Patents

Literature

52results about How to "The overall space occupied is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

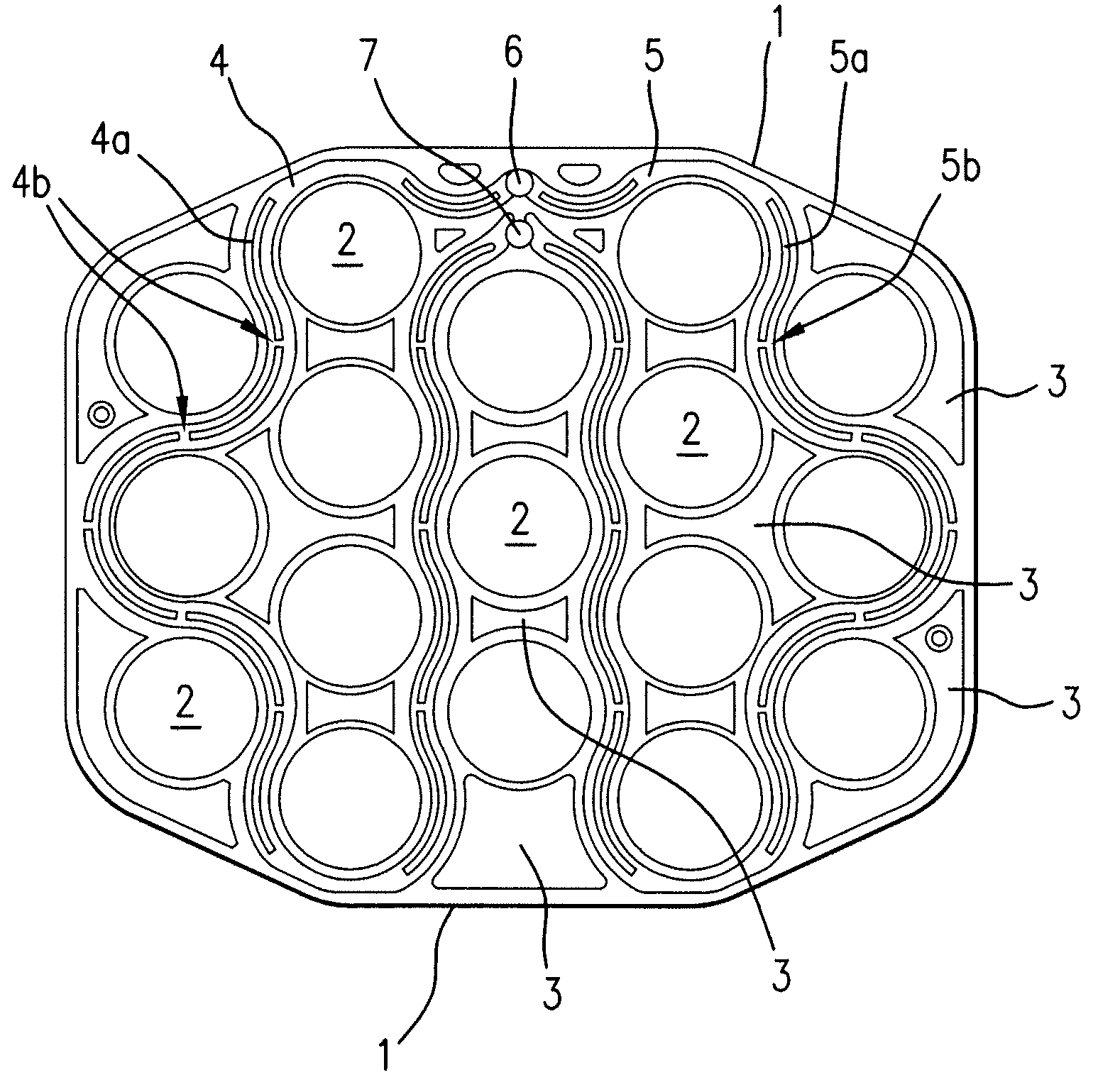

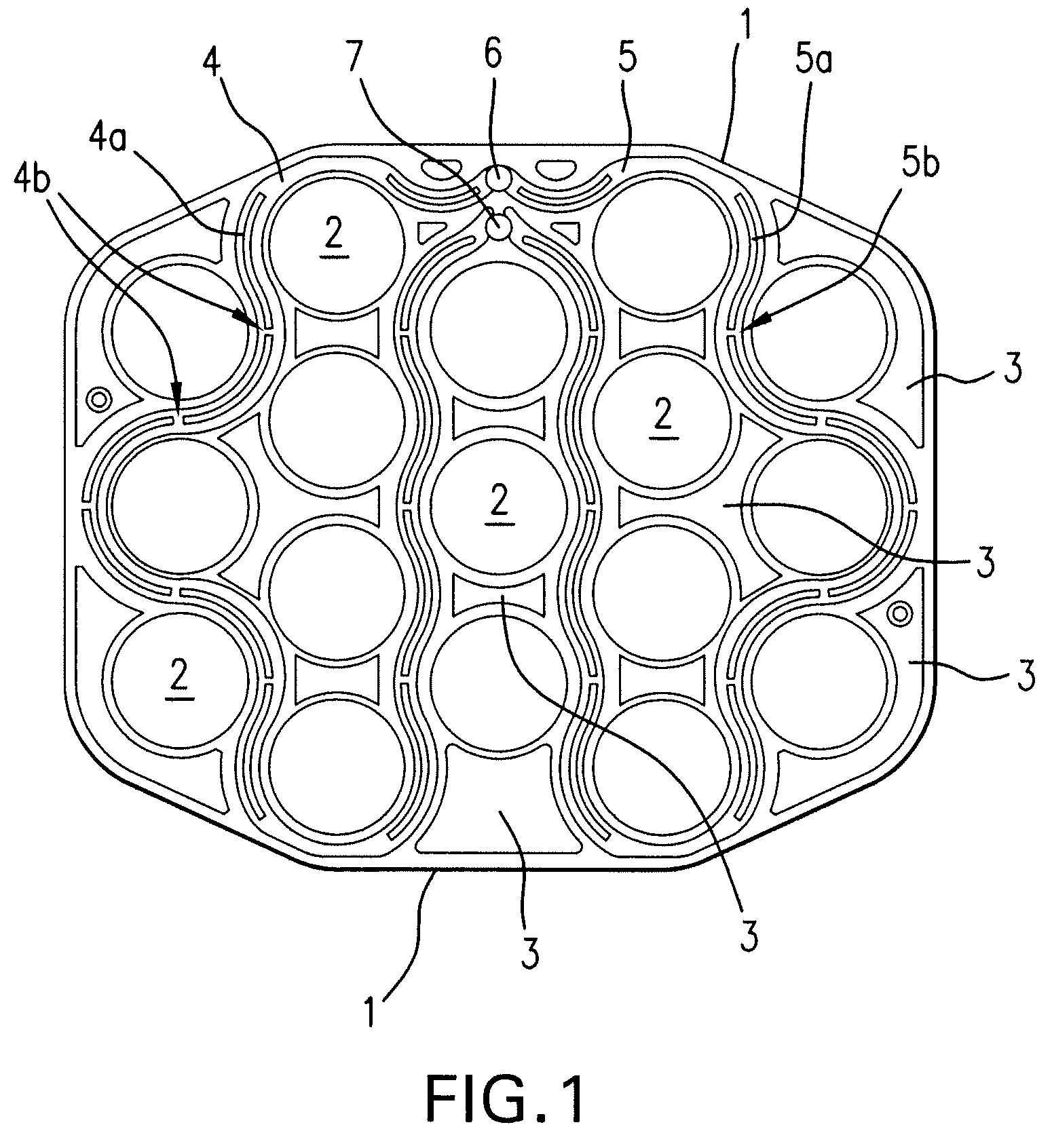

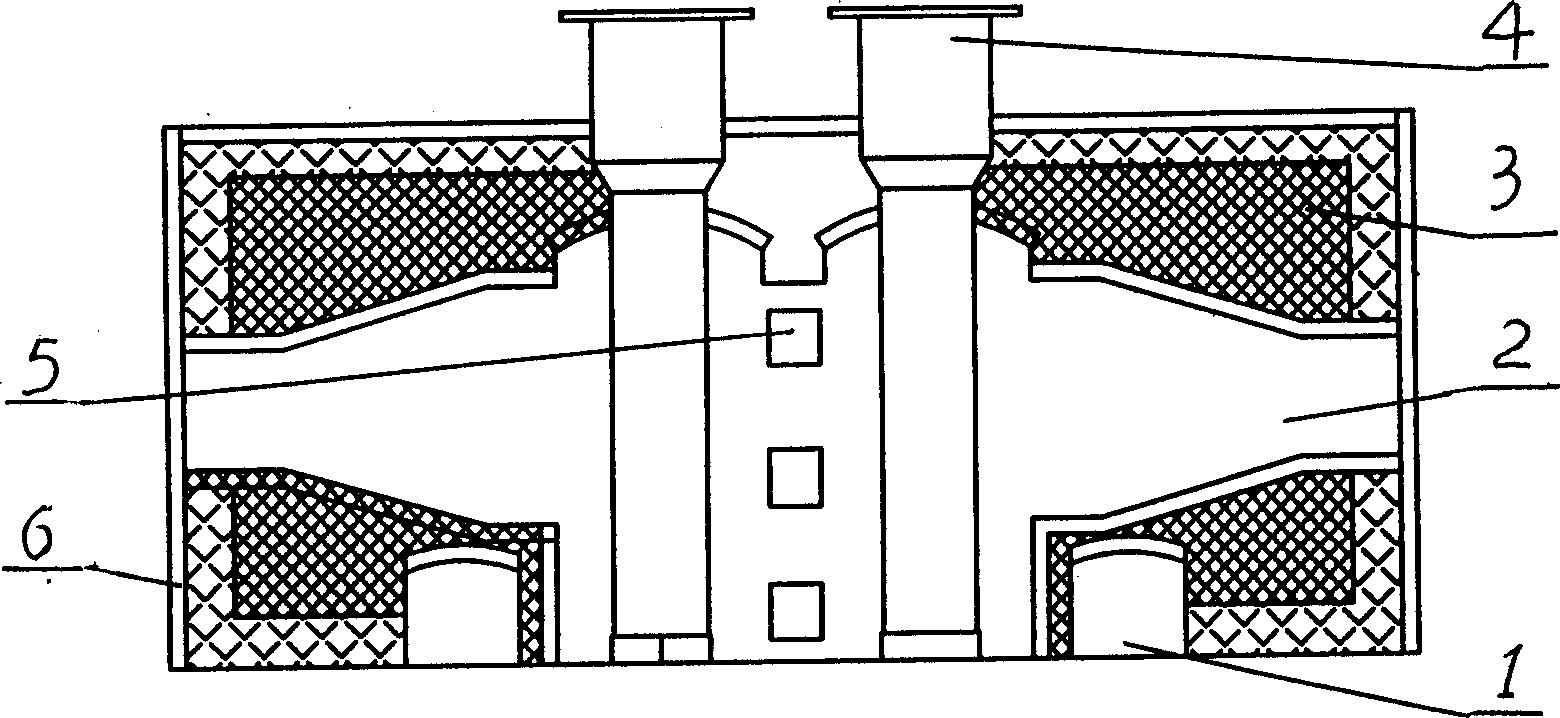

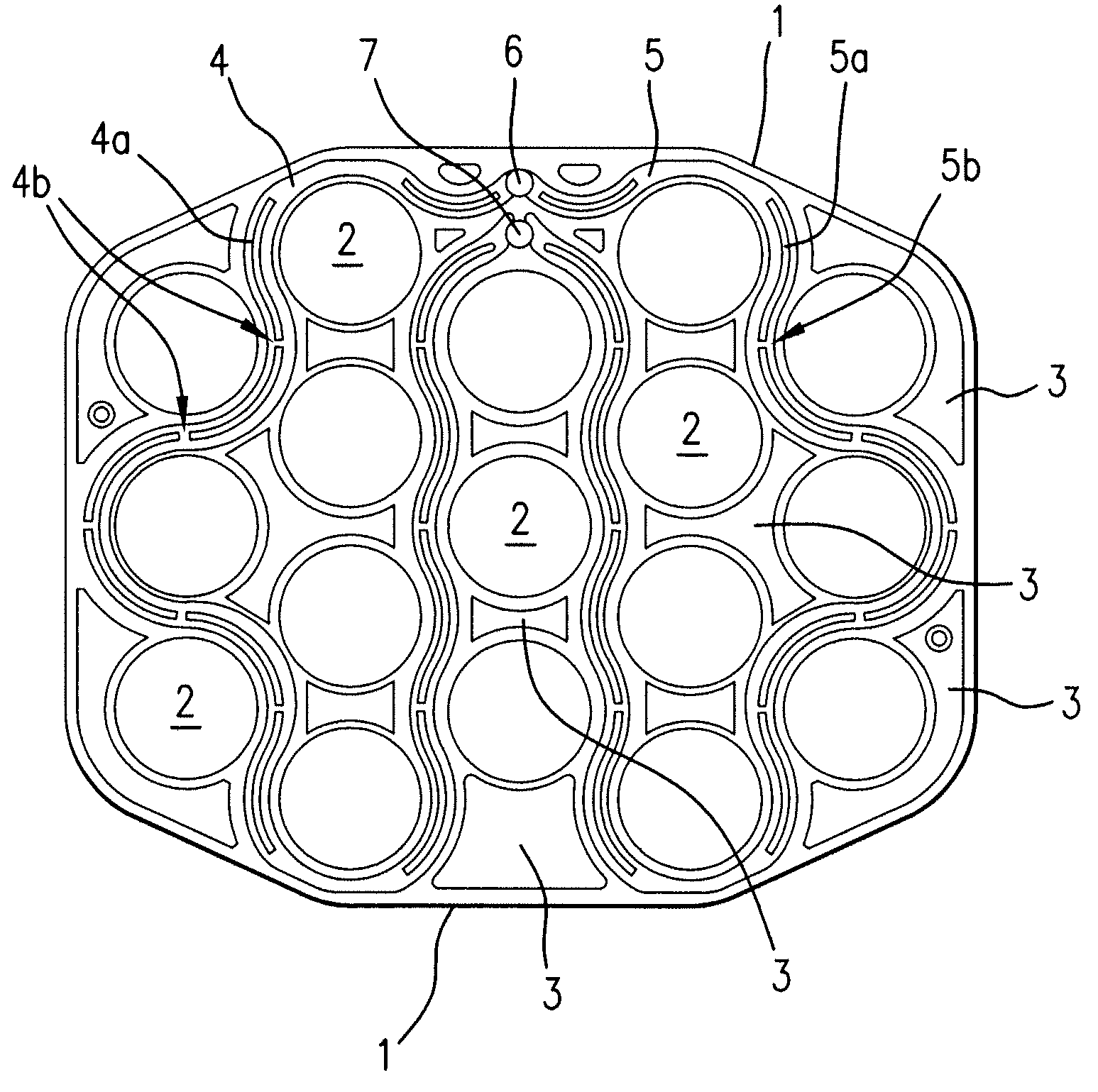

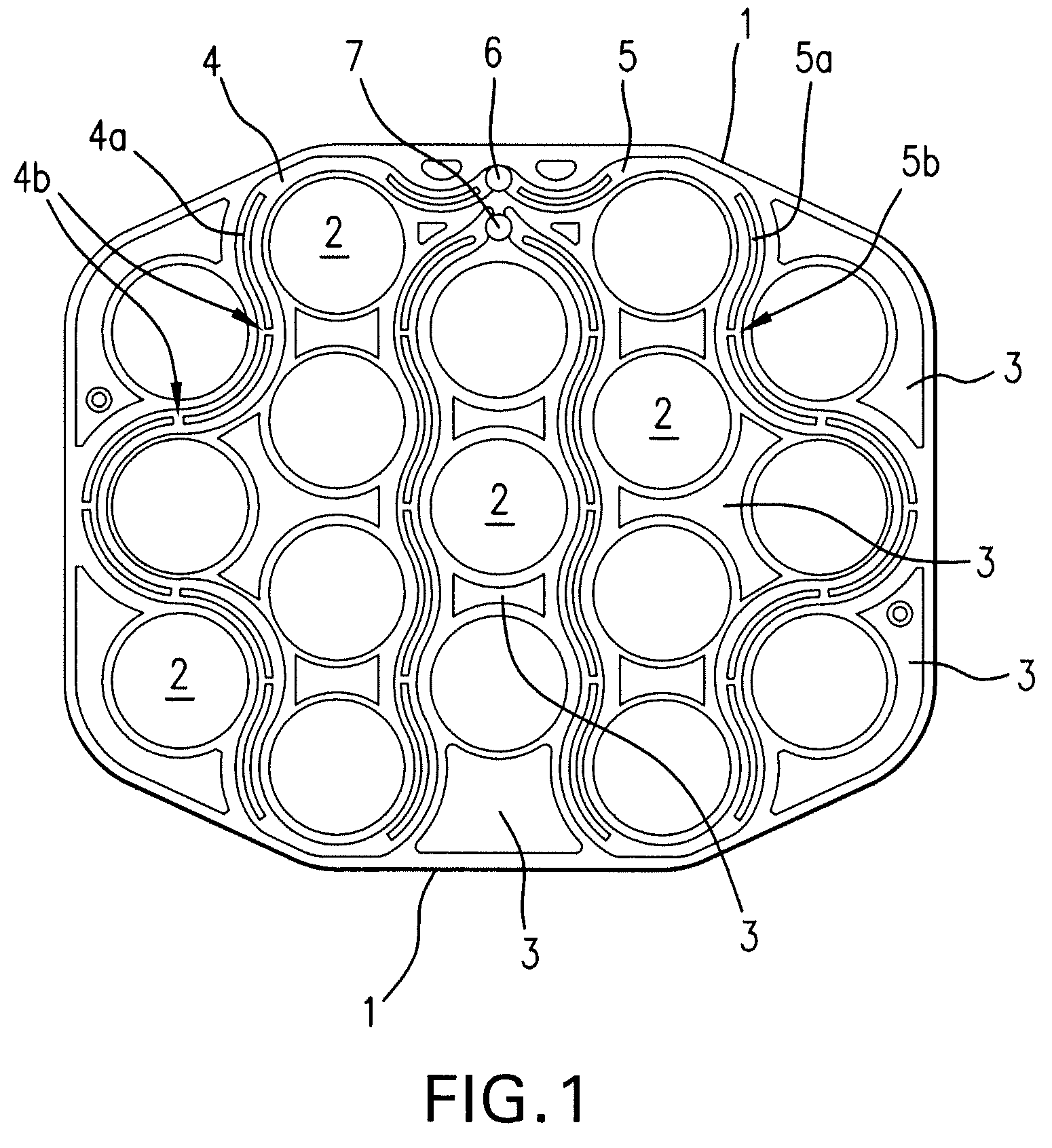

Apparatus for cooling of electrical elements

ActiveUS20090059528A1Improve cooling effectOccupies little physical spaceHeat exhanger conduitsSecondary cellsThermal contactElectrical element

Apparatus for cooling electrical elements, comprising a heat sink (1, 101, 201) through which a coolant can flow, a plurality of electrical elements (2, 102, 202) which each have a bottom surface and a side surface, with the bottom surfaces being aligned essentially on one plane, with the heat sink (1, 101, 201) having at least one channel (4, 5, 104, 105, 204, 205) through which a coolant can flow and making thermal contact with the electrical elements (2, 102, 202), characterized in that the heat sink (1, 101, 202) extends essentially parallel to the plane of the bottom surfaces, with the channel (4, 5, 104, 105, 204, 205) in the heat sink having a profile which is matched to edges of the electrical elements (2, 102, 202).

