves the friction ring and an annular gap is formed between the friction ring and the fluid channel box, the plurality of sealing rings divide the gap into a plurality of annular pressure cavities, an injection channel is formed in the fluid channel box, and the sealing medium is filled in the injection channel and the pressure cavities. In order to control water and soil pressure and various working pressure, the sealing method meets the following conditions that P<2>=P<1>+[delta]P<1>, and P<N>=P<N-1>-[delta]P<N>, [delta]P<1>>0, and [delta]P<N>>0. According to the system, the working pressure of the main drive sealing system can be linked with the soil bin pressure changes, so that the pressure bearing capacity of the main drive sealing system can be matched with the soil bin pressure changes; the shield machine working under ultra-high water and soil pressure has a higher demand for the sealing effect of the main drive sealing system, and higher working reliability is required.

Owner:TIANHE MECHANICAL EQUIP MFG

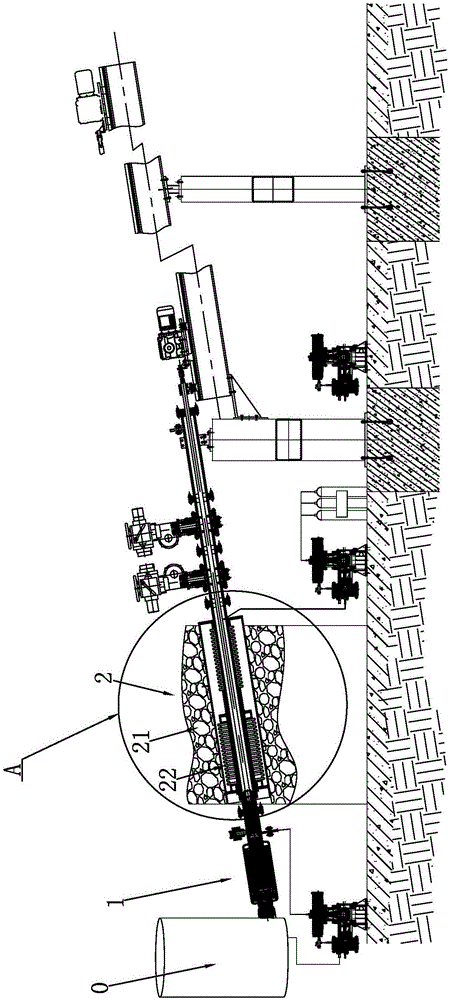

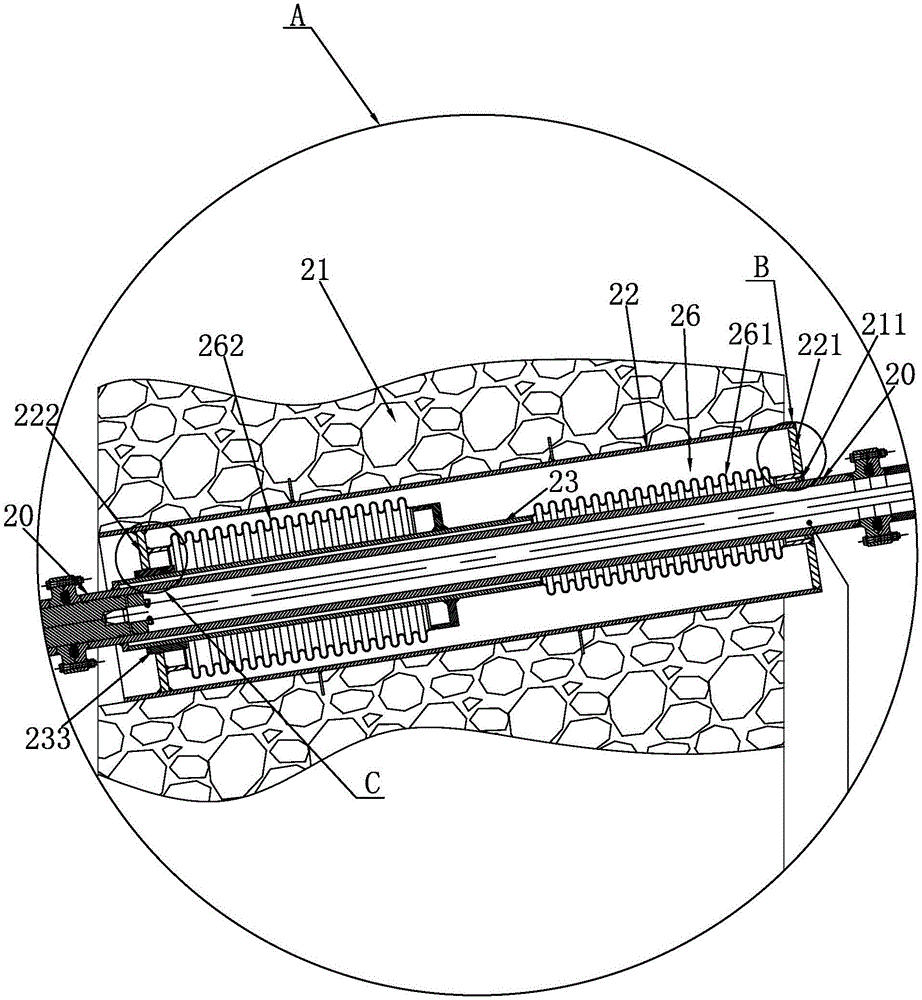

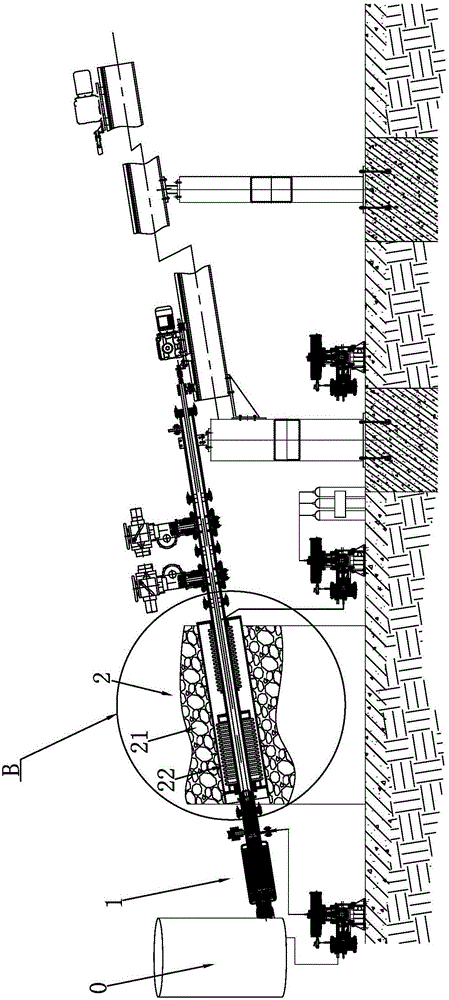

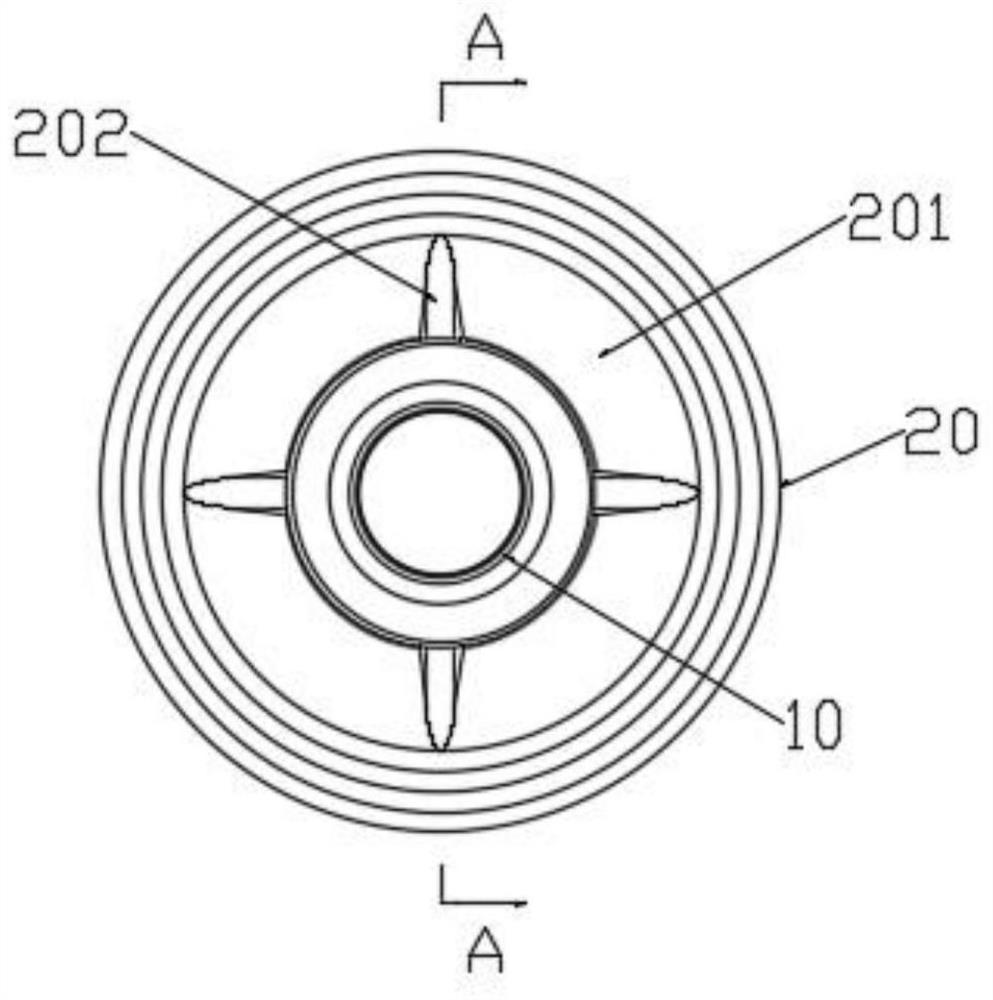

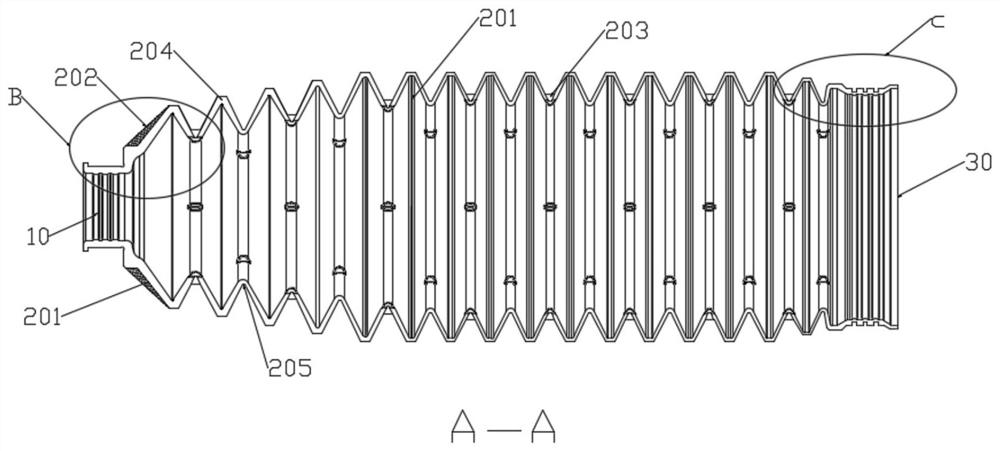

Wall penetrating body and using method thereof

