In-situ exploitation flow-heat transfer experiment device for compact oil shale

A technology for in-situ mining and experimental equipment, which is applied in the fields of production fluid, earthwork drilling, wellbore/well components, etc. The output, experimental data are true and reliable, and the experimental feasibility is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. It should be understood by those skilled in the art. The content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention. In the description of the present invention, it should be understood that the terms "first", "second", "third", "fourth", and "fifth" are only used for descriptive purposes, and are defined as "first", " The characteristics of second", "third", "fourth" and "fifth" do not indicate any order, quantity or importance, but are used only to distinguish different components.

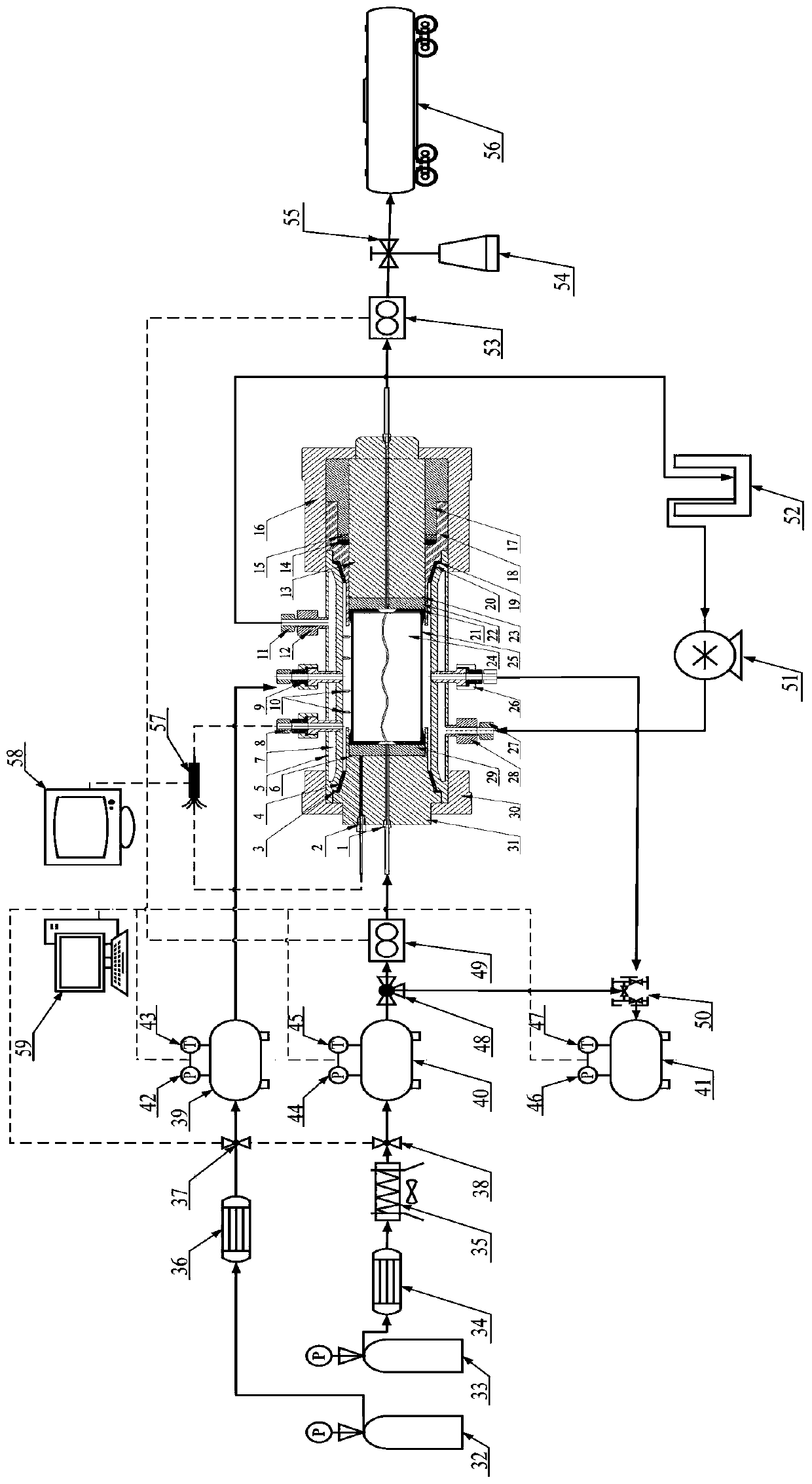

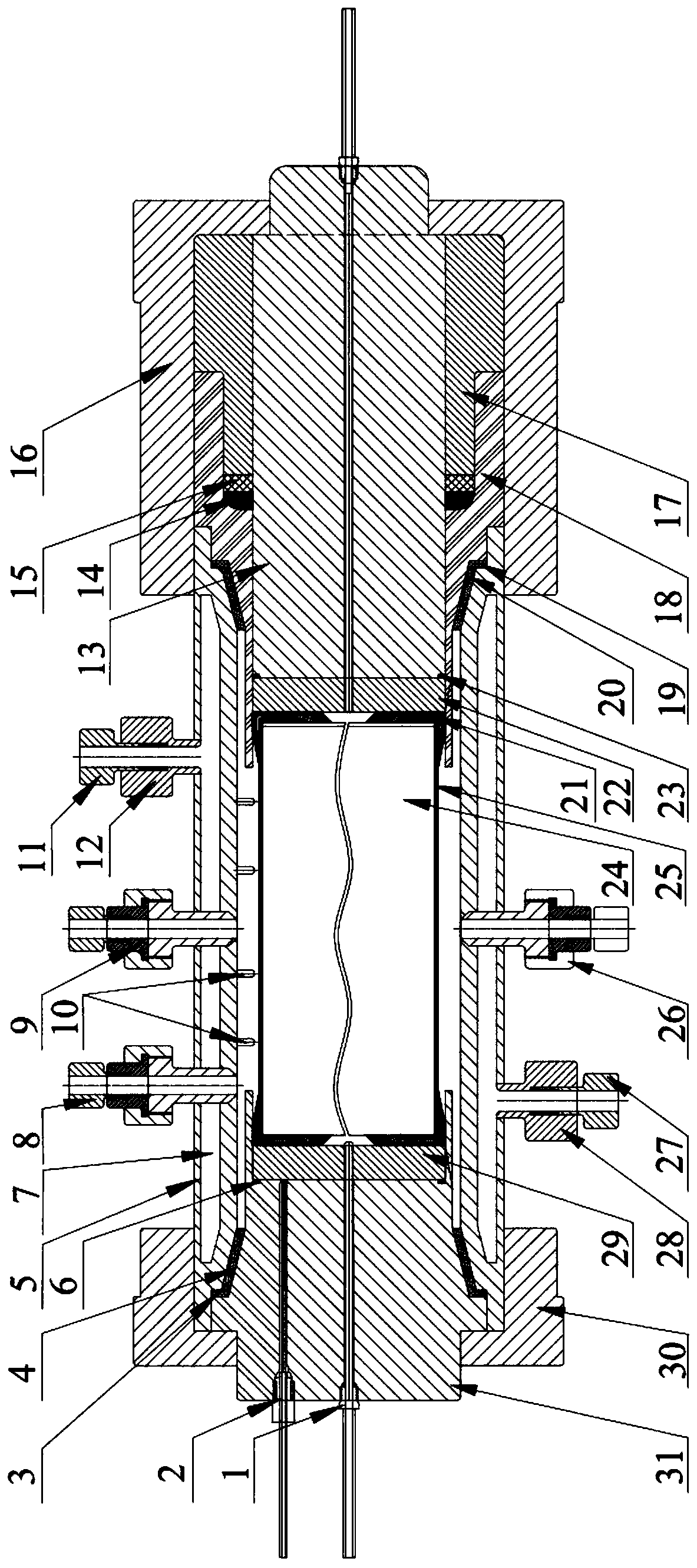

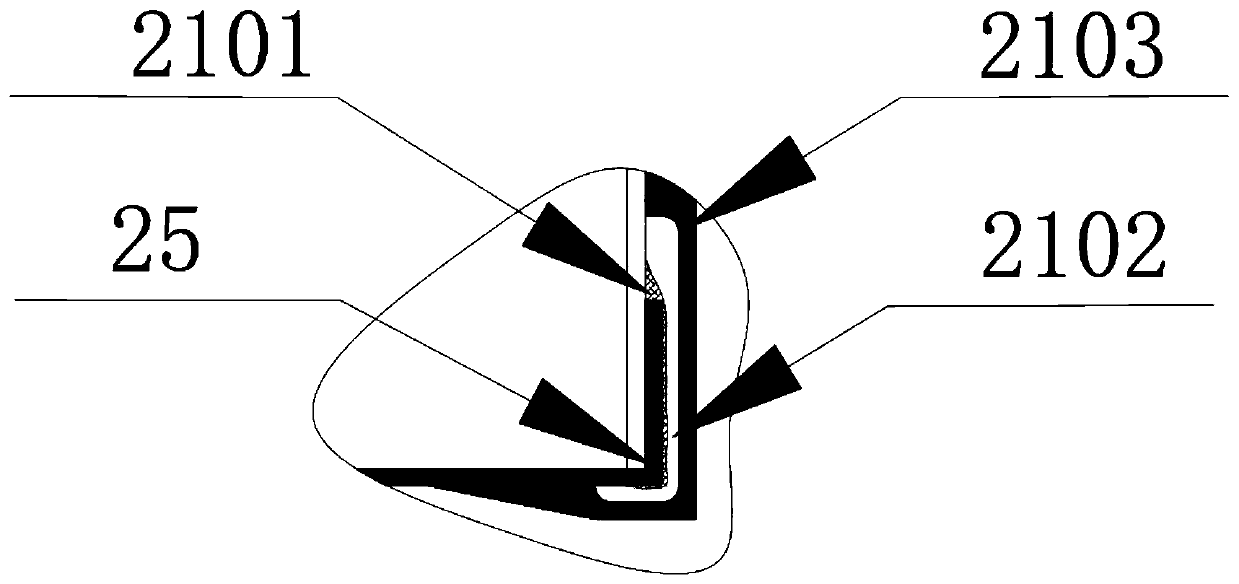

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention proposes a seepage-heat transfer experimental device for in-situ mining of tight oil shale, including a seepage-he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com