Owner:BEHR GMBH & CO KG

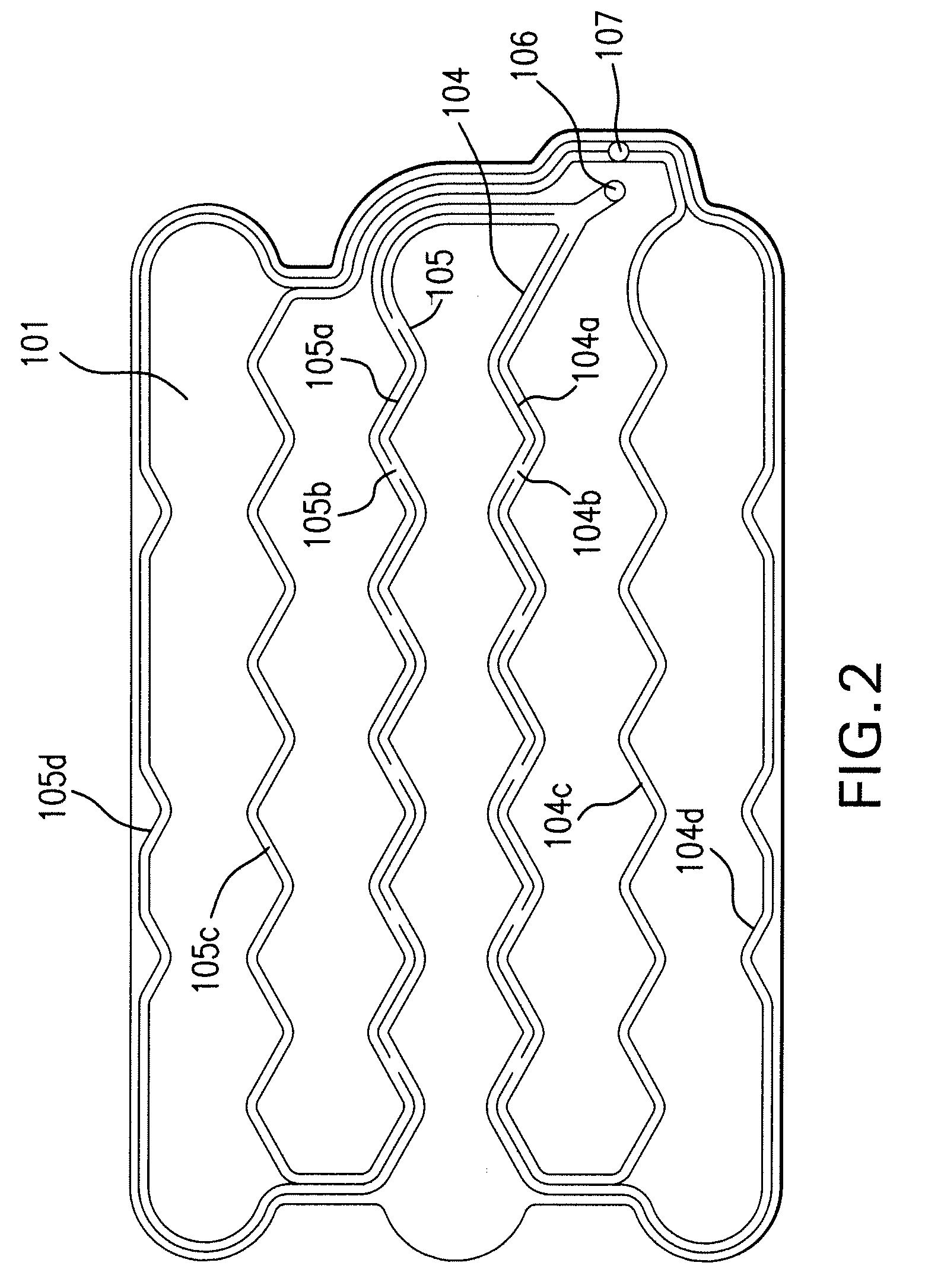

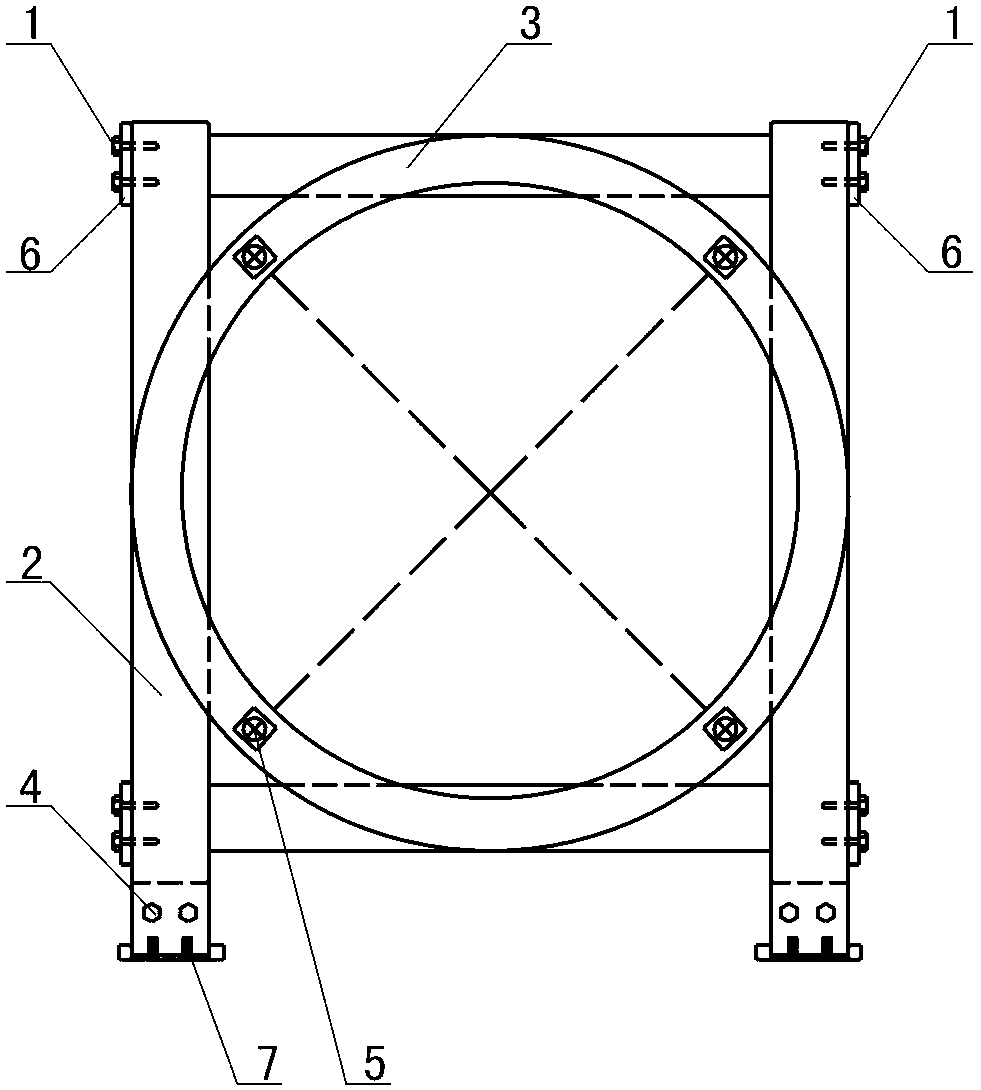

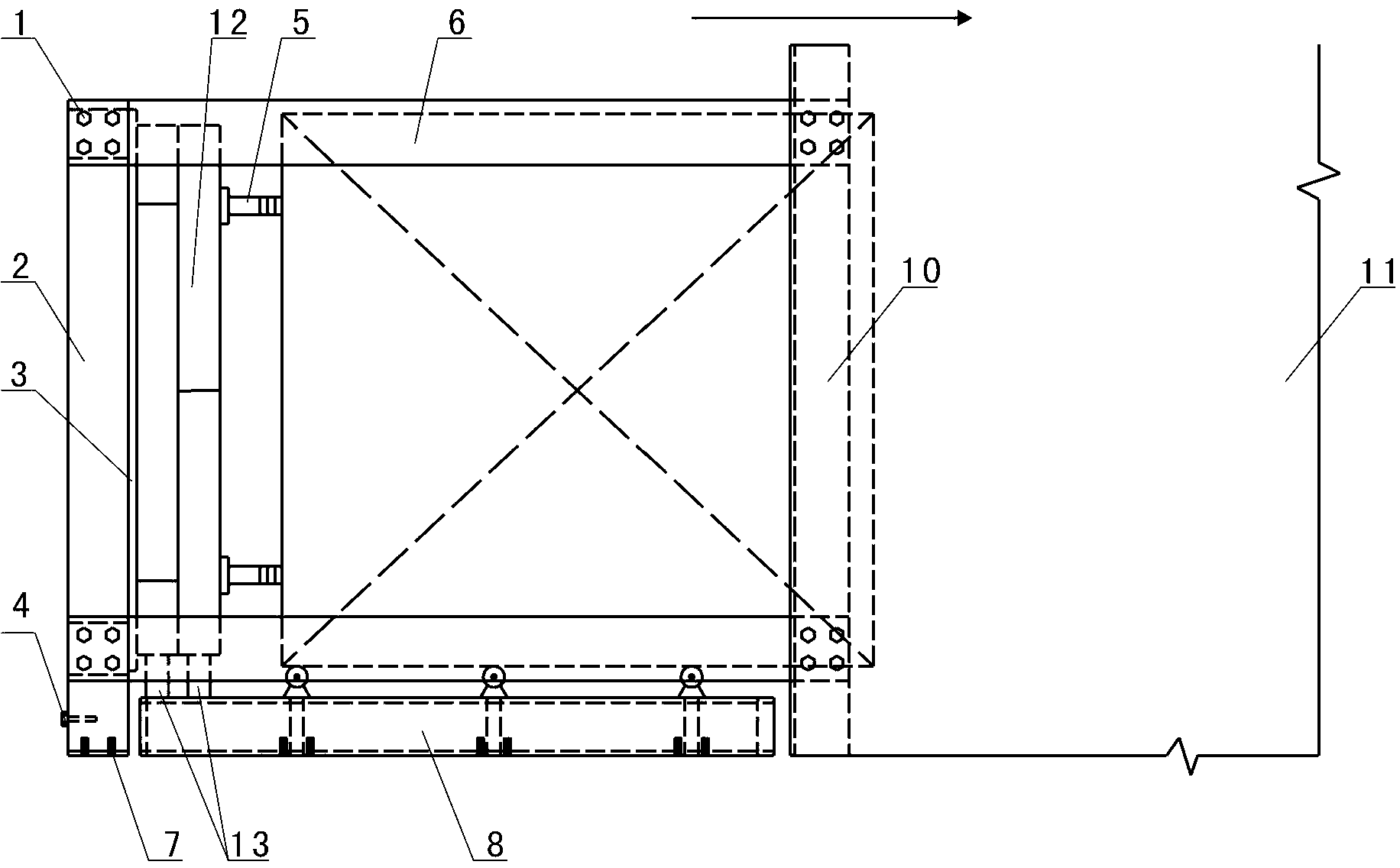

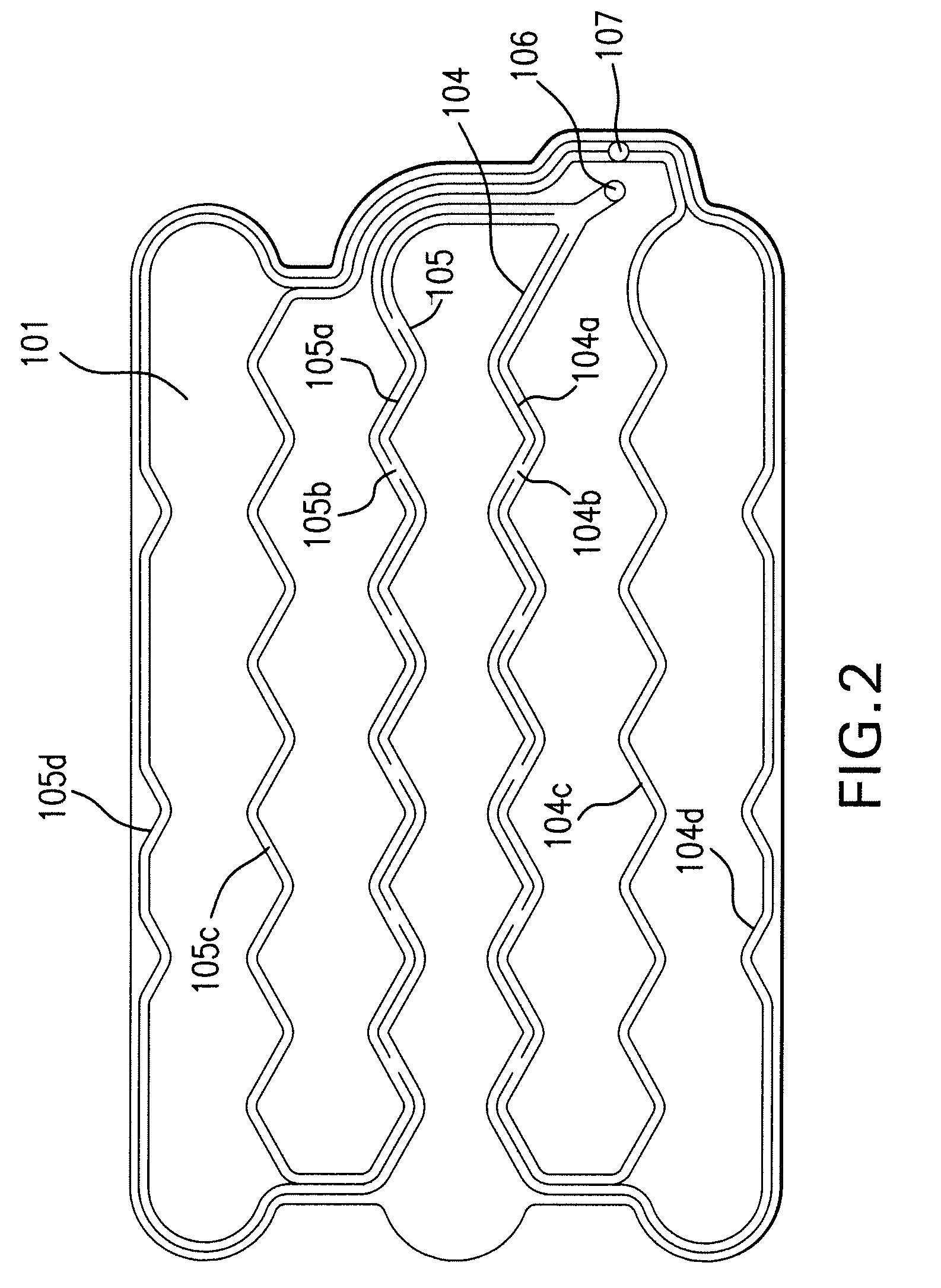

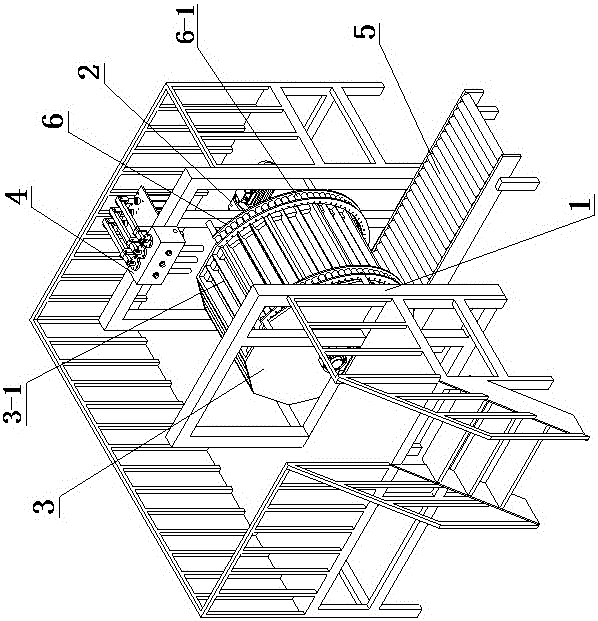

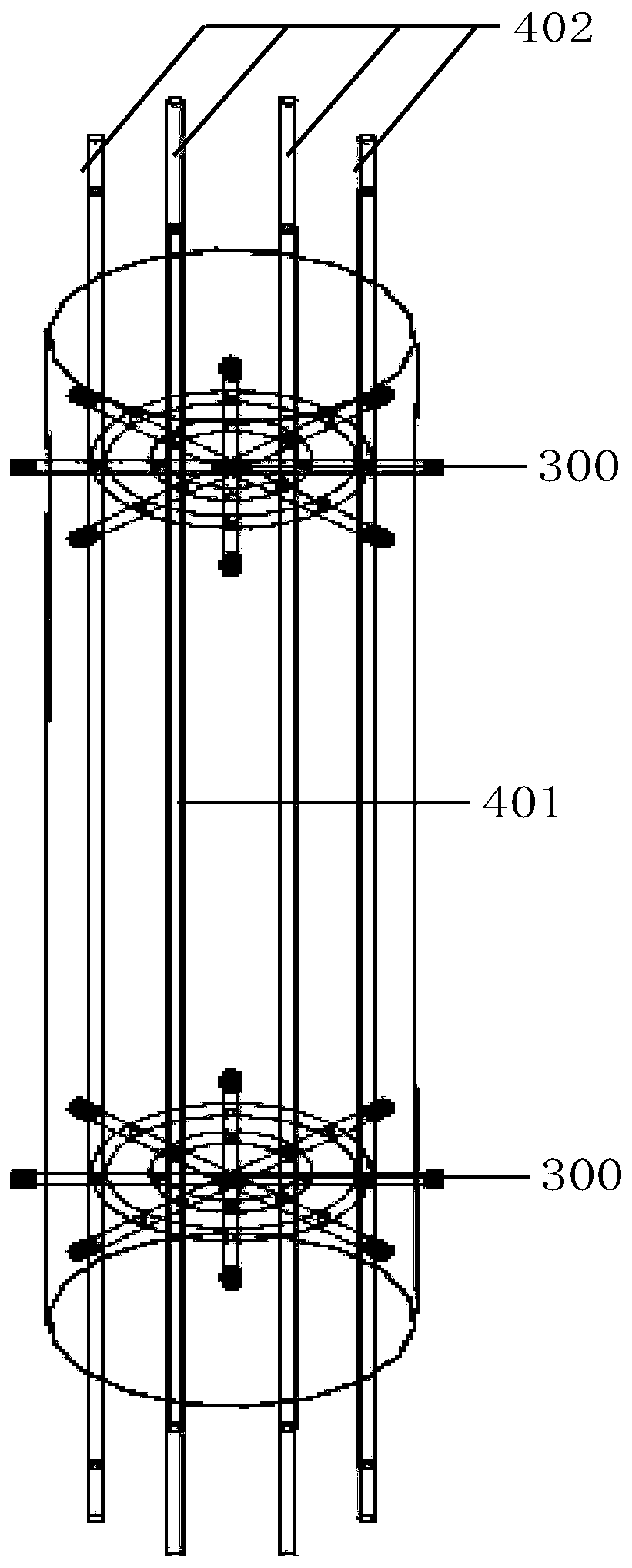

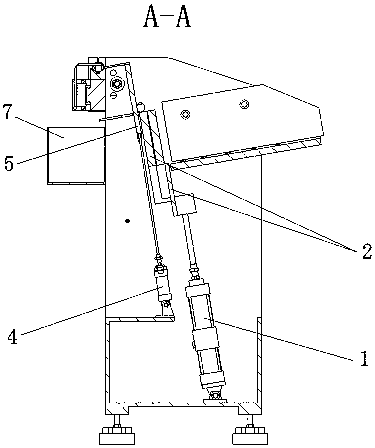

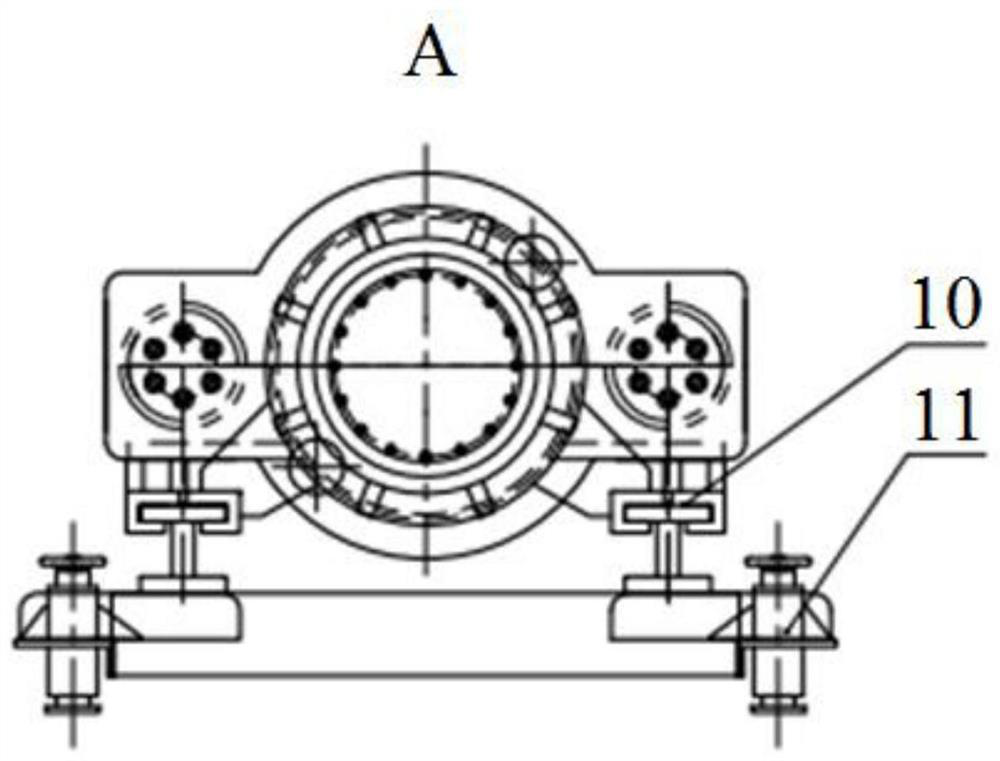

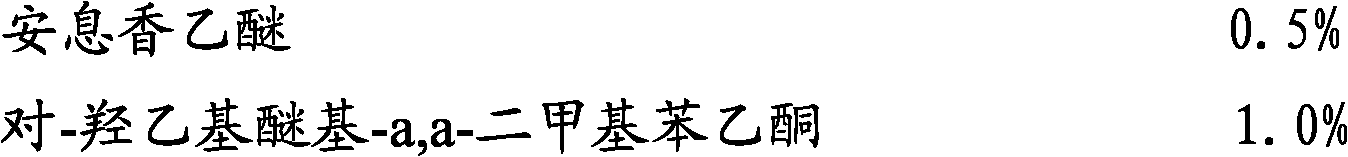

Model shield tunneling machine starting device capable of achieving self-balancing of counter-force

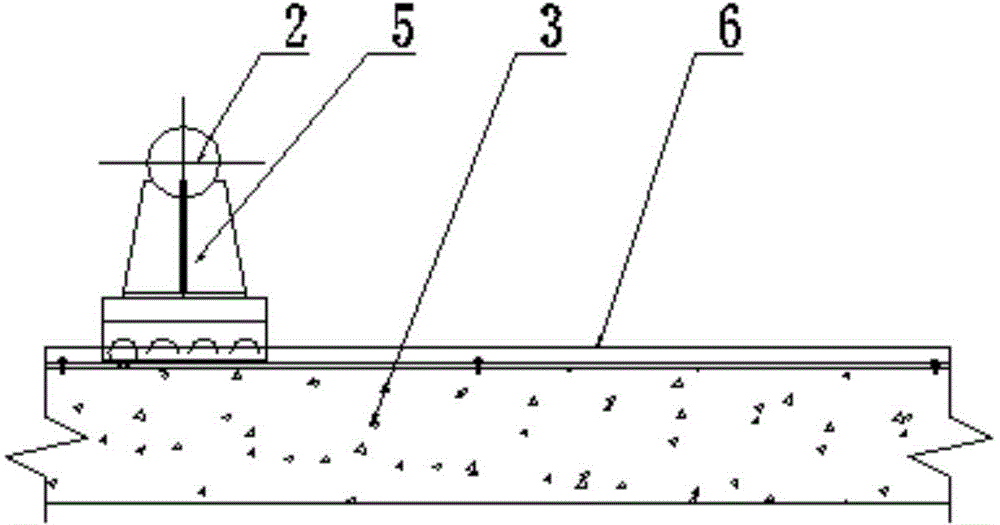

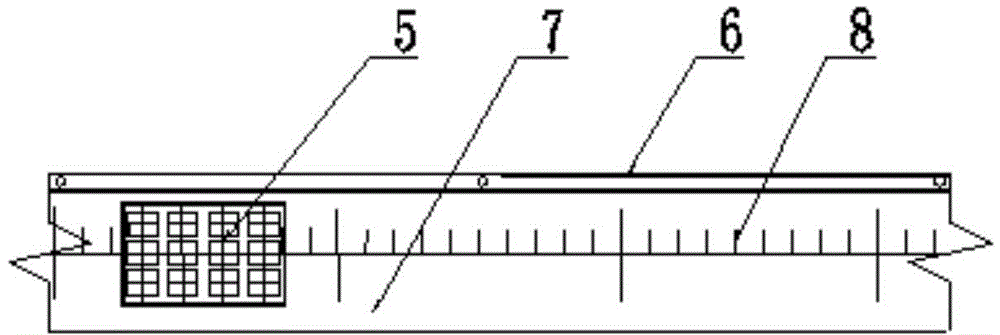

The invention discloses a model shield tunneling machine starting device capable of achieving self-balancing of counter-force. A model shield tunneling machine is arranged on the tunneling side of a test soil box frame, and hydraulic jacks are arranged at one end, far away from the test soil box frame, of the model shield tunneling machine. The model shield tunneling machine starting device comprises a counter-force seat and a guide rail, wherein the counter-force seat and the guide rail are both installed on the work ground, the counter-force seat is arranged on one side, far away from the test soil box frame, of the model shield tunneling machine, the counter-force seat and the test soil box frame are connected with each other through cross beams, and the model shielding tunneling machine is arranged on the guide rail. The model shield tunneling machine starting device capable of achieving the self-balancing of the counter-force can provide the counter-force to the model shield tunneling machine, the counter-force is transmitted to the test soil box frame through the cross beams, and therefore the self-balancing of the counter-force is achieved. Due to the fact that a reaction wall does not need to be built in the process of the model test, on the one hand, the occupied site space of test equipment is reduced and test expense is saved, on the other hand, guide can be provided for starting of the model shield tunneling machine, consistency of the staring direction and the axis direction of a tunnel cave to be built as planed is guaranteed, and posture change of the shield tunneling machine is avoided.