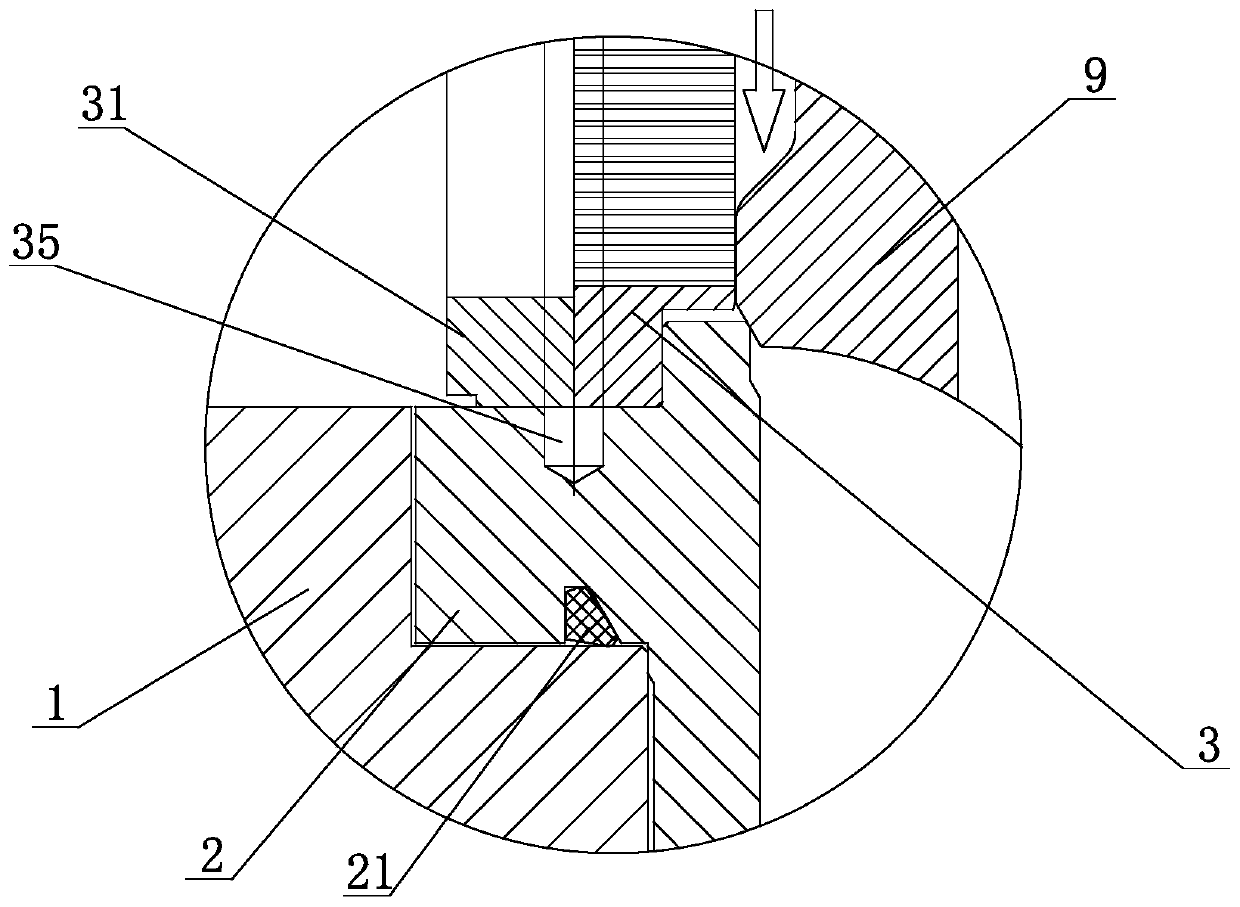

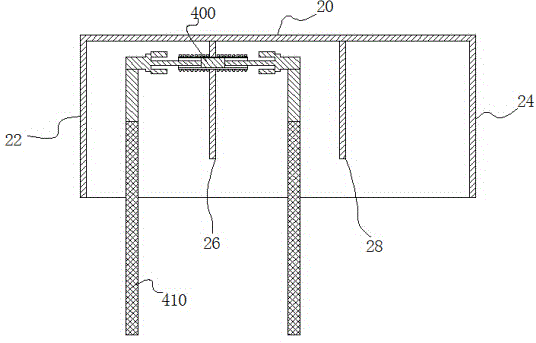

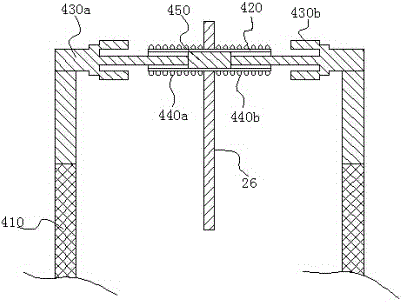

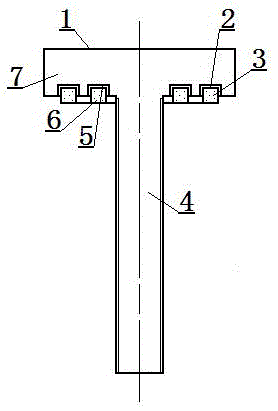

ActiveCN105221846AHigh sealing requirementsIncrease manufacturing difficultyPipesAdjustable jointsNuclear powerEngineering

The invention discloses a wall penetrating body and a using method thereof and relates to a sleeve of a protecting pipeline for sealing, in particular to a wall penetrating body for protection sealing of nuclear power wall penetration and a using method of the wall penetrating body. The wall penetrating body comprises an outer pipe (22), an inner pipe and a corrugated pipe (26), wherein the outer pipe is used for being fixed to a wall body (21); the inner pipe is arranged inside the outer pipe (22) in a sleeve mode; the two ends of the corrugated pipe are fixed together to the outer pipe (22) and the inner pipe (20) in a sealing mode respectively. The wall penetrating body is simple in structure, low in cost, easy and convenient to operate and high in linearity, coaxiality and sealing performance. The corrugated pipe (26) is adopted to seal the inner pipe (20) which can move, and dynamic sealing with high sealing performance is achieved.

