Patents

Literature

42results about How to "Prevent misalignment and deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

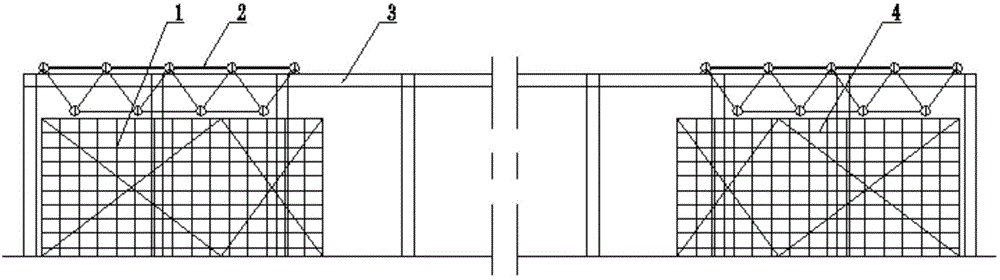

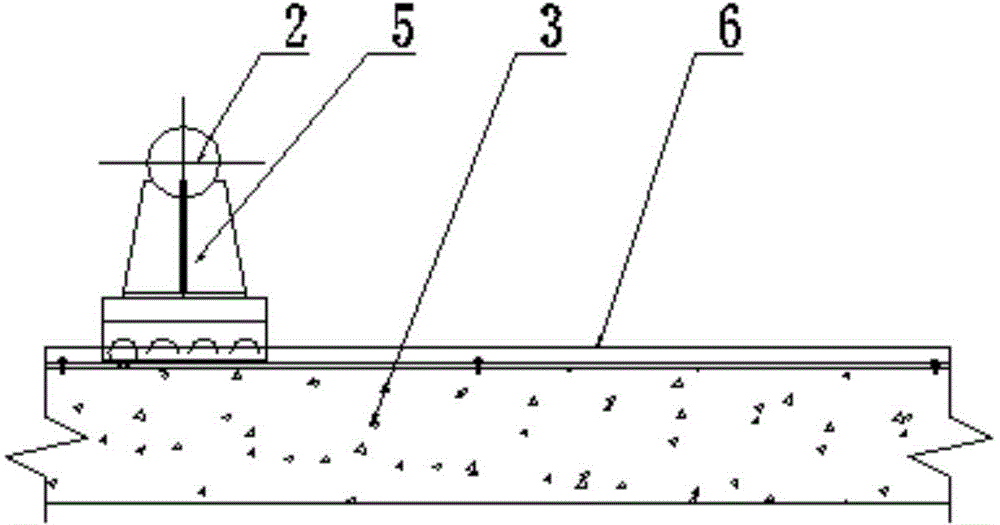

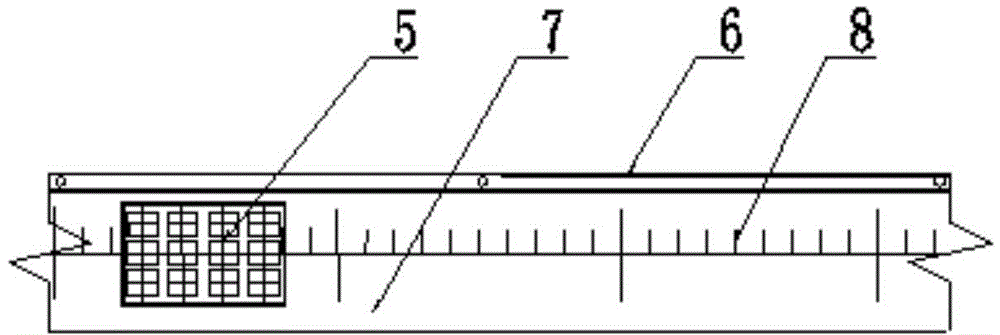

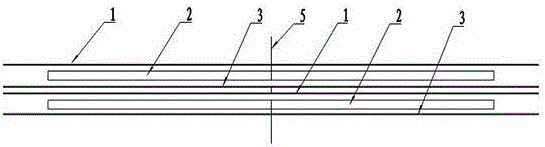

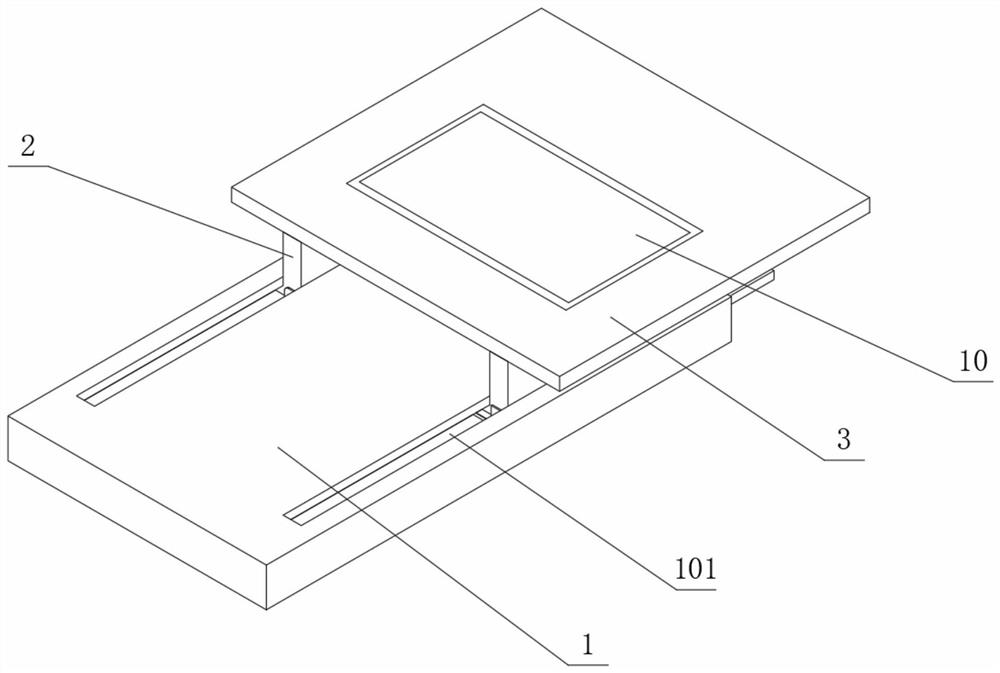

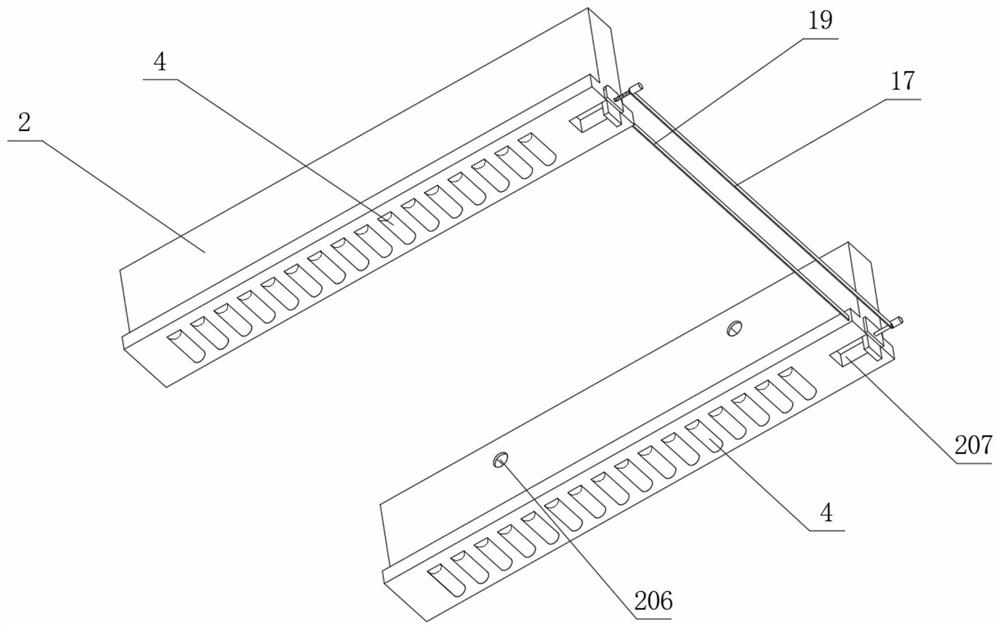

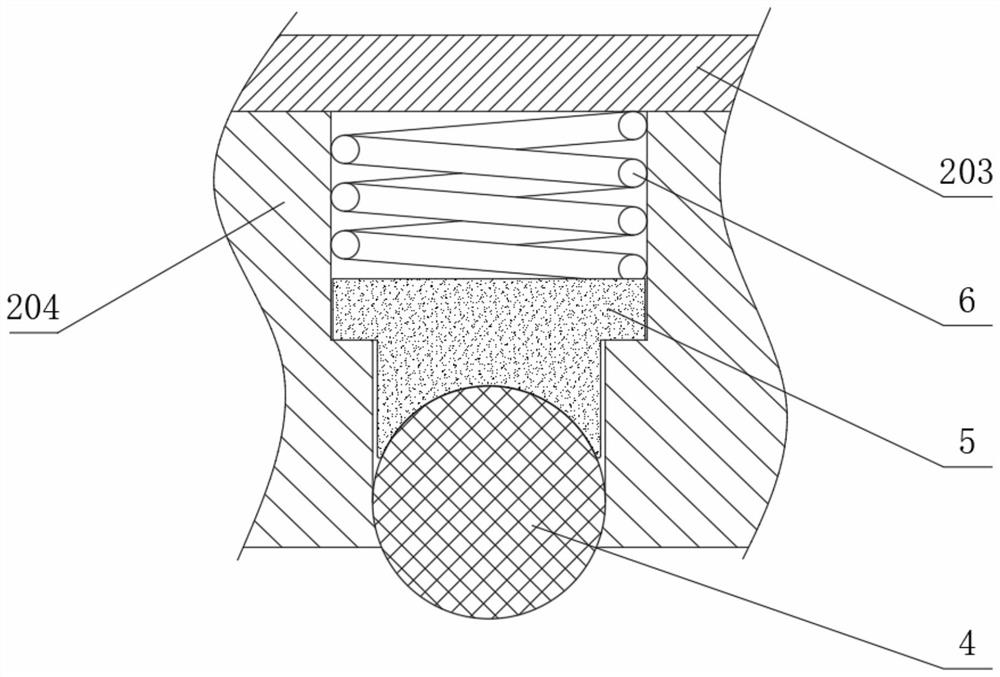

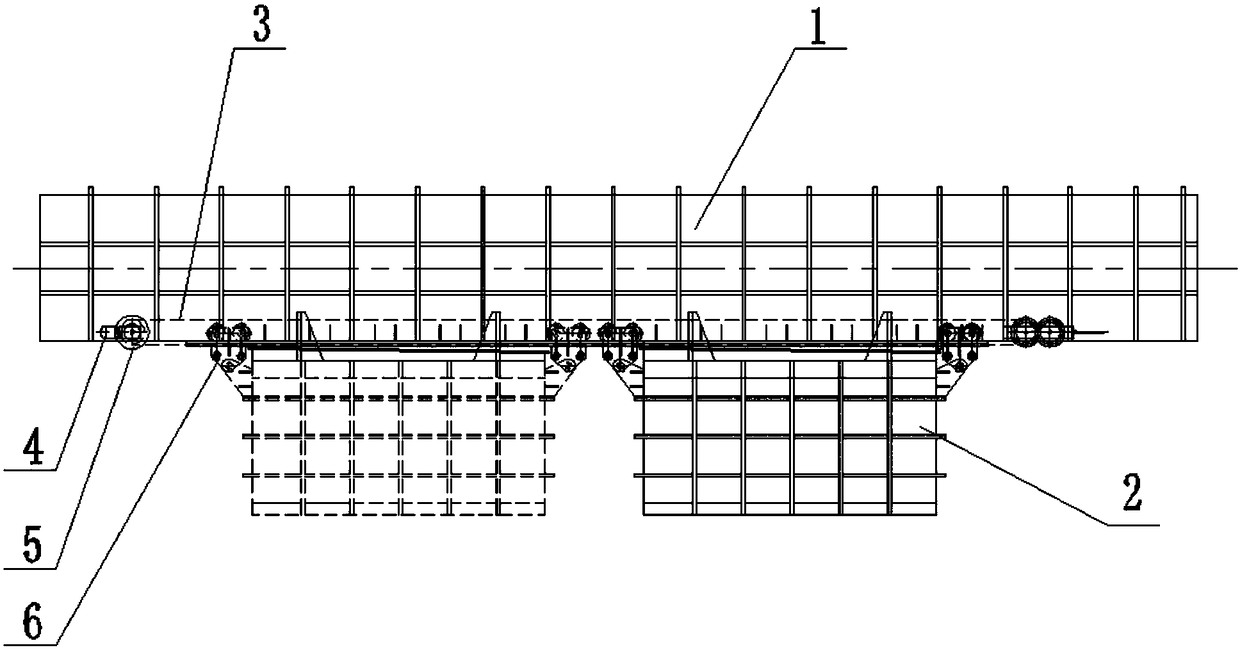

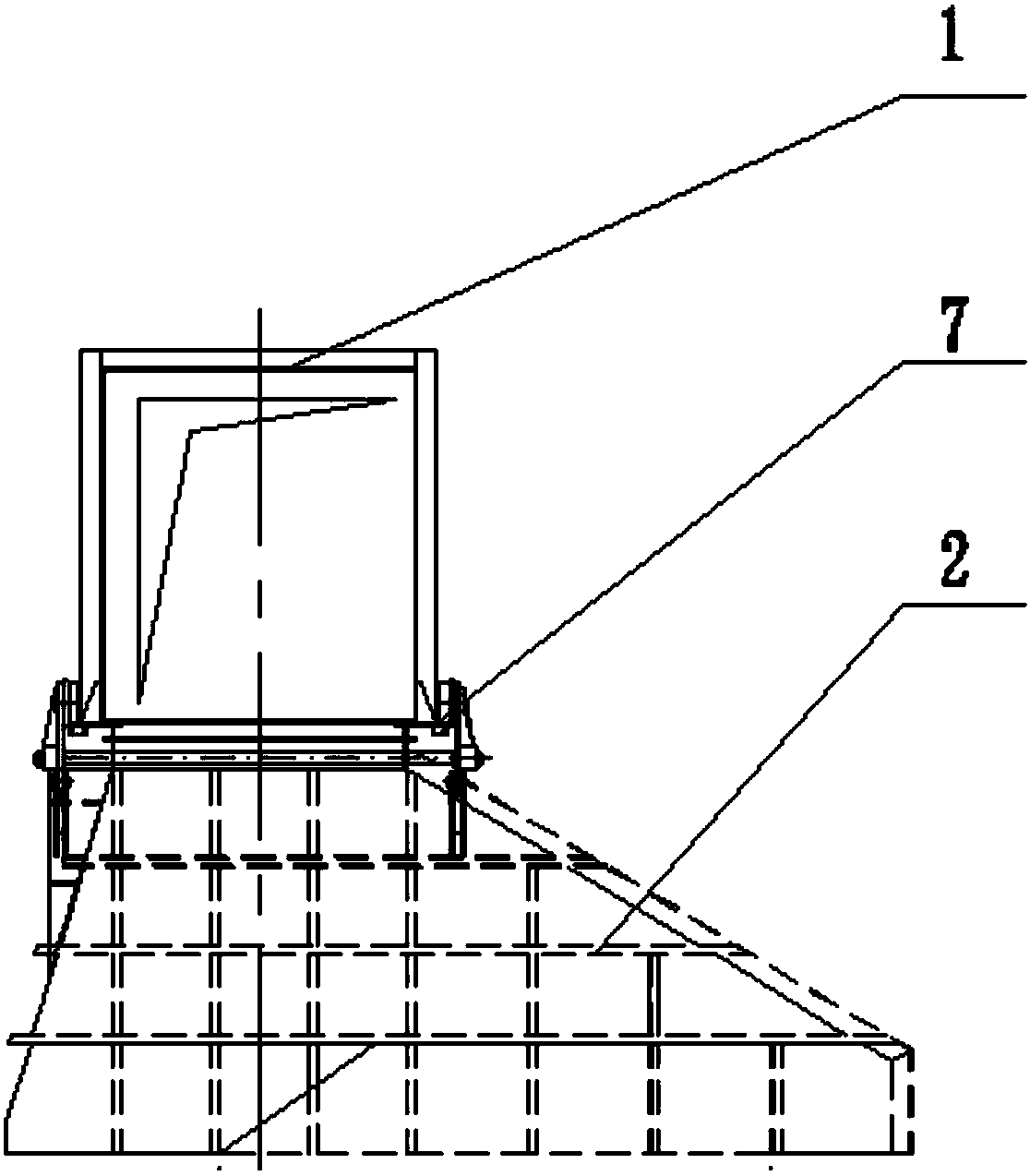

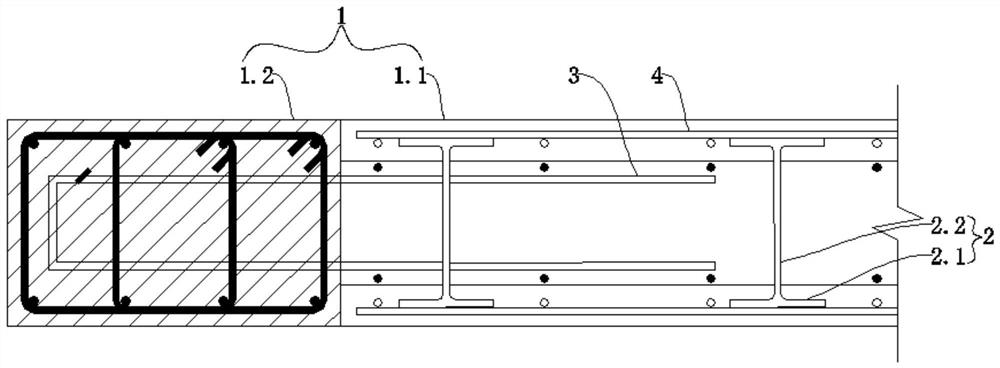

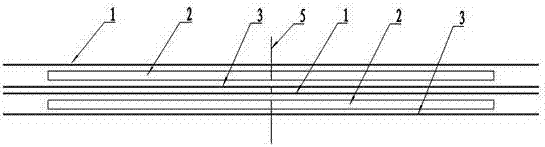

High altitude spherical net rack splicing method based on large gymnasium frame continuous beam

InactiveCN103603502AReduce occupancyShorten the construction periodBuilding material handlingContinuous beamEngineering

The invention relates to a high altitude spherical net rack splicing method based on a large gymnasium frame continuous beam. The method includes the following steps: (1) building a left installation platform and a right installation platform under two ends of the large gymnasium frame continuous beam respectively; (2) installing a slide on the large gymnasium frame continuous beam and installing net rack moving trolleys at two ends of the slide in a sliding mode; (3) dividing a high altitude spherical net rack into N sections with the length being N meters and obtained through calculation; (4) splicing an L-meter high altitude spherical net rack and erecting the net rack on the net rack moving trolleys; (5) utilizing a drawing device to draw the net rack moving trolleys to enable the L-meter high altitude spherical net rack to move forward for L meters relatively and respectively and repeating the steps to assemble the whole high altitude spherical net rack in a splicing mode to finish the splicing. The net rack splicing method can shorten construction time, a sliding moving system is simple to machine and manufacture, sliding moving operation is high in speed, occupied space is small, labor intensity of workers is reduced, and the construction period is shortened.

Owner:MCC TIANGONG GROUP

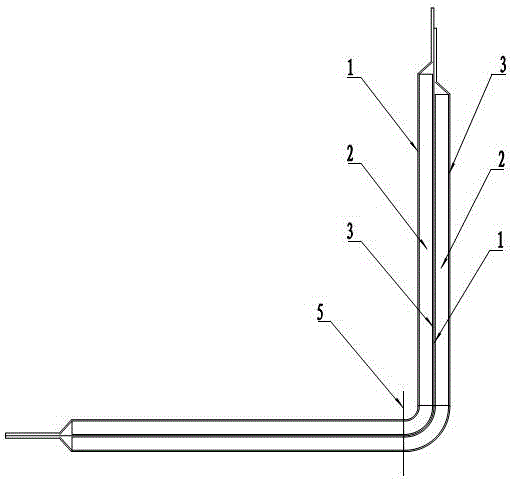

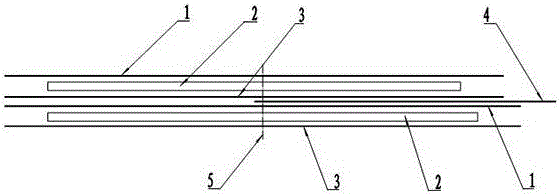

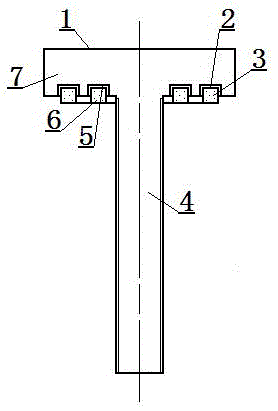

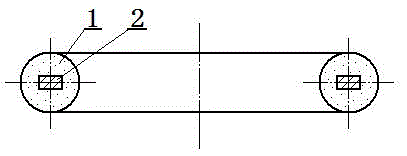

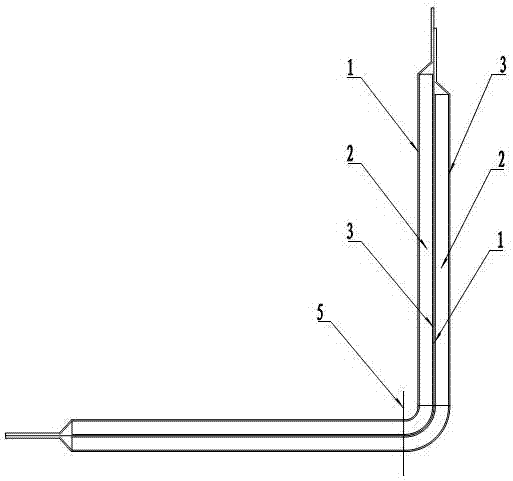

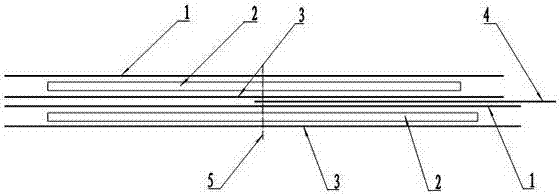

Composite busbar bending process

ActiveCN106205867AAvoid crackingPrevent misalignment and deformationSingle bars/rods/wires/strips conductorsCable/conductor manufactureBusbarEngineering

The invention discloses a composite busbar bending process, and belongs to the technical field of production of composite busbars. The composite busbar bending process comprises the following steps of (1) lamination, stacking at least two layers up and down, wherein the structure of each layer is a first insulating layer, a copper bar and a second insulating layer in sequence from top to bottom, the right part of each adjacent layer is provided with an anti-bonding layer and the left part is glued for bonding, and the length of each anti-bonding layer is greater than or equal to that of the bent and staggered part; (2) laminating and gluing; (3) bending in place; and (4) extraction of the anti-bonding layers to obtain a bent composite busbar. By the composite busbar bending process, cracking of the bent part of the composite busbar and stagger deformation between the layers can be prevented; the quality is ensured; the yield is improved; the efficiency is improved; and the cost is reduced.