Owner:SOUTHWEST JIAOTONG UNIV +1

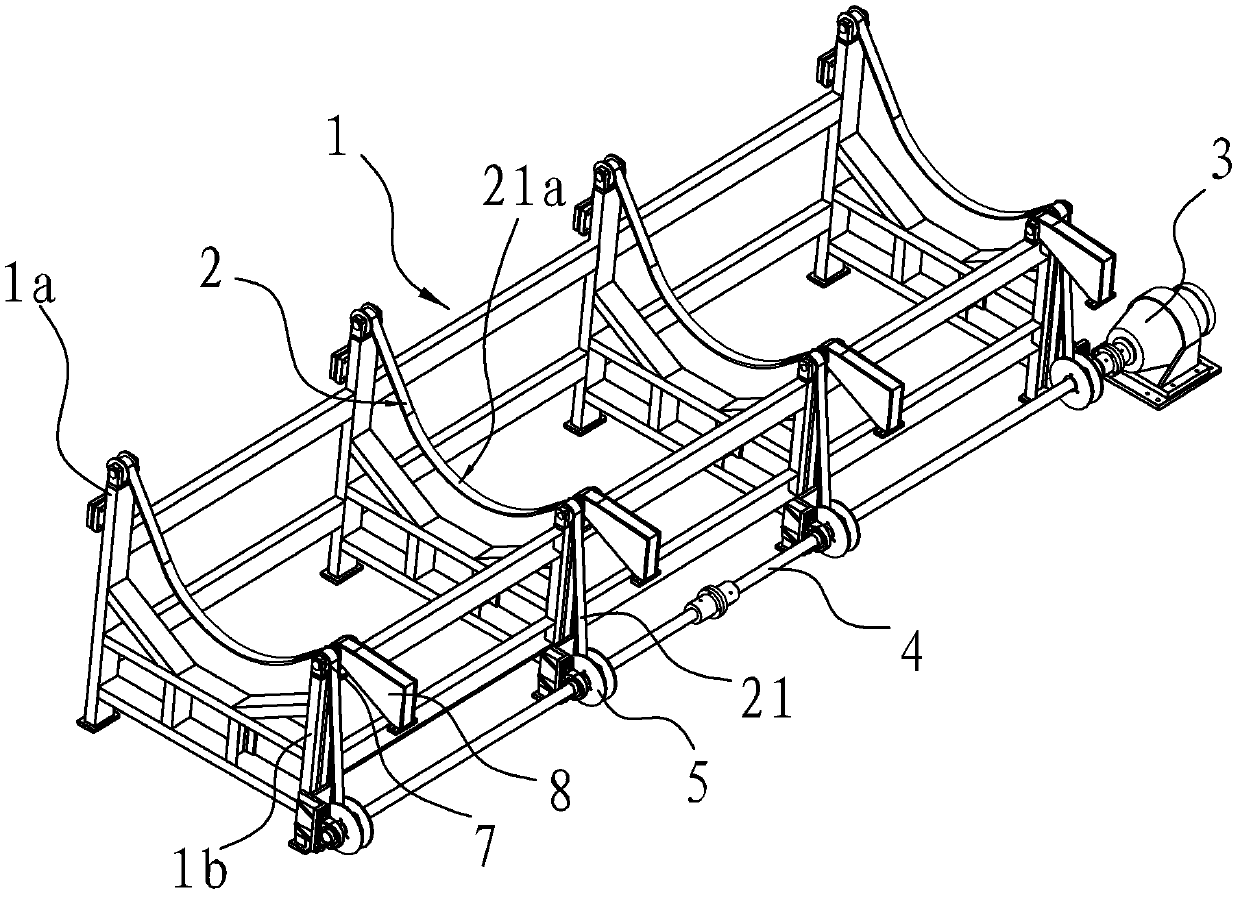

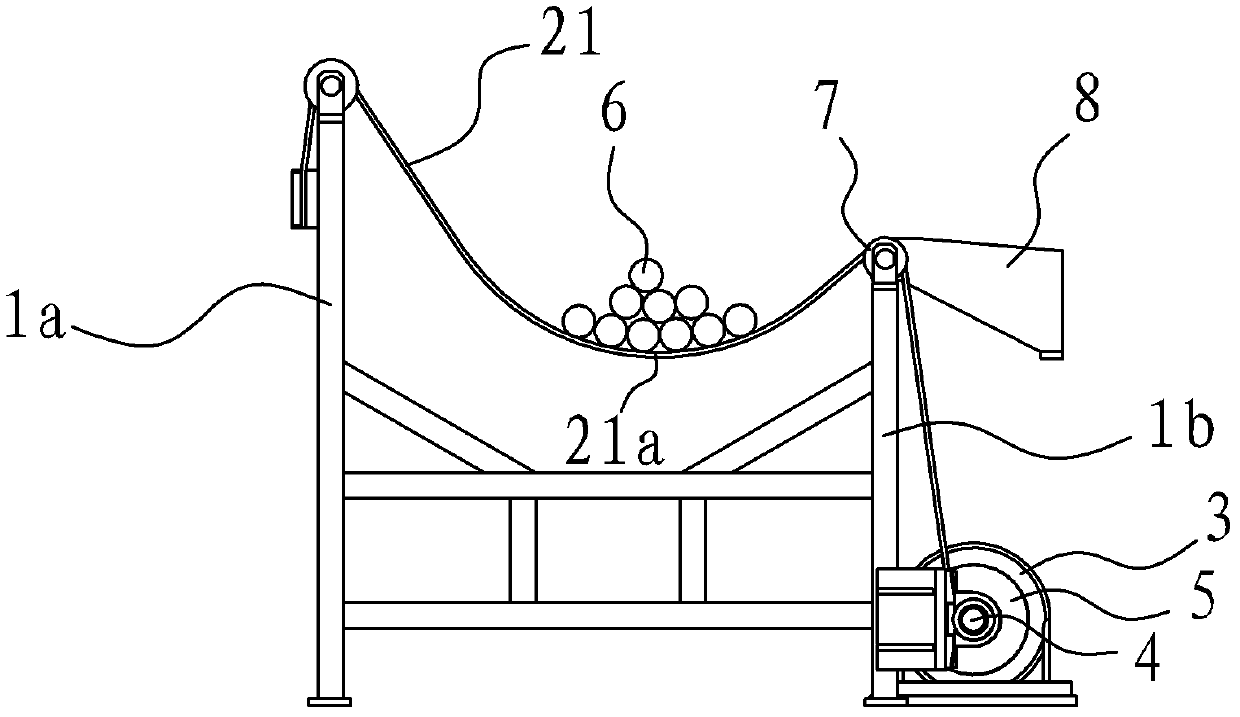

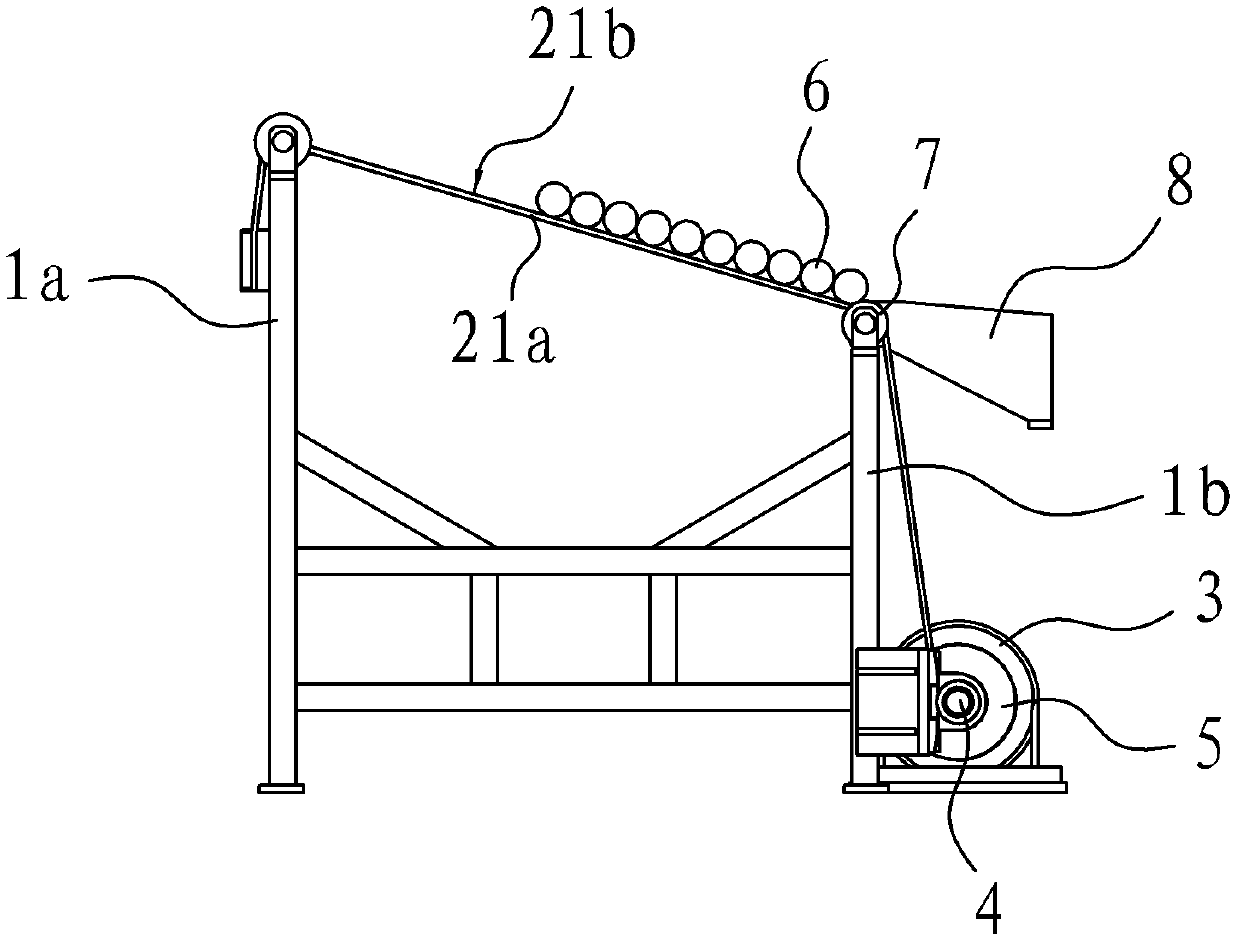

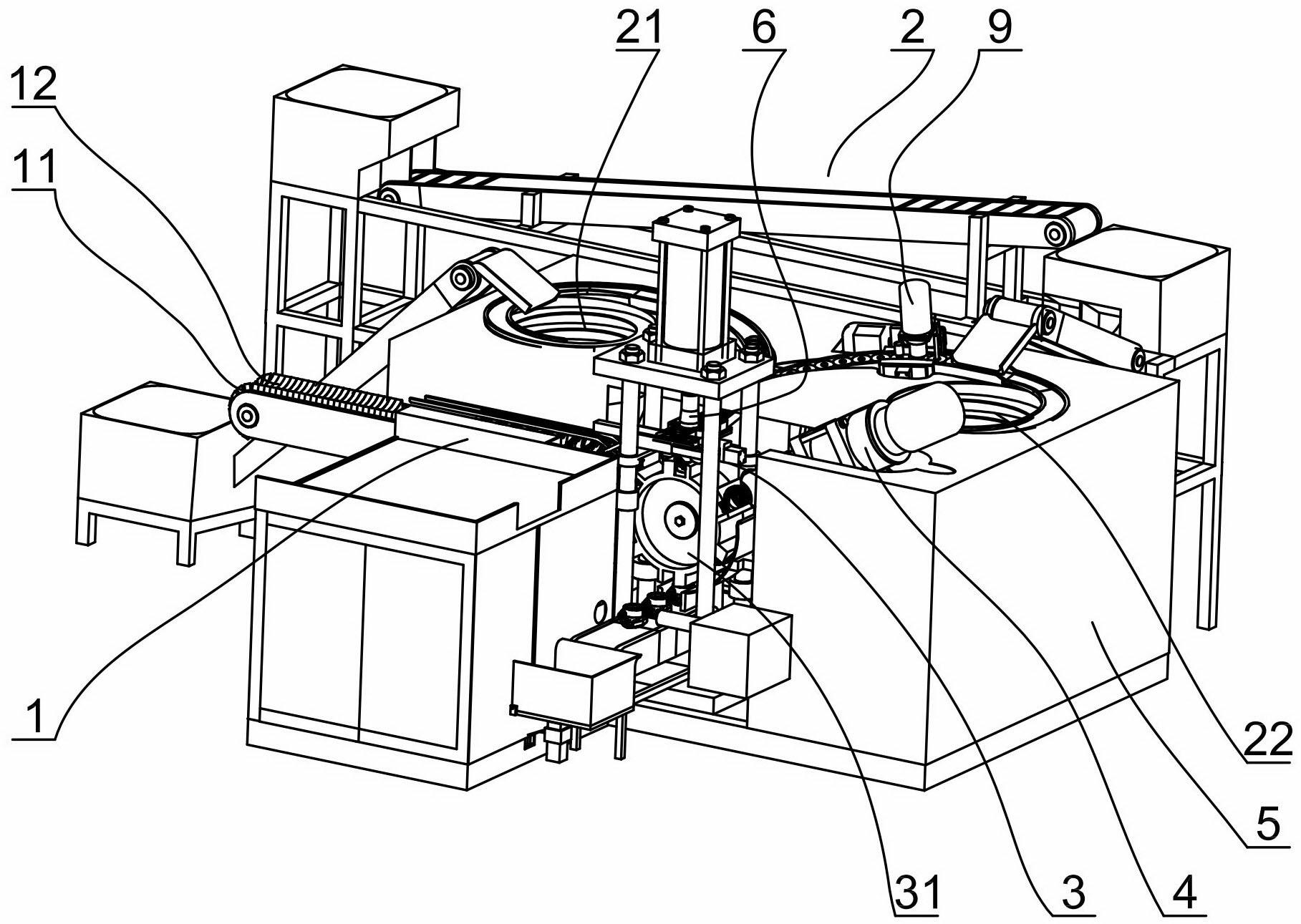

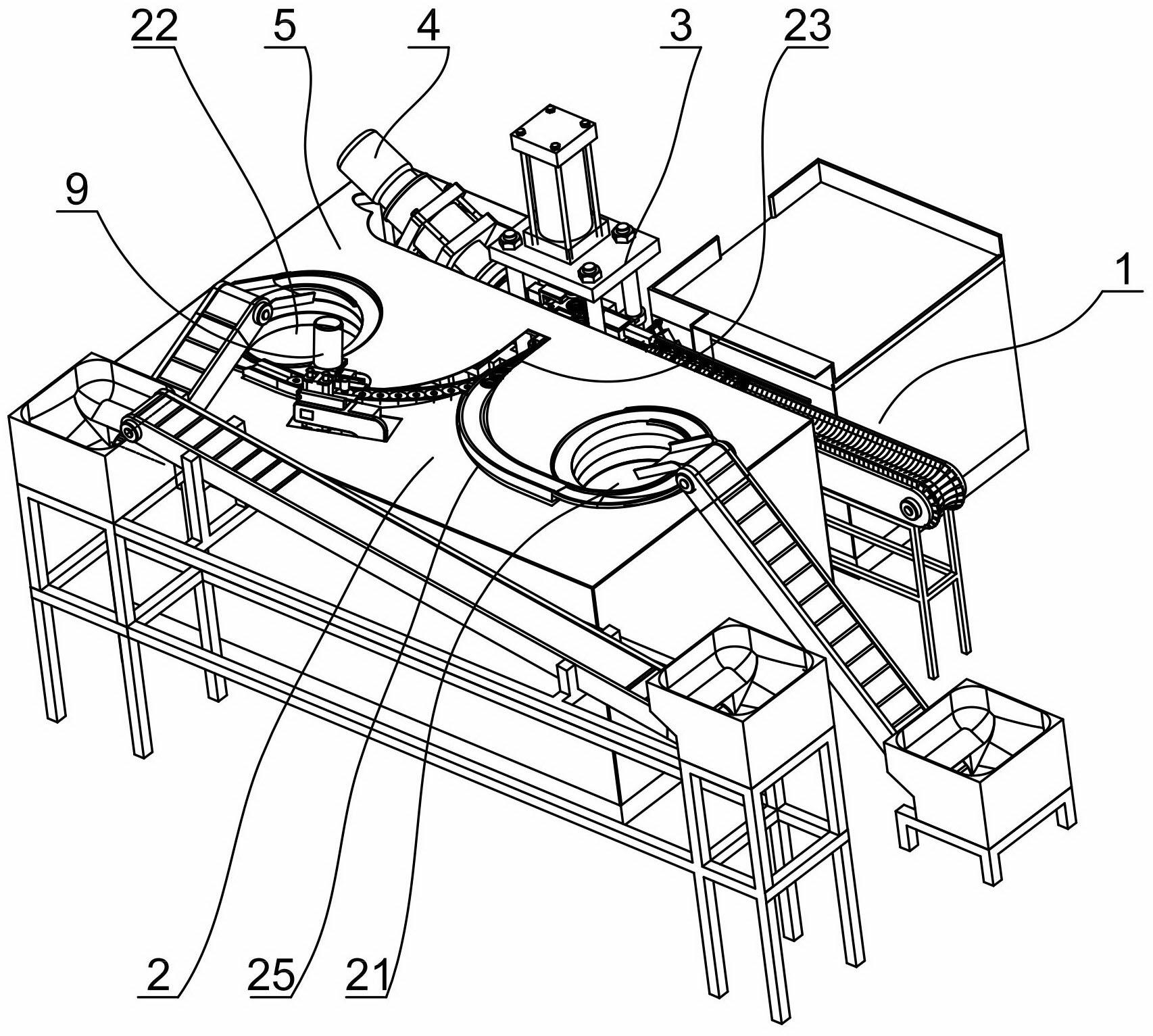

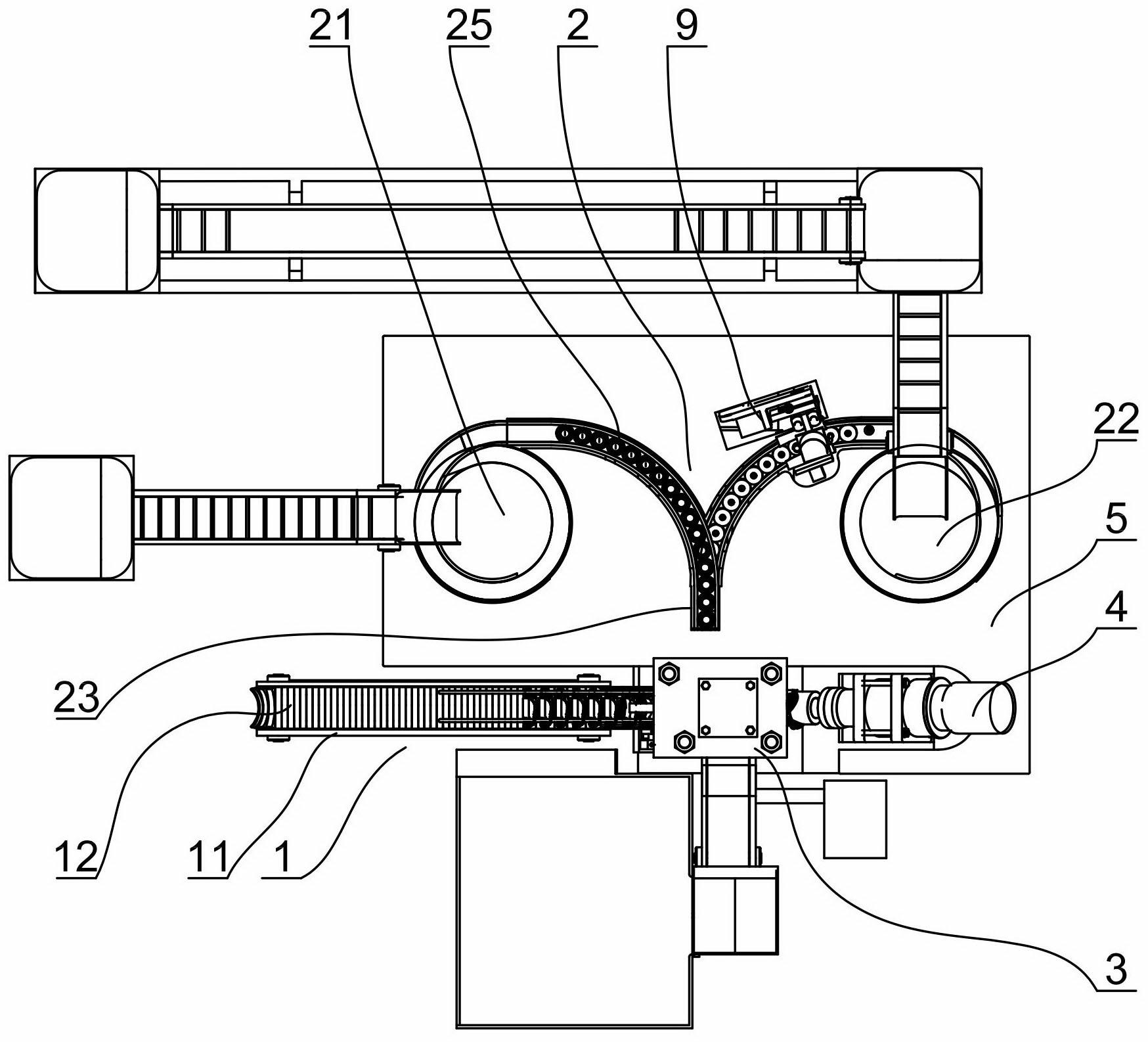

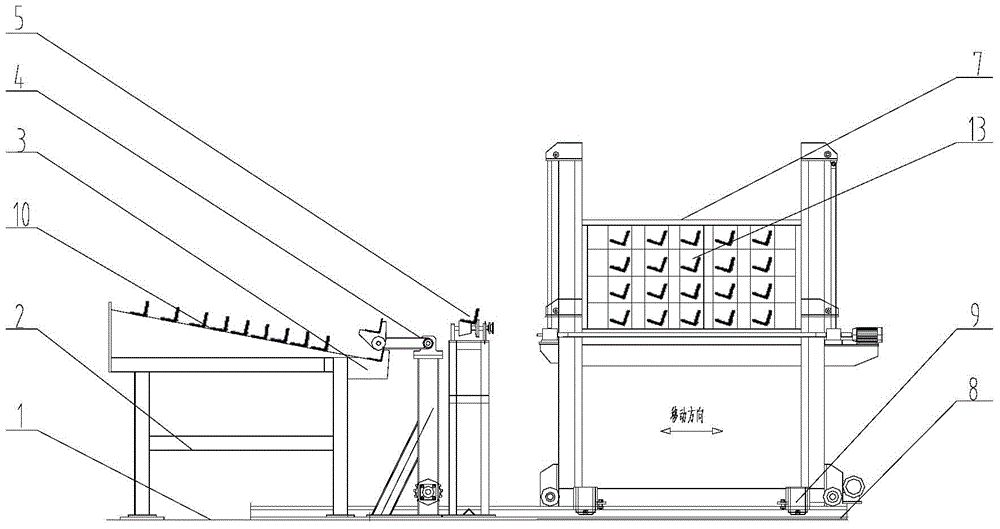

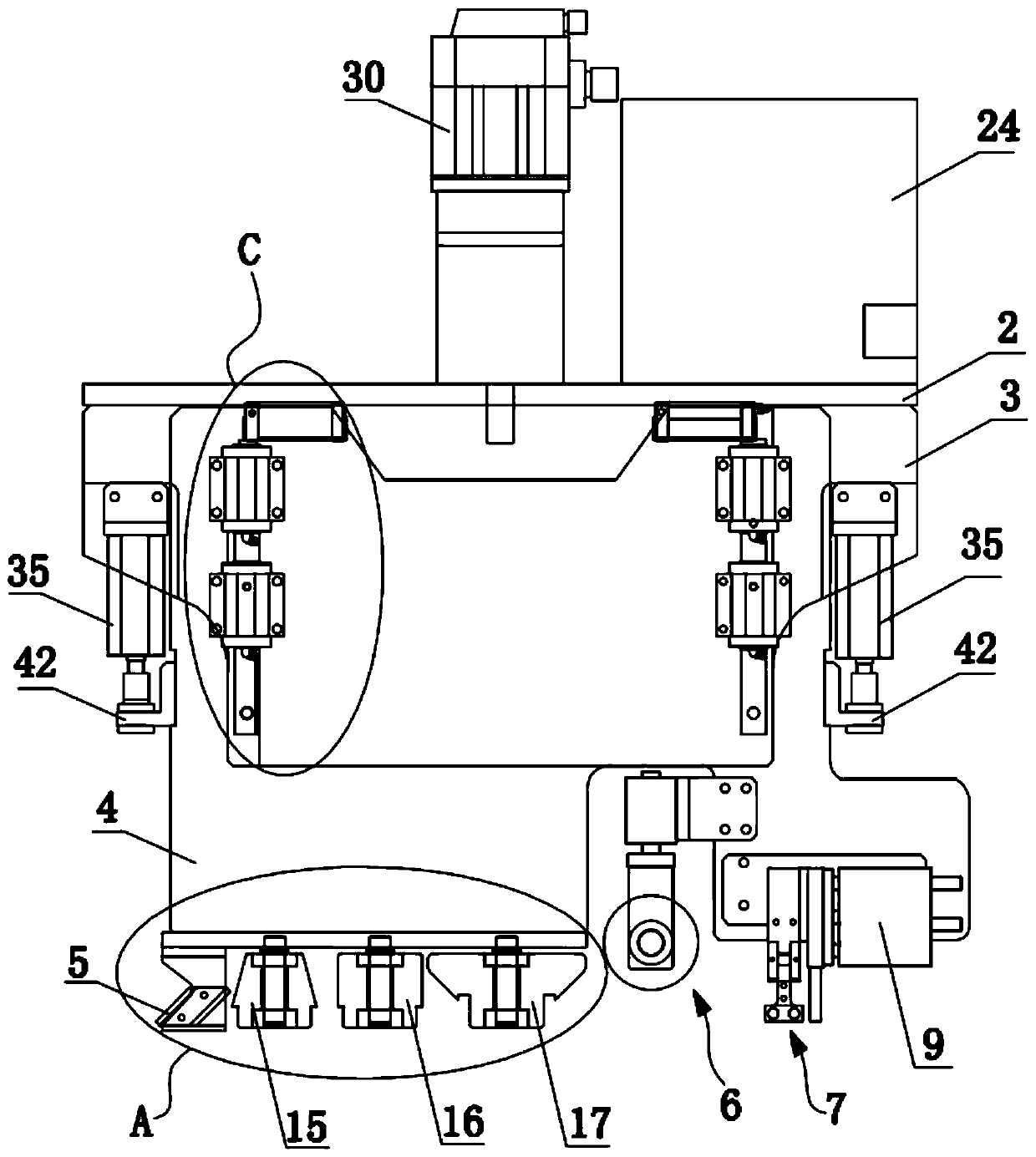

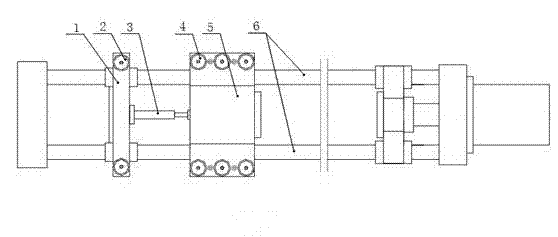

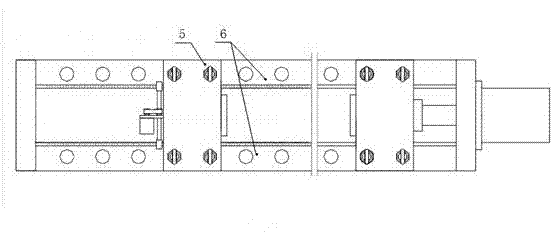

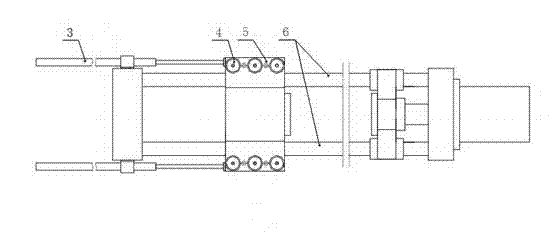

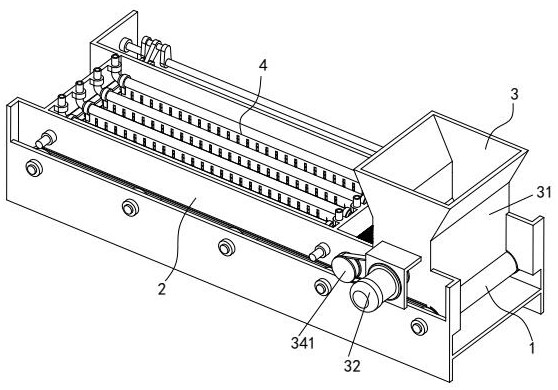

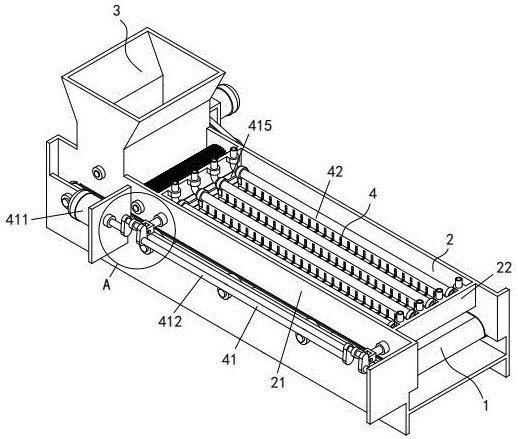

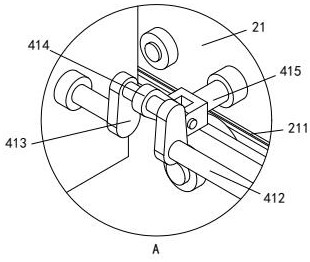

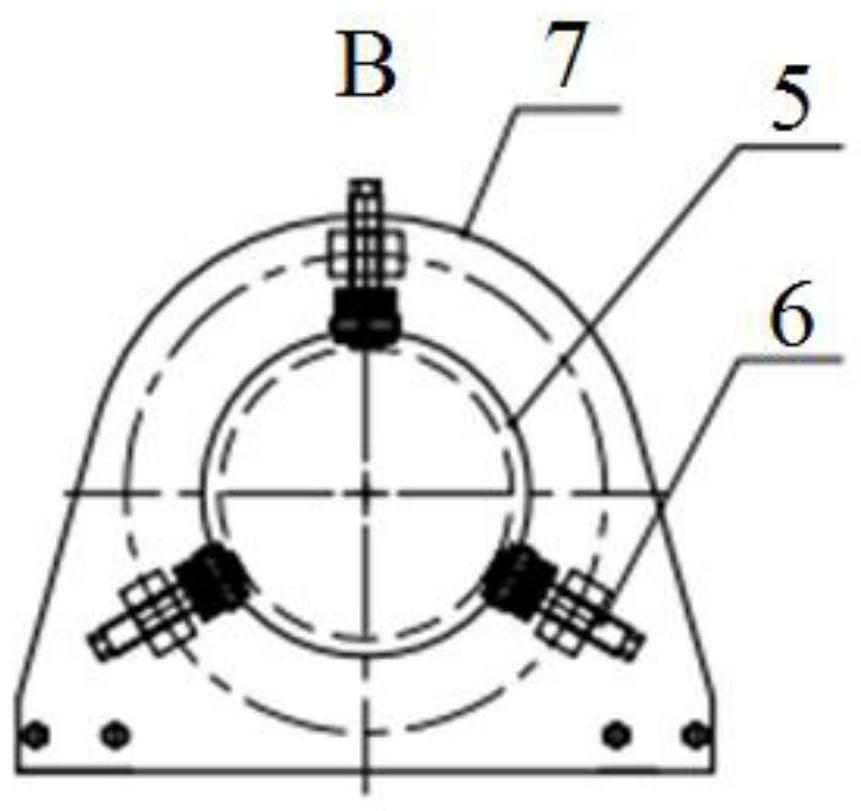

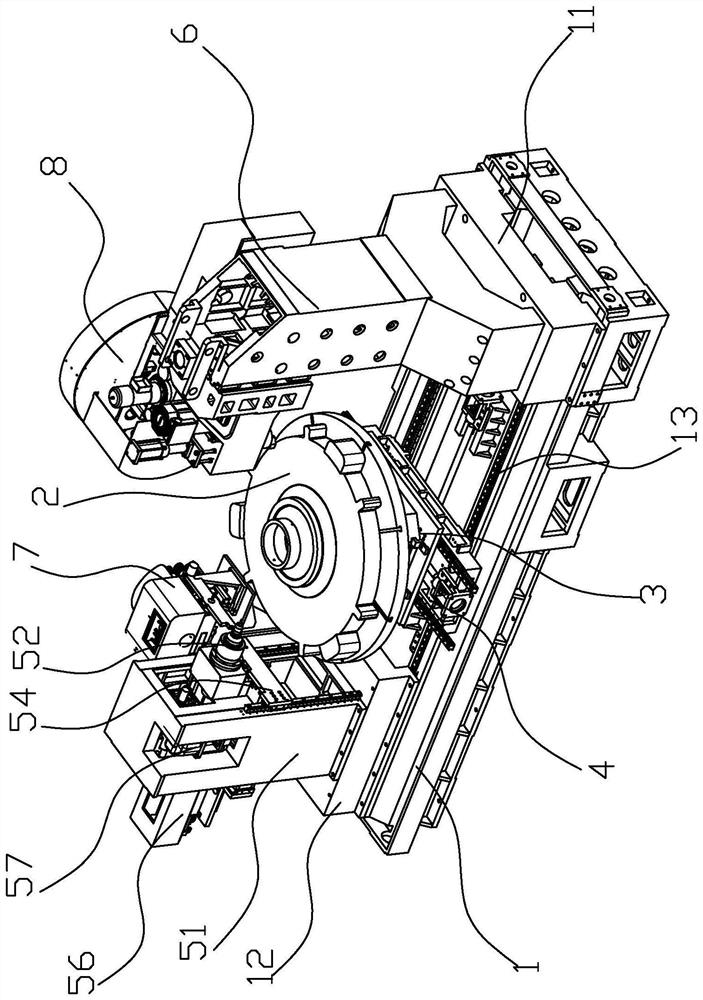

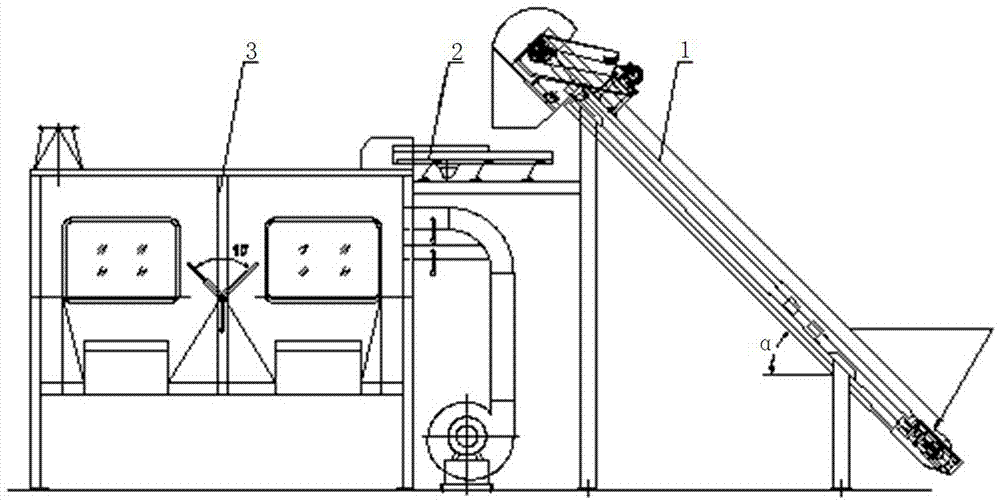

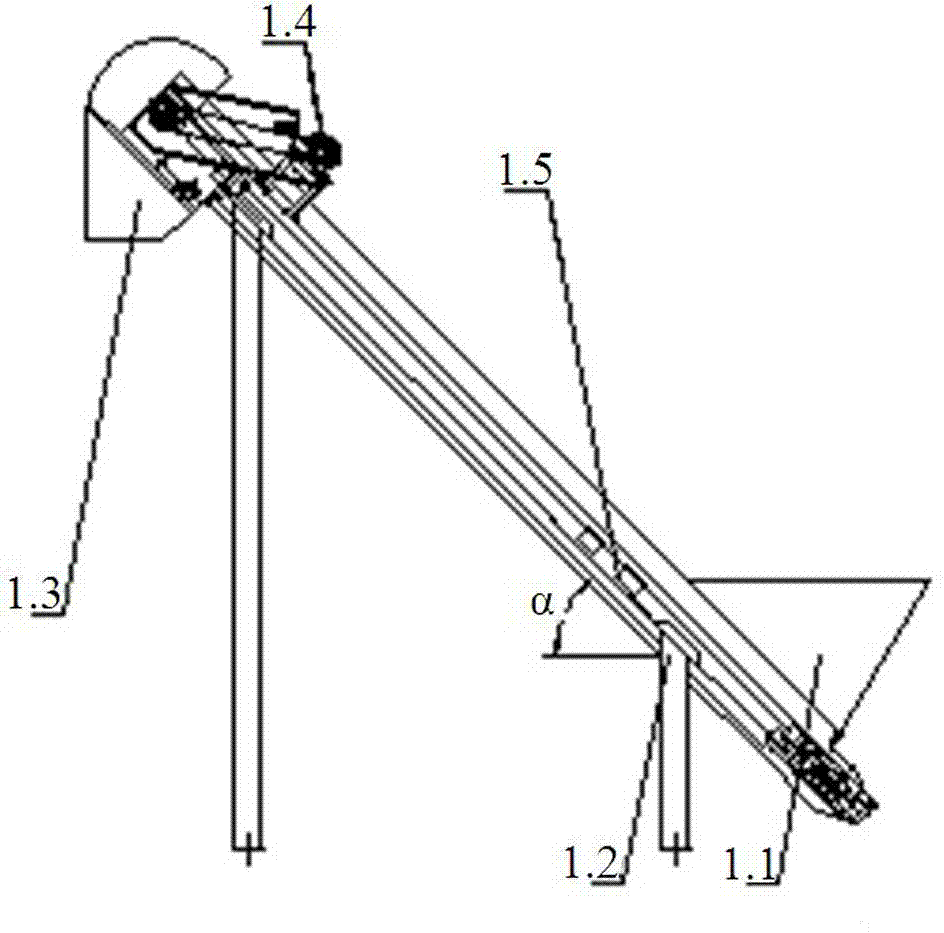

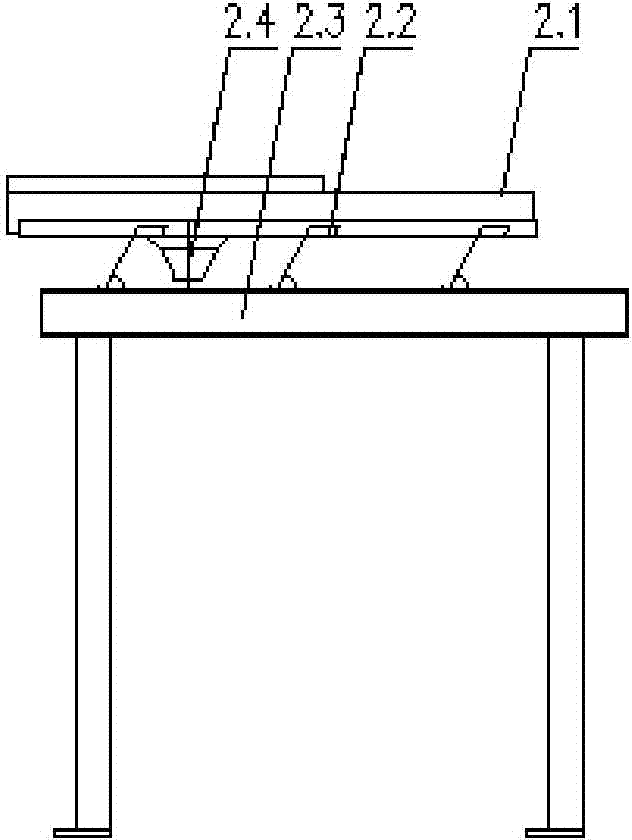

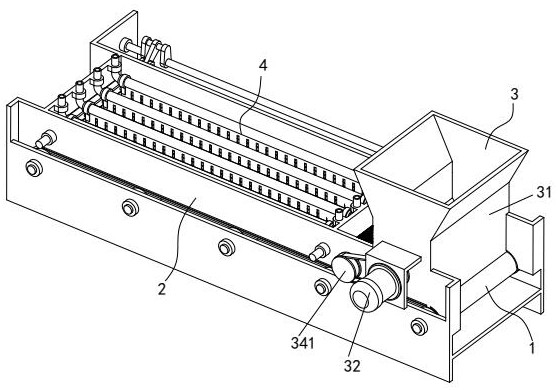

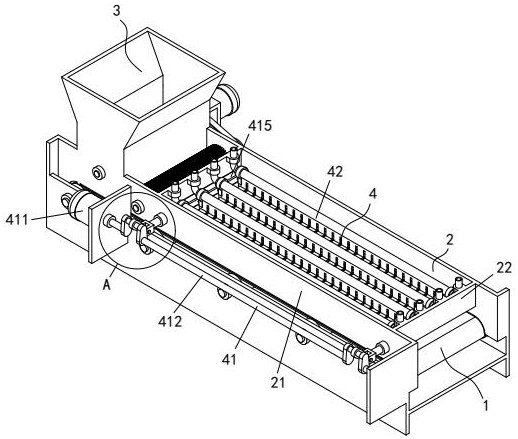

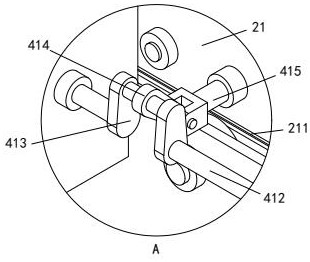

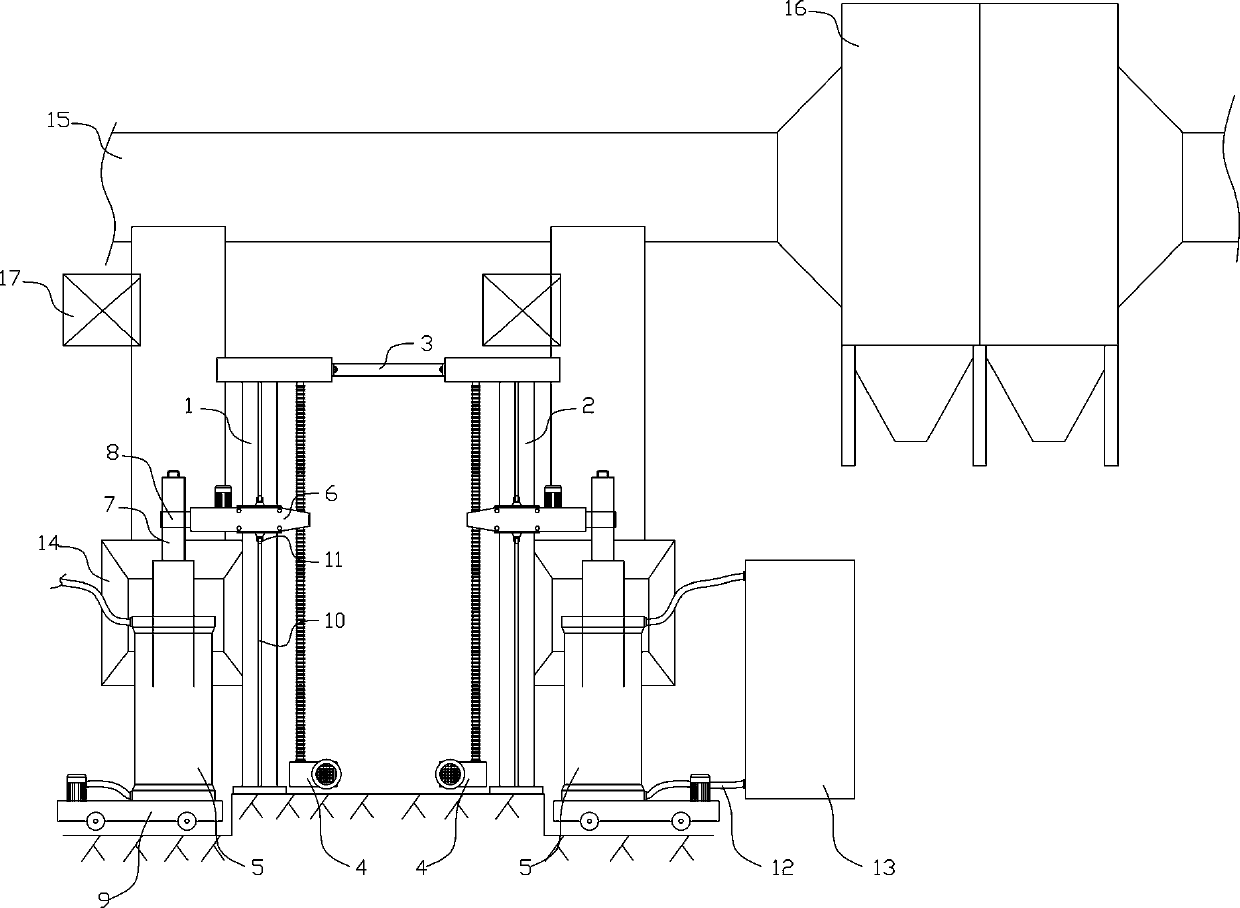

Automatic feeding device for circular sawing machine

InactiveCN102601668AReduce labor intensityThe overall space occupied is smallMetal sawing devicesMetal working apparatusCircular sawEngineering

The invention provides an automatic feeding device for a circular sawing machine, which belongs to the technical field of cutting equipment and solves the problem of low feeding and distribution efficiency of existing circular sawing machines. The automatic feeding device for a circular sawing machine is disposed on the side of an operating table of the circular sawing machine and comprises a storage rack, a shifting mechanism and a driving mechanism. The storage rack is provided with a storage portion for holding raw materials in advance, and the driving mechanism can drive the storage portion in action to enable the storage portion to form a