Owner:TIANDING SEALING TECH BEIJING CO LTD

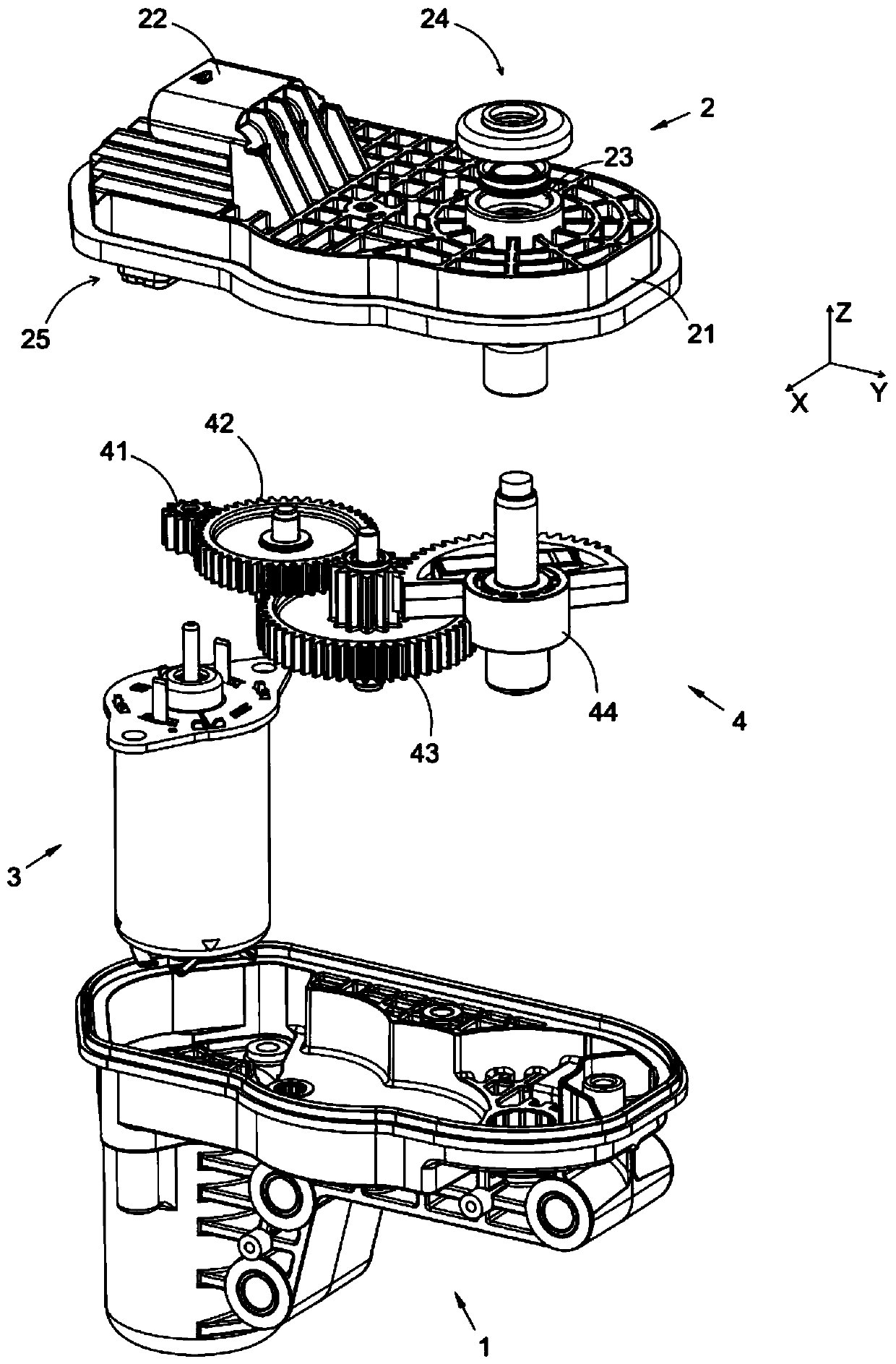

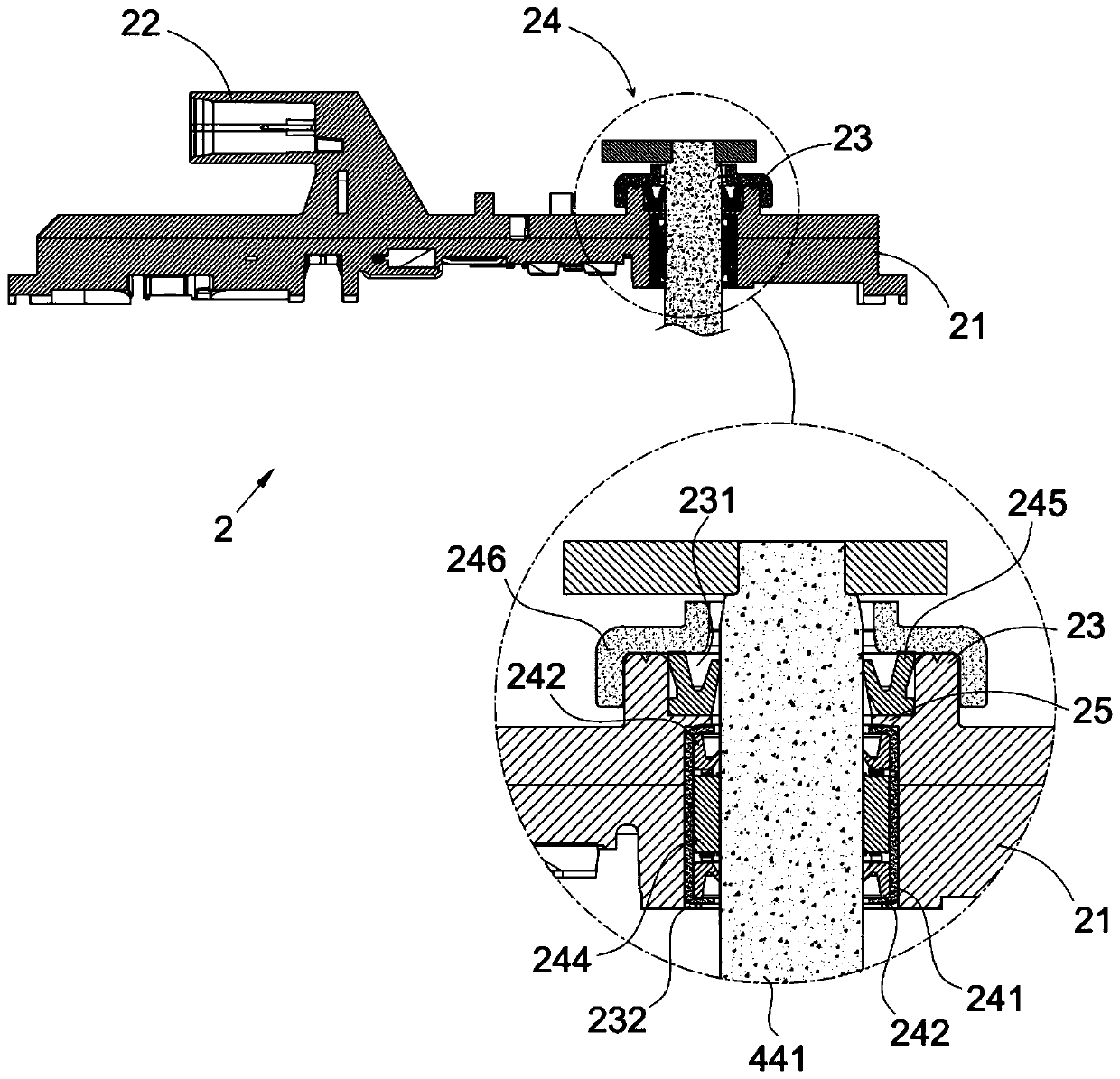

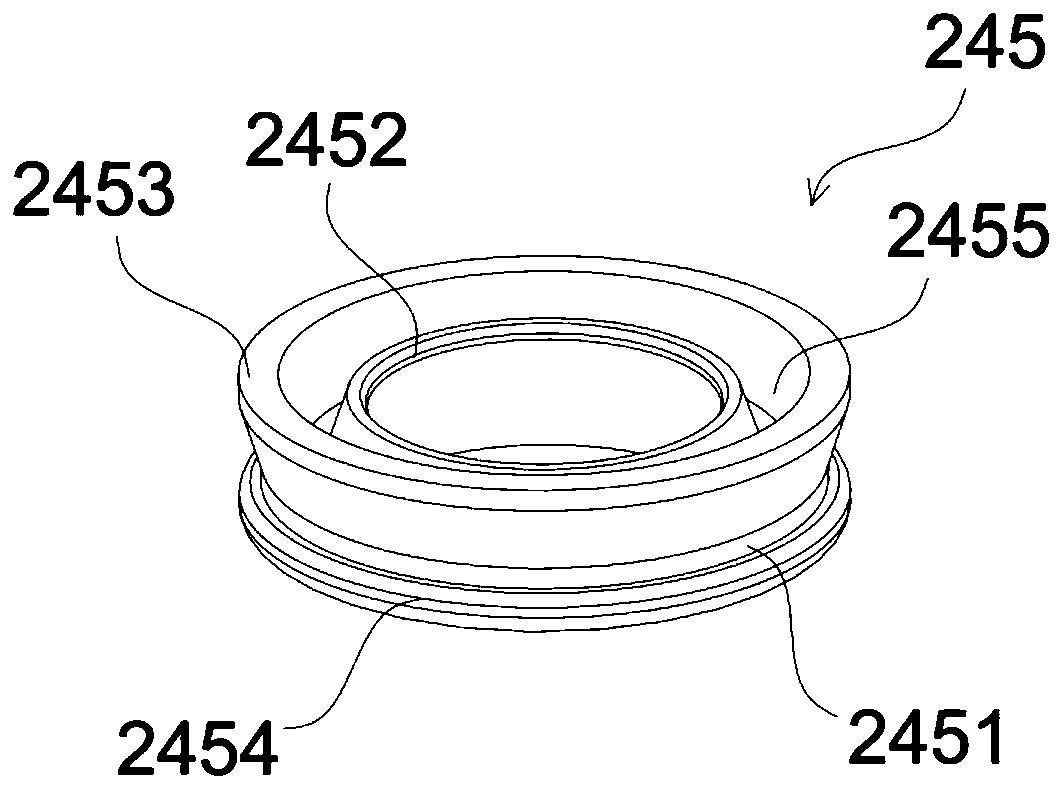

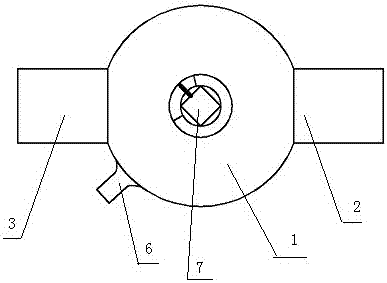

Electronic actuator

ActiveCN110206638ACompact structureEasy assembly and commissioningOperating means/releasing devices for valvesInternal combustion piston enginesGear transmissionL-shell

The invention discloses an electronic actuator. The electronic actuator comprises a lower shell and an upper shell, wherein an opening is formed in the top of the lower shell; the shape and the size of the upper shell are matched with the top of the opening of the lower shell, so that seal is formed when the upper shell and the lower shell are combined; the upper shell and the lower shell are combined to form a containing cavity located in the upper shell and the lower shell; a gear transmission mechanism is arranged in the containing cavity; a to-be-sealed cavity communicating the inside andoutside of the upper shell is arranged on the upper shell; and a sealing structure is arranged in the to-be-sealed cavity. The electronic actuator is compact in structure, and convenient in assemblingand debugging; later maintenance cost is greatly reduced, and durability is relatively higher; and high sealing requirements of the electronic actuator in a severe working environment for a long timeare met. In addition, the device is light in weight; installation stability of motors is improved; meanwhile, integrated multi-elastic-piece design is adopted, and problems that a traditional split type damping elastic piece is poor in matching performance and prone to loosening and the like are avoided; and damping effect is greatly improved.