Owner:沧州惠邦重工装备制造有限公司

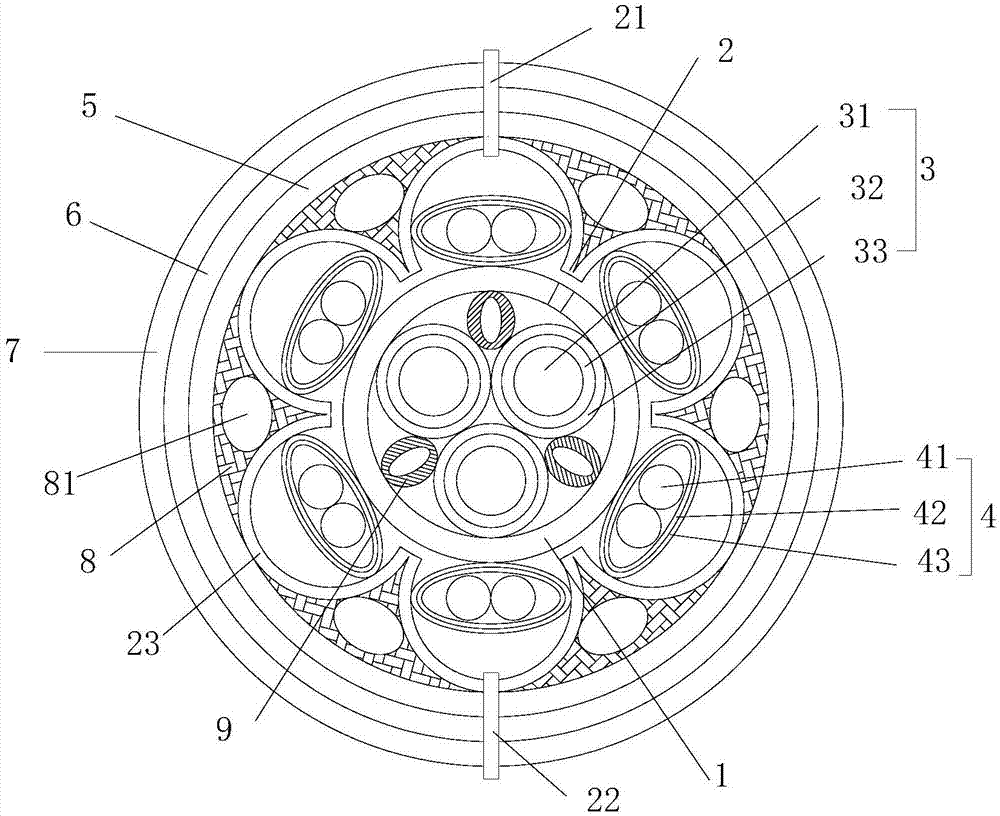

Anti-extruding stretch-proof power cable

InactiveCN107369497AAvoid destructionEasy to useInsulated cablesInsulated conductorsPower cableEngineering

The invention proposes an anti-extruding stretch-proof power cable, and the cable comprises a first elastic tube, a second elastic tube, a plurality of first conductors, and a plurality of second conductors. The first elastic tube is disposed at an inner side of the second elastic tube, and the plurality of first conductors are disposed in the first elastic tube in a parallel manner. The second conductors have the elliptical sections, and the short axis of each second conductor is set in the radial direction of the cable. Two ends of each second conductor in each arc-shaped elastic part in the long-axis direction respectively abut against the arc-shaped elastic parts. Moreover, the plurality of second conductors abut against the outer wall of the first elastic tube. The first elastic tube and the second elastic tube are employed for respectively protecting the first conductors and the second conductors, and the interior of the first elastic tube and the interior of the second elastic tube are filled with gas. When the cable is extruded, the extruding force can be buffered through the elastic deformation of the first and second elastic tubes, thereby protecting the first and second conductors from being damaged by extruding, improving the application performance of the cable in a severe environment, and prolonging the service life of the cable.

Owner:JINYUAN ELECTRIC GRP

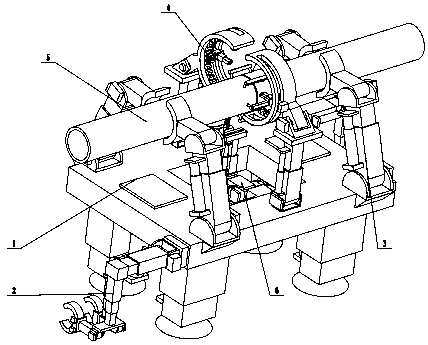

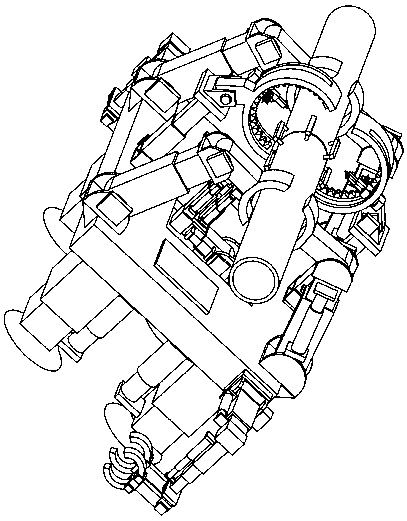

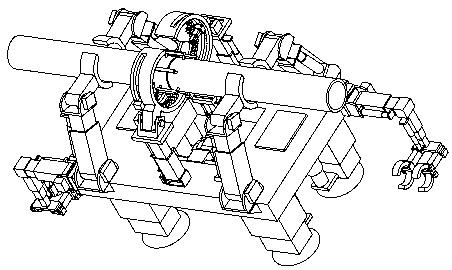

Equipment and process for pipeline welding by using auxiliary positioning device

InactiveCN109702426AEasy to fixWork lessWelding/cutting auxillary devicesAuxillary welding devicesPunchingThermal expansion

The invention discloses equipment and process for pipeline welding by using an auxiliary positioning device. The equipment comprises a base supporting part, a gripping part, a fixing part, a welding part, a pipe display part and a punching nail gun part; a first motor of the gripping part is fixedly mounted on the front end surface of a bottom plate of the base supporting part; the bottom end surface of a fourth supporting seat of the fixing part is fixedly connected with the upper end surface of a supporting plate of the base supporting part; the bottom end surface of a sixth supporting seatof a welded part and the upper end surface of the bottom plate of the base supporting part are fixedly connected; and an eighth telescopic rod is driven by an eighth servo electric cylinder to complete the adjustment of the height of an electric drill, the electric drill of the punching nail gun part punches the end parts of a first pipeline and a second pipeline, and then rake nails are stapled to the punching parts of the first pipeline and the second pipeline by a nail gun. Deformation and dislocation of the pipelines in the welding process are prevented, the strength of pipeline joints canbe strengthened, and the pipeline joints are not prone to cracking in the process of thermal expansion and contraction.

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

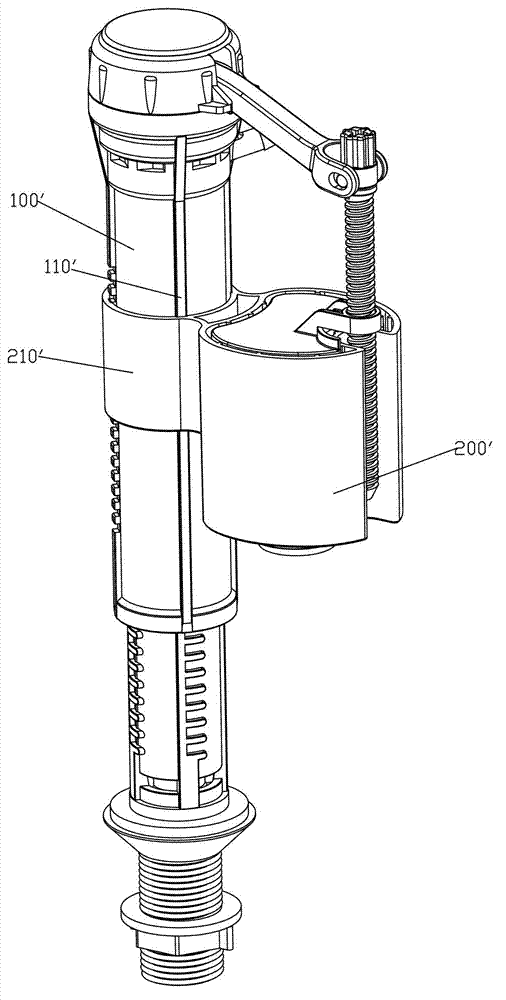

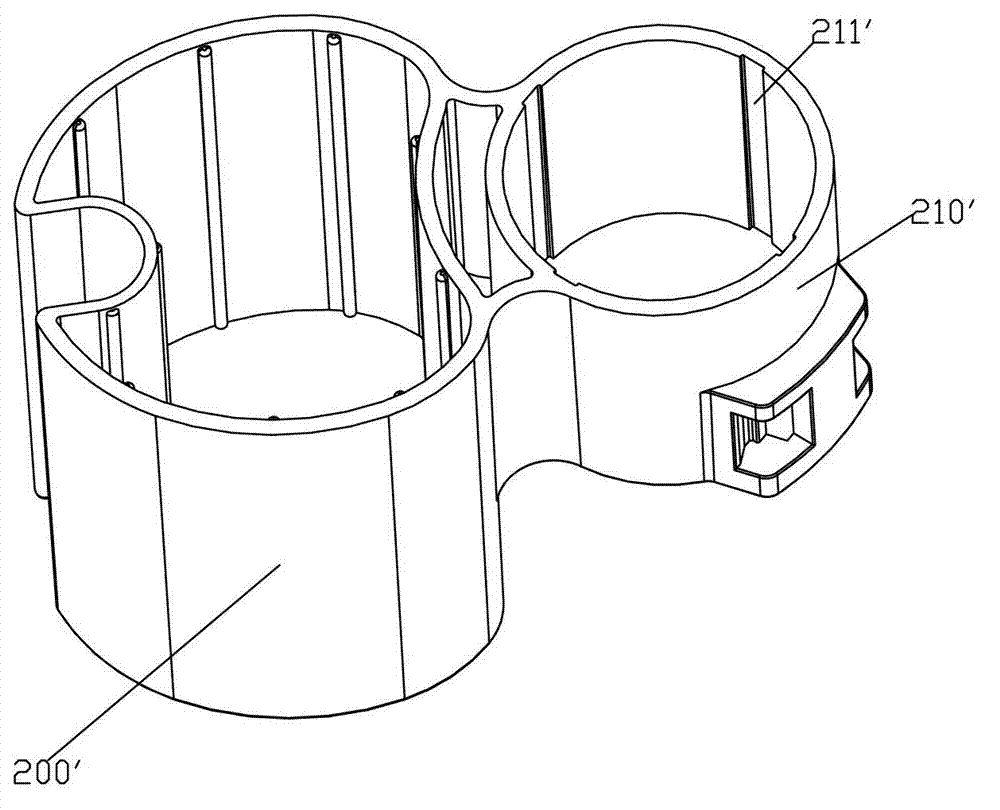

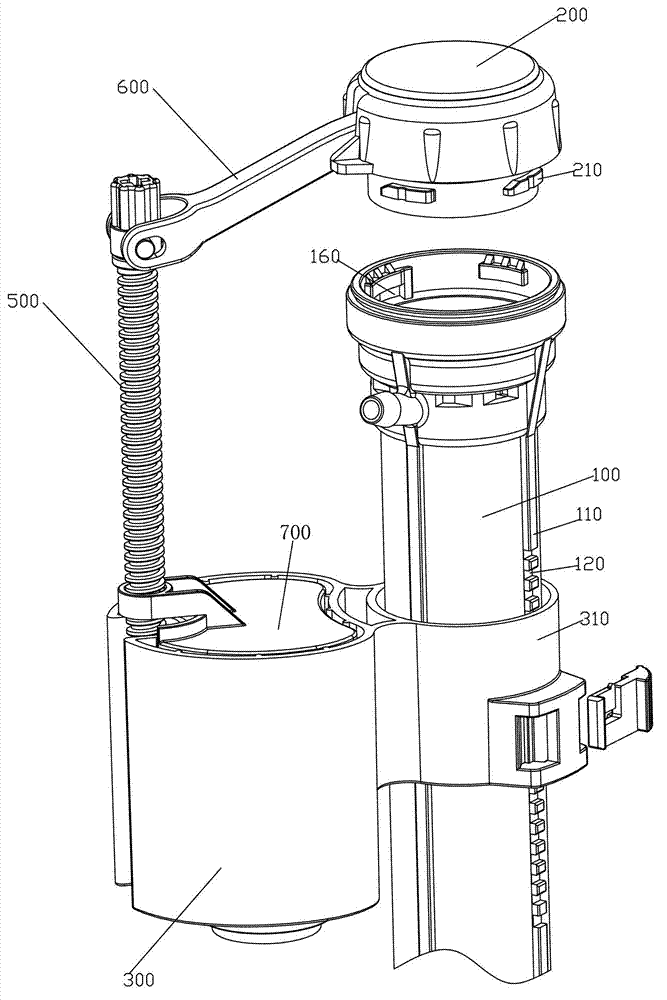

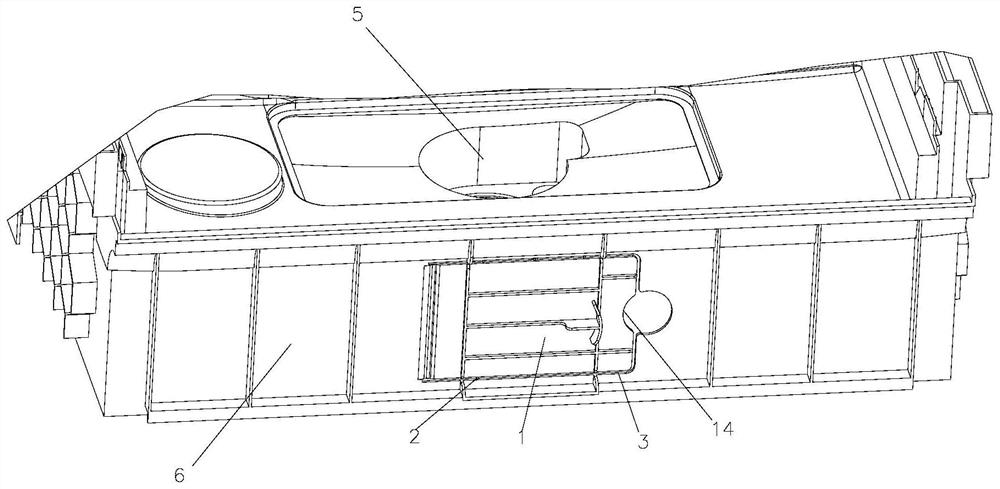

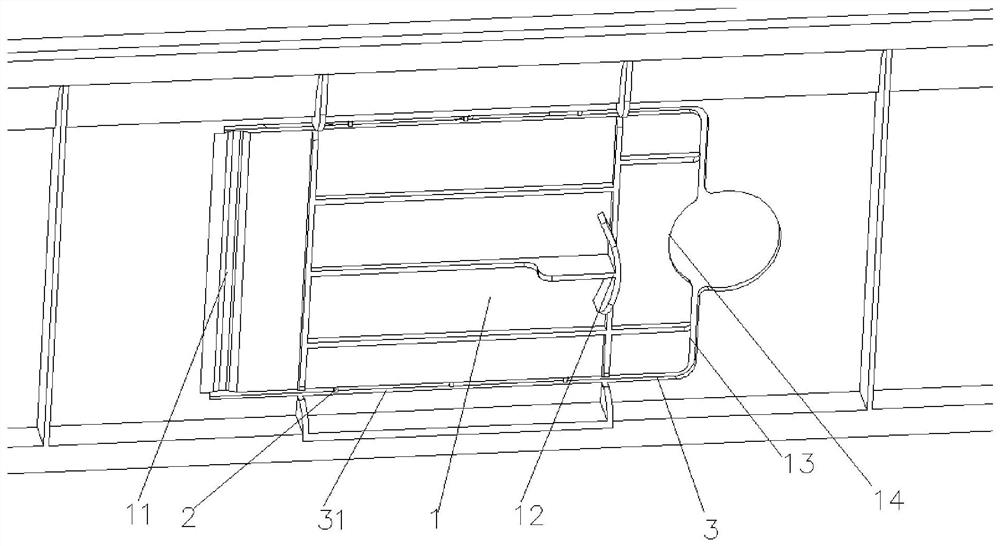

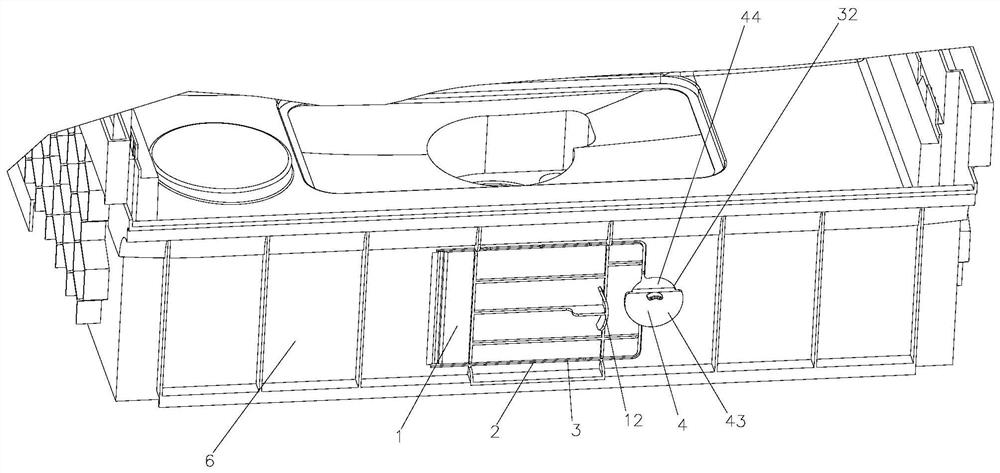

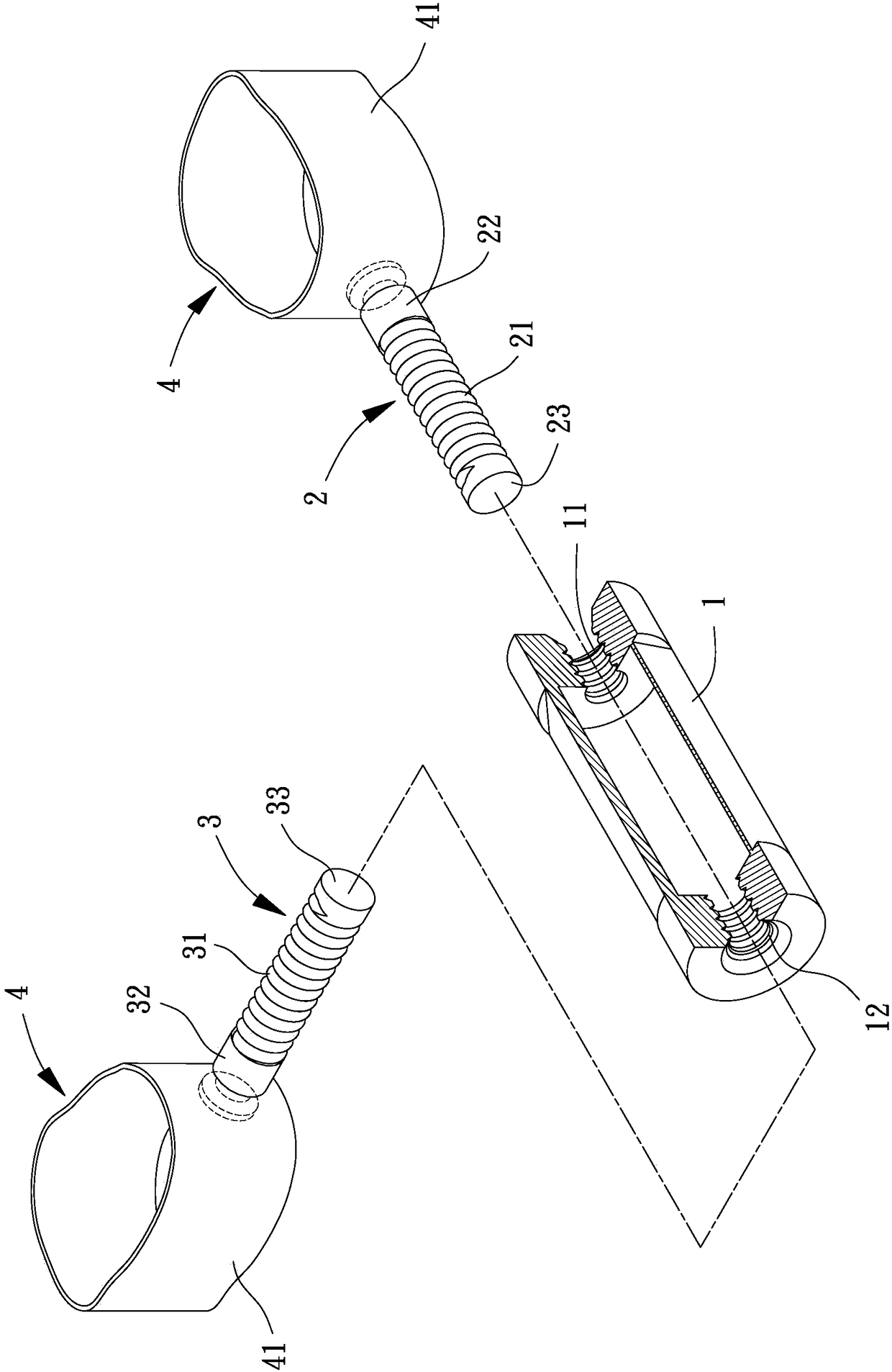

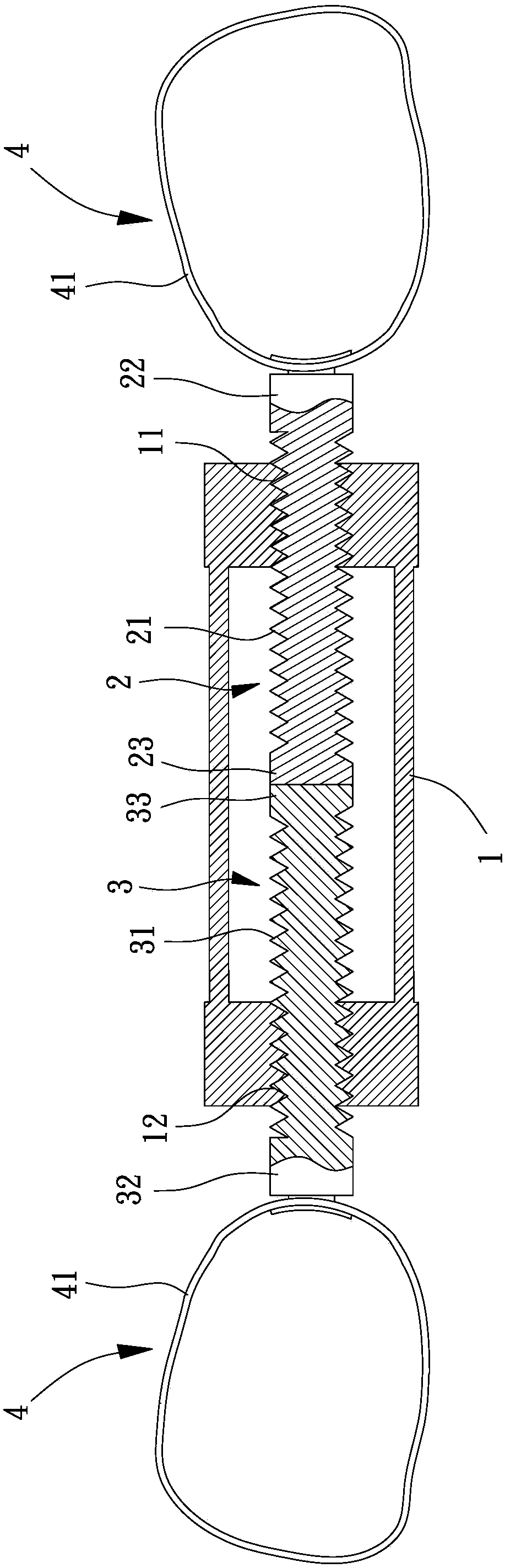

Easily-detachable structure of water inlet valve

ActiveCN102808987AQuick assemblyQuick adjustabilityOperating means/releasing devices for valvesValve housingsInlet valveEngineering

The invention discloses an easily-detachable structure of a water inlet valve, which includes a valve body and a rotating unit, wherein the rotating unit includes an upper cover and a water stop cup in transmission connection with the upper cover; the upper cover is rotationally connected with the top of the valve body; the water stop cup is rotationally connected with the valve body; and the upper cover is rotated to drive the water stop cup to synchronously rotate, so as to enable the upper cover to be connected with or separated from the valve body. The invention has the advantages that when the water inlet valve is in need of repair due to damage, as long as the rotating unit is rotated, the upper cover can be driven to be separated from the valve body, so that the parts inside the water inlet valve can be repaired and maintained, and the easily-detachable structure of the water inlet valve is convenient to dismount and convenient to maintain.

