Combined high-voltage switch cabinet

A high-voltage switchgear, combined technology, applied in the direction of pull-out switchgear, switchgear, electrical components, etc., can solve the problem of time-consuming and laborious, save space, solve the waste of space and cost, and reduce installation and use. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

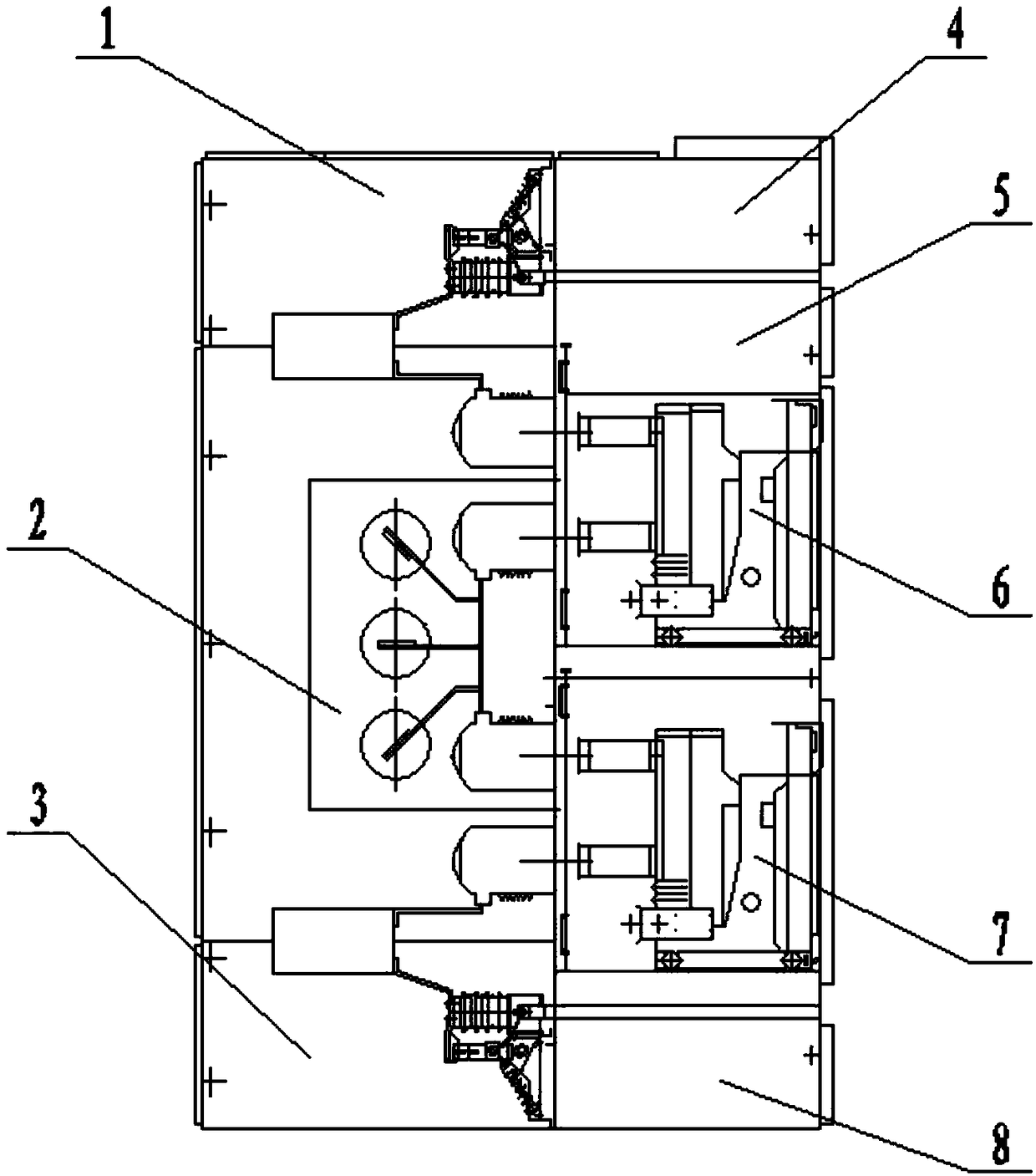

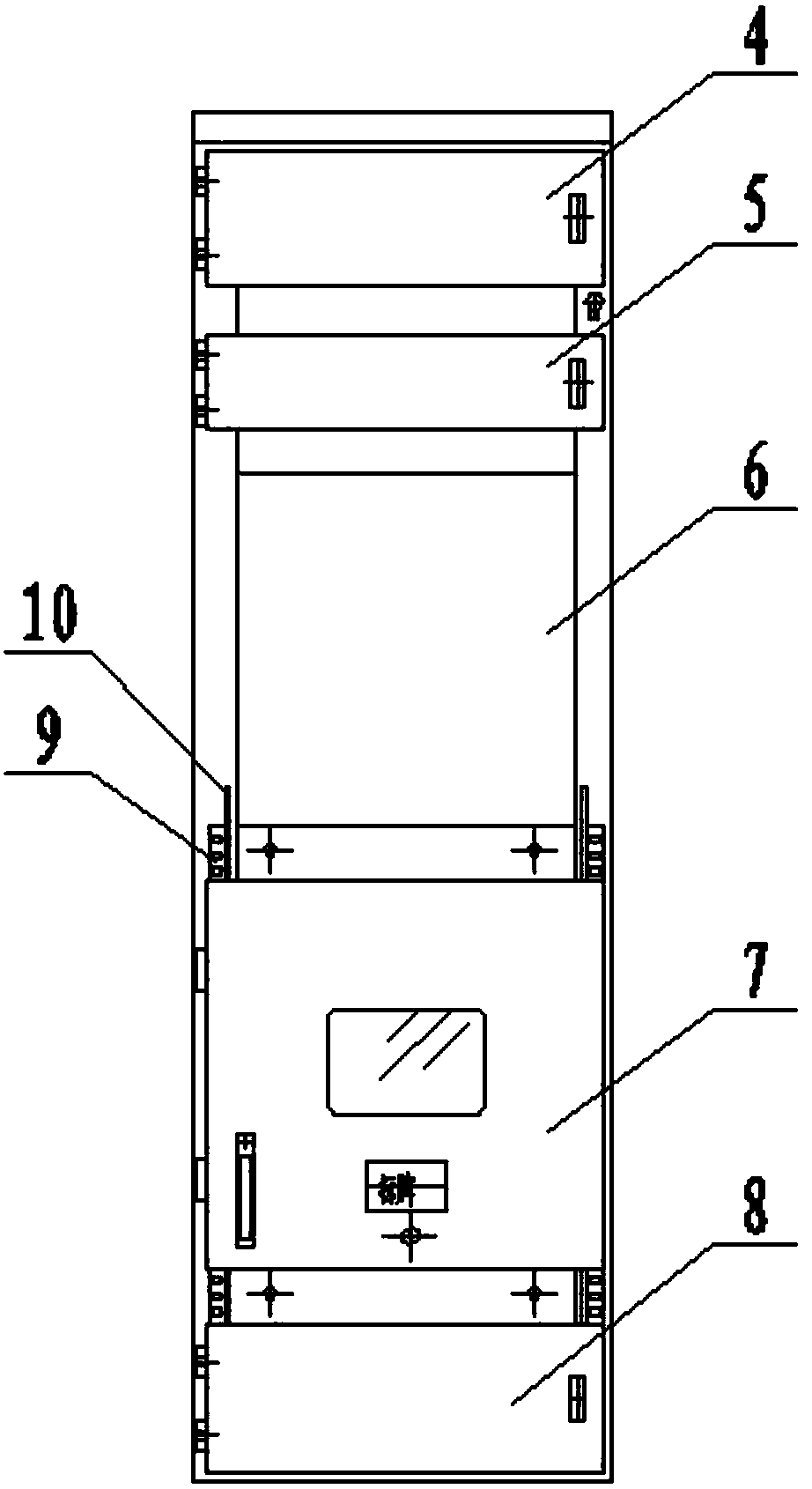

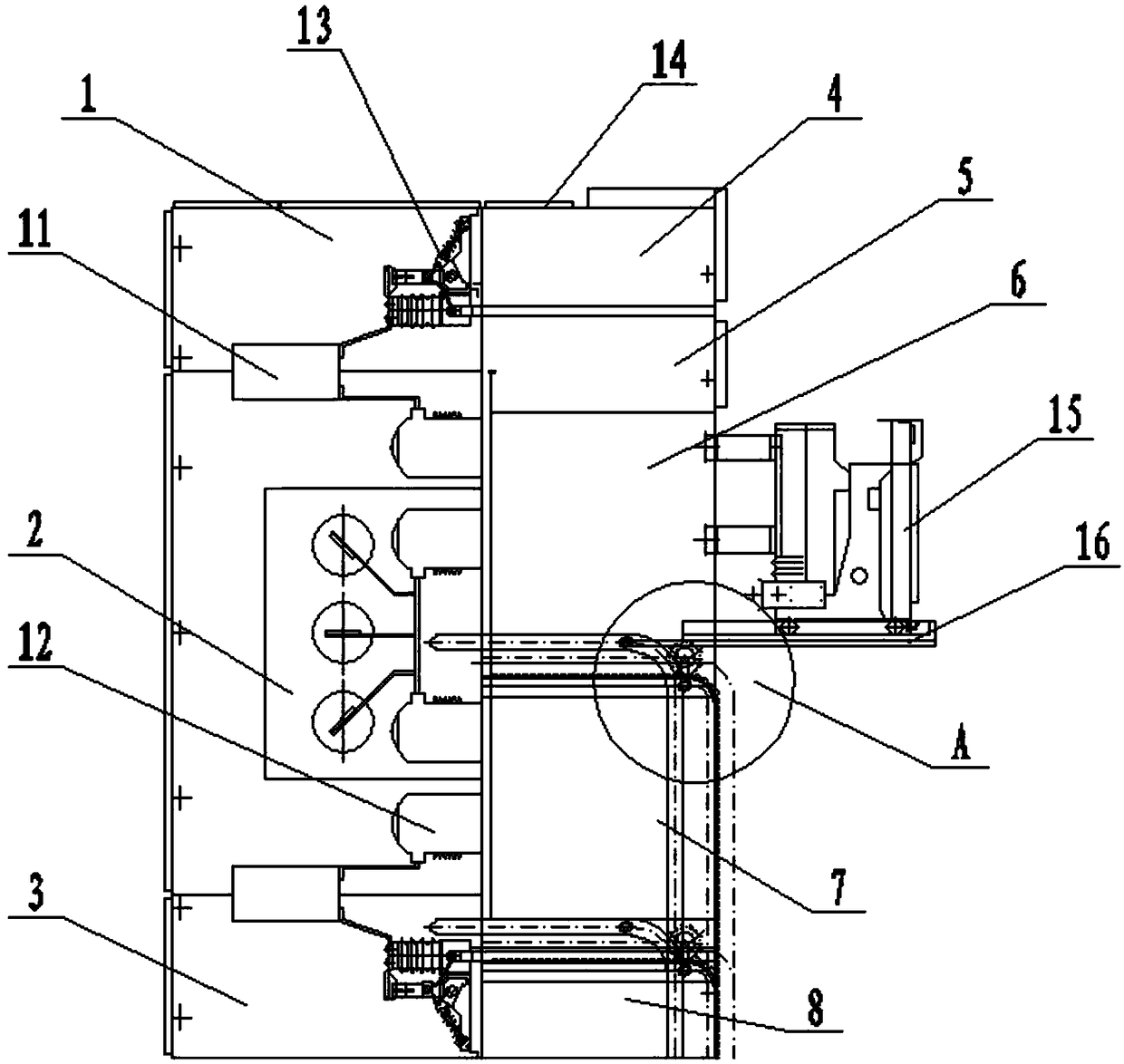

[0026] like figure 1 as shown, figure 1 and 2 As shown, a combined high-voltage switch cabinet includes a cabinet body and several electrical compartments, and the electrical compartments include an upper outlet room 1, a busbar room 2, a lower outlet room 3, a terminal row room 4, an upper instrument room 5, The upper handcart room 6, the lower handcart