Owner:FAIST EMISSION CONTROLS SUZHOU

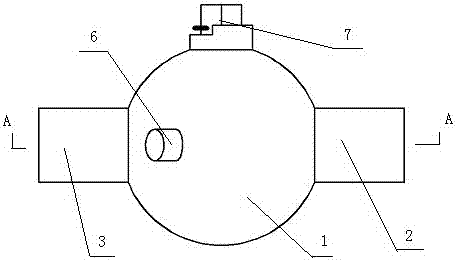

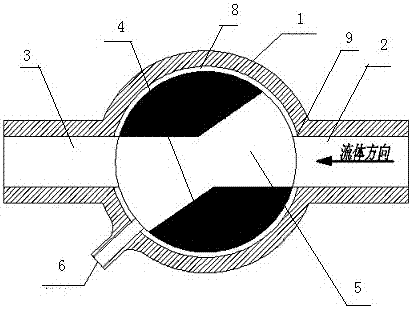

Foreign matter discharging spherical valve

PendingCN107575605AAvoid damageHigh sealing requirementsMultiple way valvesValve housingsForeign matterExternal rotation

The invention relates to the technical field of valve body manufacturing, in particular to a foreign matter discharging spherical valve. The foreign matter discharging spherical valve is composed of avalve body, a water inlet connecting pipe and a water outlet connecting pipe. The two ends of the valve body communicate with the water inlet connecting pipe and the water outlet connecting pipe correspondingly. The foreign matter discharging spherical valve is characterized in that the valve body is spherical, the spherical valve body is internally provided with a spherical inner cavity internally provided with a spherical valve core, and the middle of the spherical valve core is provided with an X-shaped fluid channel; the section of the fluid channel presents that openings are gradually enlarged from the middle towards the two ends and are symmetrical; a foreign matter and air discharging opening is formed in the position, on one side of the water outlet connecting pipe, of the valve body, and a foreign matter and air discharging pipe is arranged at the foreign matter and air discharging opening; the diameter of each end opening of the fluid channel is larger than the maximum distance between the water outlet connecting pipe and the foreign matter and air discharging pipe; and the outer side face of the spherical valve core is connected with an external rotating handle througha rotating rod. By rotating the handle, three states, namely, closing, opening and foreign matter discharging, of the X-shaped fluid channel of the spherical valve core are achieved, and the foreign matter discharging spherical valve has the advantages that the structure is simple, high-point air discharging and low-point sewage discharging are both achieved, sampling is convenient, and pressure and temperature measuring is simple.

Owner:荣成市固废综合处理与应用产业园有限公司

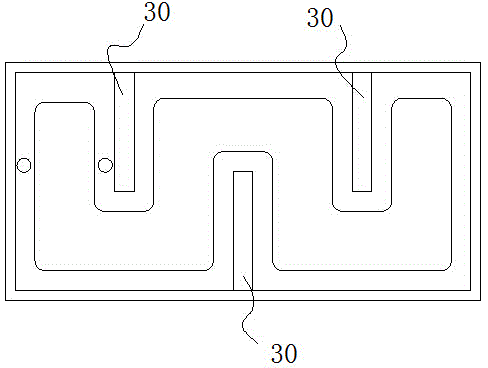

Self-circulation stirring device

InactiveCN104804996AReduce the difficulty of productionStable flowBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringPiston rod

The invention discloses a self-circulation stirring device which comprises a stirring sleeve, wherein the stirring sleeve is fixed above a gas storage plate of a biogas fermentation system and is communicated with two fermentation areas which are arranged in the gas storage plate at an interval, a pneumatic piston which separates the two fermentation areas is slidably connected in the stirring sleeve in a sleeving mode, two ends of the pneumatic piston are connected with an outer sleeve through piston rods respectively, springs are connected onto outside walls at two ends of the stirring sleeve in a sleeving mode, step cavities matched with the outside wall of the stirring sleeve are arranged on the outer sleeve, communication holes which communicate the step cavities are formed in the outer sleeve, and the outer sleeve is fixedly connected with a stirring net.

Owner:张伟伟

Method for preparing SiCf/SiC compound material by combination of chemical vapor carbon deposition process and gas phase siliconizing process

The present invention discloses a method for preparing SiCf / SiC compound material by combination of a chemical vapor carbon deposition process and a gas phase siliconizing process, comprising the following steps: taking SiC fiber as a raw material, adopting three dimensional weaving technology to prepare SiC fibre-woven pieces; taking trichloromethyl silane as a deposition material and carrying out a primary chemical vapor deposition on the SiC fibre-woven pieces with thickness of deposited SiC coating being 0.1-70 mum; then taking methane or propylene gas as a raw material and carrying out carbon deposition on SiC fibre-woven pieces by a secondary chemical vapor deposition, thus obtaining SiCf / C midbody; finally, taking simple substance silicon as a raw material and carrying out siliconizing on the SiCf / C midbody by the gas phase siliconizing process, thus obtaining the SiCf / SiC compound material. The method of the present invention has the advantages of short preparation cycle and low cost, thus being capable of preparing SiCf / SiC composite material featuring high compactness, high mechanical property and thermal conduction.