Owner:XIAMEN R&T PLUMBING TECH

Hexagon bolt with sealing rings

InactiveCN105587729ANo dislocation deformationHigh sealing requirementsEngine sealsScrewsCoaxial lineMagnet

The invention discloses a hexagon bolt with sealing rings. A bolt body comprises a screw and a head portion which are of an integral structure. The lower end face of the head portion is provided with an inner ring-shaped groove and an outer ring-shaped groove which are provided with the same coaxial line as the screw, the inner sealing ring is arranged in the inner ring-shaped groove, the outer sealing ring is arranged in the outer ring-shaped groove, and the heights and the sizes of the inner sealing ring and the outer sealing ring are the same and larger than the depths and sizes of the groove bottom of the inner ring-shaped groove and the groove bottom of the outer ring-shaped groove; the bolt body is made of a magnet material, and both the inner sealing ring and the outer sealing ring are made of rubber soft magnetic strips; and both the magnetic face of the inner sealing ring and the magnetic face of the outer sealing ring are upward, and the inner sealing ring and the outer sealing ring are attracted and attached in the inner ring-shaped groove and the outer ring-shaped groove respectively under the magnetic action. The hexagon bolt with the sealing rings has the beneficial effects that the sealing rings can be prevented from generating movement and deformation, the good sealing effect is achieved, and the sealing rings are prevented from falling off from the screw and being lost as well.

Owner:罗福仲

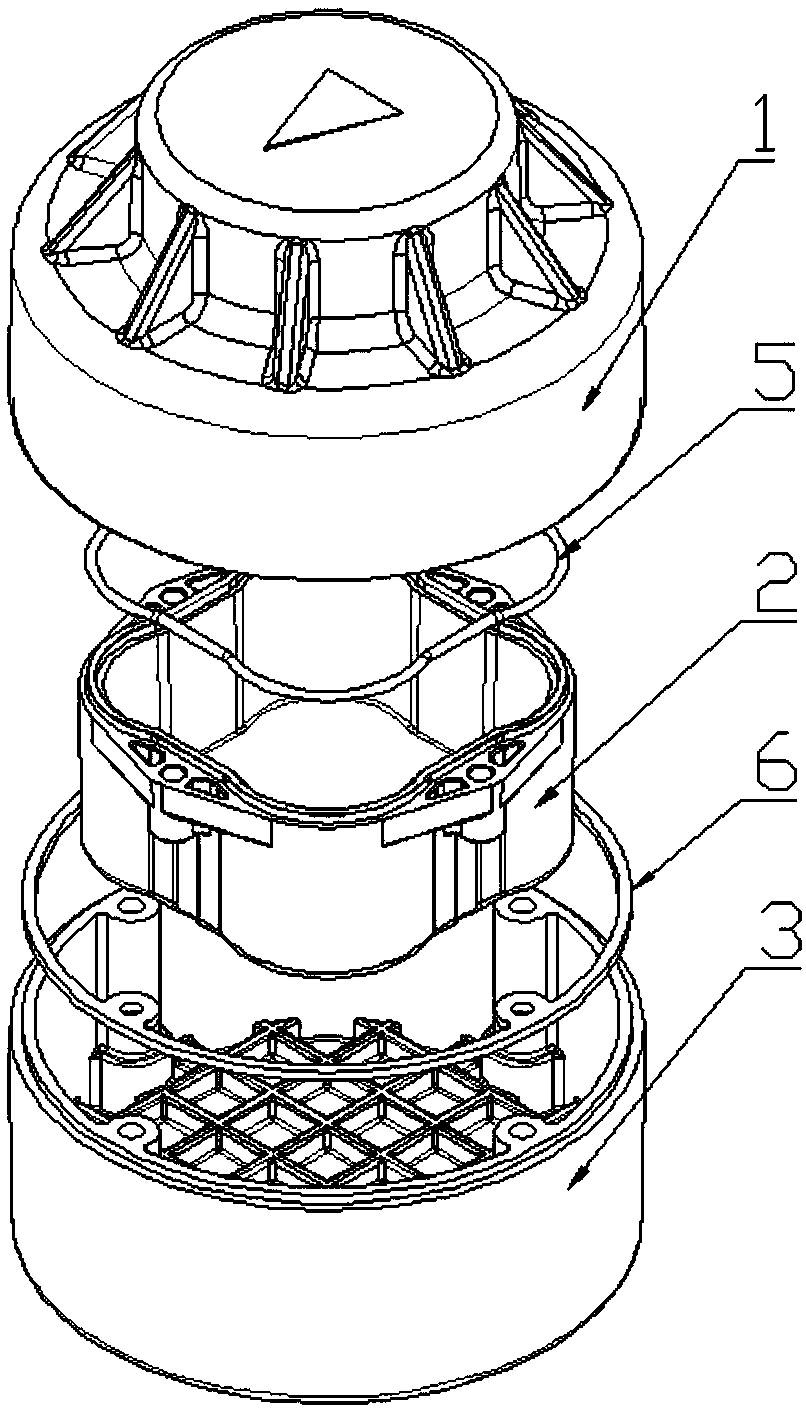

Geomagnetic vehicle inspection device with waterproofness and bearing capability

PendingCN109448396AImprove waterproof performanceAvoid enteringRoad vehicles traffic controlHermetically-sealed casingsElectrical and Electronics engineeringVehicle inspection

The invention relates to a geomagnetic vehicle inspection device with waterproofness and bearing capability. The geomagnetic vehicle inspection device with waterproofness and bearing capability includes an upper housing, an intermediate housing, a lower housing, a circuit board and a battery, wherein the intermediate housing is sleeved in the lower housing; the intermediate housing is in sealed connection with the upper housing; the lower housing and the upper housing are in sealed connection; the intermediate housing and the upper housing form a sealed accommodating cavity; the circuit boardand the battery are arranged in the accommodating cavity; the circuit board is connected with the inner wall of the upper housing; and the circuit board is electrically connected with the battery. Thegeomagnetic vehicle inspection device with waterproofness and bearing capability has a dual-layer structure, and a glue sleeve sleeves the outer side of the housing, thus preferably improving the waterproofness and the bearing capability of the vehicle inspection device.

