Parchment paper cigarette packaging structure and making methongd thereof

A packaging structure, sulfuric acid paper technology, applied in packaging, biological packaging, packaging cigarettes, etc., can solve the problems of inability to use cigarette packaging machines, whitening crease line stiffness, etc., to avoid compression deformation, dislocation, and stiffness reduction. , reduce the effect of deformation and dislocation

Active Publication Date: 2011-01-05

SHENZHEN JINJIA GRP

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, sulfuric acid paper material has good moisture-proof, oil-proof, gas-barrier properties, moderate transparency, strong decoration, and can better highlight the theme and aesthetic feeling. It is used to make high-end packaging boxes, especially cigarette packaging boxes. Cigarette products have better decoration, protection and promotional effects; however, the crease lines processed by ordinary creasing lines are used for the structural molding of sulfuric acid cartons. Due to fiber deformation and dislocation, obvious whitening occurs and the stiffness of crease lines is as high as 80-120. Cannot be used on cigarette wrapping machines

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

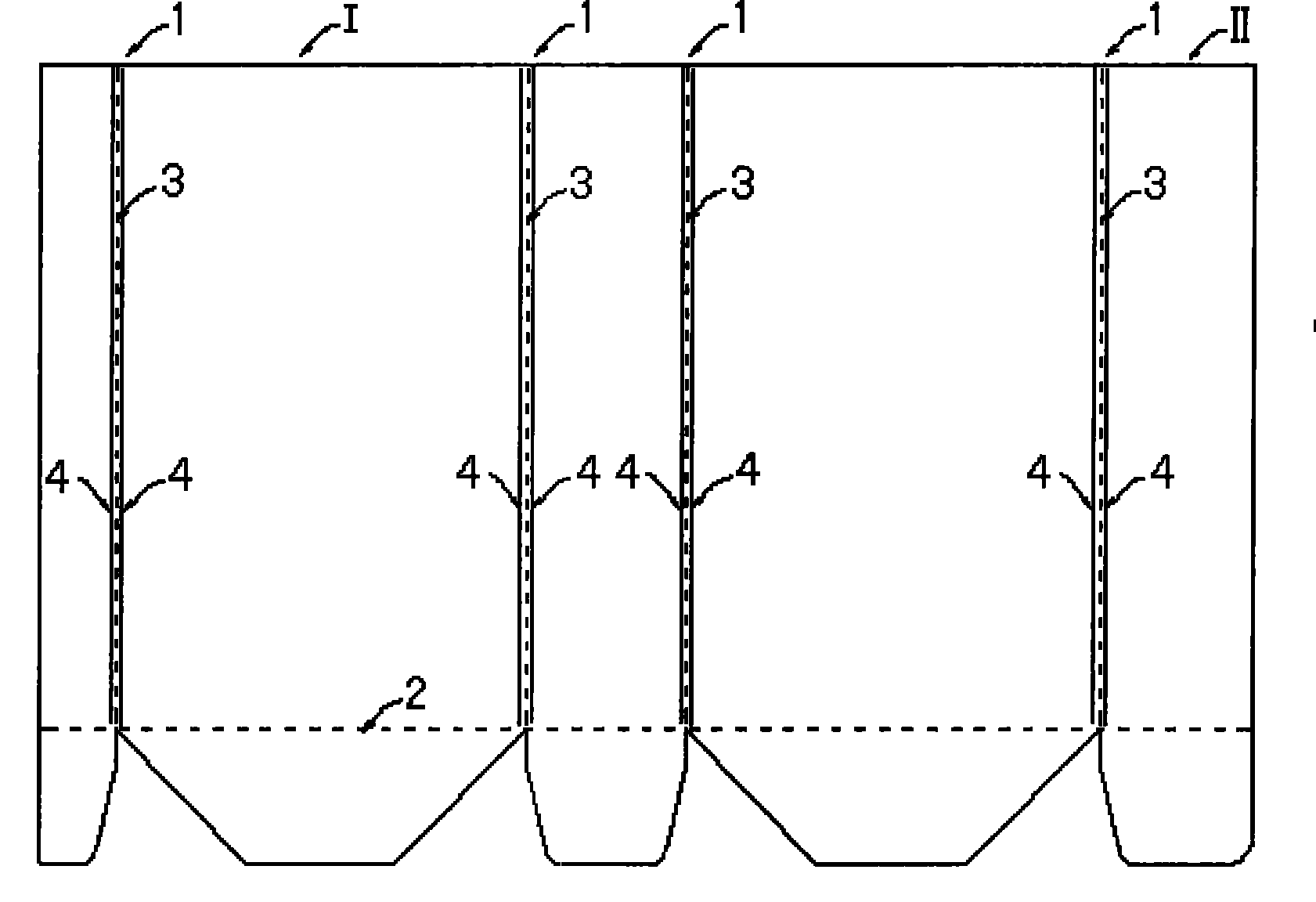

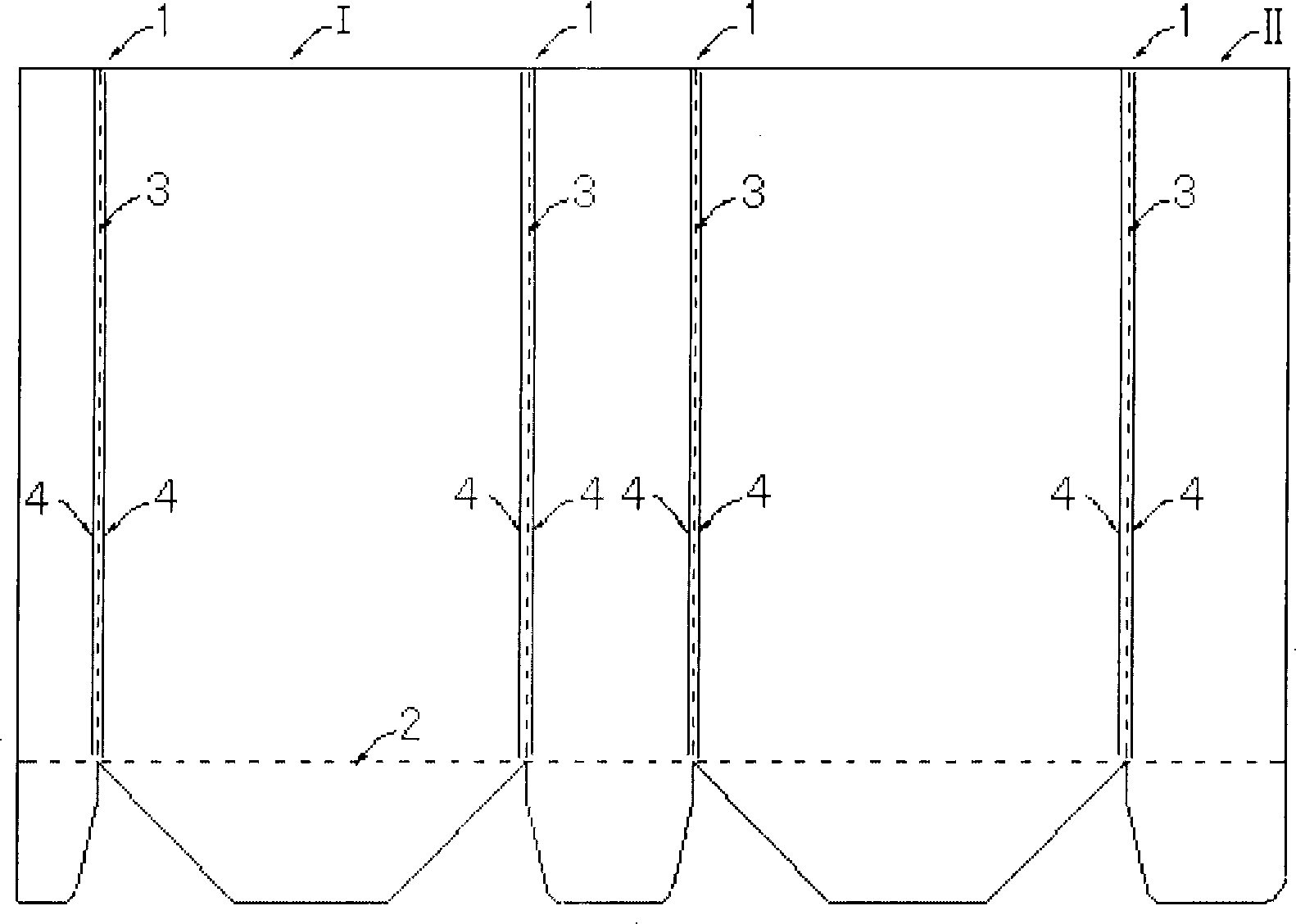

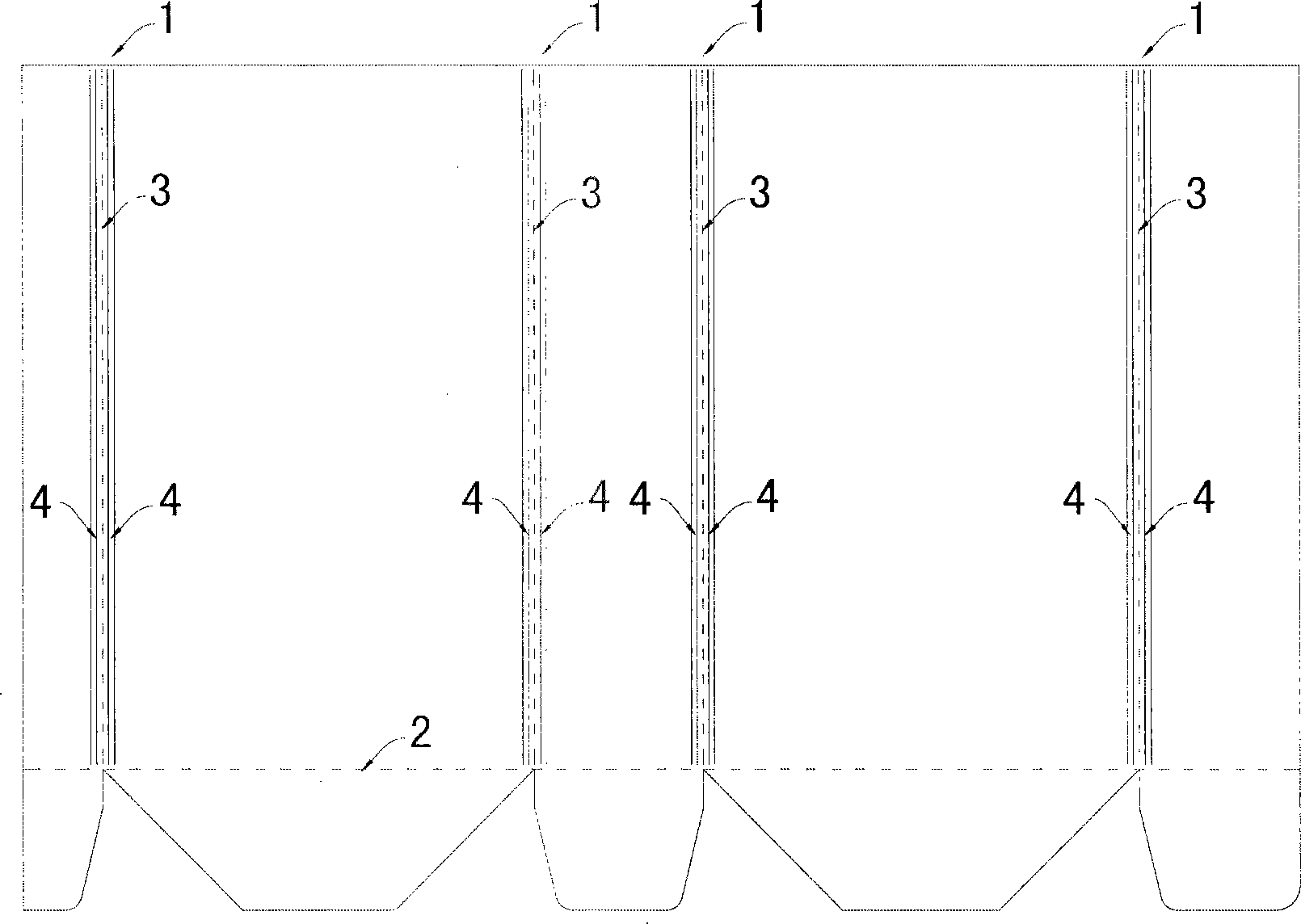

The invention provides a parchment paper cigarette packaging structure. A folding line is processed by a combination method with point penetration crush-cutting and semi-penetration crush-cutting to avoid deformation and dislocation of parchment paper fibers due to pressure when the folding line is processed, therefore, the stiffness of the folding line is greatly reduced. The stiffness of the folding line ranges from 50 to 80 after the parchment paper is formed so as to meet the requirement of domestic cigarette packaging equipment and realize the packaging production of a cigarette packaging machine.

Description

Sulfuric acid paper cigarette packaging structure and manufacturing method technical field The invention relates to a sulfuric acid paper cigarette packaging structure and a manufacturing method, and belongs to the field of cigarette packaging. Background technique At present, the sulphuric acid paper material has good moisture-proof, oil-proof, gas barrier properties, moderate transparency and strong decoration, which can better highlight the theme and aesthetics. It is used to make high-end packaging boxes, especially cigarette packaging boxes. Cigarette products have better decoration, protection and promotion effects; however, the structure of the sulfuric acid carton body is formed by the crease line processed by the general indentation line. Due to the fiber deformation and dislocation, it appears obvious whitening and the crease line stiffness is as high as 80-120. Cannot be used on cigarette packers. Therefore, there is a need for a new manufacturing method to ma...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B65D85/10B65D5/02B31B1/25B31B50/25

CPCY02W90/10

Inventor 庄德智

Owner SHENZHEN JINJIA GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com