Sealing method of high sealing quasi-horizontal drilling hole

A horizontal drilling and high-sealing technology, which is applied in the directions of sealing/isolation, earthwork drilling, gas discharge, etc., can solve the problems of difficult sealing, reduced sealing effect, and difficult effective sealing of rupture areas, etc., and achieves low cost , the effect of high sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

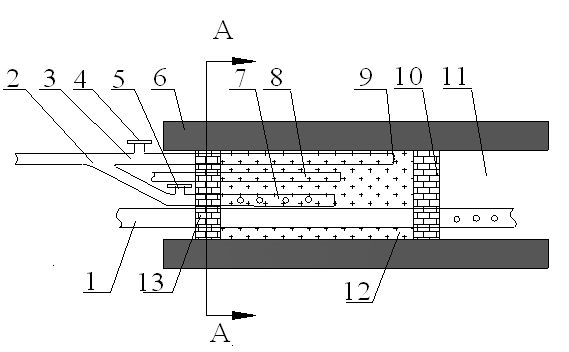

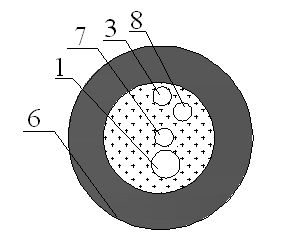

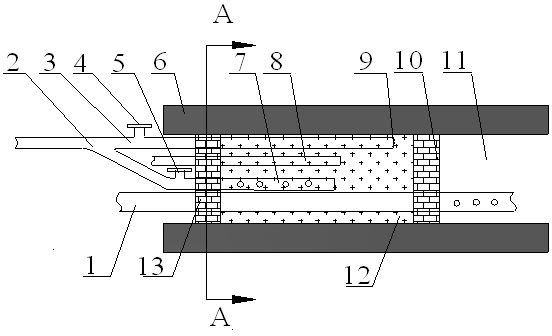

[0015] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0016] The high-tightness near-horizontal borehole sealing method of the present invention: first make a gas drainage borehole 11 conventionally in this coal seam, and the hole depth and aperture of the gas drainage borehole 11 are determined according to the actual situation on the spot (such as the depth of the hole) 100m, pore diameter Φ113mm), at a position 1.4-1.6m away from the front end of the gas drainage pipe 1, fix the I-bag double-material composite sealing material 10 with adhesive tape; After the double-material extrusion mixing in the sealing material 10 is uniform, quickly send the gas drainage pipe 1 into the drainage borehole 11 for inner layer sealing. The width is 0.5m, and the bagged double-material composite sealing material adopts PB composite sealing material including black material and white material. Fix the gas drainage pipe 1 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com