discharge slope which allows raw materials to move towards the operating table under the intrinsic gravity. The shifting mechanism is disposed between the storage rack and the operating table and used for sequentially shifting the raw materials on the discharge slope onto the operating table. The automatic feeding device is practical and convenient, labor intensity can be relieved for workers, occupied space is reduced, and production efficiency is improved. A whole bundle of bars can be directly lifted onto the storage rack, automatic continuous feeding can be realized after a rope is cut off, continuous lifting one by one is not needed, and thereby operating efficiency is greatly improved.

Owner:浙江罗森博格机床有限公司

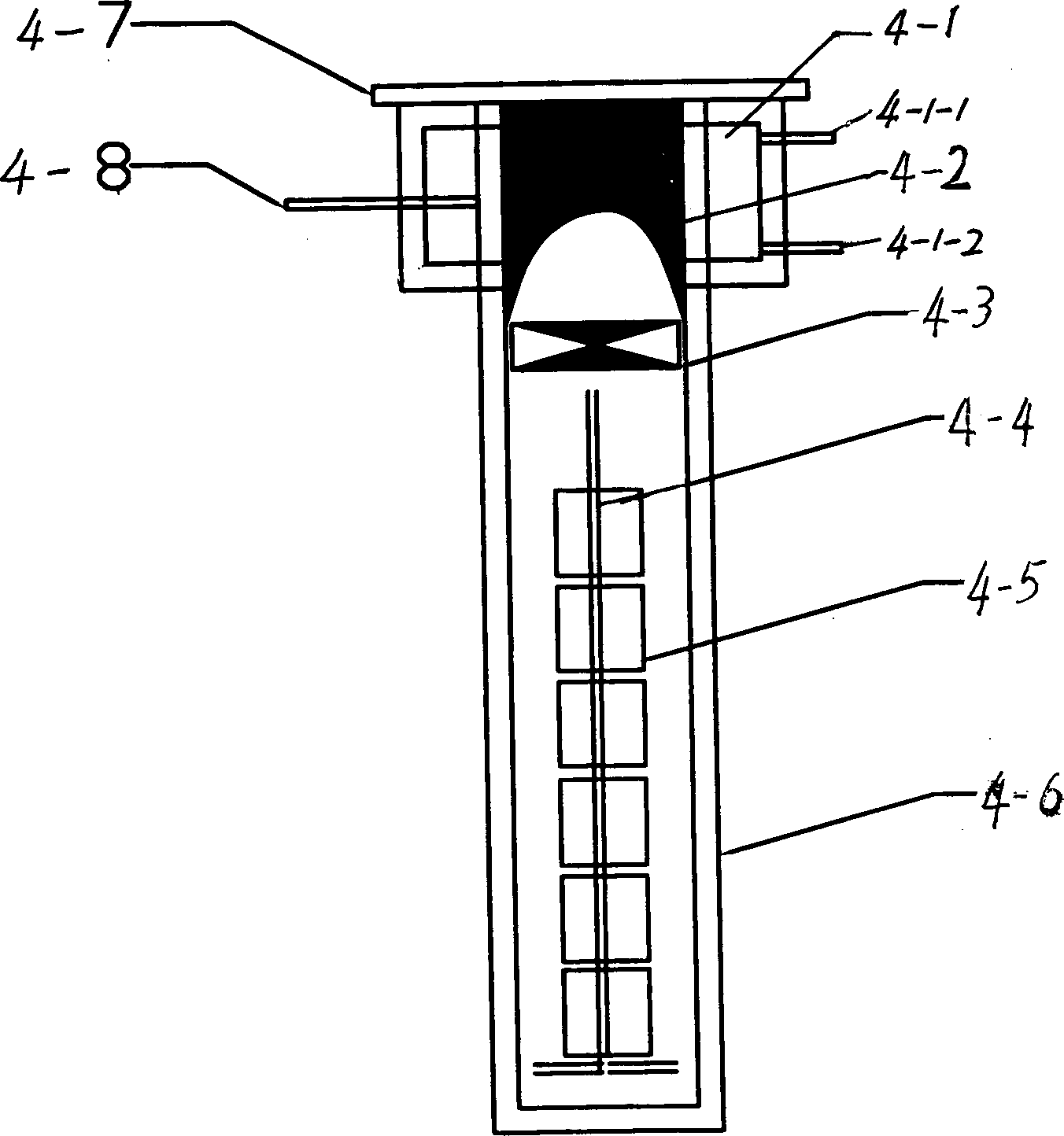

Vertical tank strontium smelting process and plant

The present invention relates to metal reducing technology and discloses a kind of vertical tank strontium smelting process and its plant. The present invention features that the vertical tank strontium smelting process to reduce strontium oxide into metal strontium with aluminium powder has high yield, high heat efficiency, short production period, small occupied space and other advantages.

Owner:WUTAI YUNHAI MAGNESIUM IND

Apparatus for cooling of electrical elements

ActiveUS8863542B2Improve cooling effectThe overall space occupied is smallAir-treating devicesDomestic cooling apparatusEngineeringThermal contact

Apparatus for cooling electrical elements, comprising a heat sink (1, 101, 201) through which a coolant can flow, a plurality of electrical elements (2, 102, 202) which each have a bottom surface and a side surface, with the bottom surfaces being aligned essentially on one plane, with the heat sink (1, 101, 201) having at least one channel (4, 5, 104, 105, 204, 205) through which a coolant can flow and making