Large-caliber ultrahigh-pressure differential steam emptying valve

An ultra-high-pressure, large-diameter technology, applied in the direction of valve lifts, valve details, and valve devices, can solve problems such as small flow cannot be adjusted, valve thrust increases, and labyrinth sleeves are scattered, so as to avoid turbulent flow at the bottom, Avoid compression and loosening, overcome the effect of surge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

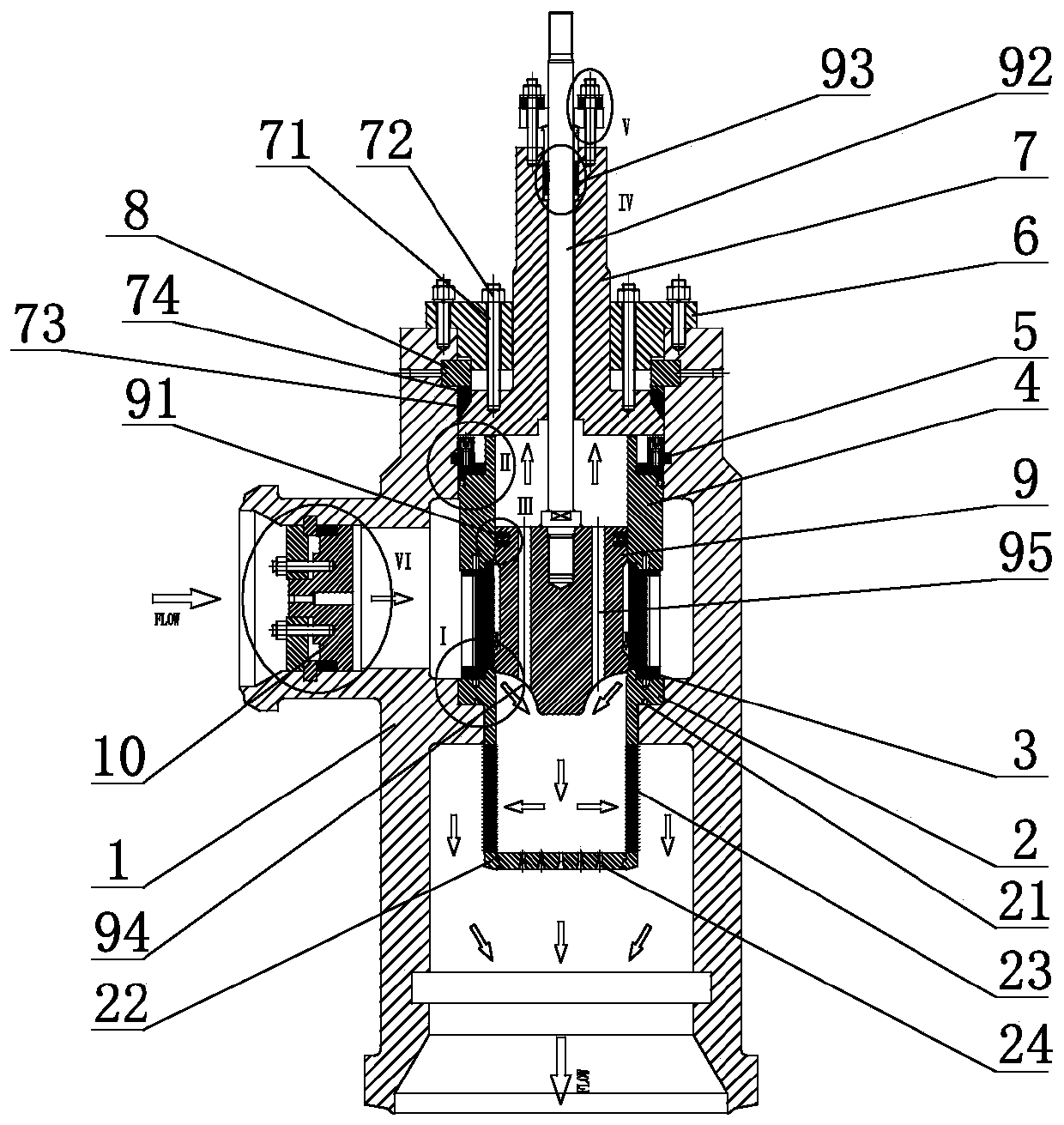

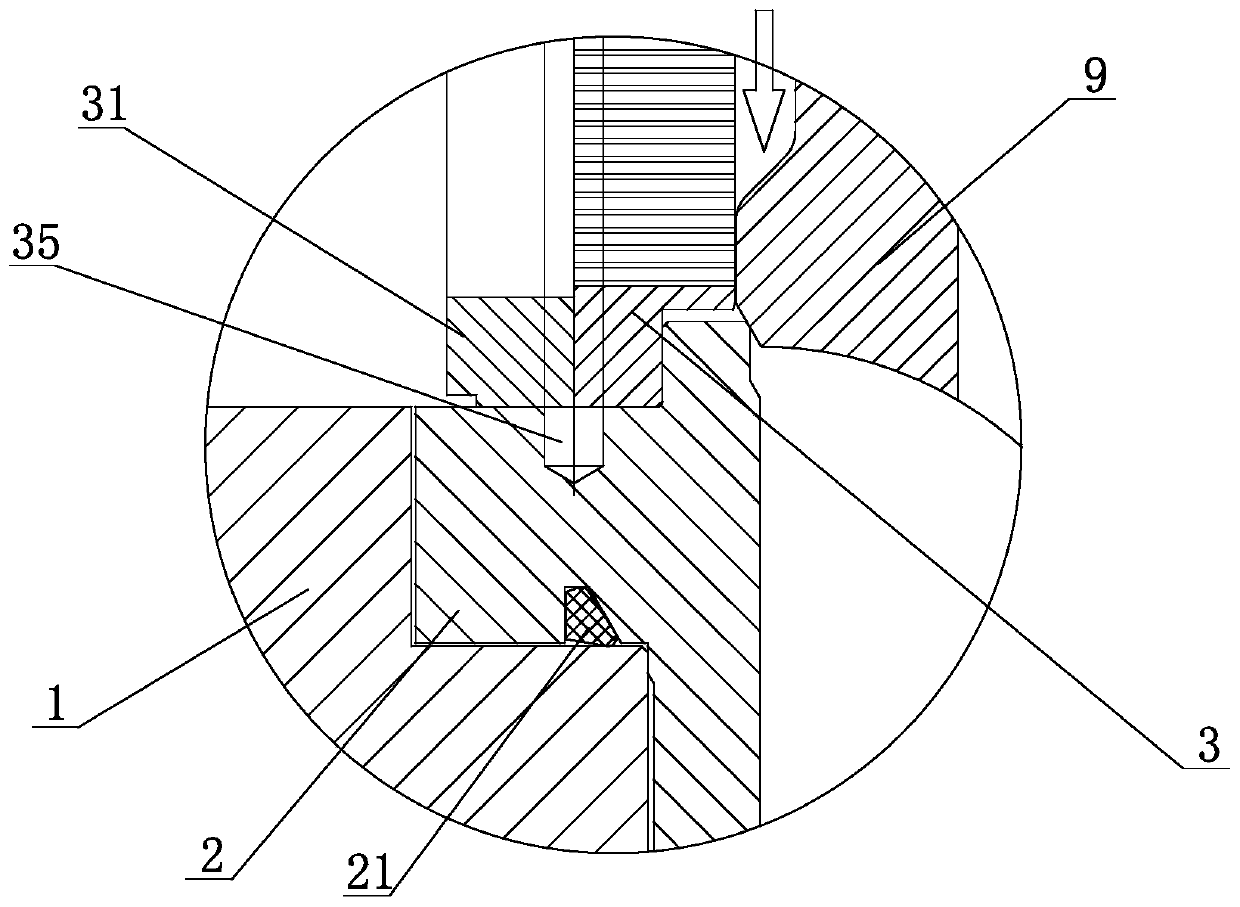

