Simple air filter element cleaning equipment

An air filter element and cleaning equipment technology, which is applied in the direction of filtration separation, filter regeneration, and dispersed particle filtration, etc., can solve the problems of secondary dust pollution, health hazards of employees, and short service life of the filter element, so as to improve the service life, Good cleaning effect and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

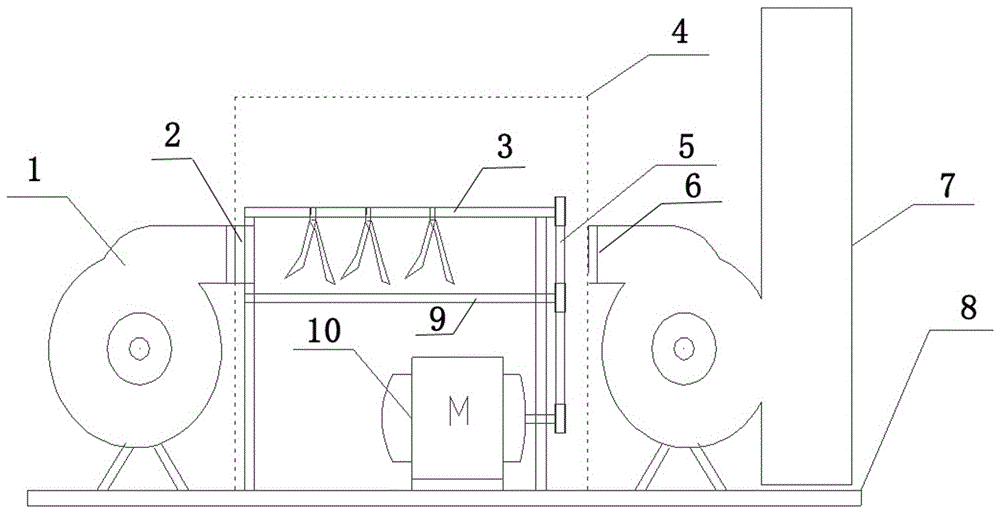

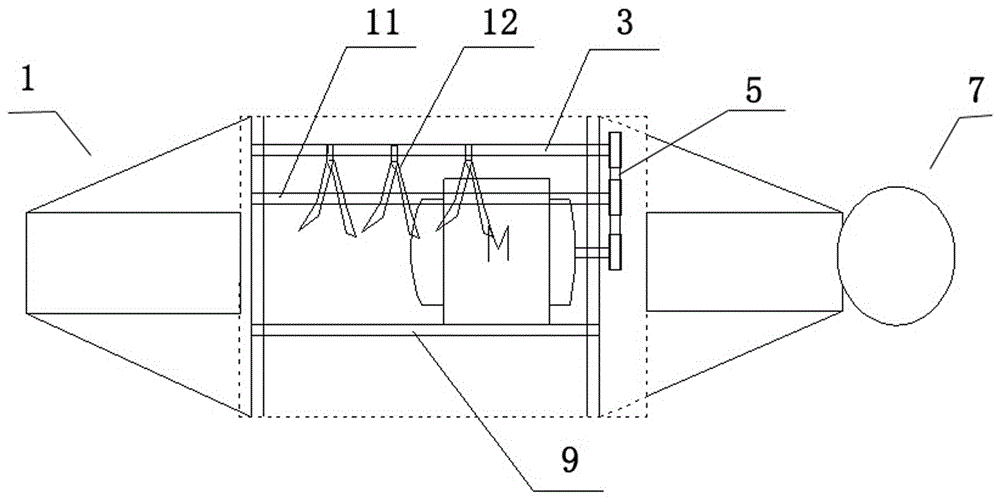

[0022] Embodiment 1: as Figure 1-2 , a simple air filter cleaning device, which is composed of a centrifugal fan 1, a single-tube bag vacuum cleaner 7, and an air filter cleaning platform 4; the air filter cleaning platform 4 is a closed cleaning platform, which is provided with an inlet port 2 and an outlet end 6, the central axes of the inlet end 2 and the outlet end 6 are coincident and parallel to the ground, the air outlet of the centrifugal fan 1 is connected to the inlet end 2, and the suction port of the single-tube bag vacuum cleaner is connected to the outlet end 6; the air The filter element cleaning platform 4 includes an air filter element support frame, a motor 10 (AC motor or DC motor), and a closed casing. The inlet port 2 and the outlet port 6 of the air filter element cleaning platform 4 are set on the closed casing. The air filter support frame is set in the closed casing and is parallel to the central axis of the inlet port and the outlet port and driven b...

Embodiment 2

[0023] Embodiment 2: as Figure 1-2 , a simple air filter cleaning device, which is composed of a centrifugal fan 1, a single-tube bag vacuum cleaner 7, and an air filter cleaning platform 4; the air filter cleaning platform 4 is a closed cleaning platform, which is provided with an inlet port 2 and an outlet end 6, the central axes of the inlet end 2 and the outlet end 6 are coincident and parallel to the ground, the air outlet of the centrifugal fan 1 is connected to the inlet end 2, and the suction port of the single-tube bag vacuum cleaner is connected to the outlet end 6; the air The filter element cleaning platform 4 includes an air filter element support frame, a motor 10 (AC motor or DC motor), and a closed casing. The inlet port 2 and the outlet port 6 of the air filter element cleaning platform 4 are set on the closed casing. The air filter support frame is set in the closed casing and is parallel to the central axis of the inlet port and the outlet port and driven b...

Embodiment 3

[0024] Embodiment 3: as Figure 1-2, a simple air filter cleaning device, which is composed of a centrifugal fan 1, a single-tube bag vacuum cleaner 7, and an air filter cleaning platform 4; the air filter cleaning platform 4 is a closed cleaning platform, which is provided with an inlet port 2 and an outlet end 6, the central axes of the inlet end 2 and the outlet end 6 are coincident and parallel to the ground, the air outlet of the centrifugal fan 1 is connected to the inlet end 2, and the suction port of the single-tube bag vacuum cleaner is connected to the outlet end 6; the air The filter element cleaning platform 4 includes an air filter element support frame, a motor 10 (AC motor or DC motor), and a closed casing. The inlet port 2 and the outlet port 6 of the air filter element cleaning platform 4 are set on the closed casing. The air filter support frame is set in the closed casing and is parallel to the central axis of the inlet port and the outlet port and driven by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com