thermal contact with the electrical elements (2, 102, 202), characterized in that the heat sink (1, 101, 202) extends essentially parallel to the plane of the bottom surfaces, with the channel (4, 5, 104, 105, 204, 205) in the heat sink having a profile which is matched to edges of the electrical elements (2, 102, 202).

Owner:BEHR GMBH & CO KG

High altitude spherical net rack splicing method based on large gymnasium frame continuous beam

InactiveCN103603502AReduce occupancyShorten the construction periodBuilding material handlingContinuous beamEngineering

The invention relates to a high altitude spherical net rack splicing method based on a large gymnasium frame continuous beam. The method includes the following steps: (1) building a left installation platform and a right installation platform under two ends of the large gymnasium frame continuous beam respectively; (2) installing a slide on the large gymnasium frame continuous beam and installing net rack moving trolleys at two ends of the slide in a sliding mode; (3) dividing a high altitude spherical net rack into N sections with the length being N meters and obtained through calculation; (4) splicing an L-meter high altitude spherical net rack and erecting the net rack on the net rack moving trolleys; (5) utilizing a drawing device to draw the net rack moving trolleys to enable the L-meter high altitude spherical net rack to move forward for L meters relatively and respectively and repeating the steps to assemble the whole high altitude spherical net rack in a splicing mode to finish the splicing. The net rack splicing method can shorten construction time, a sliding moving system is simple to machine and manufacture, sliding moving operation is high in speed, occupied space is small, labor intensity of workers is reduced, and the construction period is shortened.

