Pressure transducer and preparation method thereof

A pressure sensor and circuit board technology, applied in the direction of measuring fluid pressure, piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve product sealing and long-term stability of overload capacity Corrosion resistance and other problems, to achieve the effect of improving long-term product stability, reducing stress, and improving sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

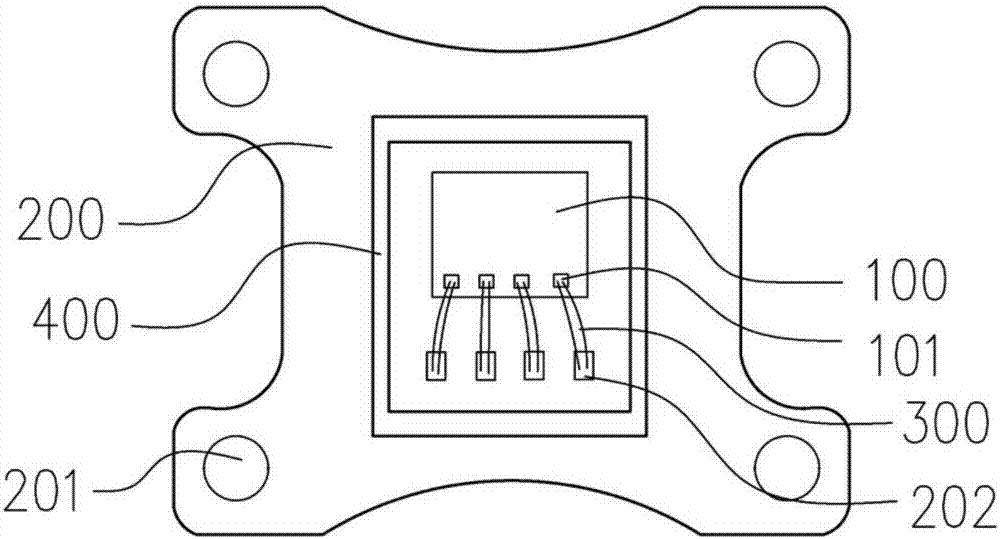

[0035] see Figure 1-3 , a pressure sensor having:

[0036] A circuit board 202, the side of the circuit board is provided with an inwardly recessed arc edge, and the circuit board is also provided with a circuit board pad 202 and a positioning hole 201;

[0037] The chip 100 is installed on the lower part of the circuit board, and the chip and the circuit board are bound by double gold wires; and the chip covering glue 700 is set to cover the chip;

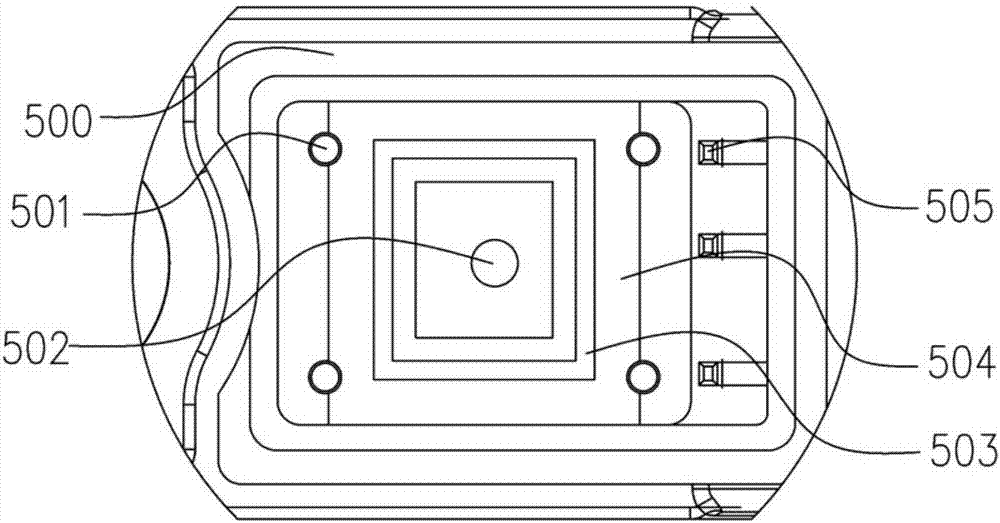

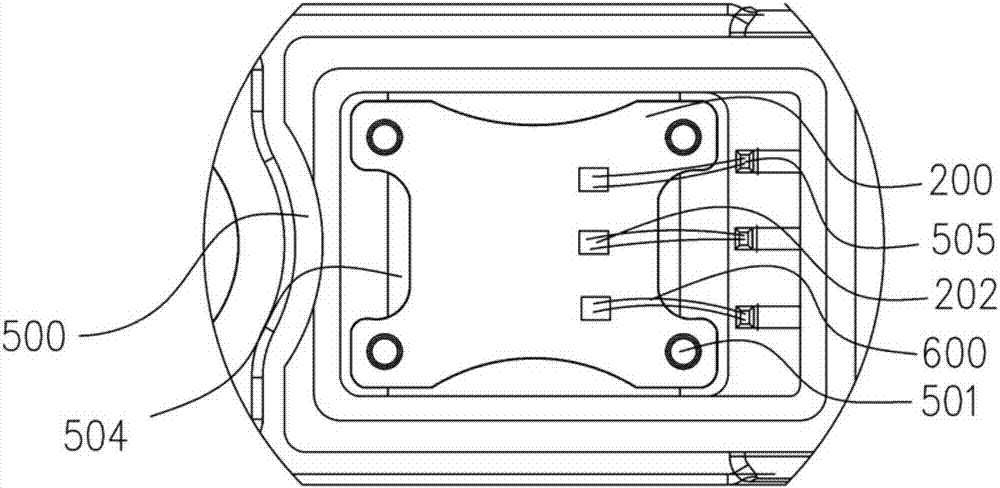

[0038] The housing 500, the housing 500 is provided with a first installation groove, the bottom of the first installation groove is provided with a second installation groove, the chip is installed in the second installation groove, and the bottom of the second installation groove is provided with a vent hole 502; The circuit board is installed in the first installation groove; steps 503 are provided around the notch of the second installation groove, and the steps 503 support the circuit board; grooves 504 are arranged on the ...

Embodiment 2

[0047] The manufacturing method of sensor, concrete implementation is as follows

[0048] 1. Chip packaging on the circuit board

[0049] Bond the MEMS chip ML808 to the circuit board through a die bonder, and fix it with a high-temperature curing adhesive. Use a 1.0mil gold wire to connect the pads of the MEMS chip and the pads 202 of the circuit board through a fully automatic bonding machine. Perform double-wire bonding, and the binding single-wire tensile force requires more than 7g. After the bonding is completed, use a manipulator to bond and fix the plastic retaining ring 400 around the periphery of the MEMS chip, and seal the chip covering glue 700 in the retaining ring 400 .

[0050] The bonding of the chip adopts 1.0mil double gold wire bonding, the gold wire has good conductivity and ductility, and the double gold wire bonding reduces the risk of the bonding wire disconnection, which improves the fatigue life of the product and the durability of the product. servic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com