Owner:NAT UNIV OF DEFENSE TECH

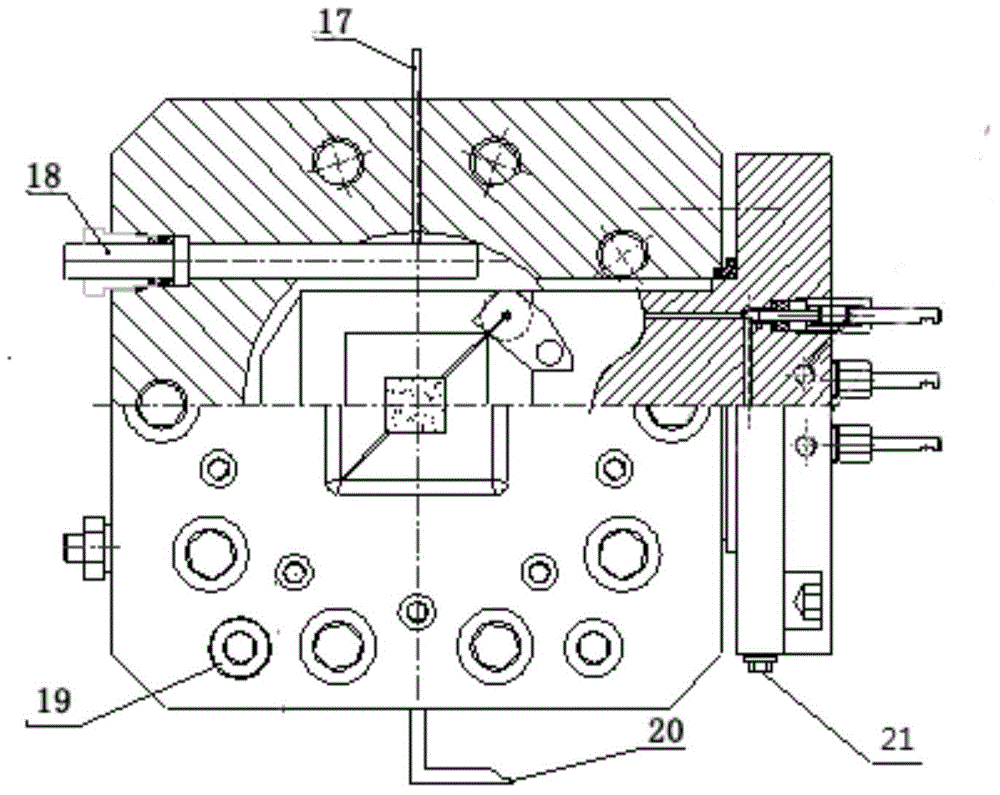

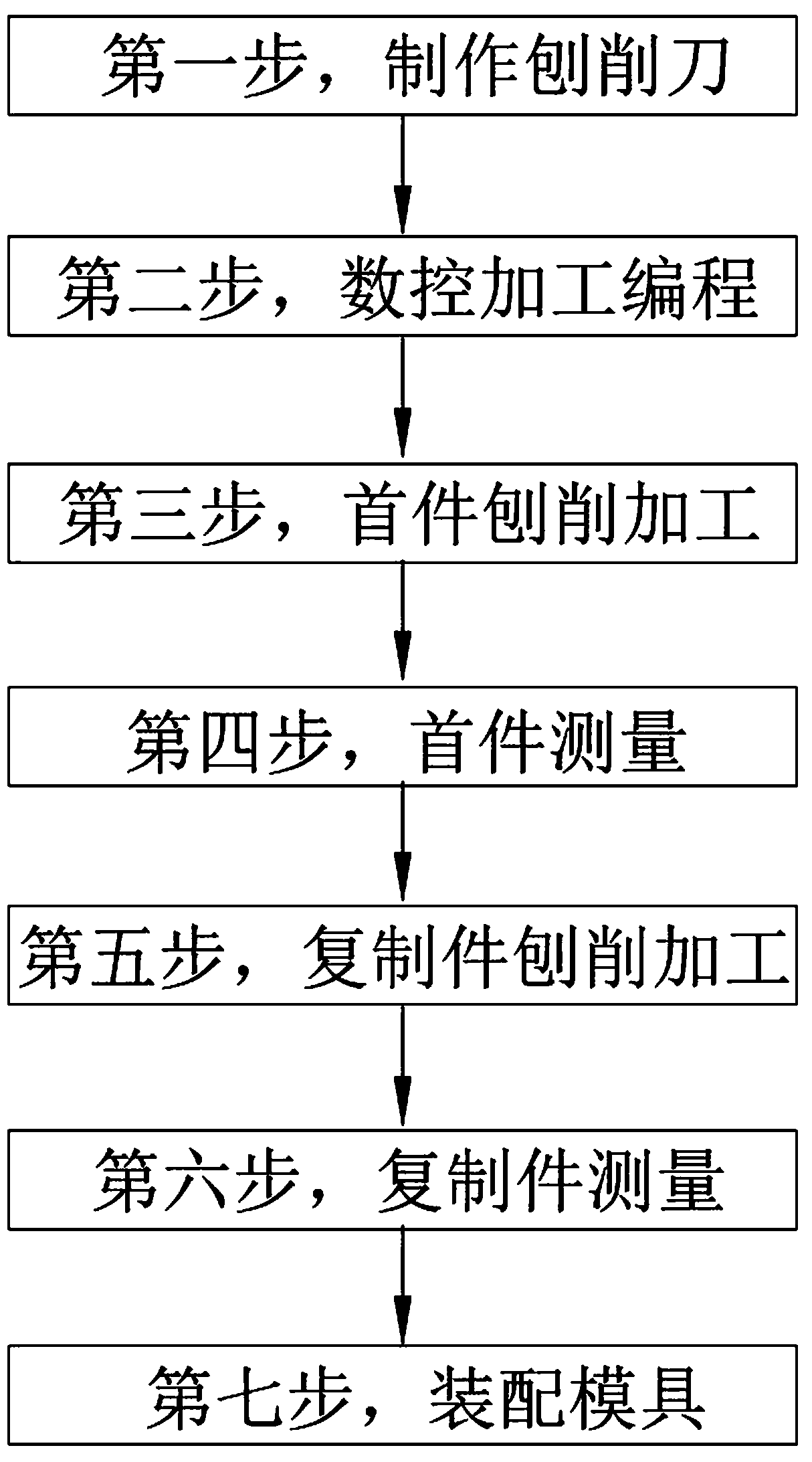

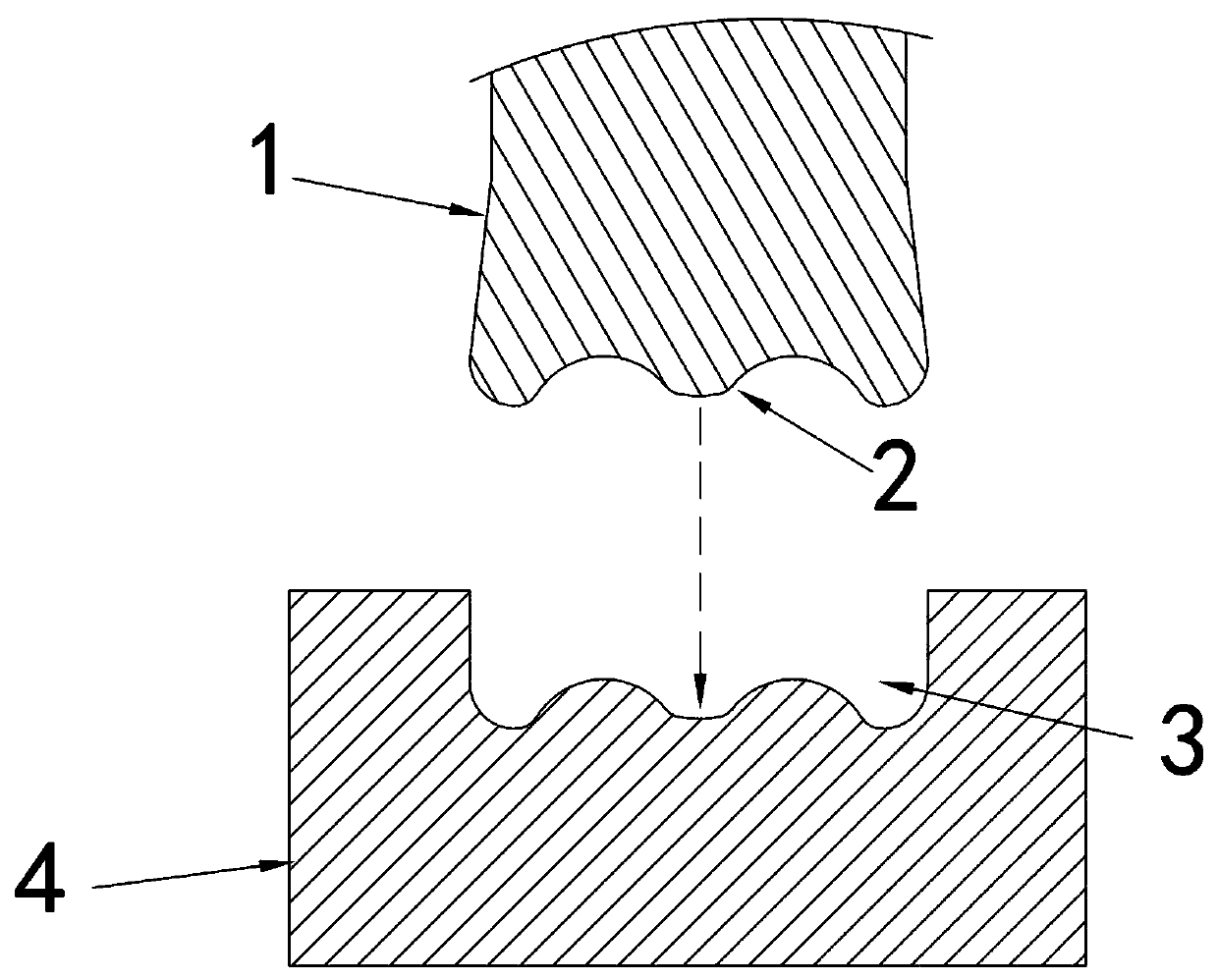

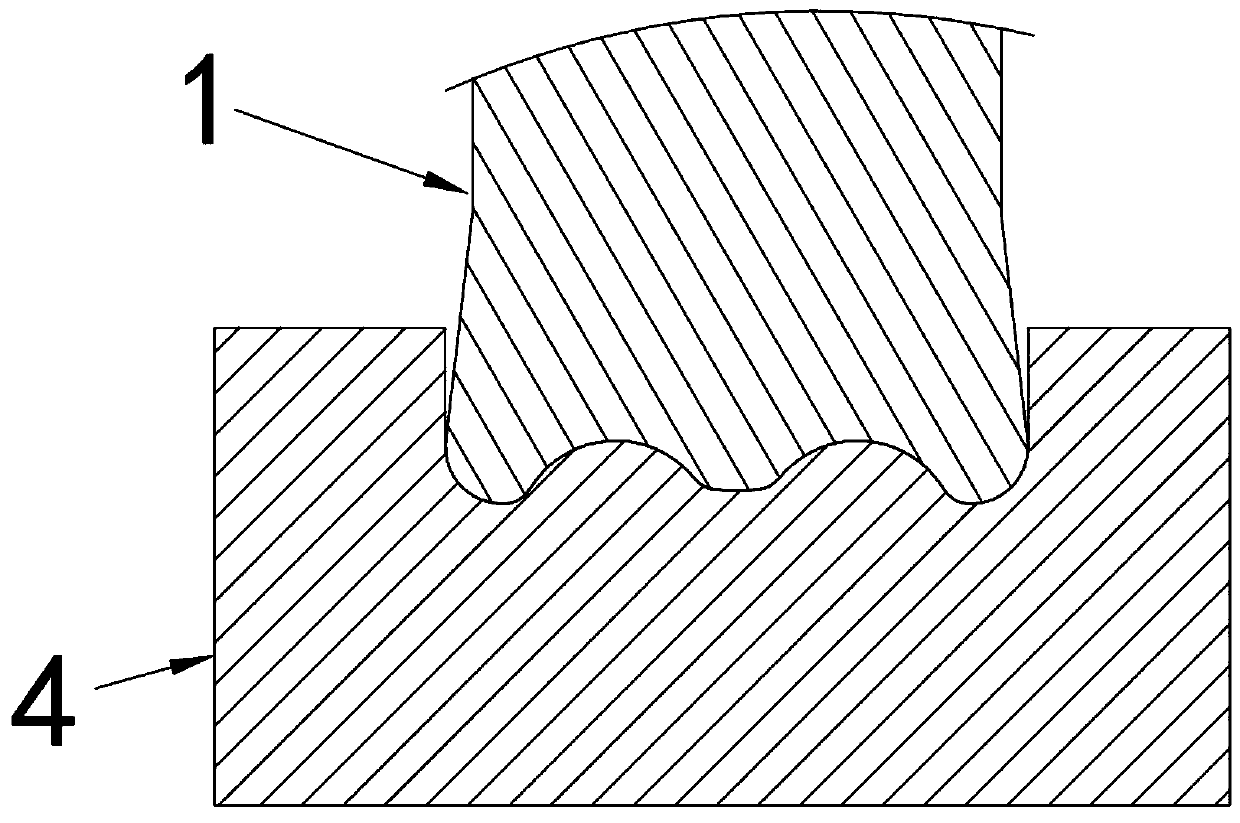

Method for processing mold with special-shaped planer

ActiveCN111375815ALess varietyLow costPlaning/slotting toolsPlaning/slotting machinesNumerical controlMachining time

The invention relates to a method for processing a mold with a special-shaped planer in the field of mold processing. The method for processing the mold with the special-shaped planer comprises the following steps of: the first step: making a planing knife; the second step: performing numerical control machining programming; the third step: planing a first piece; the fourth step: measuring the first piece; the fifth step: planing copies; the sixth step: measuring the copies; and the seventh step: assembling the mold. The self-made shaped planing knife can be used for planing processing, therefore, the variety of tools is small, the overall manufacturing cost is reduced by about 20% to 30%, and the comprehensive processing time is shortened by about 30% to 50%; the planing processing methodis used for replacing the traditional milling processing method, and the surface quality of the processed cavity is stable, which is more suitable for processing special-shaped cavity; and the planing processing method can also process a cavity that is concave along the horizontal direction, so as to ensure the integrity of the mold. The sealing ring produced by the mold manufactured by the method for processing the mold with the special-shaped planer is more suitable for precision instruments with higher sealing performance and strength requirements.