Owner:中电共建科技(北京)有限公司

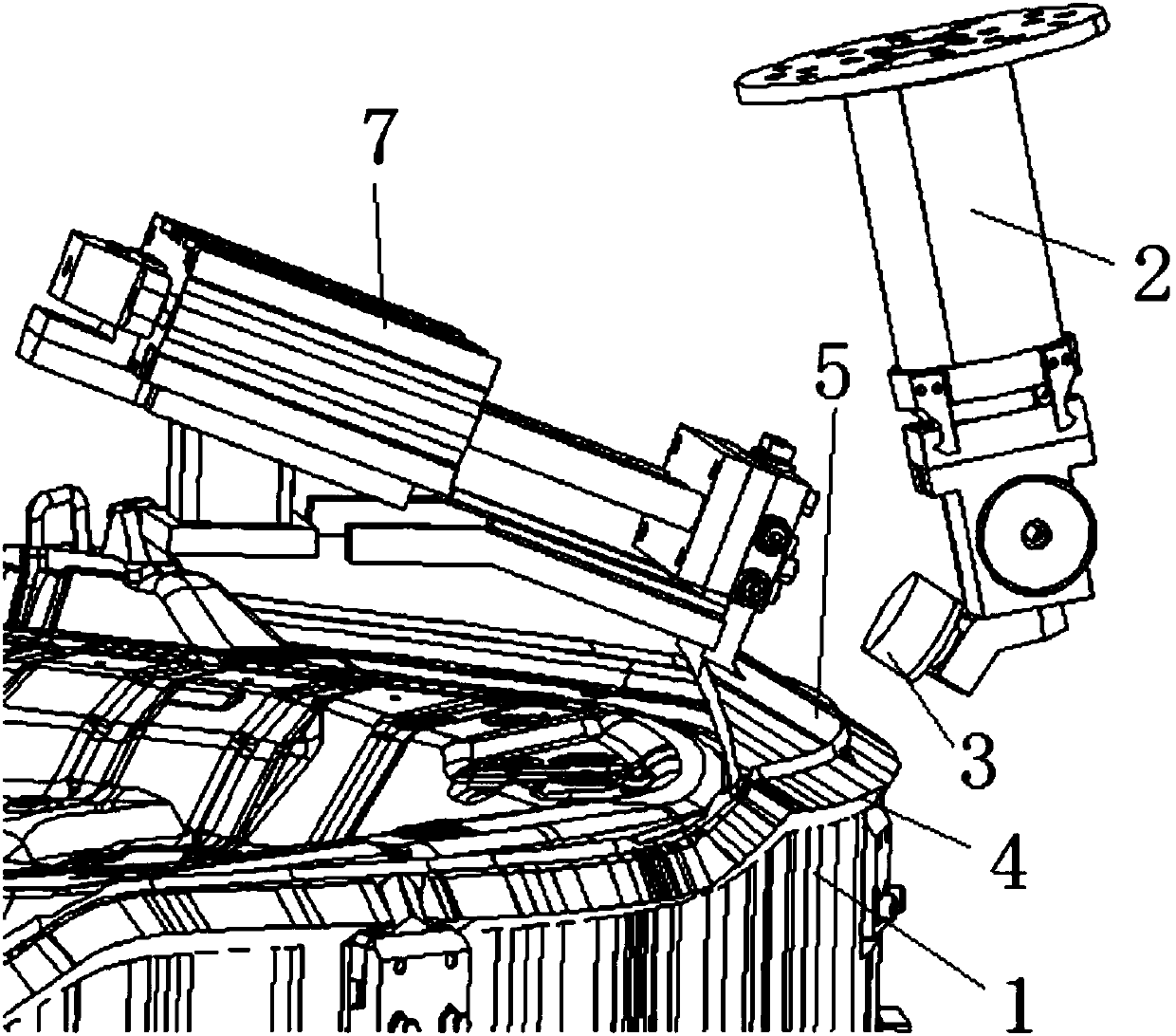

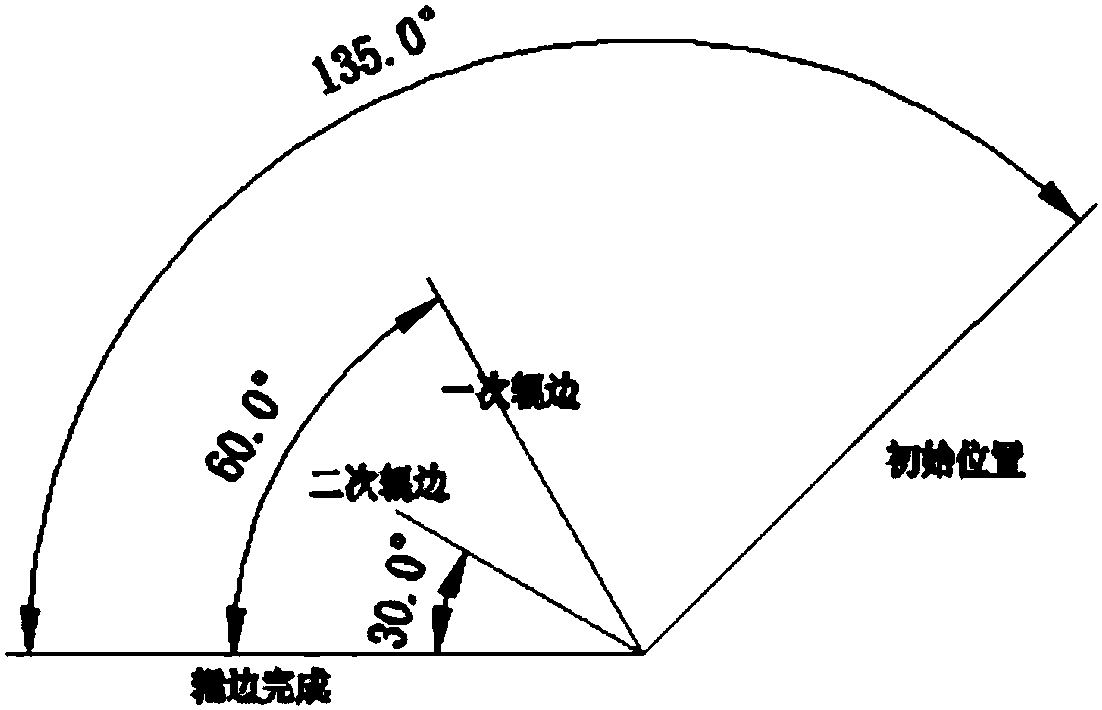

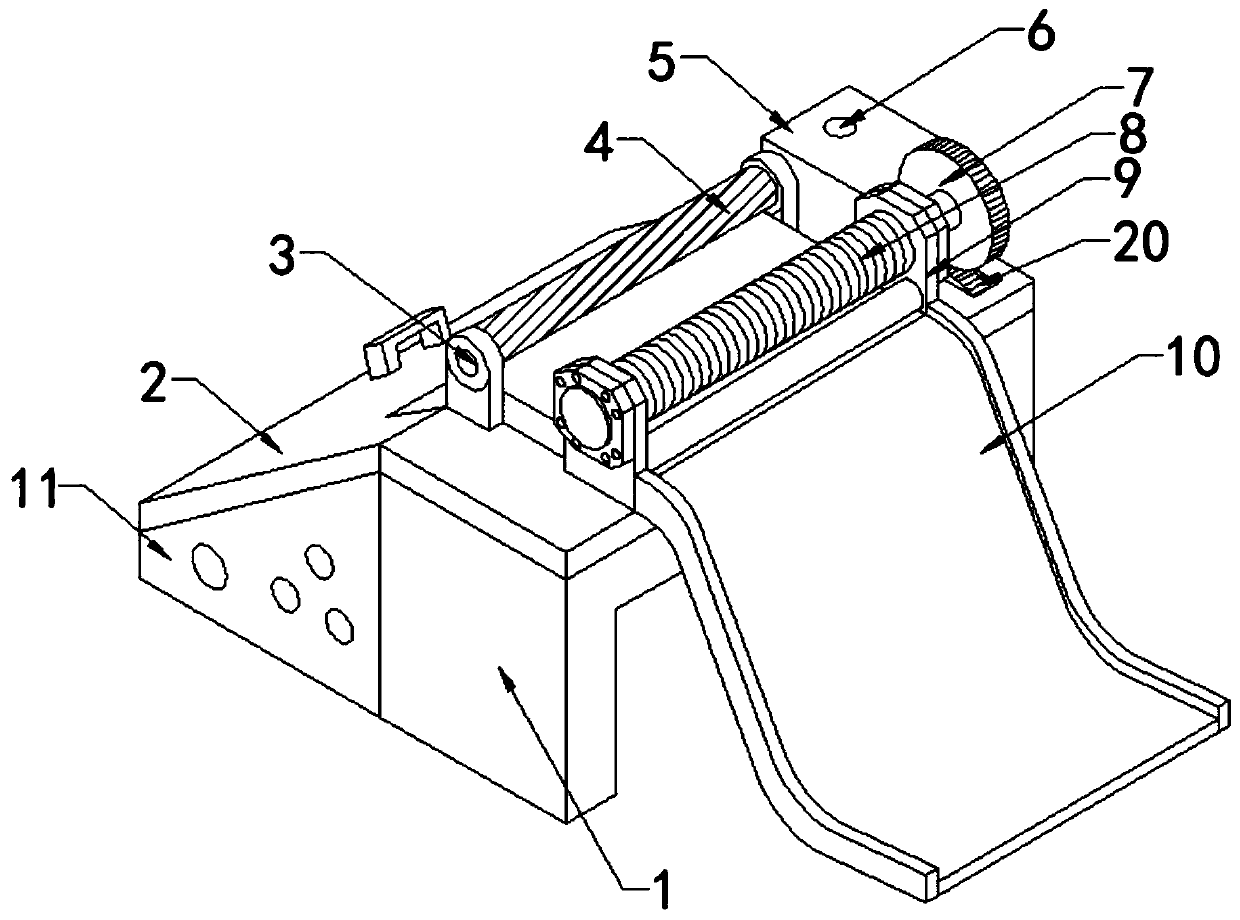

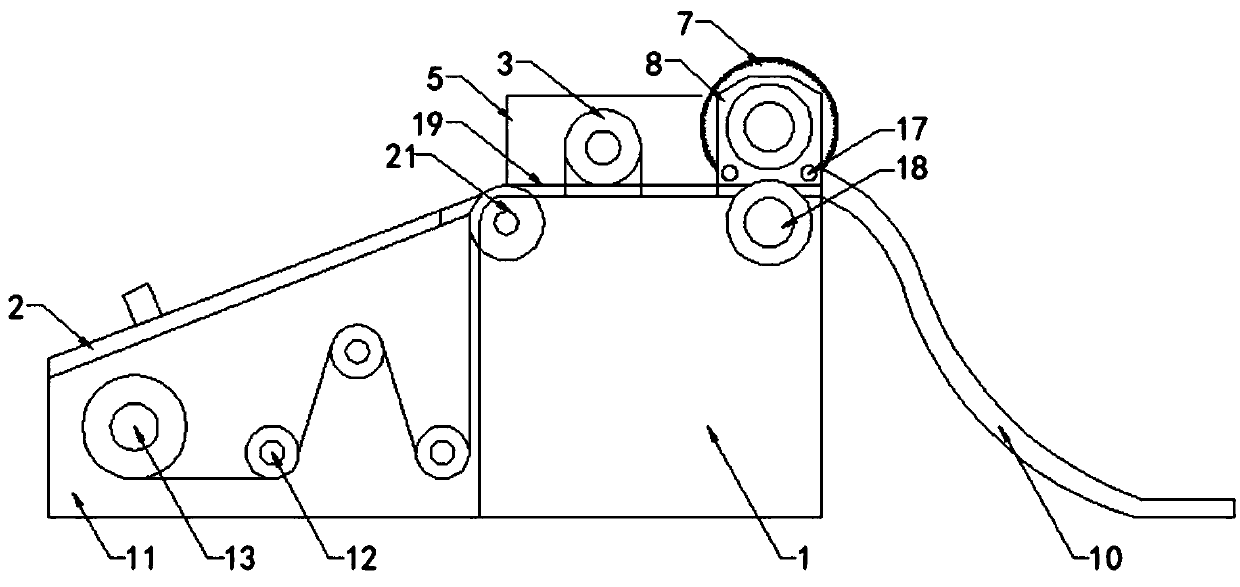

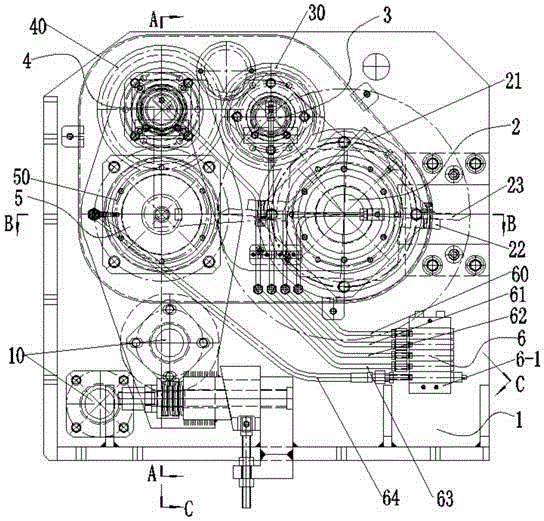

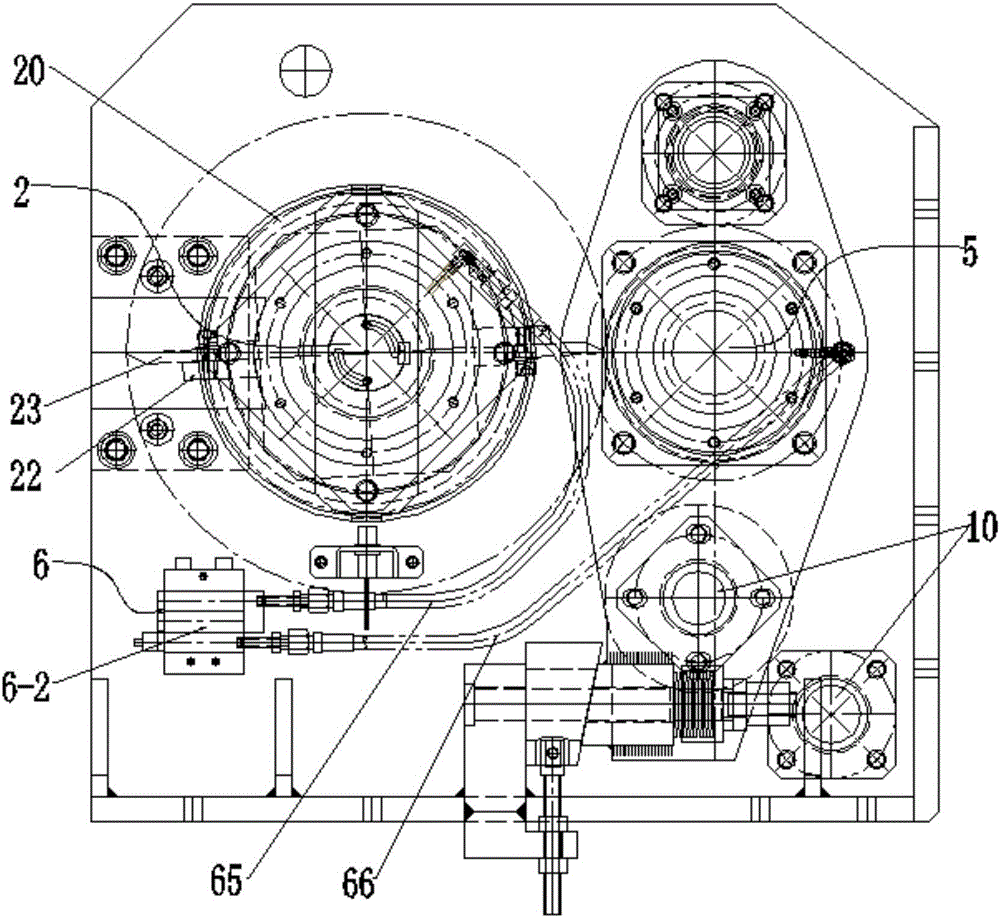

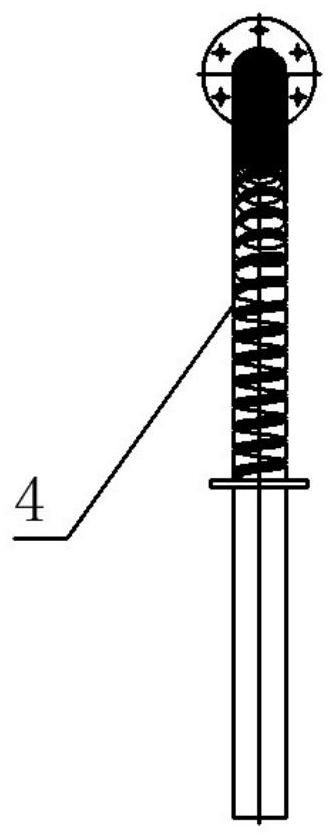

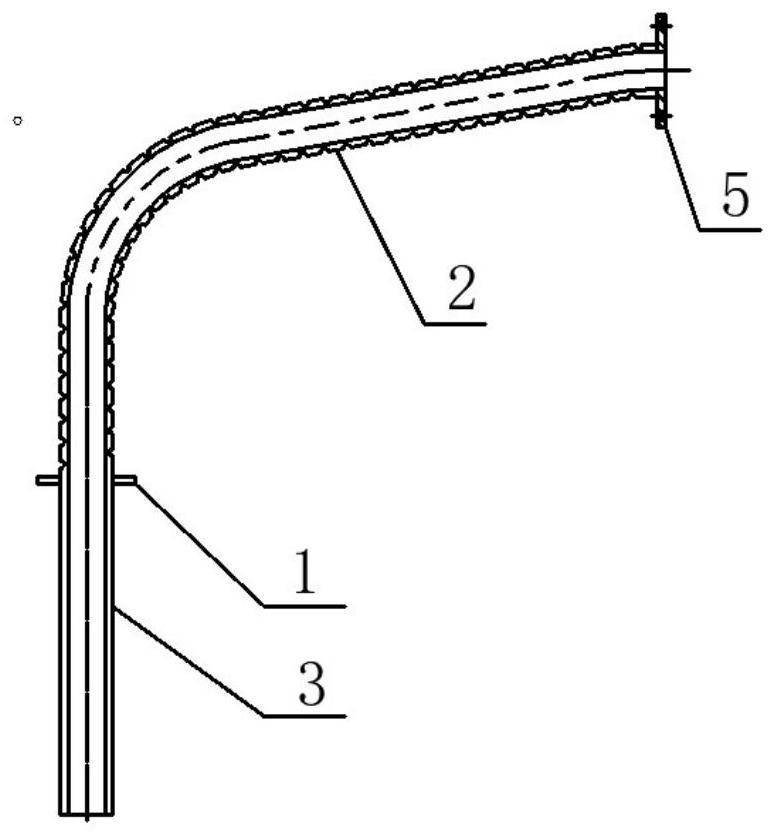

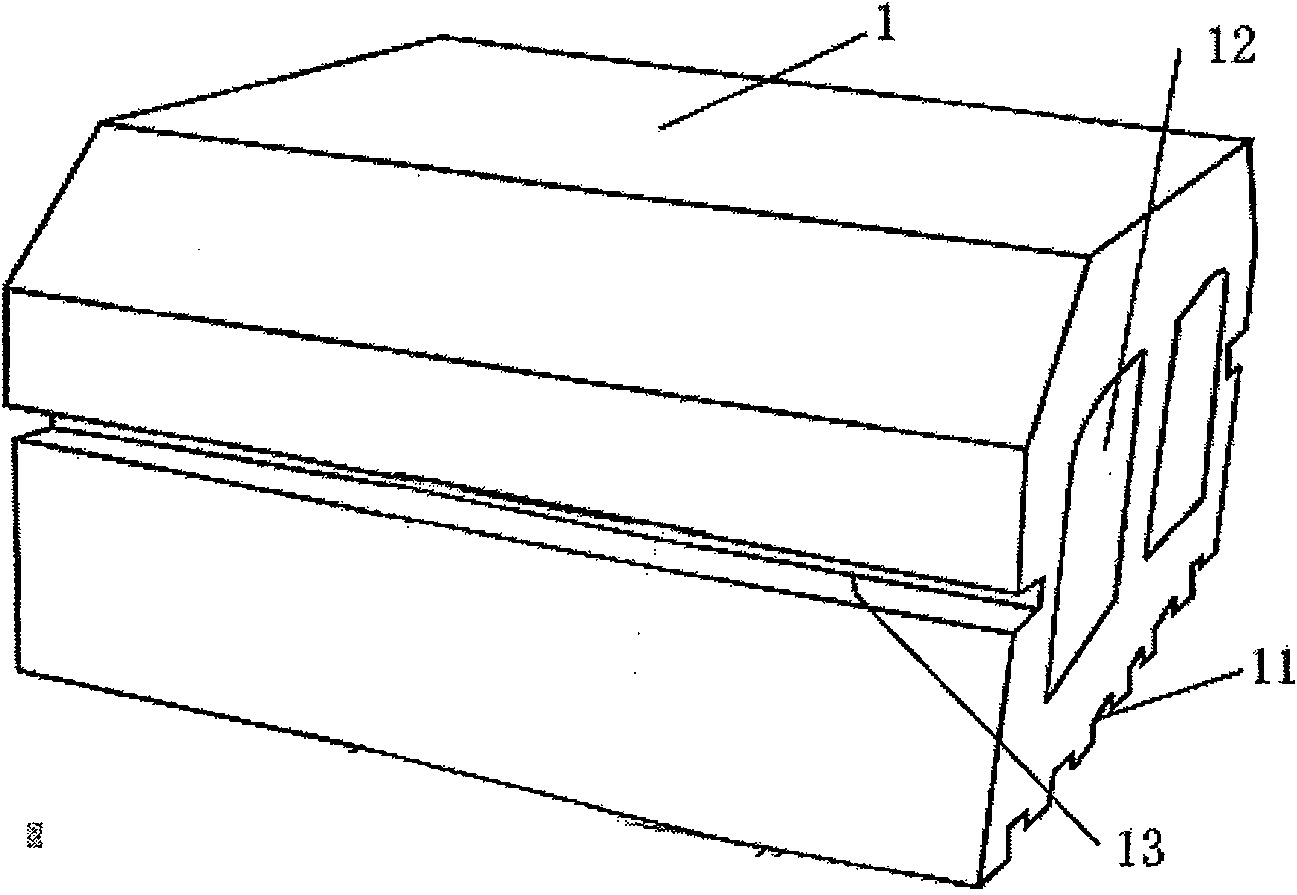

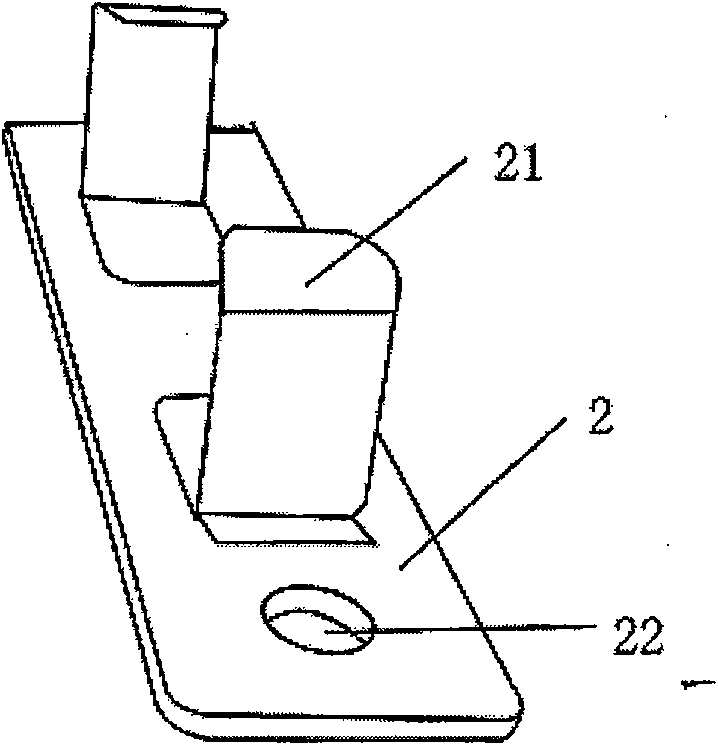

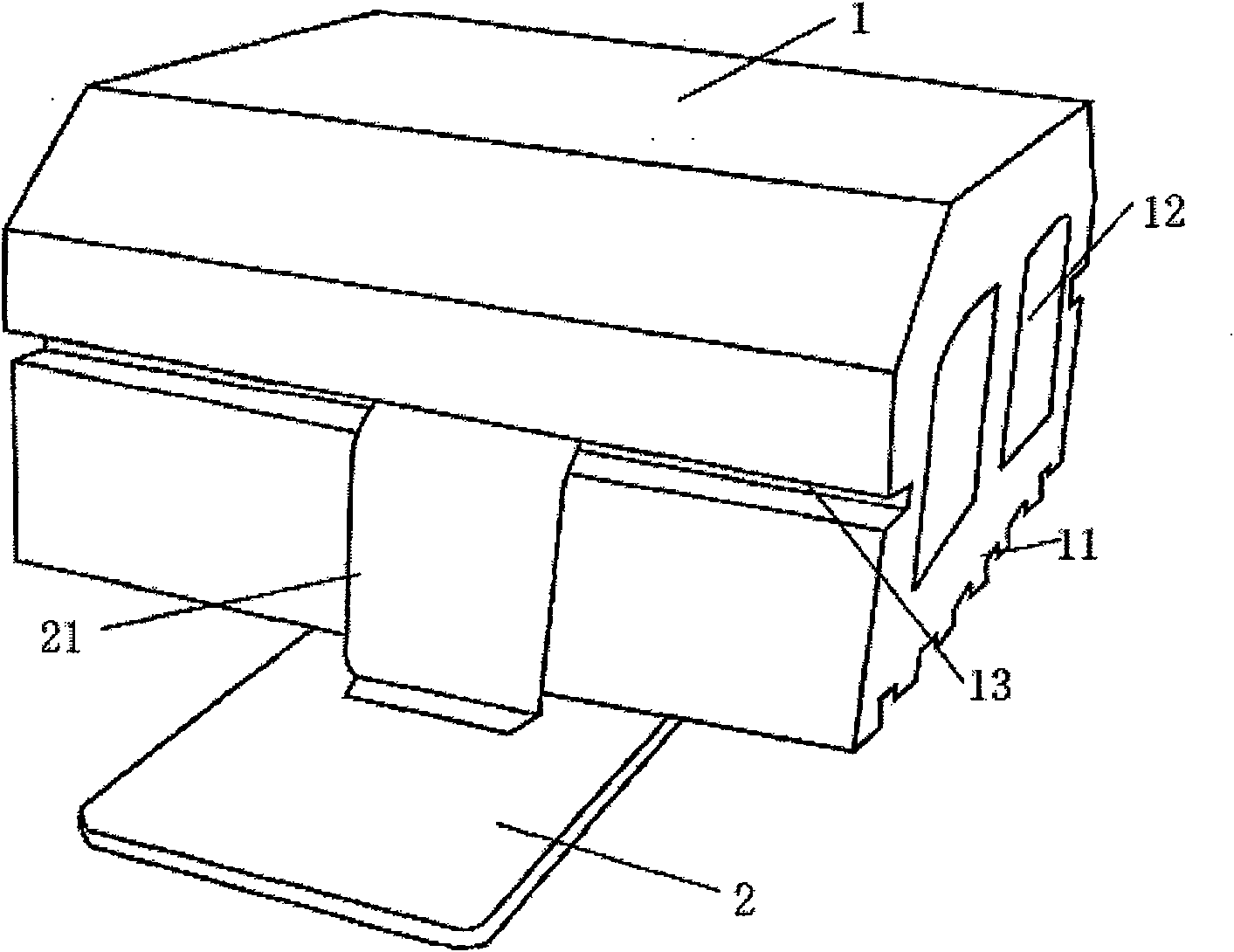

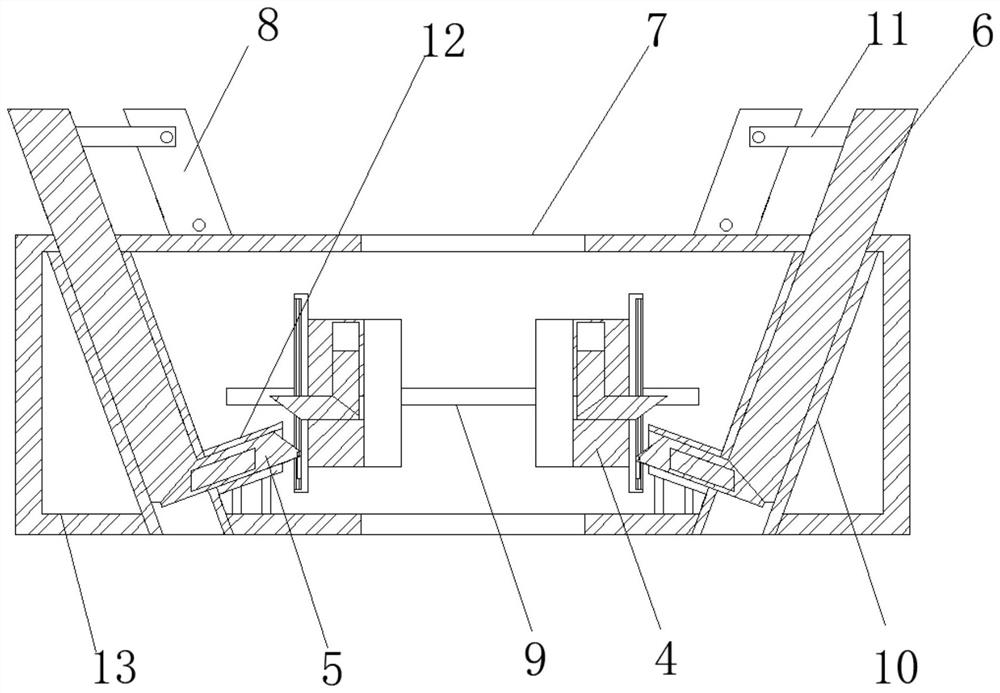

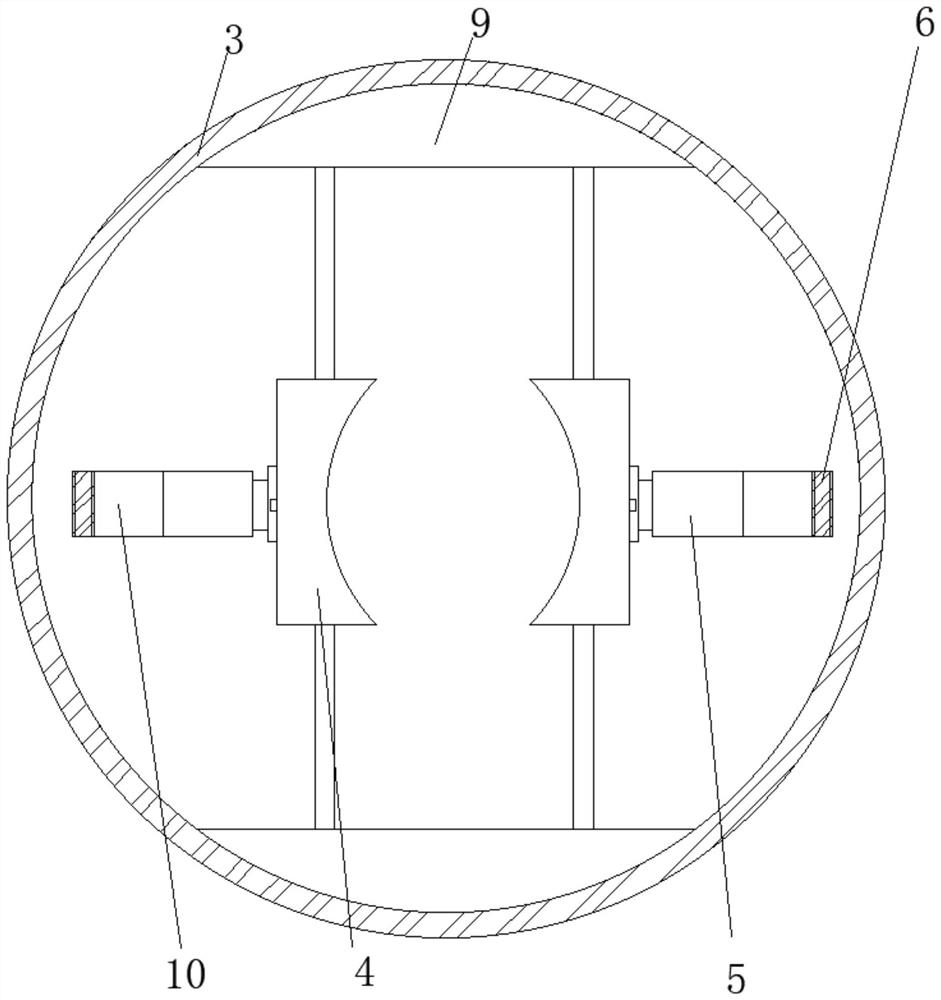

Car body door cover plate edge rolling device and edge rolling method thereof

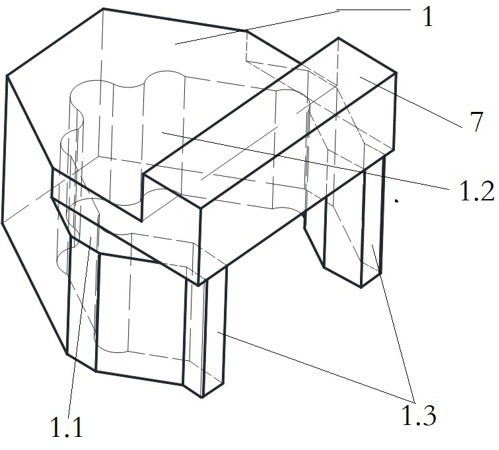

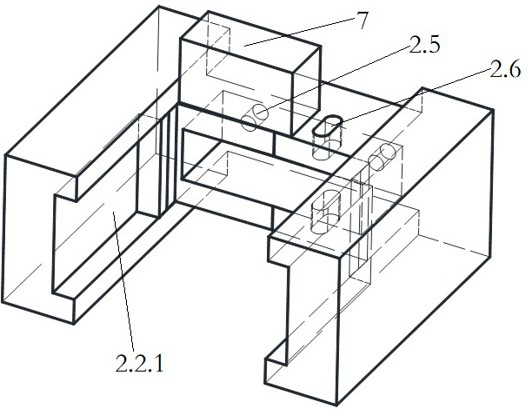

InactiveCN108031739AAvoid misalignmentPrevent misalignment and deformationVehicle componentsEngineeringDislocation

The invention discloses a car body door cover plate edge rolling device which comprises a supporting table and a robot edge rolling seat, and further comprises a profile mechanism, wherein a rolling head is connected with the lower end of the robot edge rolling seat; the profile mechanism is connected with a telescopic mechanism; a molding bed is arranged on the supporting table; and a workpiece to be subject to edge rolling is arranged on the molding bed. The invention further discloses an edge rolling method of the car body door cover plate edge rolling device. According to the edge rollingmethod, a car body door cover plate to be subject to edge rolling is fit on the molding bed; a piston rod of an air cylinder is ejected, a push rod is driven to push out, and then a pre-bent profile is driven to advance; the car body door cover plate to be subject to edge rolling is pressed by the pre-bent profile is press, and the position, to be subjected to edge rolling, of the car body door cover plate to be subject to edge rolling is pressed by the forward side of the pre-bent profile; the rolling head on the robot edge rolling seat is driven by a robot arm to carry out primary edge rolling on the car body door cover plate to be subject to edge rolling; and the piston rod of the air cylinder is contracted, and the pre-bent profile is driven to retract. The car body door cover plate edge rolling device and the edge rolling method disclosed by the invention have the following advantages: the car body door cover plate can be protected against dislocation and deformation, the productquality can be guaranteed, the production efficiency can be improved, and the cost can be reduced.

Owner:ANHUI RUIXIANG IND

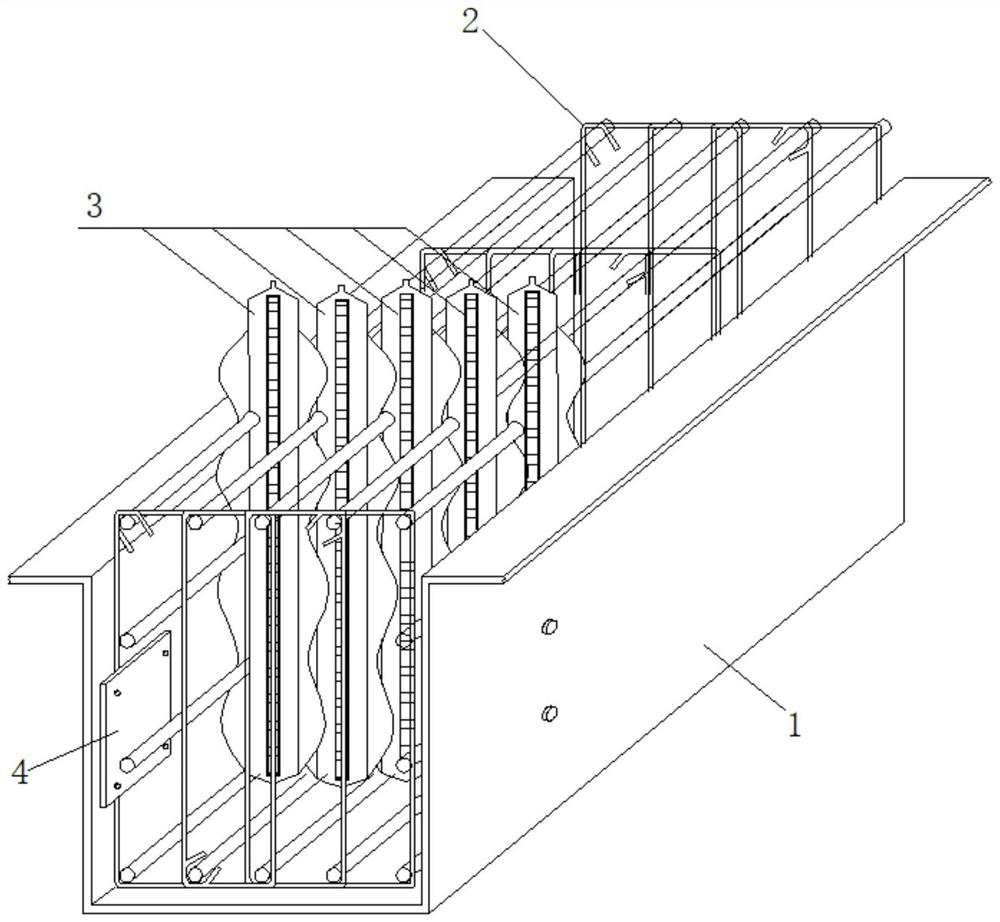

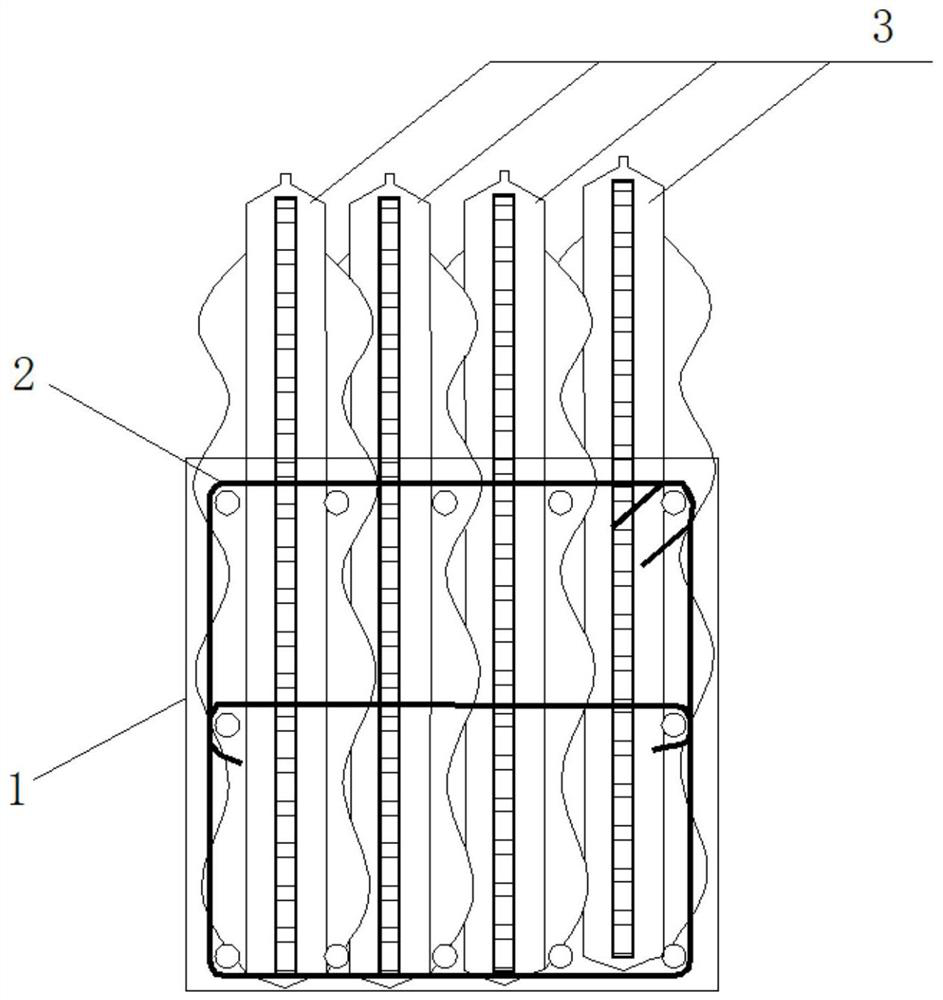

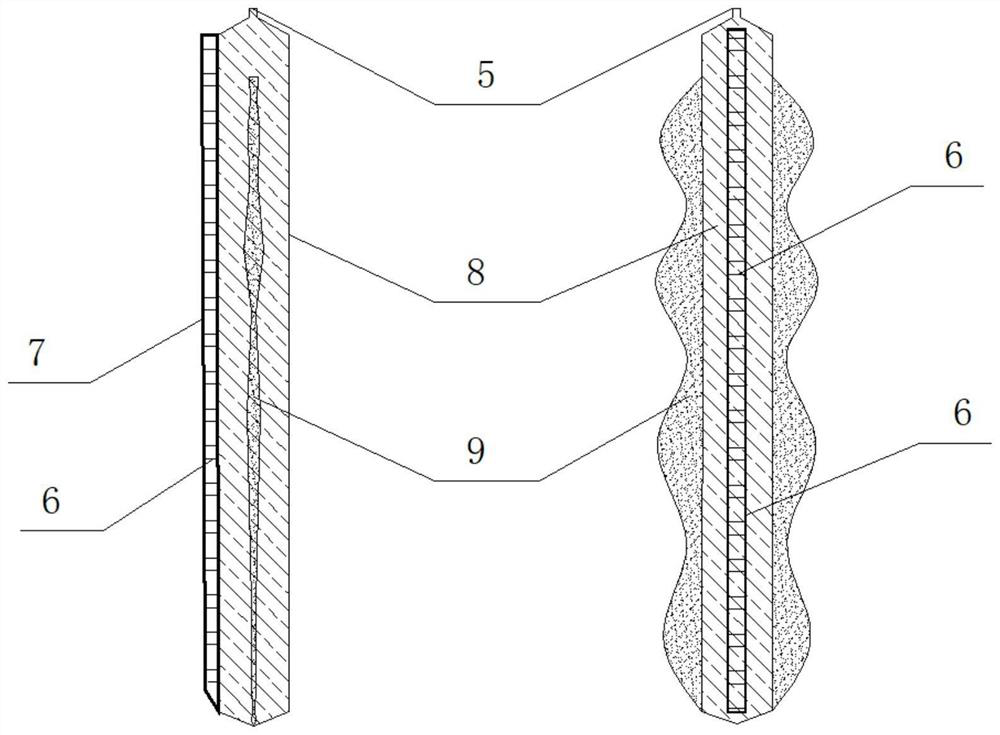

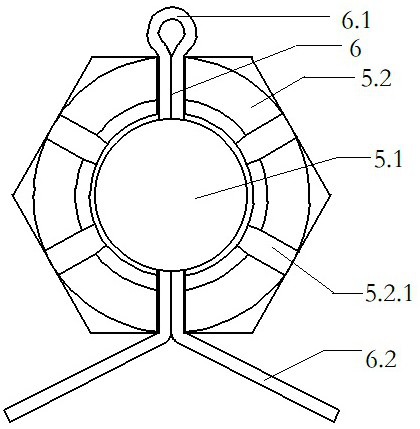

Inflatable turnover high-low grade concrete pouring blocking net air bag and mounting method thereof