Owner:MCC TIANGONG GROUP

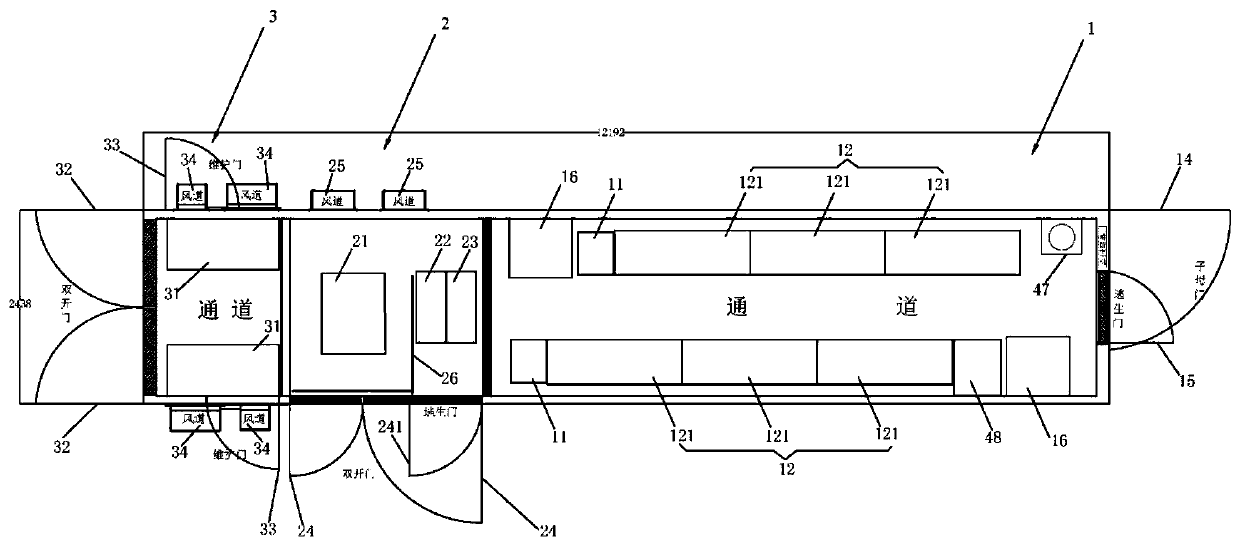

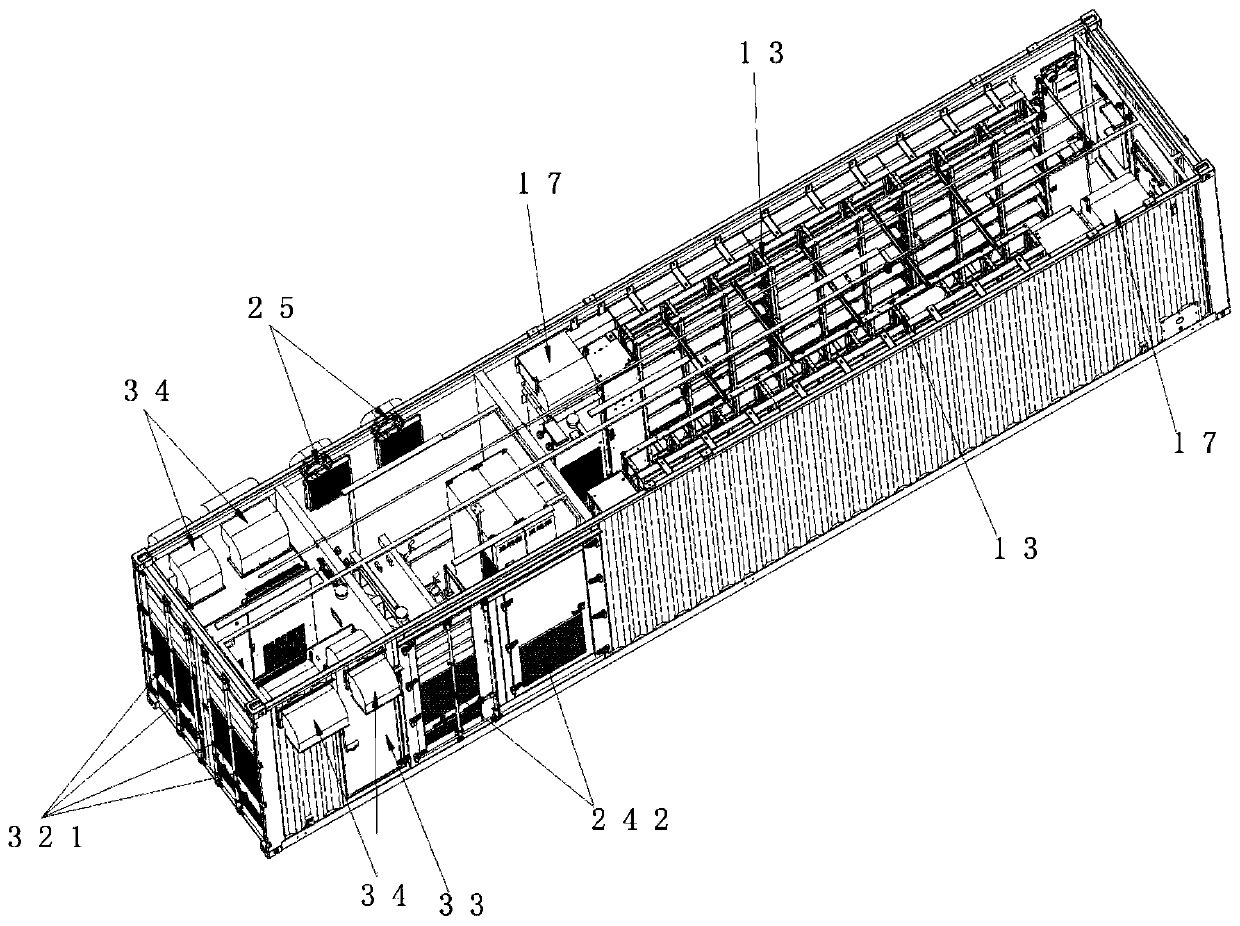

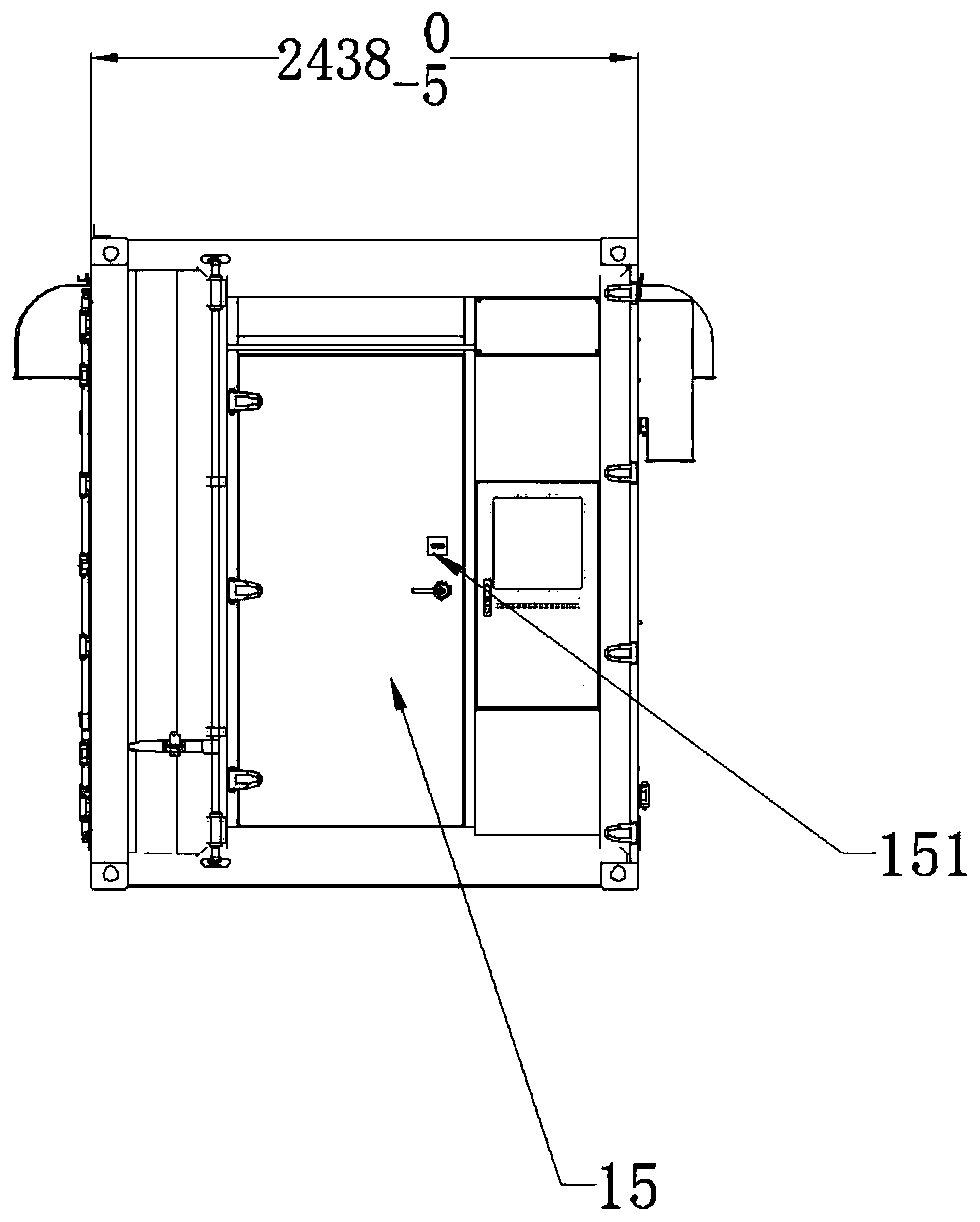

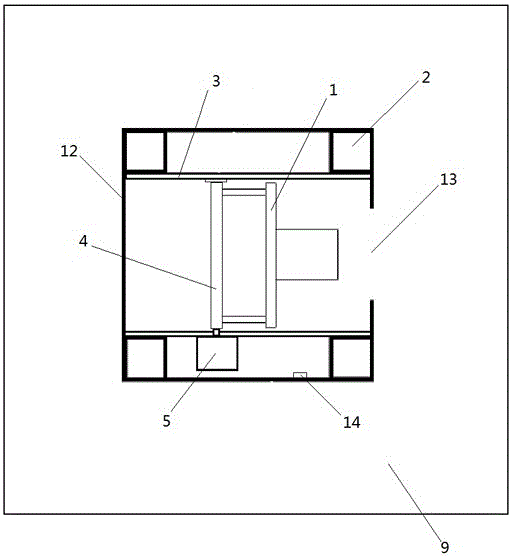

Energy storage container system and energy storage power station

PendingCN111092379AReduce volumeOccupies little spaceSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsPower gridPower station

The invention provides an energy storage container system and an energy storage power station. The energy storage container system comprises a container and an energy storage system integrated in thecontainer. The container sequentially comprises an energy storage chamber, a voltage transformation chamber and an inversion chamber from one end to the other end. The energy storage system comprisesan energy storage battery pack and a confluence cabinet which are arranged in the energy storage chamber, and the confluence cabinet is used for confluence of direct-current voltage output by the energy storage battery pack; the energy storage system also comprises a PCS inverter arranged in the inversion chamber, and the direct-current voltage after confluence of the confluence cabinet is connected to the direct-current side of the PCS inverter; and the energy storage system also comprises a transformer, a wire inlet cabinet arranged in the voltage transformation chamber and a wire outlet cabinet connected with the wire inlet cabinet, the low-voltage side of the transformer is connected with the alternating-current side of the PCS inverter, the high-voltage side of the transformer is connected with the wire inlet cabinet, and the wire outlet cabinet is used for being connected with a power grid or used for being connected with a confluence container system. The energy storage container system provided by the invention is small in size, small in occupied space, convenient to transport, move and hoist, short in cable length and low in cost.

Owner:SHENZHEN CLOU ELECTRONICS

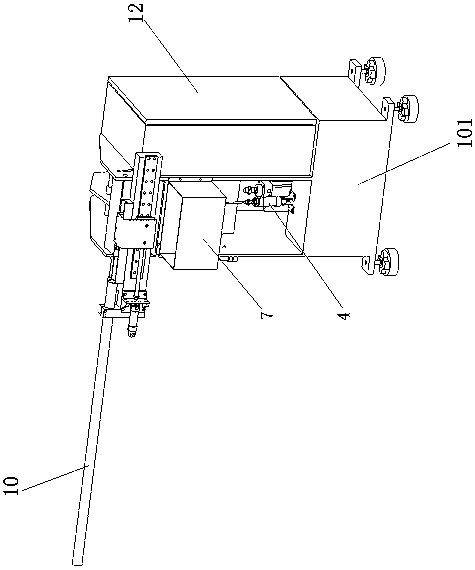

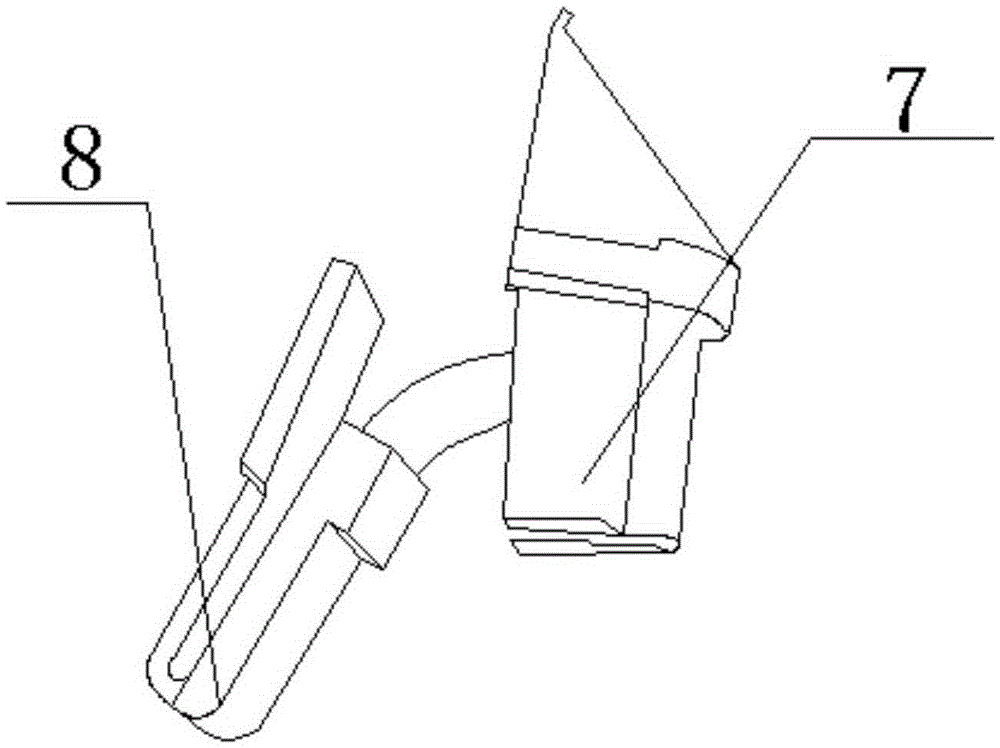

Novel automatic assembly spinning and reverting device

The invention discloses a novel automatic assembly spinning and reverting device, comprising a main body part conveying device, a packaged part conveying device, a combined mechanism, a spinning and reverting machine and a controller, wherein the combined mechanism comprises an assembling turnplate driven by a motor, axis of the assembling turnplate is transversely arranged, the circumferential surface of the assembling turnplate is provided with a plurality of main body part placing slots at equal intervals, the output end of the packaged part conveying device is provided with a packaged part outlet, a compression bar which can move up and down is arranged above the packaged part outlet, the output end of the main body part conveying device is connected with a guide slot which is arranged at one side of the assembling turnplate in an inclined manner, a central line of the guide slot is coincided with the central line of the main body part placing slot which is arranged at one side of the upper part of the assembling turnplate, and the spinning and reverting machine is arranged at the other side of the assembling turnplate opposite to the guide slot in the inclined manner. The novel automatic assembly spinning and reverting device disclosed by the invention can realize automatic feeding, assembling and reverting on a rubber supporting part; and the novel automatic assembly spinning and reverting device has a simple structure, is easy to manufacture and has reasonable layout, less occupied site and space and high production efficiency.

Owner:NINGBO TUOPU GROUP CO LTD

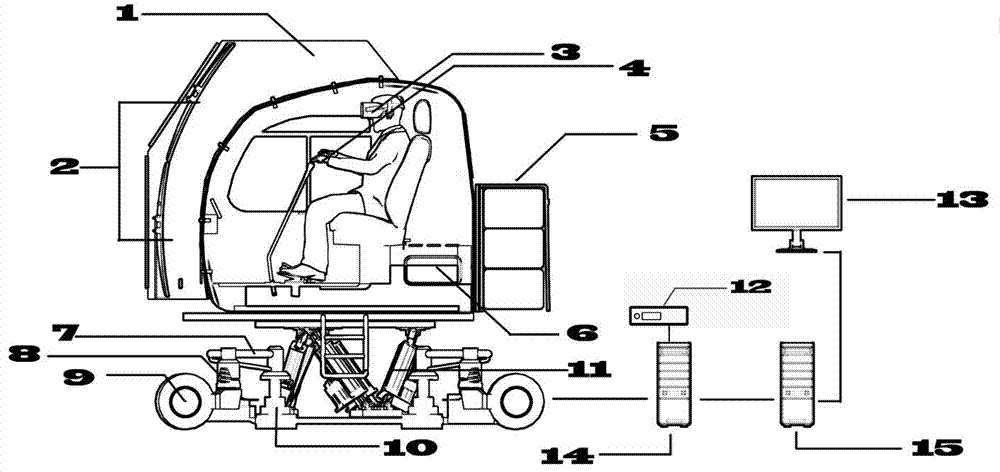

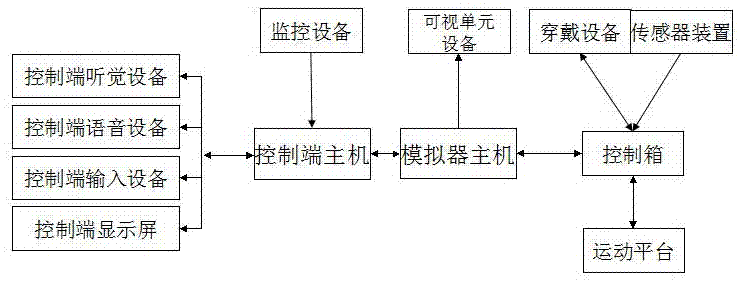

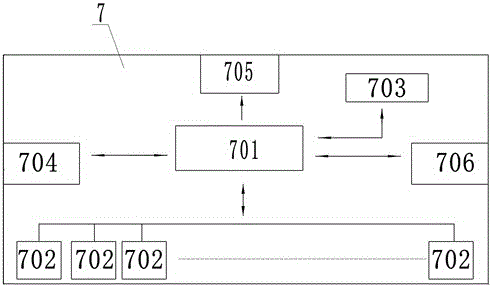

Simulation training apparatus

PendingCN107293177AOccupies little spaceImprove training effectCosmonautic condition simulationsSimulatorsTraining effectInput device

The invention relates to a simulation training apparatus. The simulation training apparatus specifically comprises a control terminal module and a client module, the control terminal module comprises control terminal hearing equipment, control terminal voice equipment, control terminal input equipment, a control terminal display screen and a control terminal host, the client module comprises a simulation driving cabin, a motion platform, a motion support, a control box and a simulator host, the simulation driving cabin is also provided with visual unit equipment, wearable equipment and monitoring equipment, the control terminal hearing equipment, the control terminal voice equipment, the control terminal input equipment, the control terminal display screen, and the monitoring equipment are separately connected with the control terminal host, the control terminal host is connected with the simulator host, the visual unit equipment and the control box are separately connected with the simulator host, and the wearable equipment, a sensor apparatus, and the motion platform are separately connected with the control box. According to the apparatus, hidden risks of real machine training can be avoided, the training effect is effectively improved, and the training period is shortened.

