A kind of vanadium-chromium-titanium alloy plate and preparation method thereof

A technology of titanium alloy plate and alloy plate, which is applied in the field of metal plastic processing, can solve the problems of high price and limit the popularization and application of alloys, achieve good effect, reduce the probability of cracks on the processed surface, and achieve the effect of uniform heating and temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

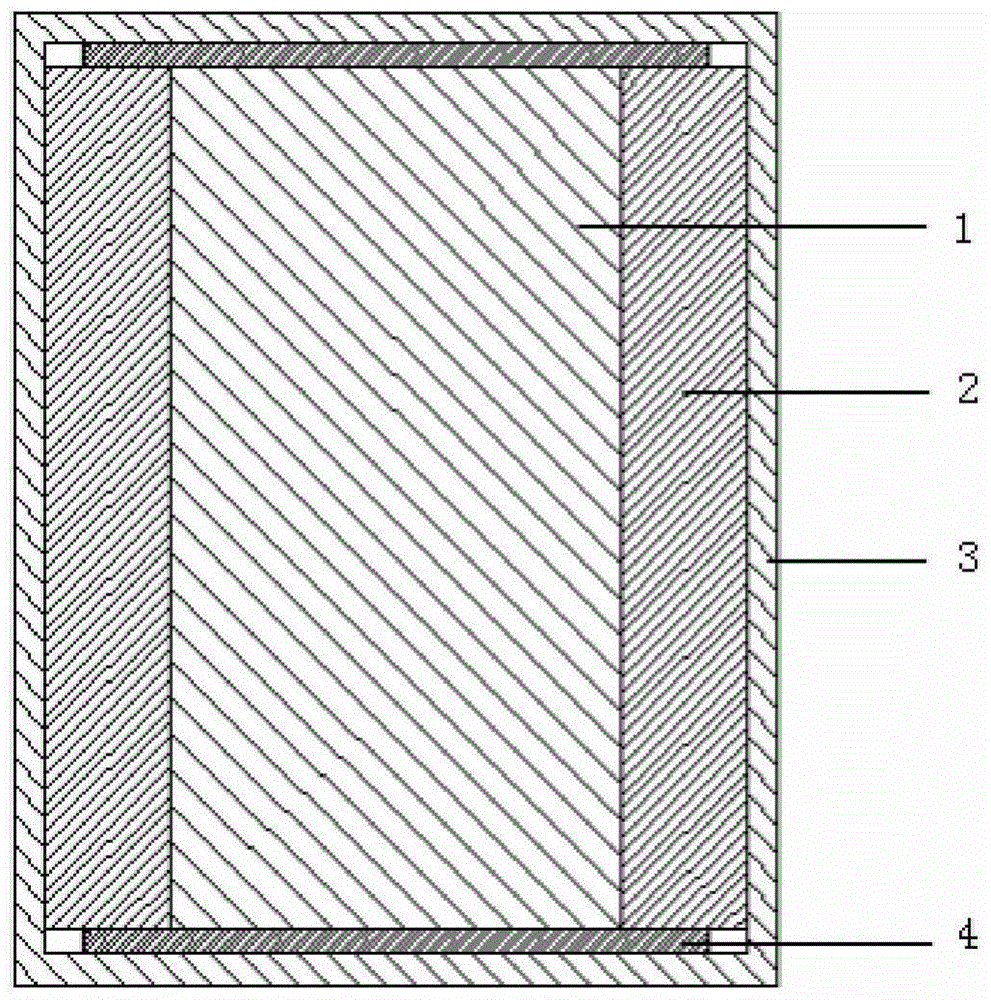

Image

Examples

preparation example Construction

[0042] A kind of preparation method of vanadium-chromium-titanium alloy plate of the present invention comprises the following steps:

[0043] a. Prepare V 88-94%, Cr 2.9-6%, Ti 2.6-6% according to the weight percentage of the raw material composition of the alloy plate, and the balance is unavoidable impurities with a total mass≤0.5%;

[0044] b. Use the raw material prepared in step a to obtain the crude product of V-Cr-Ti alloy by metallothermic reduction method, and melt it into a standard V-Cr-Ti alloy ingot in a vacuum environment, and heat it in a vacuum furnace at 3 to 20°C Heat up to 1000-1350°C at a rate of 1 / min, keep warm for 0.5-8h, and cool down to room temperature with the furnace under vacuum;

[0045] In this step, the alloy raw material is prepared by metallothermic reduction method + vacuum induction refining method to obtain alloy ingots under the standard requirements, and heat treatment in a vacuum heating furnace can eliminate casting stress and make the...

Embodiment 1

[0064] (1) Prepare V 92%, Cr3.9%, Ti4% according to the weight percentage of the raw material composition of the alloy plate, and the balance is the unavoidable impurities of the total mass≤0.5%;

[0065] (2) Using Ca thermal reduction method + two times of water-cooled copper crucible vacuum induction melting V-3.9wt%Cr-4wt%Ti alloy ingot, put the ingot into a vacuum heating furnace and raise the temperature to 1100 at a rate of 5°C / min After 1 hour of heat preservation at ℃, the vacuum degree in the furnace is 5×10 -3 Pa, after the heat preservation is over, the vacuum is cooled with the furnace;

[0066] (3) Cut a cylindrical billet with a thickness of 50mm on the ingot after vacuum annealing and chamfer the corners. -3 Pa, then the temperature was raised to 800°C at a rate of 5°C / min, and the holding time was 1h; after the holding time was completed, the sheath was sealed and welded to obtain an alloy forged sheath body.

[0067] (4) Heat the alloy forging sheath body in...

Embodiment 2

[0076] (1) Prepare V 90%, Cr 5.3%, Ti 4.6% according to the weight percent of the raw material composition of the alloy plate, and the balance is unavoidable impurities of total mass≤0.5%;

[0077] (2) Adopt Ca thermal reduction method + three water-cooled copper crucible vacuum induction smelting to obtain V-5.3wt%Cr-4.6wt%Ti alloy ingot, put the ingot into a vacuum heating furnace and heat up to After holding at 1100°C for 1 hour, the vacuum in the furnace is 5×10 -3 Pa, after the heat preservation is over, the vacuum is cooled with the furnace;

[0078] (3) Cut a cylindrical billet with a thickness of 40mm from the ingot after vacuum annealing and chamfer the corners. -3 Pa, then the temperature was raised to 800°C at a rate of 10°C / min, and the holding time was 1h; after the holding time was completed, the sheath was sealed and welded to obtain an alloy forged sheath body.

[0079] (4) Heat the alloy forging sheath body in a box-type resistance furnace at a rate of 10°C / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com