PendingCN114856197AIncrease stiffnessAvoid deformation and misalignmentClimate change adaptationBuilding material handlingReinforced concreteArchitectural engineering

The invention belongs to the technical field of building construction, particularly relates to an inflatable turnover high-low grade concrete pouring blocking net air bag and an installation method thereof, and provides the following scheme aiming at the problems that in the concrete pouring process, concrete overflowing is likely to happen, the blocking net effect is poor, and the cost input is high. Comprising a reinforced concrete beam and blocking net air bag bodies distributed at equal intervals, a reinforcement cage is arranged on the inner side of the reinforced concrete beam, the blocking net air bag bodies are connected to the reinforcement cage at equal intervals, reinforcing plates are symmetrically arranged on the inner side of the reinforced concrete beam, and the two reinforcing plates make contact with the outer walls of the two sides of the reinforcement cage respectively. The device is easy to use, can flexibly meet the requirements of blocking nets of beams with different cross sections, is easy to operate and apply on site, reduces the site operation difficulty of workers, effectively solves the common quality problem of appearance color difference of high-grade and low-grade concrete pouring, reduces the investment of a traditional fast and easy closing-up steel wire net, reduces the later repair cost, and improves the construction quality.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

Pyrography machine lower plate seat capable of automatically adjusting levelness

The invention relates to a pyrography machine lower plate seat capable of automatically adjusting levelness, which comprises a horizontal bottom plate, two parallel sliding chutes are formed in the top end of the bottom plate, a supporting seat in sliding connection with the sliding chutes is arranged in the sliding chutes, and a drawing board in clamping connection with the supporting seat is arranged at the top end of the supporting seat; a plurality of roller grooves are formed in the bottom end of the supporting seat in the length direction of the sliding grooves, rollers are arranged in the roller grooves, and shaft sleeves connected with the roller grooves in an up-down sliding mode are arranged between the roller grooves and the rollers. According to the pyrography machine lower plate seat capable of automatically adjusting the levelness, the rollers moving up and down in the roller grooves are used for keeping parallel to an upper plate, the situation that the lower plate seat cannot be tightly attached to the upper plate after being heated and deformed is effectively prevented, and the pyrography effect is guaranteed; the base plate is supported by a base capable of automatically adjusting the horizontal position, the base corrects the height difference of the four corners of the base by recognizing the inclined direction, the adjusting mode is accurate and reliable, and the levelness of the base and the drawing board on the base is effectively guaranteed.

Owner:福建欣弘机电设备有限公司

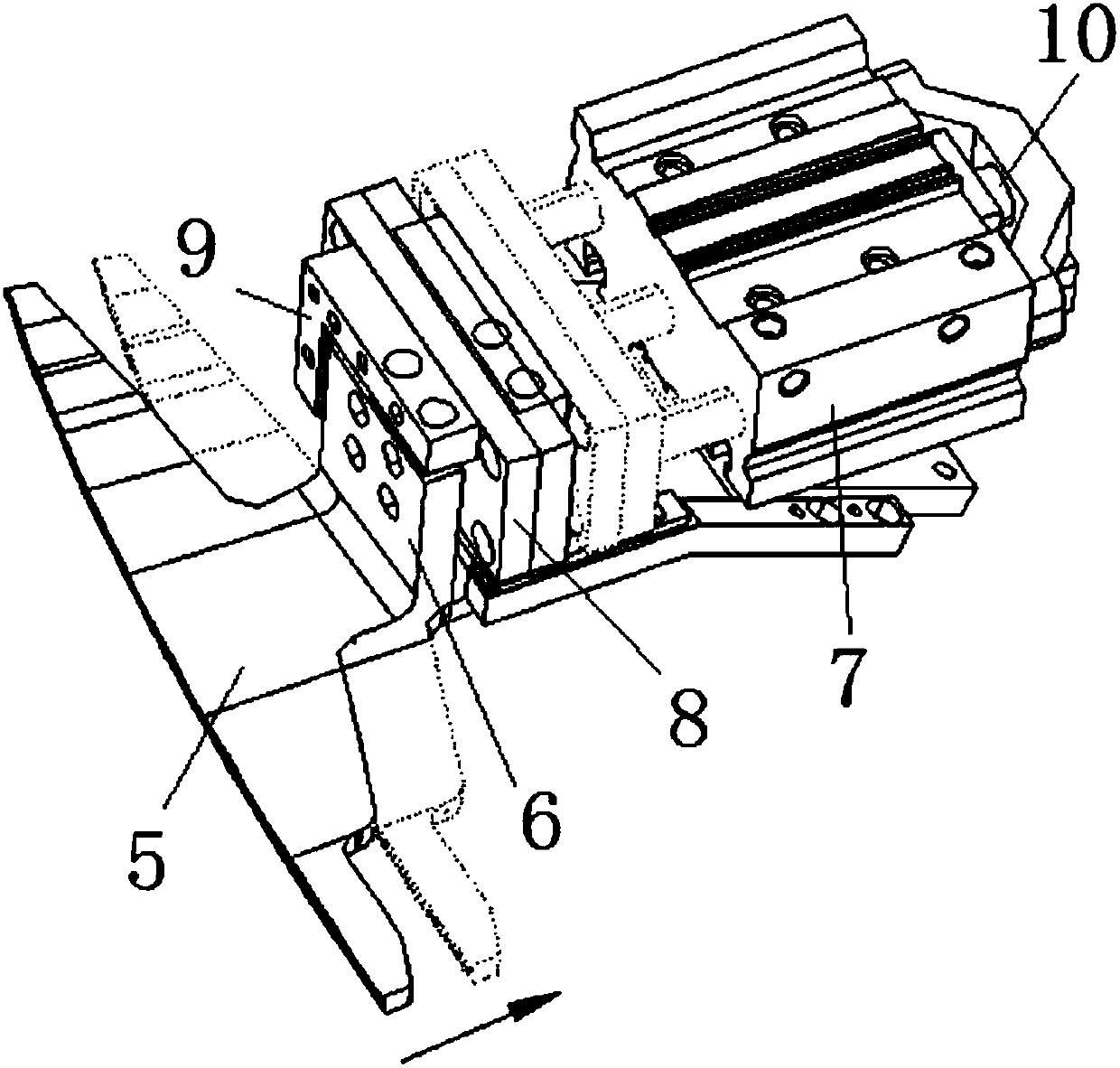

Slitting machine for lithium battery machining use

PendingCN111299681APrevent misalignment and deformationNo manual operationShearing machinesShearing machine accessoriesMachiningIndustrial engineering

The invention discloses a slitting machine for lithium battery machining use. The slitting machine comprises a workbench and a raw material box; one side of the workbench is fixedly connected with theraw material box, a material roller is fixedly installed in the raw material box, and one side of the material roller is fixedly provided with three material tightening rollers; a dustproof cover ishinged to the top of the raw material box, and the side, close to the workbench, of the dustproof cover is provided with a discharging outlet; and the top of the workbench is fixedly connected with aguide plate, and the two sides of the guide plate are both fixedly provided with first bearing seats and second bearing seats. According to the slitting machine for lithium battery machining use, a lithium battery electrode slice raw material is stored in the raw material box, a dust preventing and protecting effect is achieved, two slitting wheels cooperate to conduct slitting machining on the lithium battery electrode slice raw material, the situation that material dislocation and deformation occur during machining, and thus, a machined product cannot be used is prevented through limiting fixing wheels, the rejection rate is decreased, machining equipment does not need to be operated by manpower and is convenient and safe to use, and the machining efficiency is high.

Owner:广东省秦田科技有限公司

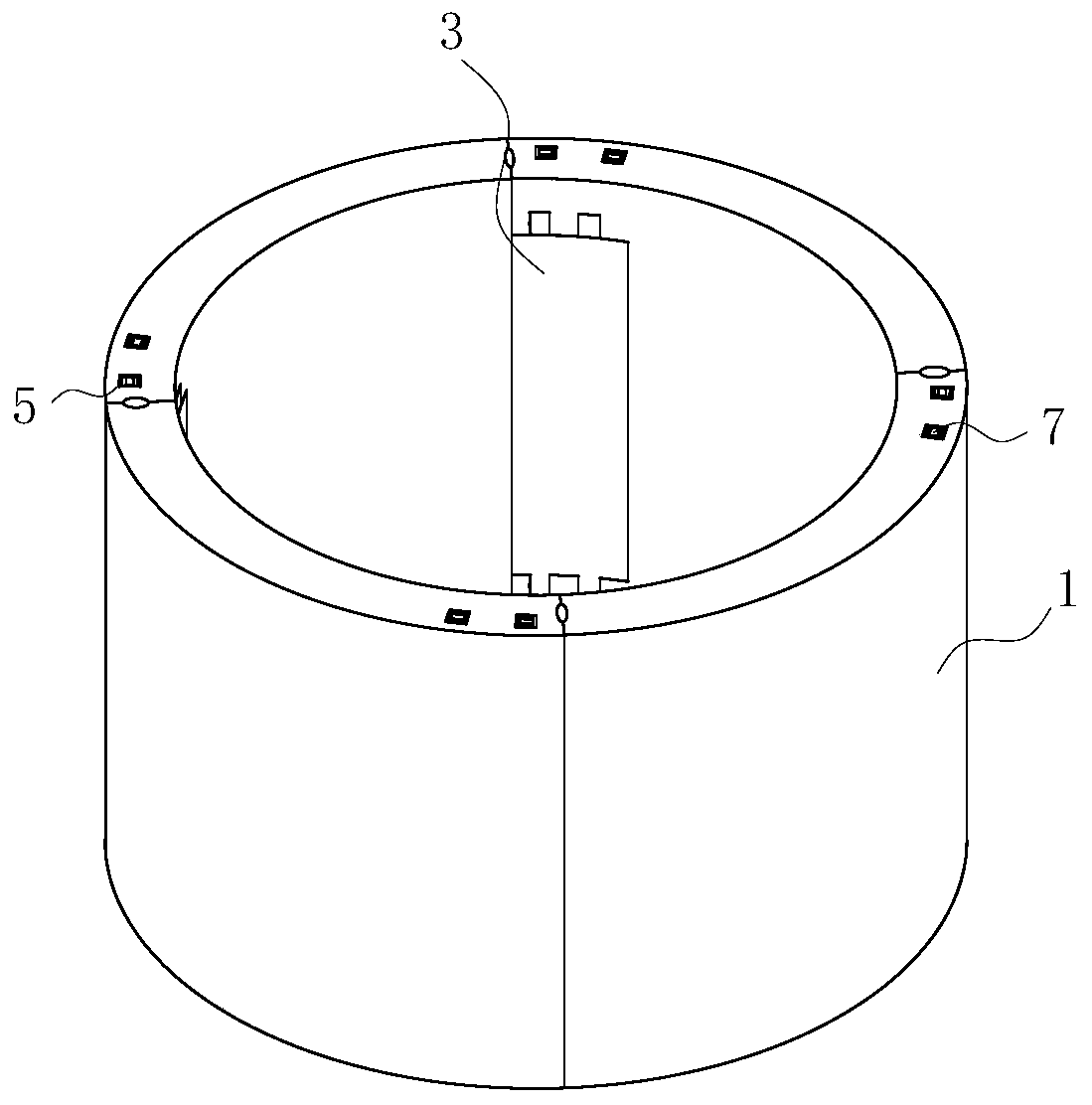

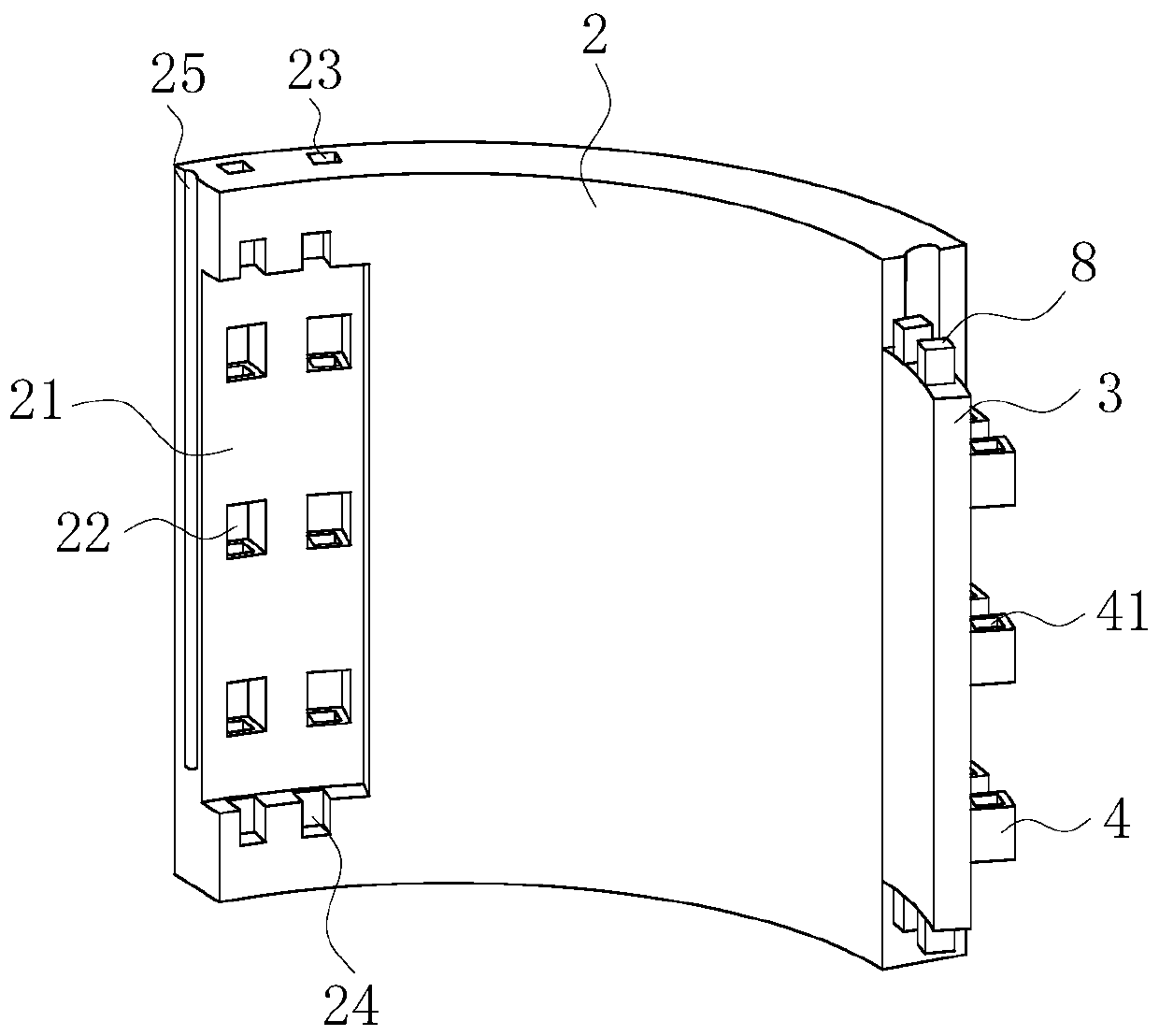

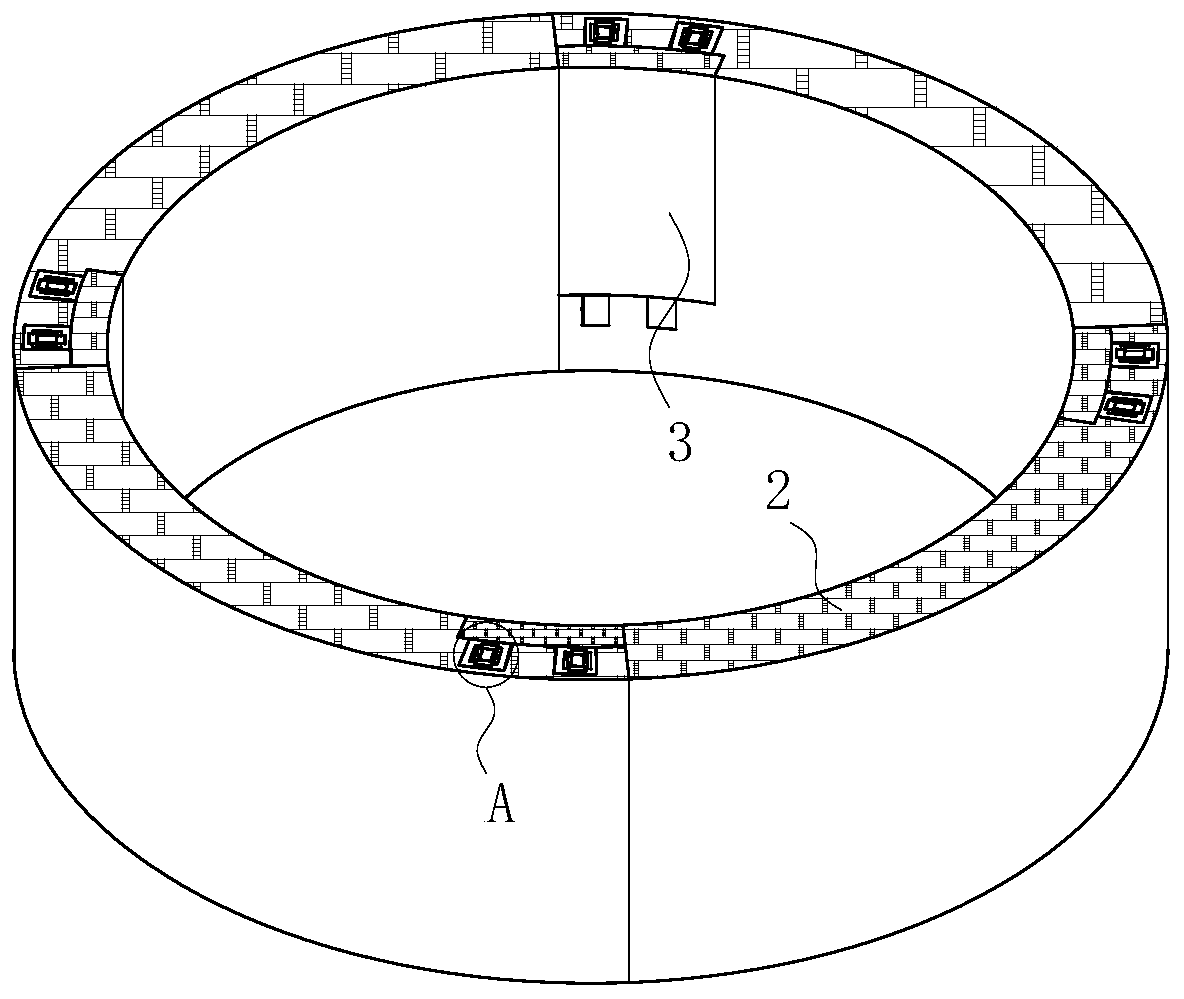

Refractory block and glass furnace

InactiveCN111517622AExtended service lifeImprove life and installation stabilityGlass furnace apparatusEngineeringStructural engineering

The invention belongs to the technical field of refractory blocks, and particularly relates to a refractory block and a glass furnace. The refractory block comprises a refractory block body, and the refractory block body is formed by splicing a plurality of arc-shaped refractory slabs; a mounting groove is formed in the inner wall of one side of each arc-shaped refractory slab, and a clamping plate is arranged on the other side of each arc-shaped refractory slab; a plurality of square inserting holes are uniformly formed in the inner wall of each mounting groove and are formed in the verticaldirection of the inner wall of the mounting groove; a plurality of square inserting blocks are uniformly arranged on the outer side wall of each clamping plate, and the plurality of square inserting blocks are inserted into the plurality of square inserting holes; square inserting cavities are formed in the upper end surface of one side of each arc-shaped refractory slab, and the square insertingcavities are communicated with the plurality of square inserting holes which are vertically formed; square inserting strips are inserted into the square inserting cavities in an extruding manner, andsynchronously penetrates through square communicating cavities. The locally damaged or broken refractory block body can be conveniently maintained and replaced, so that the service life of the refractory block body is prolonged.