room 7 and the lower instrument room 8, the upper outlet room 1, the busbar room 2 and the lower outlet room 3 are arranged at the rear of the cabinet from top to bottom, and the cabinet door is connected with the cabinet by bolts ; The terminal row room 4, the upper instrument room 5, the upper handcart room 6, the lower handcart room 7 and the lower instrument room 8 are arranged in the front of the cabinet from top to bottom, one side of the cabinet door is hinged with the cabinet body, and the other side is set The door lock is connected to the cabinet body; the upper outlet room 1, the busbar room 2, the lower outlet ro...

Embodiment 2

[0035] The main structure of this embodiment is similar to Embodiment 1, and the operation method is the same, and the difference is that: Image 6 As shown, the driving wheel 20 is a sprocket, the track 9 is a chain, and the transmission device is a worm gear reducer 24 . Worm gear reducer 24 is mainly composed of transmission parts worm gear, shaft, bearing, box and its accessories, and can be divided into three basic structural parts: box, worm gear, bearing and shaft combination. The box body is the base of all accessories in the worm gear reducer 24, and is an important accessory to support and fix the shafting components, ensure the correct relative position of the transmission accessories and support the load acting on the reducer. The main function of the worm gear is to transmit the motion and power between the two interlaced shafts, and the main function of the bearing and the shaft is to transmit power, run and improve efficiency. Worm gear reducer 24 can realize s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com