Si-B-C gradient anti-oxidation coating of carbon/carbon composite material and preparation method of Si-B-C gradient anti-oxidation coating

A carbon composite material and anti-oxidation coating technology, applied in the field of Si-B-C gradient anti-oxidation coating and preparation, can solve the problems of limited service life of the coating system, unsatisfactory oxidation protection effect, high volatility of boric acid glass, etc. , to achieve the effect of improving antioxidant performance, short experimental period and small fiber damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

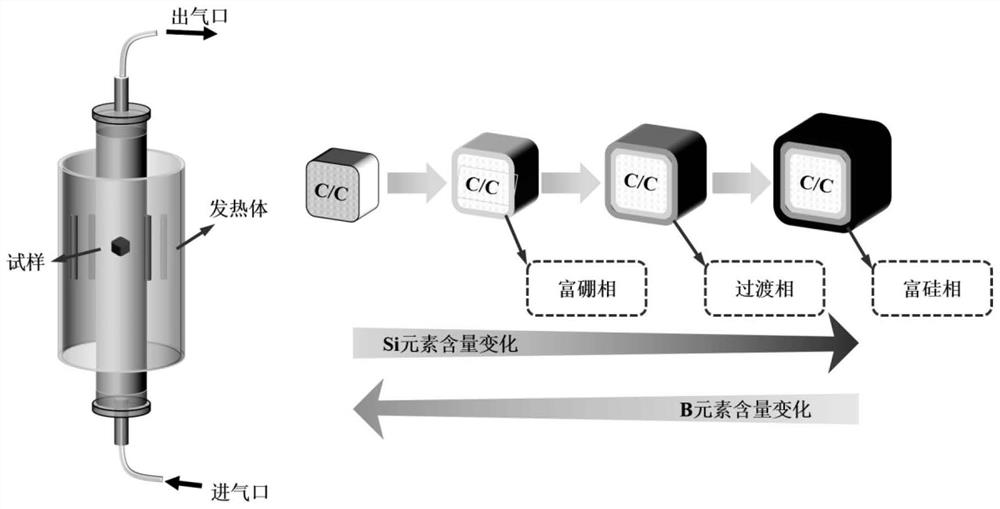

Method used

Image

Examples

Embodiment 1

[0037] 1): Using a two-dimensional C / C composite material with a density of 1.7g / cm3 as the matrix, cut samples with a size of 10mm×10mm×10mm from the C / C composite material, and use 400 mesh SiC sandpaper for all samples Polish, then ultrasonically clean with ethanol, and dry in an oven at a temperature of 60-100°C for 2-4 hours.

[0038] 2): Suspend the C / C substrate in the deposition area of the vertical resistance furnace, evacuate to below -0.09Mpa, pass Ar as the protective gas, and raise the furnace temperature to 950°C at a heating rate of 3-10°C / min , when the temperature in the furnace reaches the deposition temperature, the diluted Ar, the reaction H2 and the boron source BCl3 are first introduced, and then the bubbling method is used to bring methyltrichlorosilane (MTS) into the reaction zone for deposition. During this process, the gas flow rate The control range is: dilute Ar: 500-600ml / min, react H 2 : 900-1000ml / min, boron source BCl 3 : 500ml / min, MTS: 0.1...

Embodiment 2

[0042] 1): Using a two-dimensional C / C composite material with a density of 1.7g / cm3 as the matrix, cut samples with a size of 10mm×10mm×10mm from the C / C composite material, and use 400 mesh SiC sandpaper for all samples Polish, then ultrasonically clean with ethanol, and dry in an oven at a temperature of 60-100°C for 2-4 hours.

[0043] 2): Suspend the C / C substrate in the deposition area of the vertical resistance furnace, evacuate to below -0.09Mpa, pass Ar as the protective gas, and raise the furnace temperature to 1050°C at a heating rate of 3-10°C / min , when the temperature in the furnace reaches the deposition temperature, the diluted Ar is first introduced, and the reaction H 2 and boron source BCl 3 , and then use the bubbling method to bring methyltrichlorosilane (MTS) into the reaction zone for deposition. The gas flow control range during this process is: dilute Ar: 500-600ml / min, react H 2 : 900-1000ml / min, boron source BCl 3 : 500ml / min, MTS: 0.1-0.2g / min;...

Embodiment 3

[0047] 1): Using a two-dimensional C / C composite material with a density of 1.7g / cm3 as the matrix, cut samples with a size of 10mm×10mm×10mm from the C / C composite material, and use 400 mesh SiC sandpaper for all samples Polish, then ultrasonically clean with ethanol, and dry in an oven at a temperature of 60-100°C for 2-4 hours.

[0048] 2): Suspend the C / C substrate in the deposition area of the vertical resistance furnace, evacuate to below -0.09Mpa, pass Ar as the protective gas, and raise the furnace temperature to 1150°C at a heating rate of 3-10°C / min , when the temperature in the furnace reaches the deposition temperature, the diluted Ar is first introduced, and the reaction H 2 and boron source BCl 3 , and then use the bubbling method to bring methyltrichlorosilane (MTS) into the reaction zone for deposition. The gas flow control range during this process is: dilute Ar: 500-600ml / min, react H 2 : 900-1000ml / min, boron source BCl 3 : 500ml / min, MTS: 0.1-0.2g / min;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com