Owner:张云鹏

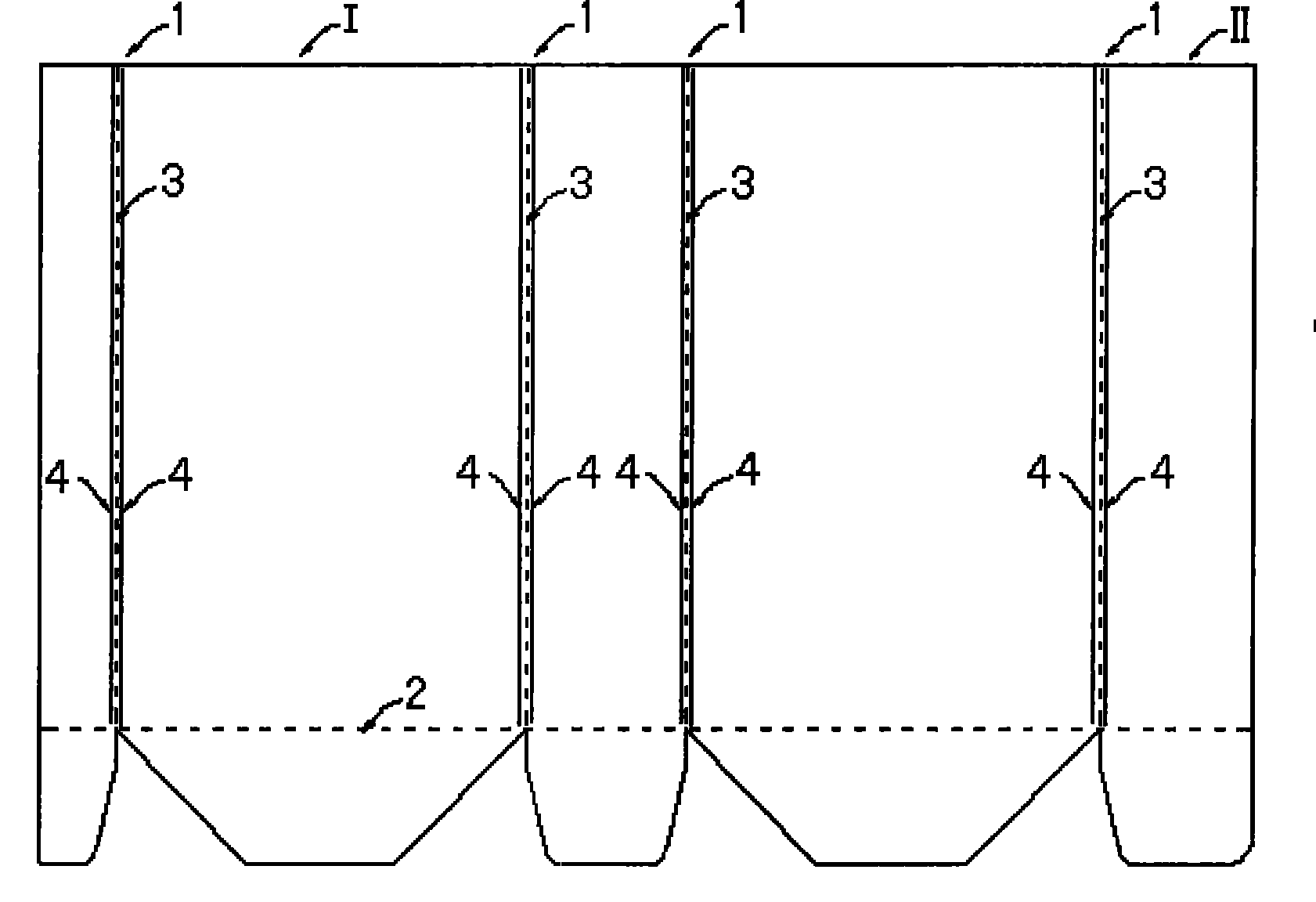

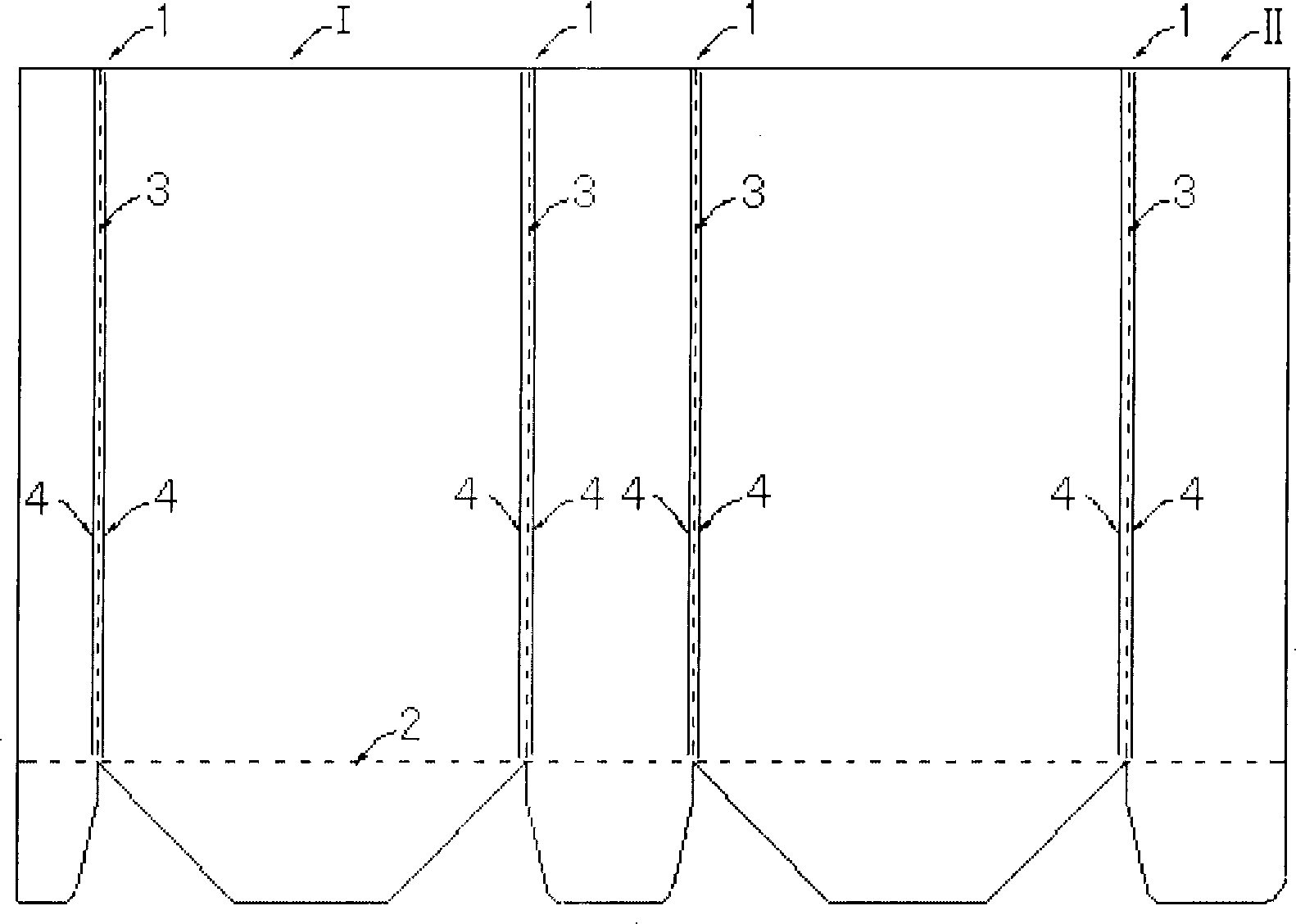

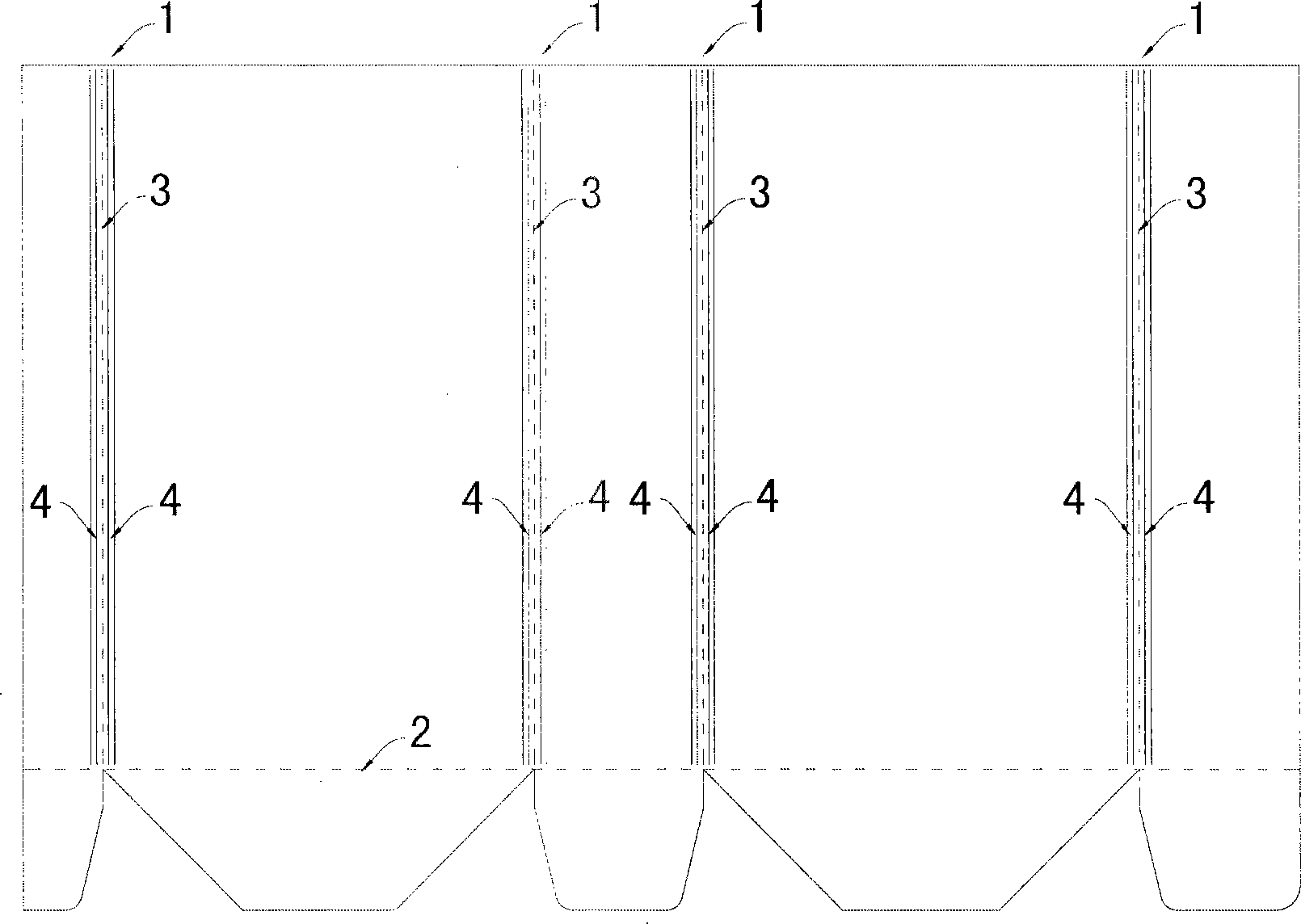

Parchment paper cigarette packaging structure and making methongd thereof

ActiveCN101602422BRelieve stiffnessAvoid compressive deformation and misalignmentContainers for flexible articlesPackaging cigaretteFiberBiochemical engineering

The invention provides a parchment paper cigarette packaging structure. A folding line is processed by a combination method with point penetration crush-cutting and semi-penetration crush-cutting to avoid deformation and dislocation of parchment paper fibers due to pressure when the folding line is processed, therefore, the stiffness of the folding line is greatly reduced. The stiffness of the folding line ranges from 50 to 80 after the parchment paper is formed so as to meet the requirement of domestic cigarette packaging equipment and realize the packaging production of a cigarette packaging machine.

Owner:SHENZHEN JINJIA GRP

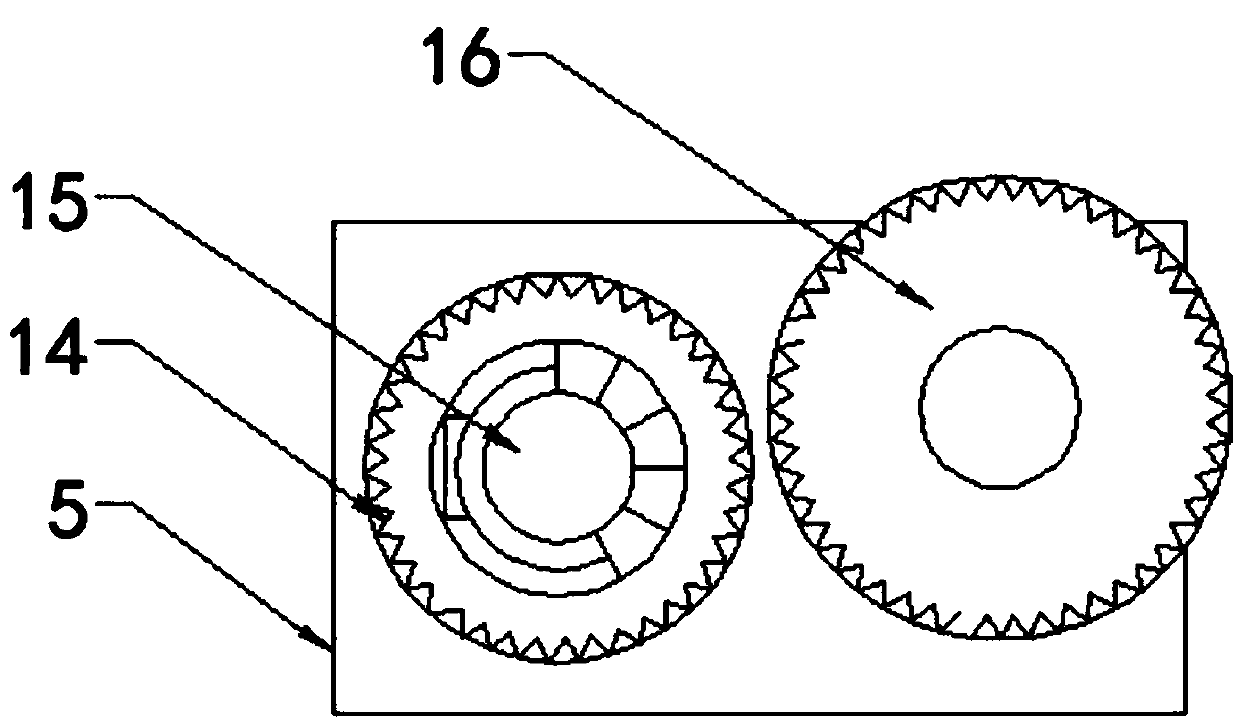

Hobbing cutter device for rubber cutting

InactiveCN106826984AAchieve entryImprove cutting efficiencyMetal working apparatusAgricultural engineering

The invention discloses a hob device for rubber material cutting, which comprises a frame, a hob shaft, a reversing shaft, a retaining shaft, an anvil roller and a lubricating system, wherein the lower end of the frame is provided with two braces, the The two ends of the hob shaft are connected to the frame through bearings, the reversing shaft is connected to one side of the frame through bearings, the two ends of the retaining shaft are connected to the frame through bearings, and the two ends of the anvil roller are connected to the frame through bearings. Connected with the frame, the lubricating system is set on the side of the frame to realize the cutting of the rubber material and improve the cutting efficiency.

Owner:WUHU NEW UNIVERSAL ENVIRONMENTAL SCI TECH

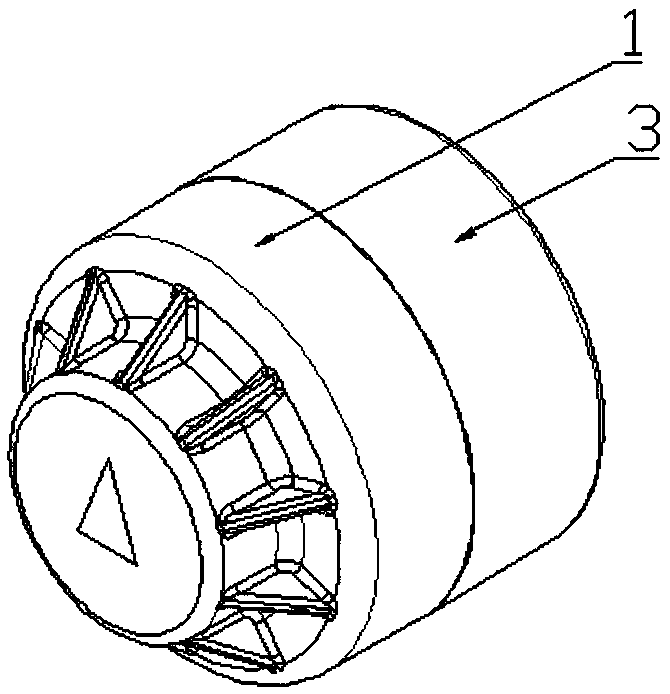

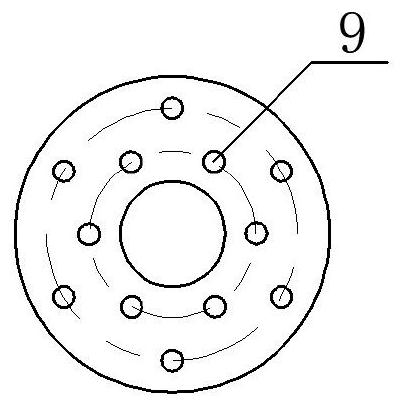

Exposed heating type riser tube

ActiveCN112743063ASolve the problem of difficult heatingPressure relief backflow smoothlyMolten bathEngineering

The invention provides an exposed heating type riser tube. The exposed heating type riser tube comprises a riser tube body, a riser tube head and a heating mechanism; The riser tube body comprises a molten pool inserting section (3) and an air exposing section (2), the tail end of the air exposing section (2) is connected with the riser tube head, a spiral groove (4) is arranged on the outer side of the air exposing section (2), and a plurality of blind holes (9) are formed in the riser tube head. The heating mechanism is divided into two parts. One part of the heating mechanism is uniformly wound on the spiral groove (4) of the riser tube body; and the other part of the heating mechanism is inserted into the built-in blind holes (9) of the riser tube head. The air exposing section of the riser tube is integrally heated through the mode that the riser tube body winds part of the heating mechanism and part of the heating mechanism is inserted into the interior of the riser tube head, and the problem that an exposed conformal riser tube is difficult to heat is solved.

Owner:SHANGHAI JIAO TONG UNIV +2

Blast Furnace Taphole Sliding Ventilation Device

ActiveCN105886685BExtended service lifeAvoid deformationTuyeresDust arrestersFailure rateReciprocating motion

Owner:武汉朗涤环保科技工程有限公司

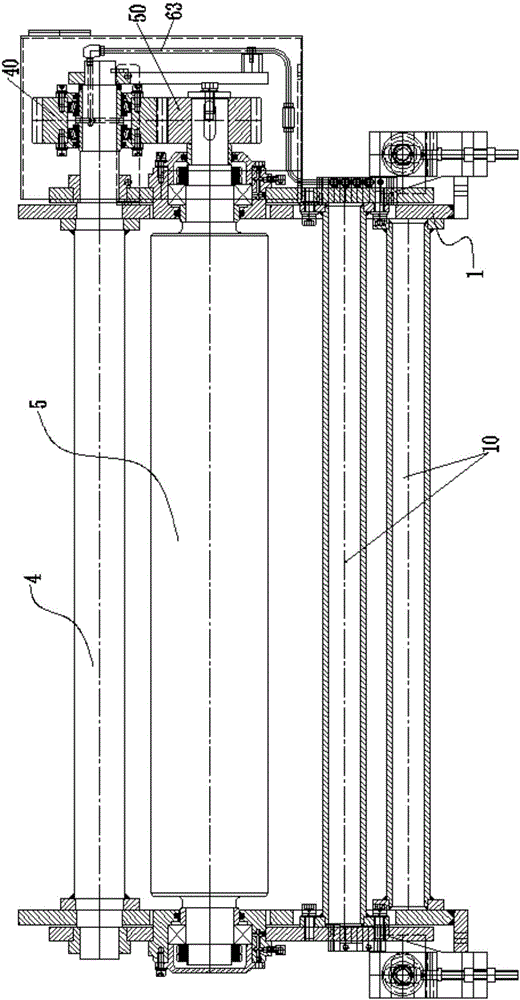

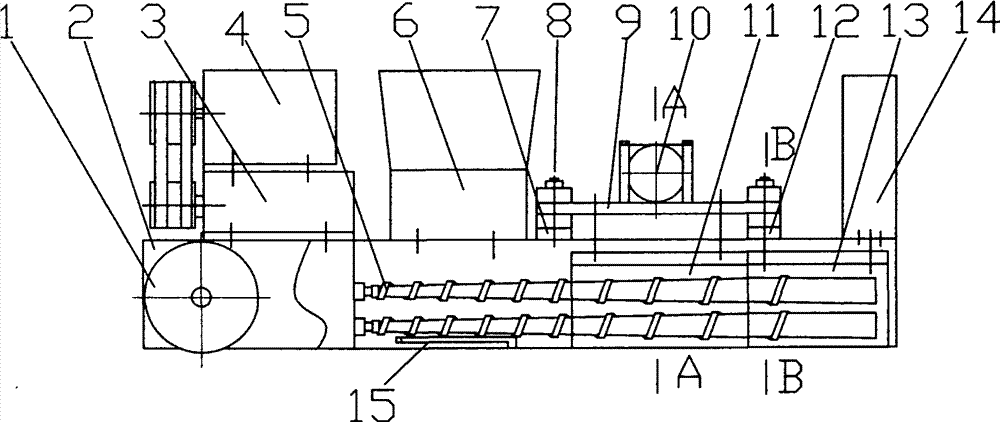

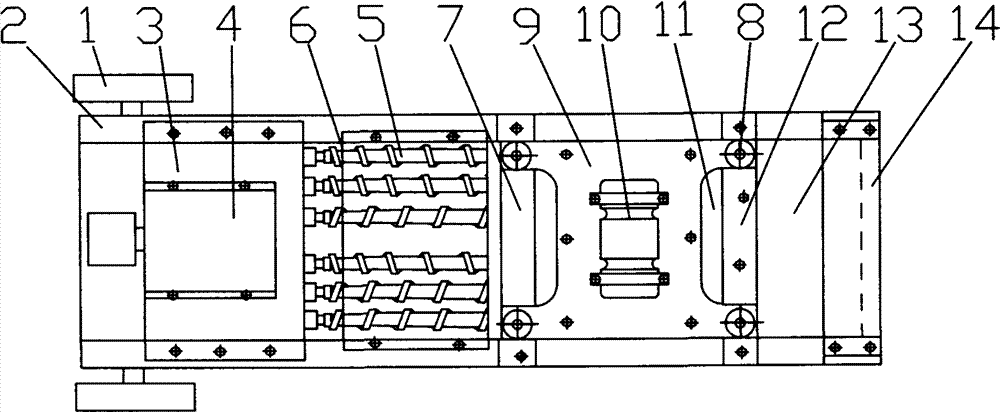

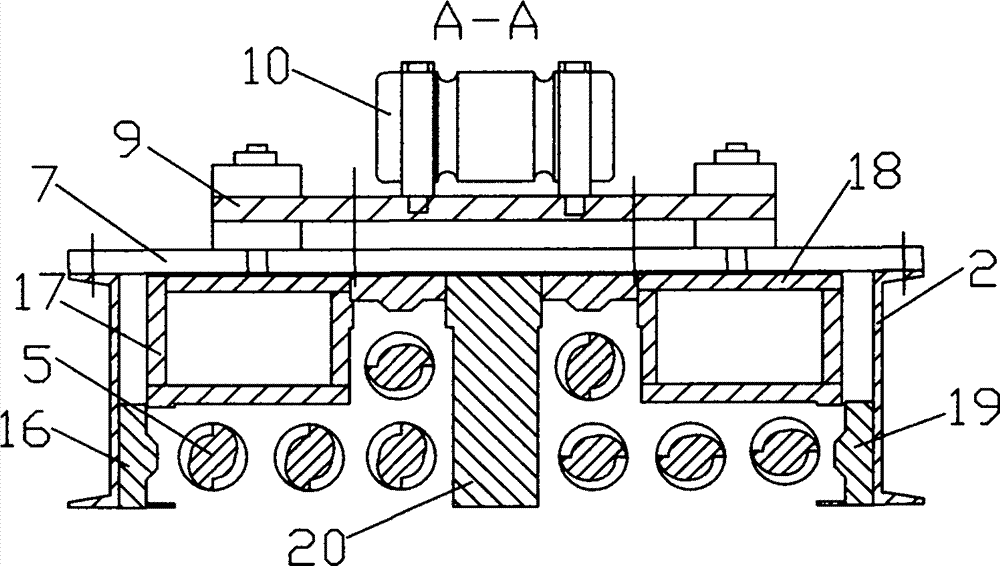

Double-row extrusion molding machine for L-shaped lightweight partition boards

InactiveCN104325544AImprove butt strengthOvercoming Butt Seam ProblemsCeramic shaping apparatusButt jointMolding machine

The invention discloses a double-row extrusion molding machine for L-shaped lightweight partition boards. The double-row extrusion molding machine comprises a reduction gearbox; the reduction gearbox is a distributed transmission double-layer output shaft reduction gearbox for a special lightweight partition board forming machine; a spiral reamer is connected with the output shaft of the reduction gearbox in a double-row L shape; a lower vibration plate welding part comprises a left lower vibration plate welding part and a right lower vibration plate welding part; a space plate plate is arranged between the left lower vibration plate welding part and the right lower vibration plate welding part; a forming plate welding part comprises a left forming plate welding part and a right forming plate welding part which correspond to the left lower vibration plate welding part and the right lower vibration plate welding part; a double-row L-shaped cavity is formed among the lower vibration plate welding part, the forming plate welding part, the space plate, a left wallboard, a right wallboard and the ground. The L-shaped lightweight partition boards produced by the machine are applied to right angles of two perpendicular walls, butt joints do not exist between the wallboards and the side faces of the wallboards, the butt joint strength between the wallboards at the right angles of the two perpendicular walls is improved, and the long existing problem of the butt joints is solved.