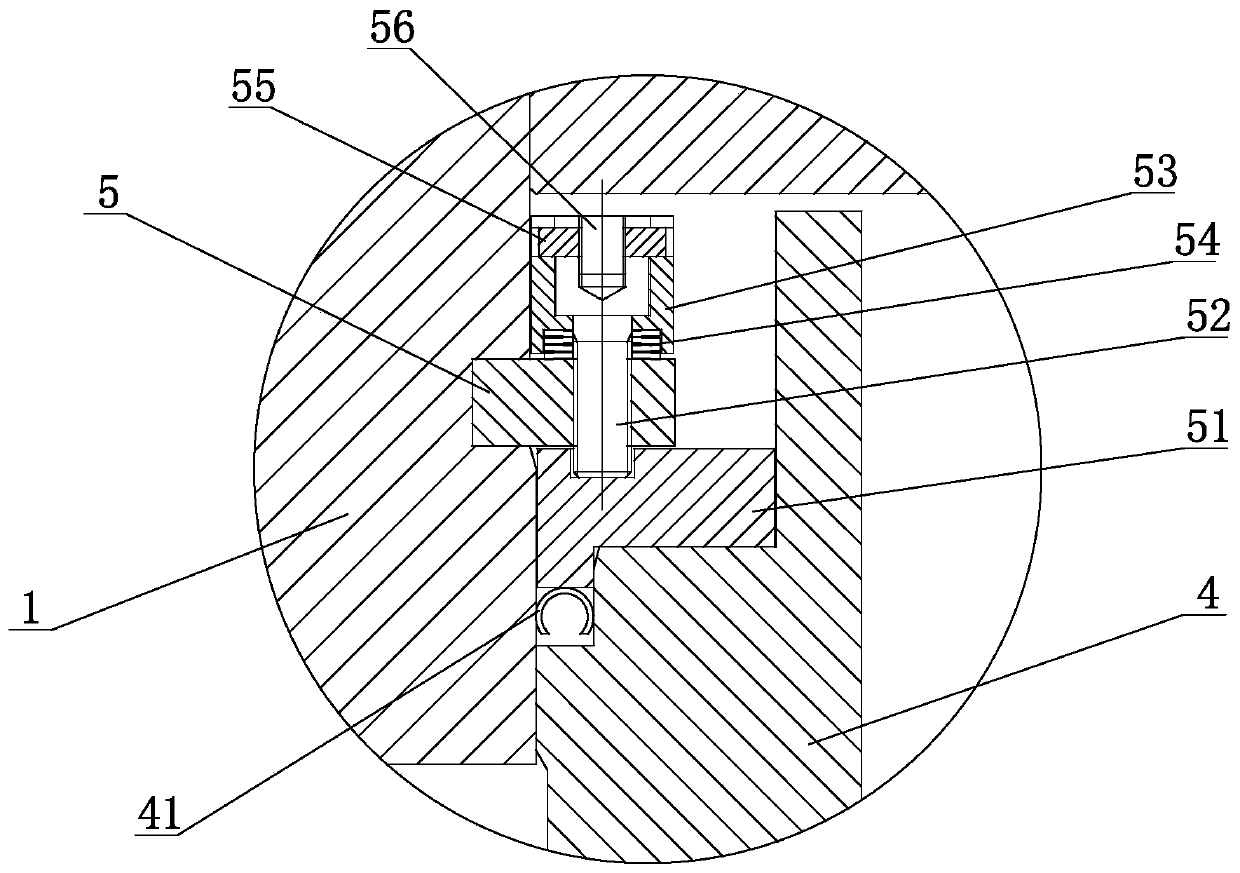

[0037] Such as figure 1As shown, the large-diameter ultra-high pressure differential steam vent valve of this embodiment includes a valve body 1, and a self-sealing valve seat 2 is arranged in the valve body 1, and a labyrinth sleeve 3 and a pressure ring 4 are connected to the self-sealing valve seat 2 in sequence, and the pressure ring 4 is connected to the valve body 1. The ring 4, the labyrinth sleeve 3 and the self-sealing valve seat 2 are compressed in the valve body 1 through the compression ring 5 connected in the valve body 1, and the upper end of the valve body 1 is connected to the valve cover pressure plate 6 through the pressure plate bolts and the pressure plate nuts. , the bonnet pressure plate 6 is pierced with a self-sealing bonnet 7, the sealing end of the self-sealing bonnet 7 located in the valve body 1 is connected to the bonnet pressure plate 6 through the bonnet adjusting bolt 71 and the bonnet nut 72, and the sealing end is connected to the valve body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com