Owner:东莞市星品精密模具有限公司

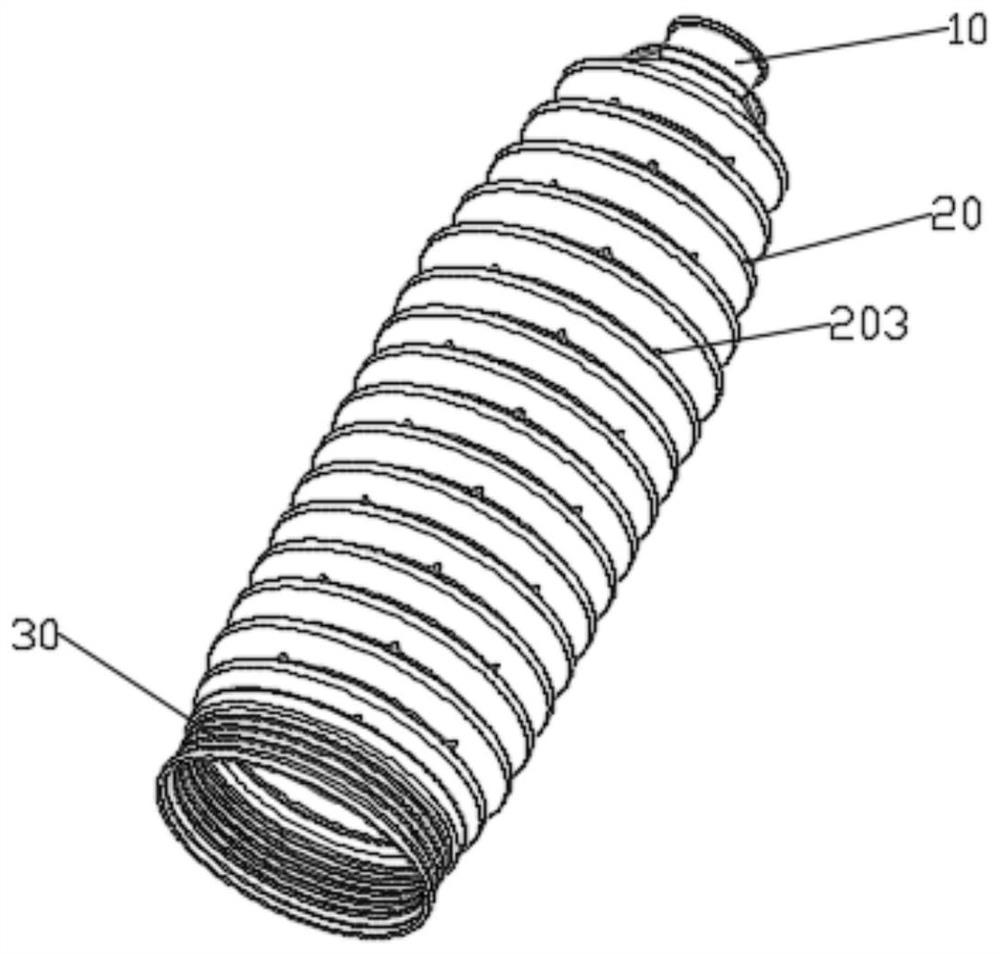

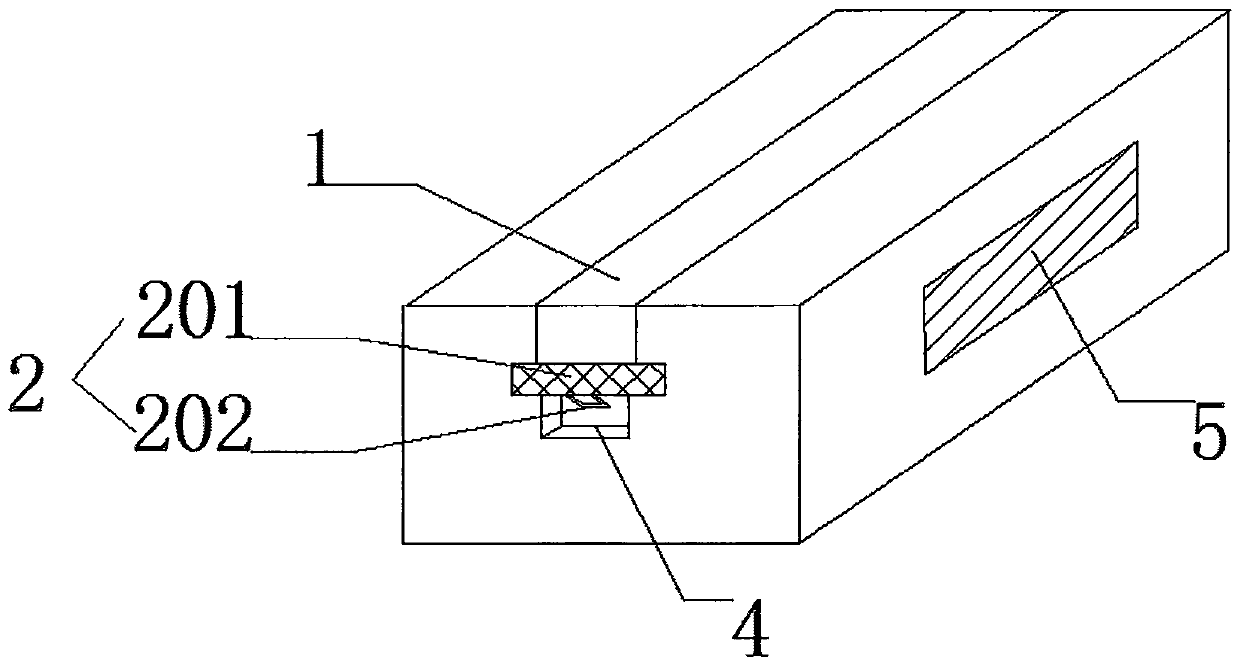

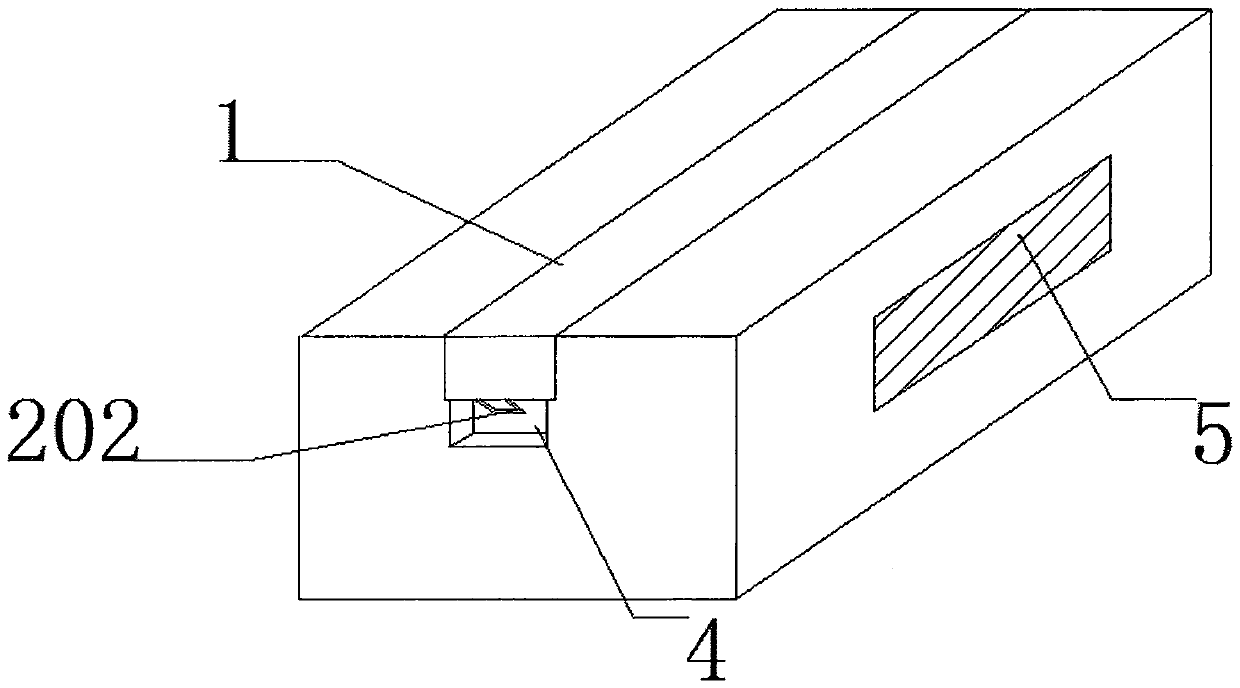

Compression-resistant steering protective cover

InactiveCN113525502AHigh sealing requirementsImprove sealingMechanical steering gearsStructural engineeringMechanical engineering

The invention discloses a compression-resistant steering protective cover. The protective cover comprises a first mounting end, a second mounting end and an elastic corrugated cover arranged between the first mounting end and the second mounting end, a plurality of reinforcing ribs are evenly distributed on the inclined face of the connecting position of the elastic corrugated cover and the first mounting end in the circumferential direction, the elastic corrugated cover is provided with a plurality of wave crest sections protruding outwards in the axial direction, the elastic corrugated cover is provided with a plurality of wave trough sections recessed inwards in the axial direction, and a plurality of fixing ribs are fixedly installed on the wave trough sections. According to the protective cover, the four reinforcing ribs are arranged on the inclined face of the end of the elastic corrugated cover, the strength of the inclined face of the elastic corrugated cover is enhanced, deformation generated by high temperature and high pressure is resisted, and meanwhile the situation that when the elastic corrugated cover stretches out and draws back, the inclined face collapses to cause abnormal sound, and use of the protective cover is affected is prevented; and the plurality of fixing ribs are arranged between two adjacent wave trough sections in a staggered mode, so that the strength of the elastic corrugated cover is improved, and the high-temperature deformation resistance of the protective cover is improved.

Owner:ANHUI ZHONGDING RUBBER PLASTIC PROD CO LTD

Novel packaging adhesive tape and packaging box comprising same

InactiveCN110203509AAccurate separationEasy to tear offRigid containersFilm/foil adhesive release linersEngineeringMechanical engineering

The invention relates to a novel packaging adhesive tape and a packaging box comprising the same. The adhesive tape comprises a viscous tape, and at least one end of the viscous tape is connected witha lifting portion used for assisting separation of the viscous tape from a to-be-packaged object. The viscous tape and the to-be-packaged object can be rapidly and accurately separated, so that the viscous tape is more easily torn away, and the problem that due to inconvenient tearing, an object is taken out by gashing a packaging gap of a viscous tape, and then the to-be-packaged object is thrown away and has no secondary recycling value is avoided.

Owner:宋一飞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com