Owner:河南四海建材设备有限公司

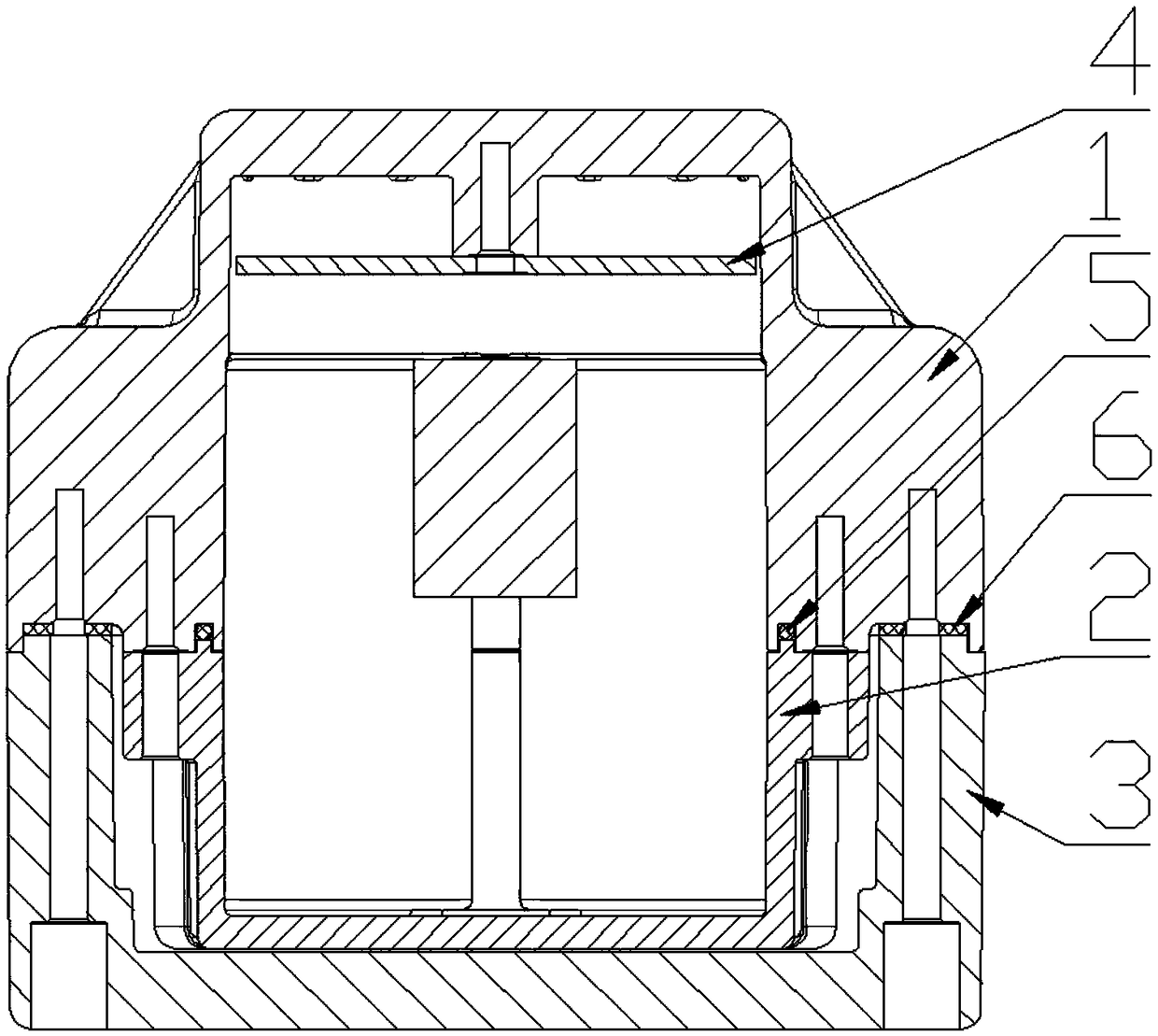

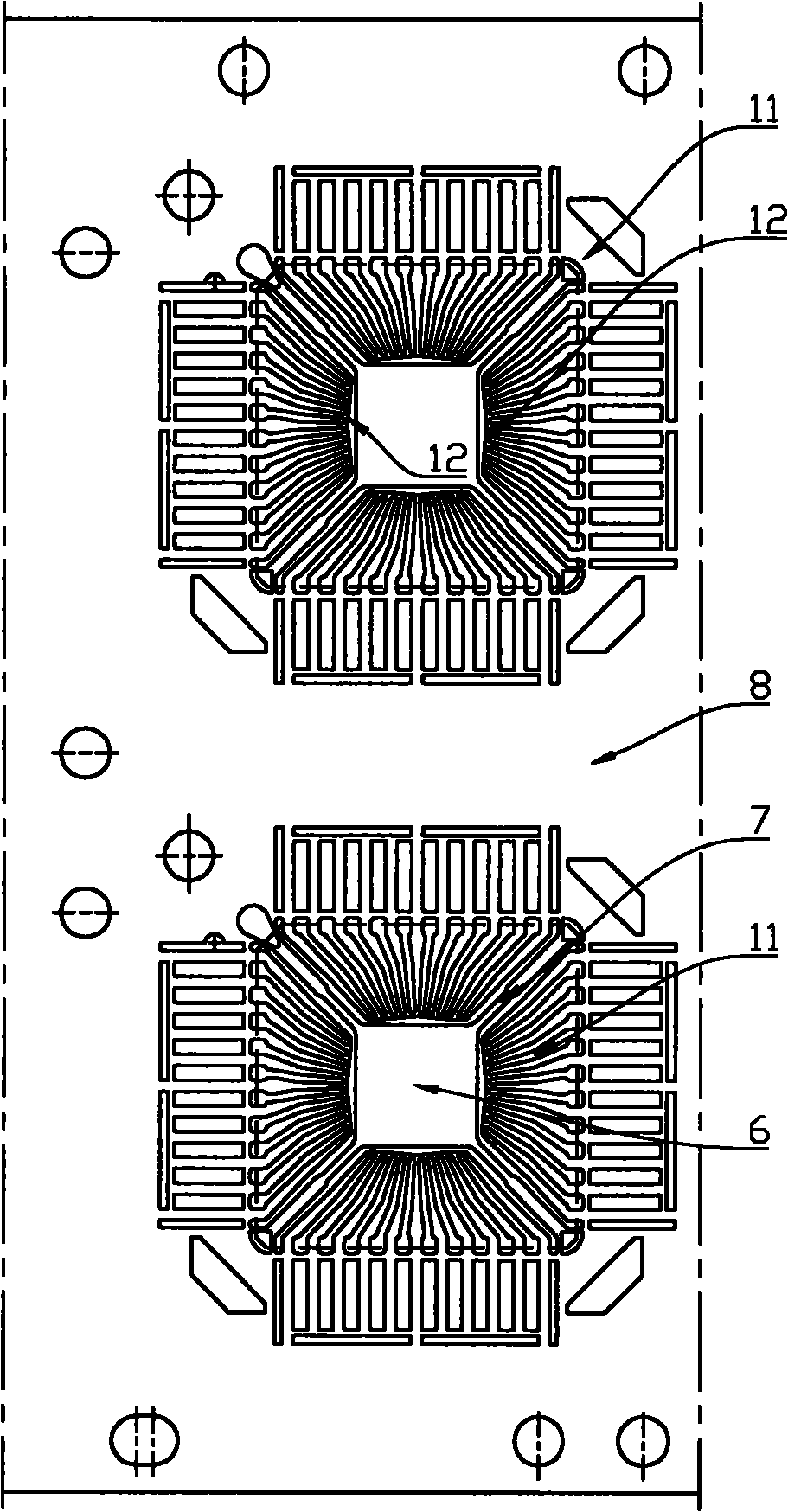

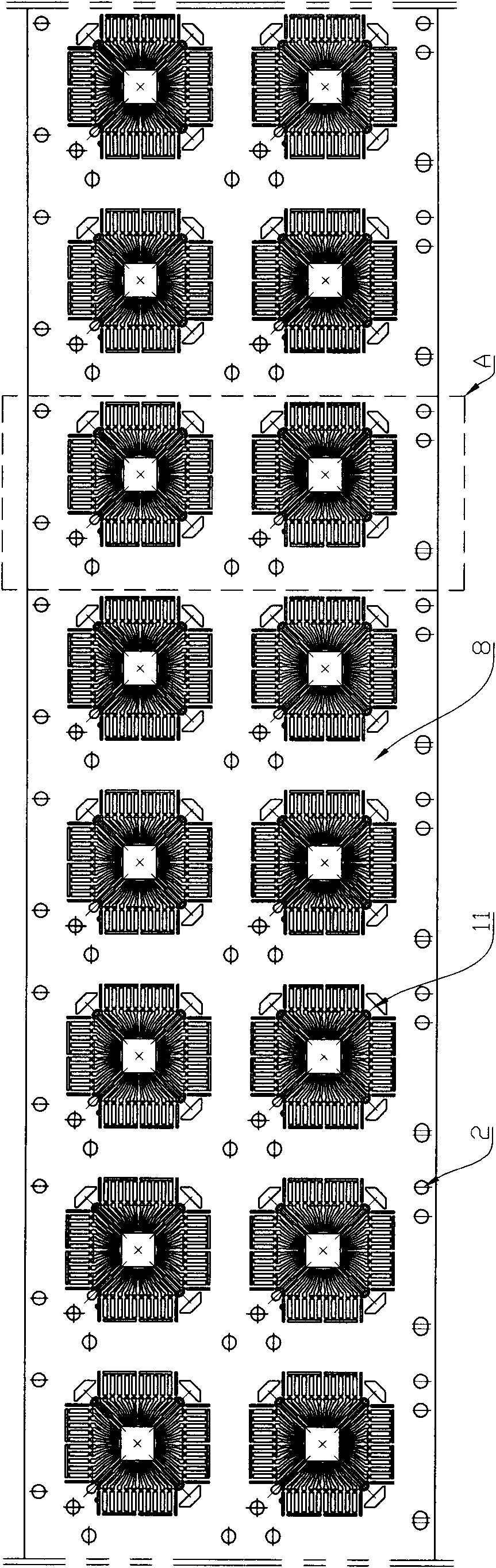

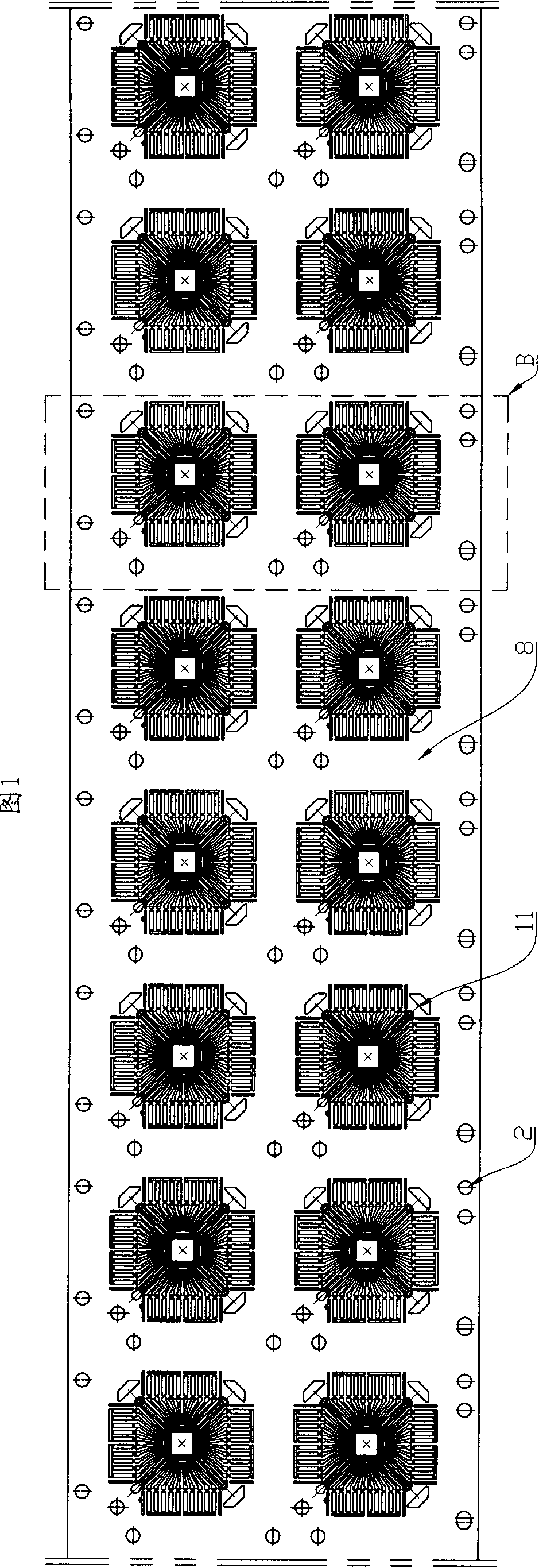

Method for manufacturing large-scale integrated circuit lead frame

ActiveCN101630644BAlleviate and reduce warpageAvoid hook misalignment and deformationSemiconductor/solid-state device detailsSolid-state devicesState of artSingle plate

The invention discloses a method for manufacturing a large-scale integrated circuit lead frame, which overcomes the defect of lower index qualification rate of the coplanarity and the displacement of pins of a lead frame manufactured in the prior art. The method comprises the following steps: (1) continuously stamping: continuously stamping a zone ring with a lead frame original blank on a die; (2) continuously electroplating: electroplating the zone ring with the lead frame original blank, wherein the electroplating area comprises the root welding area of the pins and the front surface of the chip island; and (3) slicing and confirming the size: cutting and flaking the electroplated zone ring to obtain a single plate lead frame piece, wherein in the step of continuous stamping, a connecting rib for connecting the end parts of a plurality of pins at each side into a whole is retained at one end of the pins in the lead frame original blank approaching to the four sides of the chip island, and in the step of slicing and confirming the size, when the zone ring is cut and the size is confirmed, the connecting rib of the end parts of the pins approaching to the four sides of the chip island is also cut off to obtain a finished lead frame. The invention can greatly improve the qualification rate of the coplanarity and the displacement of the pins of the finished lead frame.

Owner:NINGBO HUALONG ELECTRONICS

a dishwasher

ActiveCN110680260BGuaranteed StrengthAvoid deformationTableware washing/rinsing machine detailsStructural engineeringMechanical engineering

The invention discloses a dishwasher. The dishwasher comprises a casing, the casing is provided with an inspection opening, and an inspection door matching the inspection door; connecting ribs are arranged between the inspection door and the inspection opening to connect each other, so that The above connecting ribs are disconnected when the access door is first opened / closed. The invention is provided with an inspection door and an inspection port for easy maintenance in the dishwasher, so that the dishwasher can be repaired and maintained without disassembling the machine when the dishwasher fails. The invention uses connecting ribs to fix the inspection door before use, which not only can The access door is effectively fixed, and the overall structural strength of the shell with an opening on the side wall is improved, which can prevent dislocation of the access door or deformation of the shell / access door caused by transportation drop or collision.

Owner:QINGDAO HAIER DISHWASHER

Displacement deformation-difficult O-shaped sealing ring

InactiveCN105587745APrevent misalignment and deformationImprove sealingEngine sealsWashersMaterials science

Owner:罗福仲

Bamboo-plastic composite floor and pavement method thereof

Owner:ANHUI SENTAI WPC GRP CO LTD

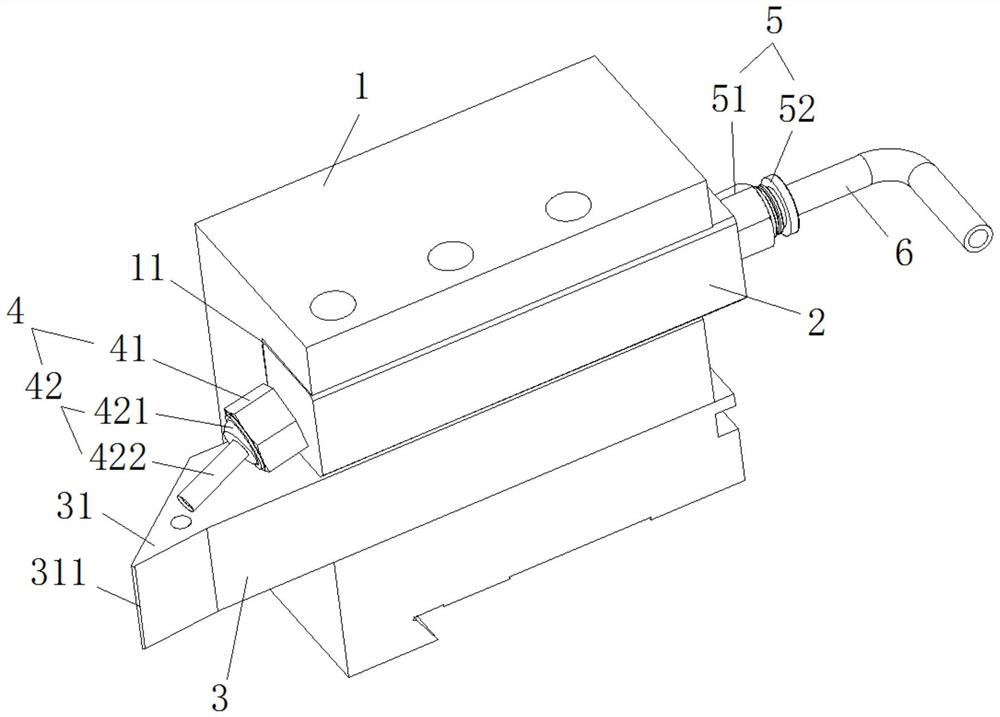

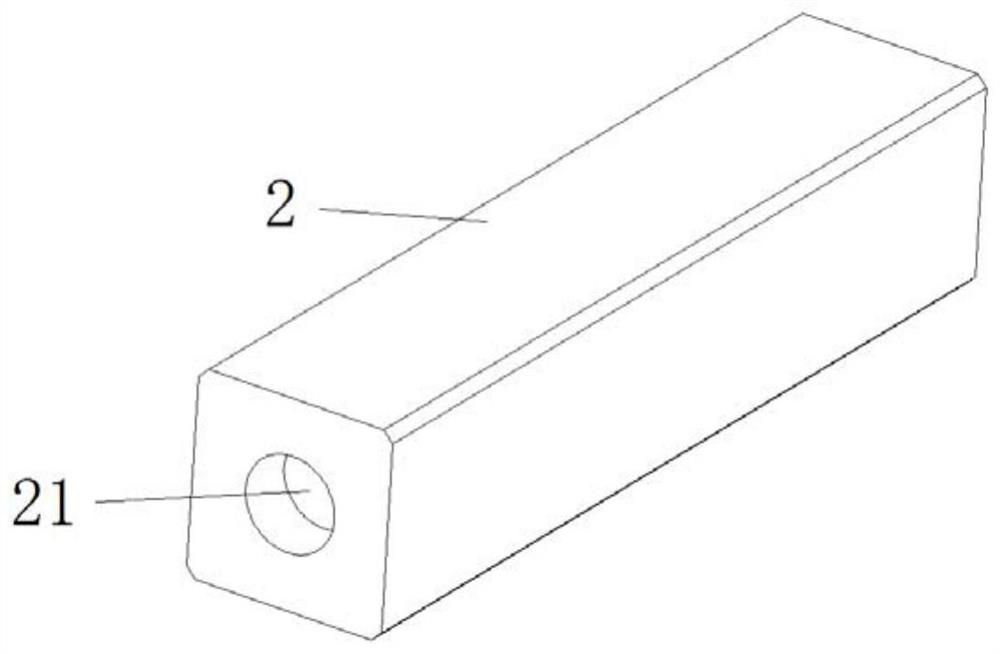

Tool rest cooling structure for machine tool

The invention provides a tool rest cooling structure for a machine tool, and belongs to the technical field of machine tool machining. According to the tool rest cooling structure for the machine tool, a flow guide hole penetrating through the two ends and a nozzle and a connection joint which are arranged at the two ends of the flow guide hole are formed in a cutter pressing block; the connection joint is connected with a cutting fluid feeding pipe; a spray head of the nozzle faces a cutter head of a cutter; the existing cutter pressing block structure is fully used as a conveying pipeline, cooling of a machined position and blowing-away operation of sweeps are achieved, cost is reduced, the conveying stroke of cutting fluid is only the width of a tool apron within the range of the tool apron, and the conveying stroke is shortened; and meanwhile, the pressure bearing capacity is better, pipeline bending is not needed, the deformation and dislocation problems are avoided, the structural strength is higher, the shaking problem in the using process is avoided, stability is better, adjustment only needs to be conducted once in the initial installation process, the problems of inconvenience and heavy workload caused by subsequent repeated adjustment are avoided, the arrangement space is saved, the installation limitation is small, the adaptability is higher, and the use performance of the machine tool is improved easily.

Owner:宁波品上精密机床有限公司

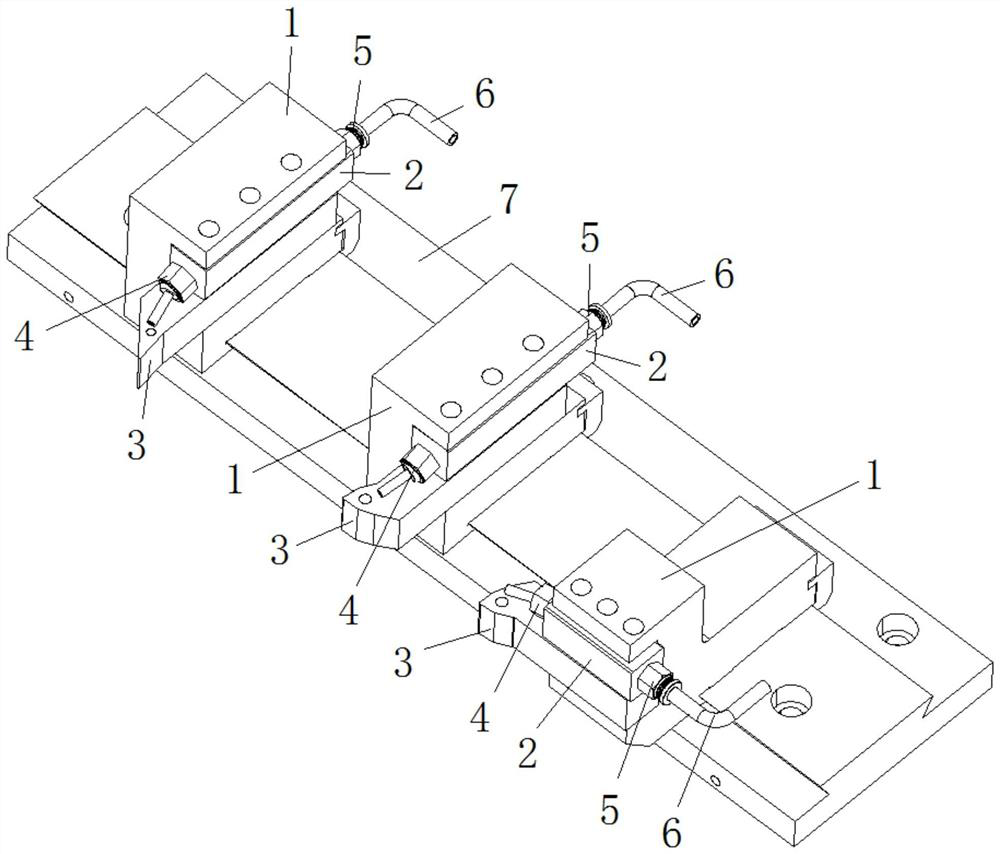

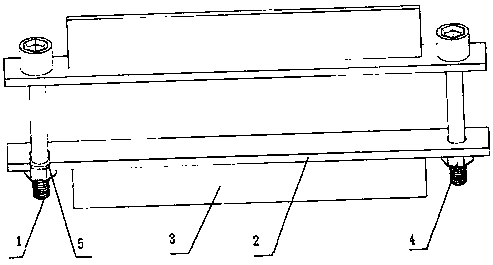

Alkaline pocket type battery shell seal welding fixture

The invention discloses an alkaline pocket type battery shell seal welding fixture, which comprises two strip-type clamping plates, wherein a space, capable of containing a battery shell, close to each of two ends, is formed in the middle of each strip-type clamping plate, the space is provided with two bolts with a nut on one end, a baffle plate is perpendicularly mounted on the middle part of the outer surface of each of the two clamping plates in a transverse direction; a screw lateral inlet / outlet is formed at the position corresponding to the bolt on the side wall of one of the clamping plates. According to the alkaline pocket type battery shell seal welding fixture disclosed by the invention, the clamping plates and the adjusting bolts are used for fixing and limiting a workpiece tobe welded and then performing hot plate welding and sealing, so that the welding surface can be evenly stressed, the phenomena of deformation, dislocation and air leakage are prevented, and the welding quality is ensured; the alkaline pocket type battery shell seal welding fixture has the advantages that the use is flexible and convenient, the working efficiency is improved and waste is avoided.

Owner:HENAN HENGMING FENGYUN POWER SOURCE

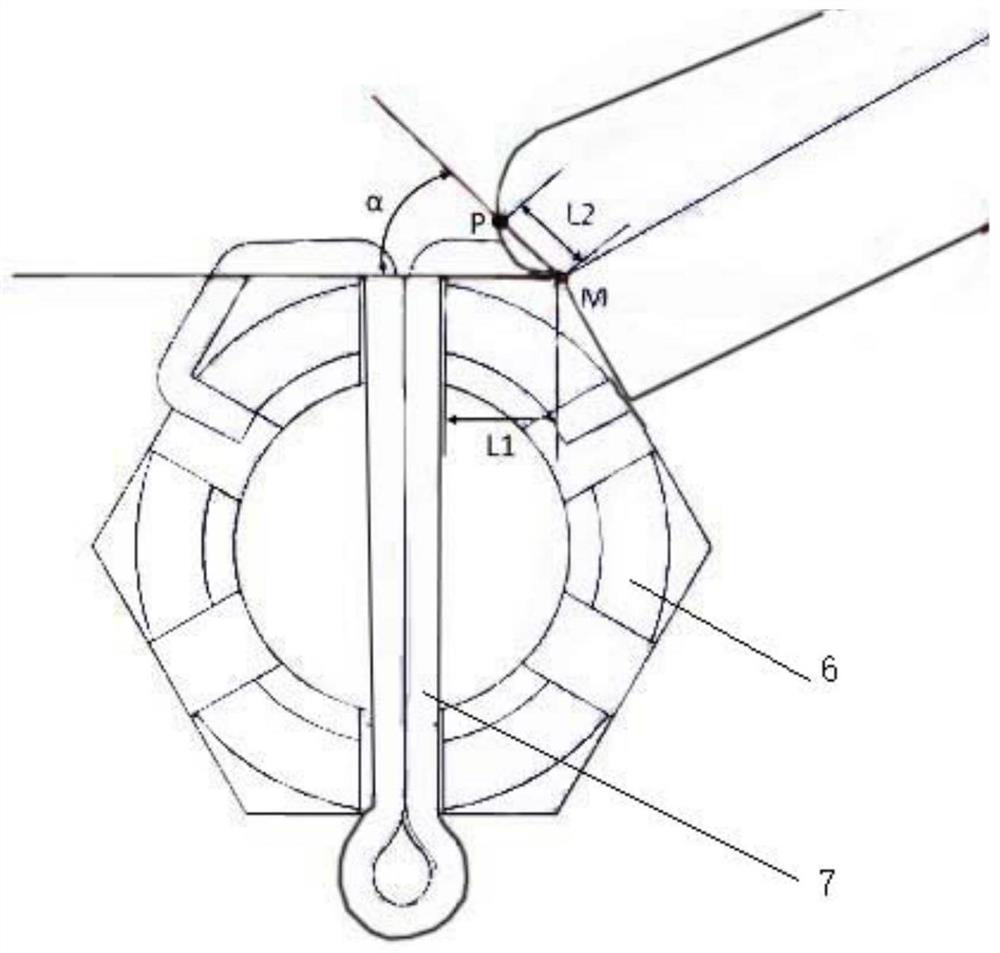

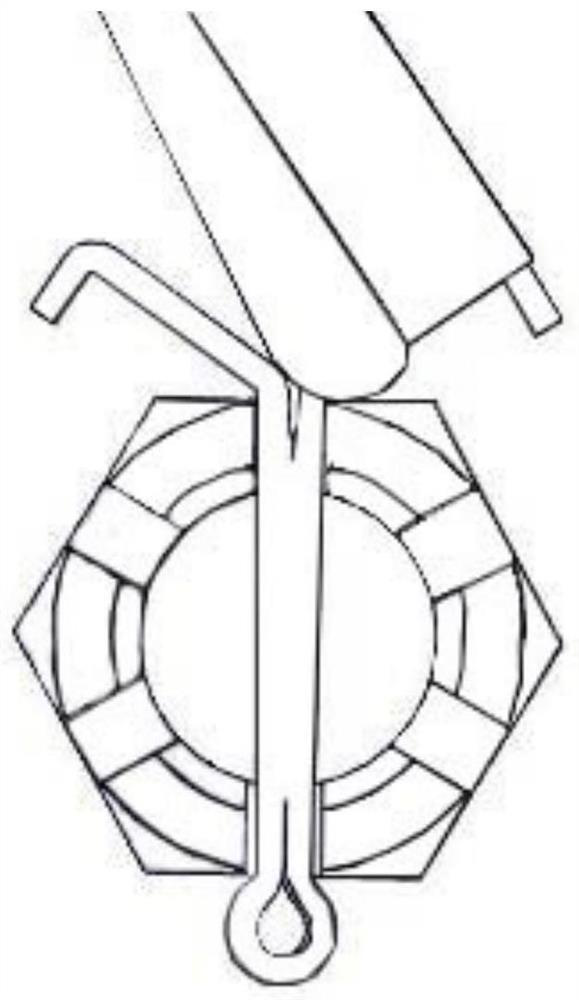

Quick dismounting device and method for cotter pin

ActiveCN113427431AAvoid deformation and misalignmentQuick releaseMetal-working hand toolsPhysicsEngineering

The invention discloses a quick dismounting device and method for a cotter pin, and belongs to the field of assembly. The quick dismounting device comprises two clamping parts which are movably riveted with each other. Each clamping part comprises a clamping area and a holding area connected with the clamping area, each clamping area comprises a clamping piece and a supporting piece, and the clamping pieces and the supporting pieces are located on the same horizontal plane. Each clamping piece comprises a clamping end, wherein a clamping cutting edge is arranged at the end portion of the clamping end, and each supporting piece comprises an arc-shaped supporting end. The clamping cutting edges are additionally arranged at the end portions of the clamping parts, the clamping cutting edges are partially sunken into the tail of the cotter pin under the action of clamping force, the cotter pin can be effectively clamped, deformation and dislocation of the cotter pin in the disassembling process are avoided, and the cotter pin is prevented from sliding and loosening in the clamping process. A jaw is additionally arranged and can pinch off the tail part of the opened cotter pin, so that the residual cotter pin forms a barrier-free pin, the cotter pin is conveniently pulled out, a nut and a bolt are not damaged, and the disassembly is quicker after direct pulling.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

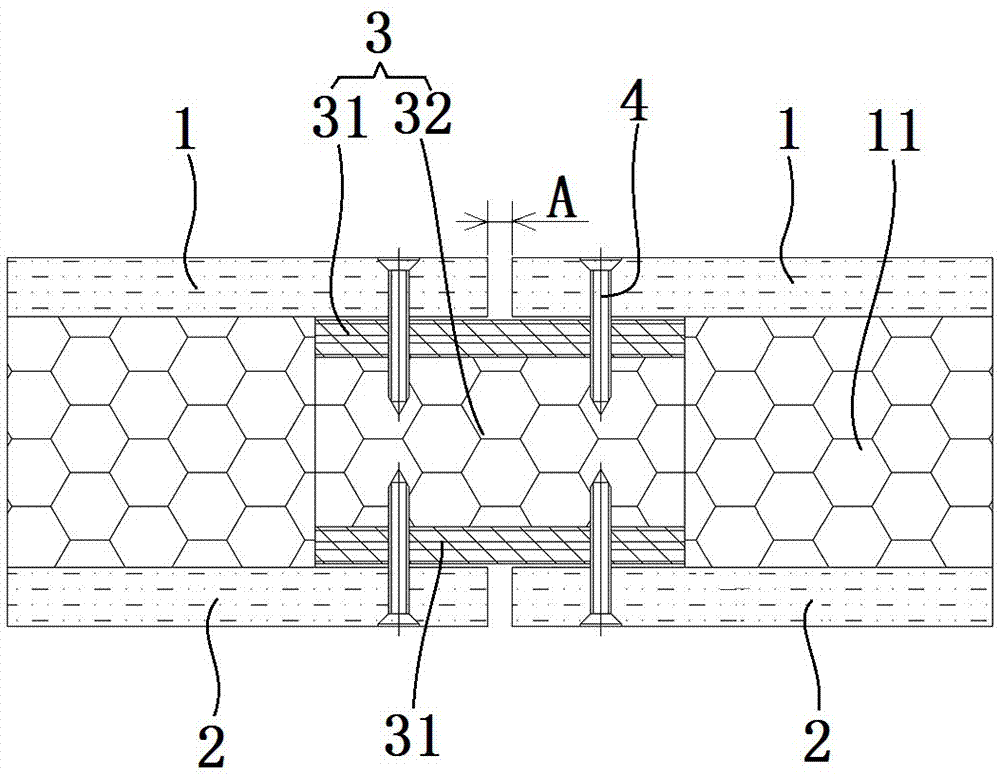

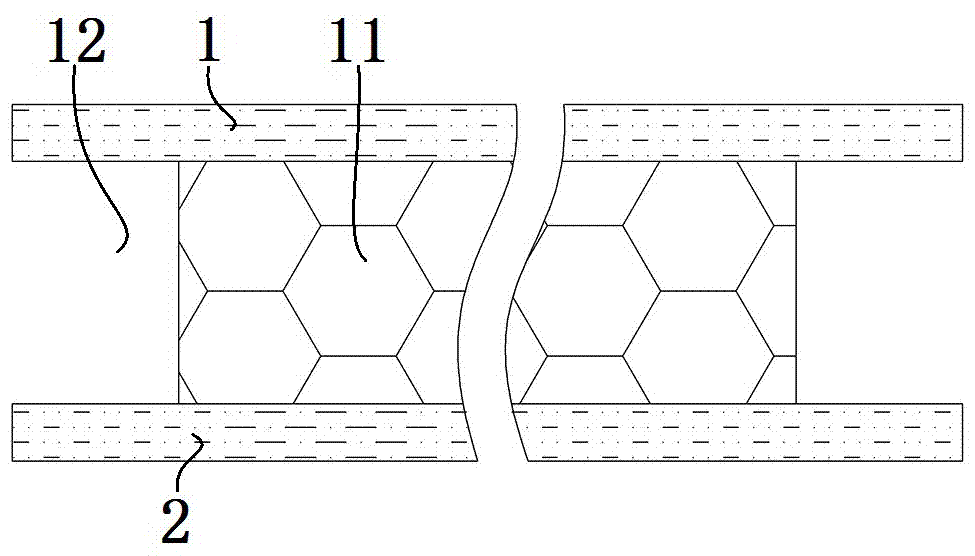

Connecting structure for wall bodies at two sides of prefabricated composite wall and method thereof

InactiveCN112681558AUniform and stable up and down forcePrevent misalignment and deformationArtificial islandsWallsEngineeringRebar

The invention discloses a connecting structure for wall bodies at two sides of a prefabricated composite wall and a method thereof, and relates to the technical field of composite wall assembly. The connecting structure comprises a composite wall and a plurality of groups of connecting parts; the connecting parts are arranged at the front side and the rear side of the composite wall; the connecting parts are I-shaped; the height of the connecting parts is 300-400 mm; and the distance between every two adjacent connecting parts at the same side is 500-600 mm. The connecting method includes the steps that S1, steel bars are fixed and placed at the front side and the rear side of the composite wall, then an upper formwork and a lower formwork are built at the front side and the rear side of the composite wall, and the multiple connecting parts are built between the two formworks; S2, pouring is conducted between the two formworks on the front face of the composite wall, and the connecting parts are pre-buried in the two formworks; S3, a trolley is turned over for die assembly; and S4, pouring is conducted on the two formworks on the back face of the composite wall, the connecting parts are pre-buried in the formworks, and a finished product is manufactured. The connecting structure for the wall bodies at two sides of the prefabricated composite wall and the method thereof have the advantages that the integrity of the composite wall can be guaranteed, the factors of water and electricity pre-burying are considered, deformation and dislocation of the wall bodies at the two sides can be avoided, and the secondary pouring integrity effect is improved.

Owner:CHENGDU CHENGTOU YUANDA CONSTR TECH CO LTD

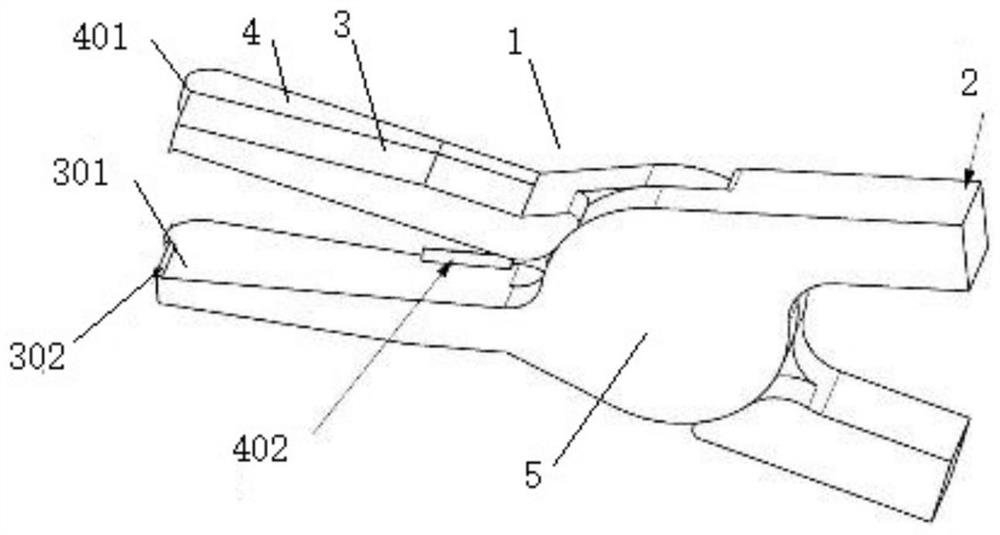

A Composite Busbar Bending Process

ActiveCN106205867BAvoid crackingPrevent misalignment and deformationSingle bars/rods/wires/strips conductorsCable/conductor manufactureBusbarEngineering

The invention discloses a composite busbar bending process, and belongs to the technical field of production of composite busbars. The composite busbar bending process comprises the following steps of (1) lamination, stacking at least two layers up and down, wherein the structure of each layer is a first insulating layer, a copper bar and a second insulating layer in sequence from top to bottom, the right part of each adjacent layer is provided with an anti-bonding layer and the left part is glued for bonding, and the length of each anti-bonding layer is greater than or equal to that of the bent and staggered part; (2) laminating and gluing; (3) bending in place; and (4) extraction of the anti-bonding layers to obtain a bent composite busbar. By the composite busbar bending process, cracking of the bent part of the composite busbar and stagger deformation between the layers can be prevented; the quality is ensured; the yield is improved; the efficiency is improved; and the cost is reduced.

Owner:沧州惠邦重工装备制造有限公司

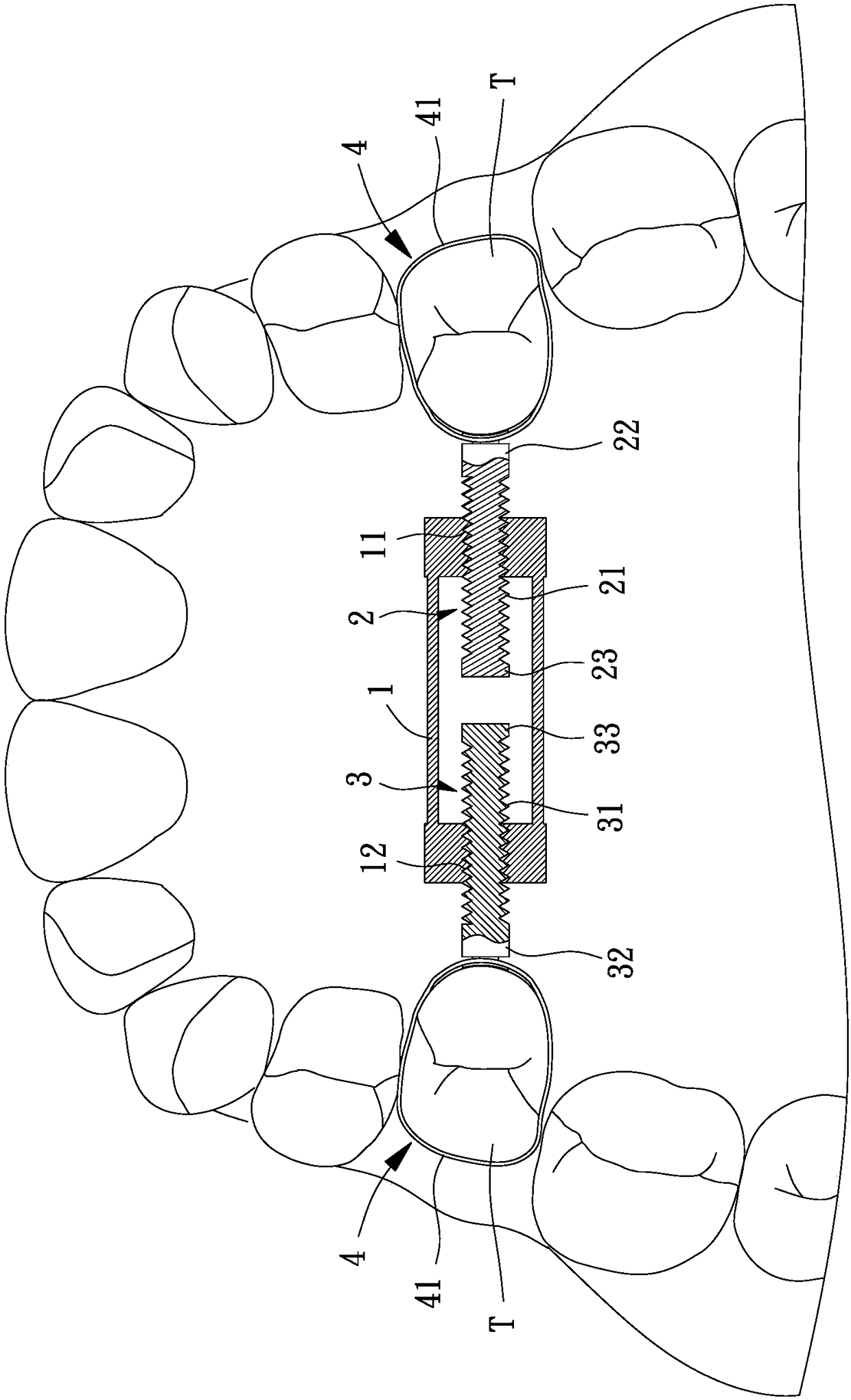

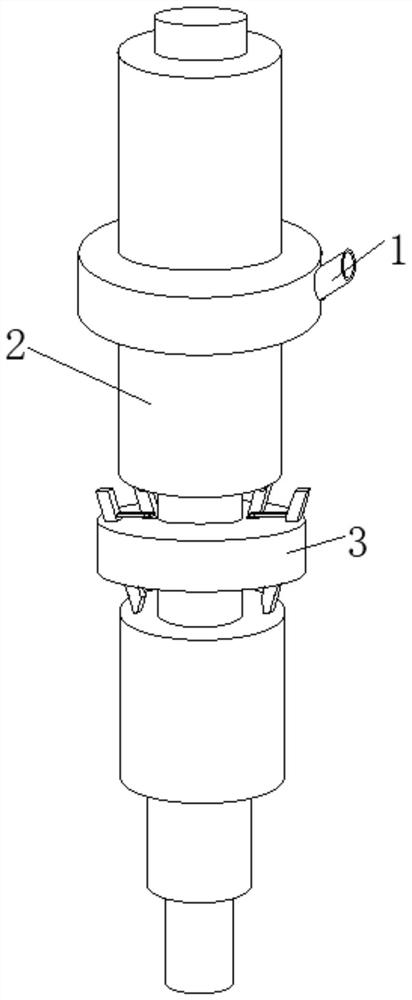

Tooth jaw maintaining device

Owner:METAL INDS RES & DEV CENT

Common rail type marine diesel injector

ActiveCN114837866AEven by forceRealize supporting workFuel injection apparatusMachines/enginesMarine engineeringCommon rail

The invention discloses a common-rail marine diesel injector which comprises a common-rail injector body, a clamping piece located at the lower end of the common-rail injector body and a reinforcing mechanism connected to the outer side of the common-rail injector body in a sleeving mode. The reinforcing mechanism comprises a shell, a horizontal guide rail, a clamping piece, a first channel and a second channel, wherein the shell is connected to the joint of the outer side of the common-rail oil injector body in a sleeving mode and provided with a through hole, the horizontal guide rail is arranged on the inner wall of the shell, and the clamping piece is in sliding connection with the horizontal guide rail and used for clamping and fixing the common-rail oil injector body. The driving piece is slidably sleeved with the second channel and used for driving the clamping piece to horizontally slide in the horizontal guide rail, and the first wedge rod is slidably sleeved with the first channel; according to the common rail type marine diesel engine fuel injector, supporting operation and double reinforcing operation of the reinforcing mechanism on the common rail fuel injector body are achieved, the service life of the common rail fuel injector body is guaranteed, and normal use of the common rail fuel injector is further guaranteed.

Owner:ANQING CSSC DIESEL ENGINE

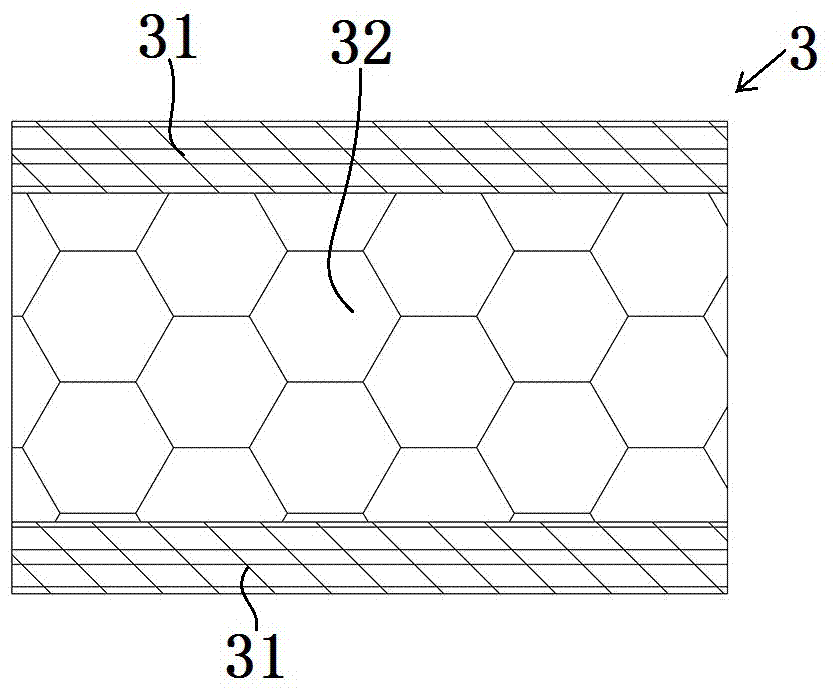

Assembly type composite panel and heat insulation boards thereof

PendingCN106939652AImprove connection strengthPrevent misalignment and deformationHeat proofingStructural engineeringMechanical engineering

The invention relates to an assembly type composite panel and heat insulation boards thereof. The assembly type composite panel comprises at least two heat insulation boards connected in sequence, each the heat insulation board comprises an inner face panel and an outer face panel, wherein a filling layer is arranged between the two face panels, and a slot is formed between the inner and outer face panels at the position of a connection end of the two adjacent heat insulation boards; a bridge connection piece is inserted in the slotting and the upper side face of the bridge connection piece is attached to the outer face panels of the two adjacent heat insulation boards, and the lower side face of the bridge connection piece is attached to the inner face panels of the two adjacent heat insulation boards, so that a connection piece does not need to be arranged at the connection end of the heat insulation boards, misplacement and deformation of the connection piece, the face planes and the bridge connection piece are avoided when the temperature changes, deformation of nails in the connection position due to shearing force is avoided, and the connection strength between the heat insulation boards is improved; and when installing is conducted, the bridge connection piece is directly installed in the slot of one heat insulation board, then the other heat insulation board is installed on the bridge connection piece, and the installation process is convenient.

Owner:HENAN TIANFON ENERGY SAVING PANEL SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com