Owner:KEDUN TECH CO LTD

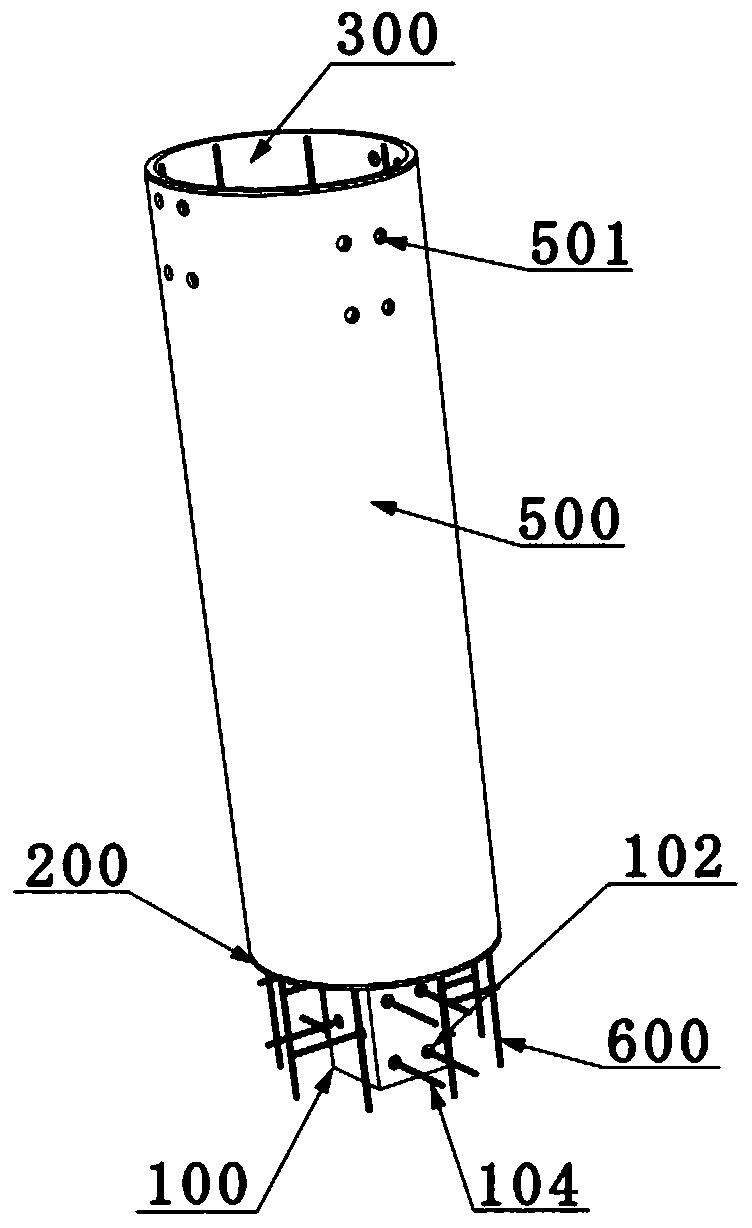

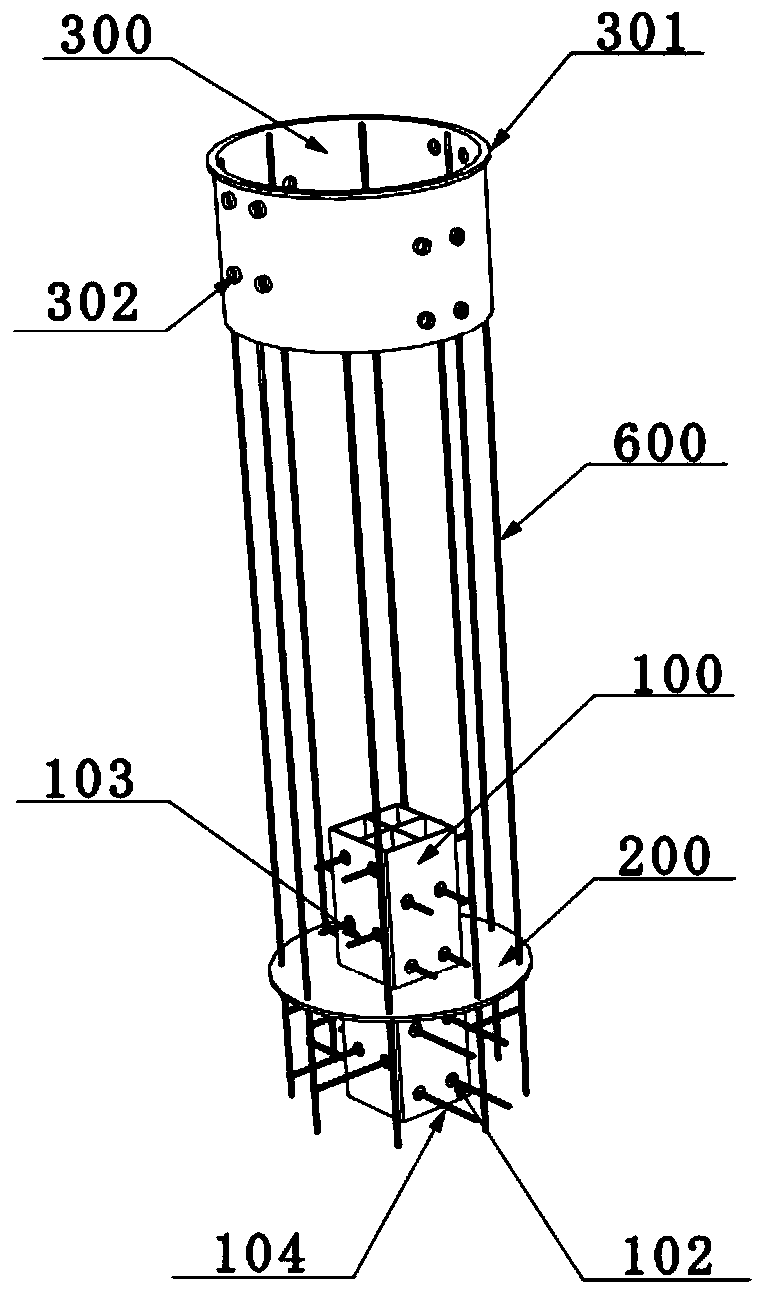

Precast segmental bridge pier and application of precast segmental bridge pier in bridge construction

ActiveCN109989339AImprove bearing capacityIncrease stiffnessBridge structural detailsPunchingResource utilization

The invention discloses a precast segmental bridge pier and application of the precast segmental bridge pier in bridge construction. The precast segmental bridge pier comprises a columnar bridge pierbody and a protecting jacket, wherein the two ends of the bridge pier body are provided with a steel inner container and a connecting piece respectively, and the connecting piece comprises a connecting steel plate fixed to the end of the bridge pier and a PBL connecting cylinder which penetrates through the connecting steel plate. Shear force connecting holes are formed in the PBL connecting cylinder, first punching bars are inserted into the shear force connecting holes in the end, inserted into the bridge pier body, of the PBL connecting cylinder, and the shear force connecting holes in theend, stretching out of the bridge pier body, of the PBL connecting cylinder are provided with second punching bars. Upright wall holes are formed in the side wall of the steel inner container, and installation holes are formed in the side wall of the bridge pier body; the protecting jacket comprises two protecting jacket plates, and fixing holes, right facing the upright wall holes, are formed inthe protecting jacket plates. The precast segmental bridge pier can be quickly assembled at a low construction risk, the initial imperfection is low, the bearing safety is ensured, the resource utilization rate is high, less pollution to the environment is caused, and the precast segmental bridge pier is economical and durable.

Owner:SOUTHWEST JIAOTONG UNIV

Automatic lead ingot molding machine

The invention discloses an automatic lead ingot molding machine. A lead flow distributor, a material receiving apparatus and a lead ingot carrier roller group are respectively arranged right above and below a roller-type lead ingot mold; various side surfaces of a regular-prism-shaped lead ingot mold are respectively provided with a plurality of lead ingot mold grooves, and each lead ingot mold groove is provided with a cooling water pipeline with one end closed along the direction of a central rotating shaft; the central rotating shaft disposed at the closed end of the cooling water pipeline is connected with a servo reduction motor, and the central rotating shaft at the other end is provided with a water outlet pipeline communicated with the cooling water pipeline; a water inlet pipe enters the cooling water pipeline of the roller-type lead ingot mold by virtue of the water outlet pipeline of the central rotating shaft; the front side of the roller-type lead ingot mold is provided with a pair of lead ingot dropping prevention baffle bars in proximity to each other; and the opening and closing of a lead fluid valve of the lead flow distributor and the operation and stopping of the servo reduction motor are controlled by a control unit. The automatic lead ingot molding machine is compact in structure, small in floor occupation space, simple to operate, time-saving, labor-saving, high in production efficiency and low in cost.

Owner:FENGFAN

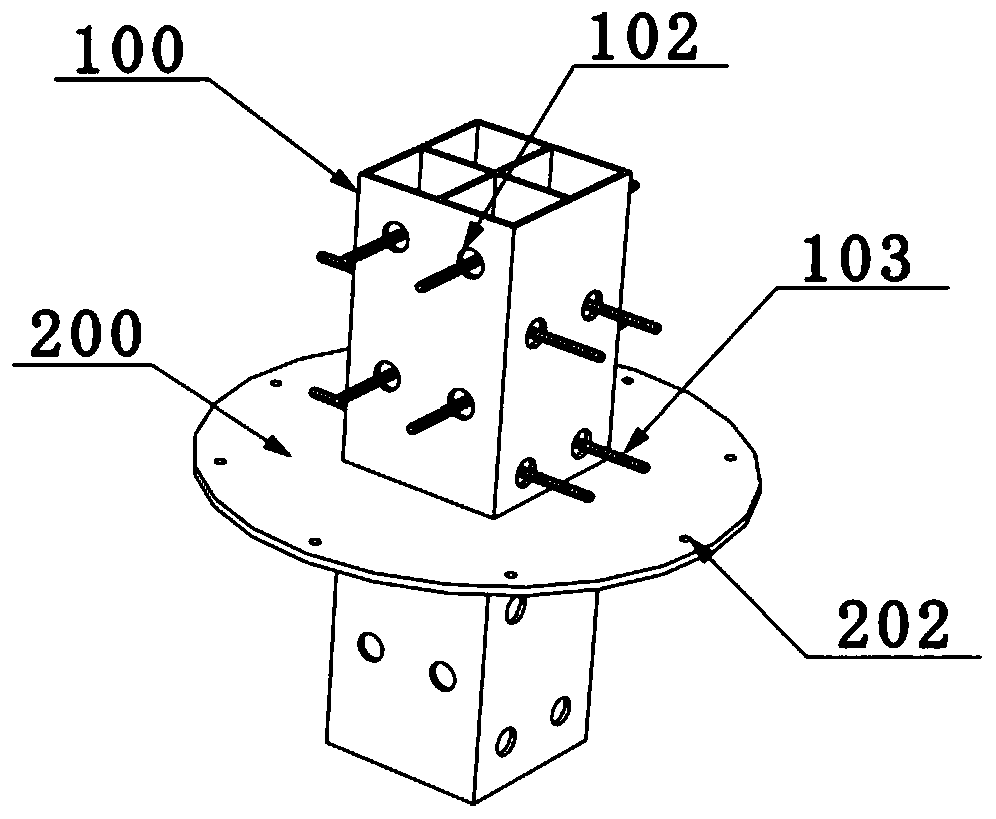

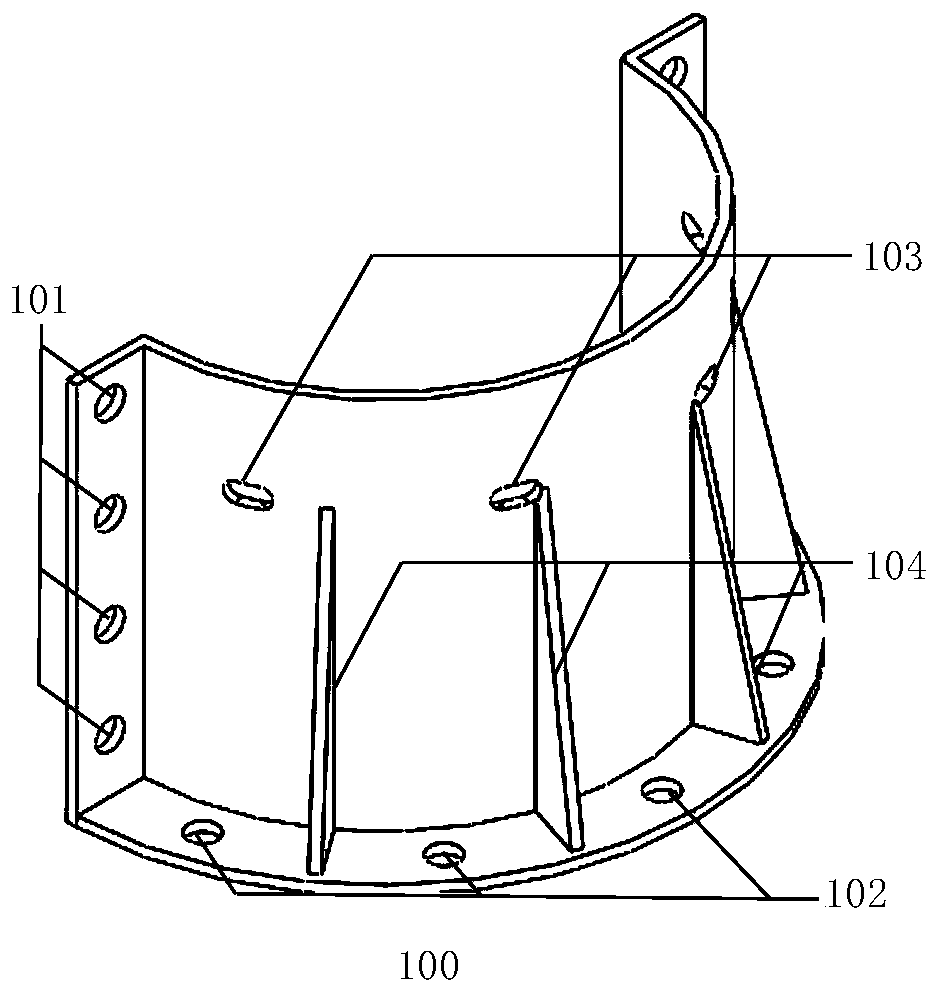

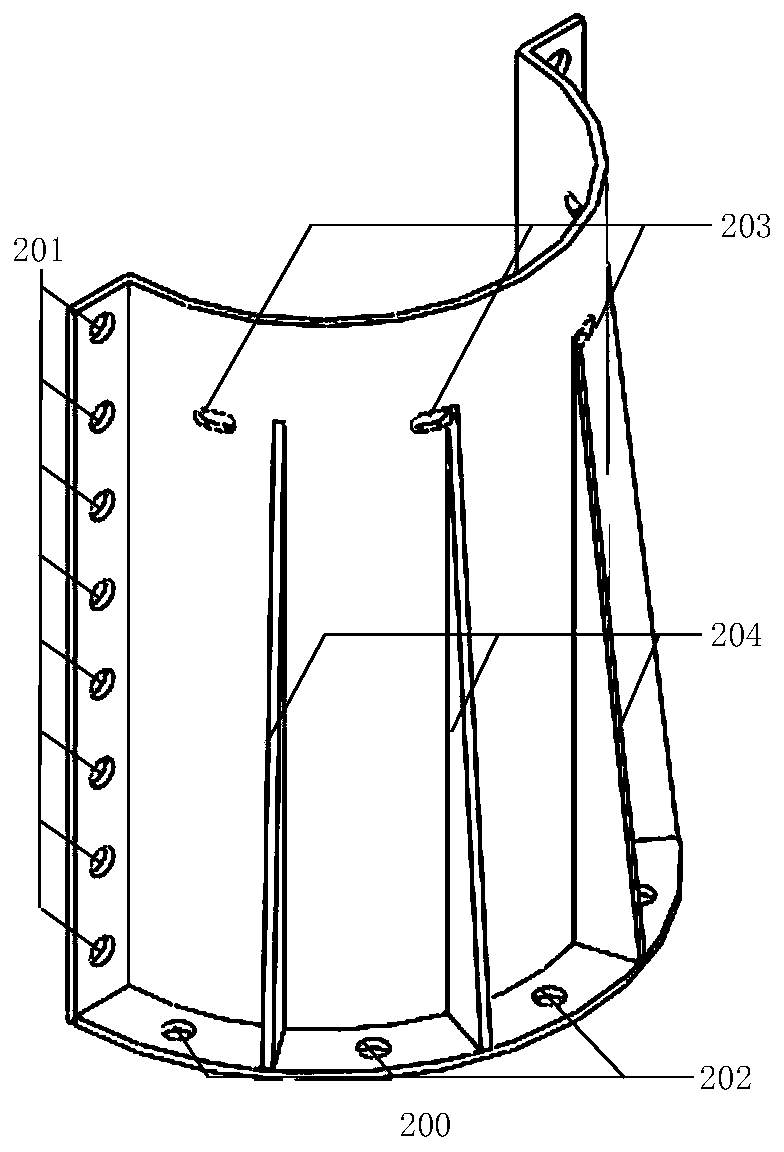

Segment prefabricated assembled pier steel member and construction method and application

ActiveCN110387826AFirmly connectedAct as a templateBridge structural detailsBridge erection/assemblyRebarPrefabrication

The invention discloses a segment prefabricated assembled pier steel member which comprises a short steel component, a long steel component and anchoring positioning steel bars, a plurality of first reinforcing ribs are arranged on the short steel component, first vertical bolt holes are formed in the two ends of the short steel component, and a plurality of first horizontal bolt holes are formedin the lower end steel plate; a plurality of second reinforcing ribs are arranged on the long steel component, second vertical bolt holes are formed in the two ends of the long steel component, and aplurality of second horizontal bolt holes are formed in the lower end steel plate; the anchoring positioning steel bars are uniformly scattered in a steel reinforcement cage, spiral teeth are arrangedat the outer ends of the anchoring positioning steel bars respectively, and a plurality of matched reinforcing steel bars are arranged at the inner sides. The invention further provides a construction method and application adopting the steel component. A structural steel component is used for being adopted as a template and a supporting upper portion structure, temporary anchoring is performed,the construction safety is improved, the component can be disassembled after construction is completed to be recycled, and finally, factory prefabrication and on-site rapid assembling construction operation of bridge piers can be achieved.

Owner:SOUTHWEST JIAOTONG UNIV

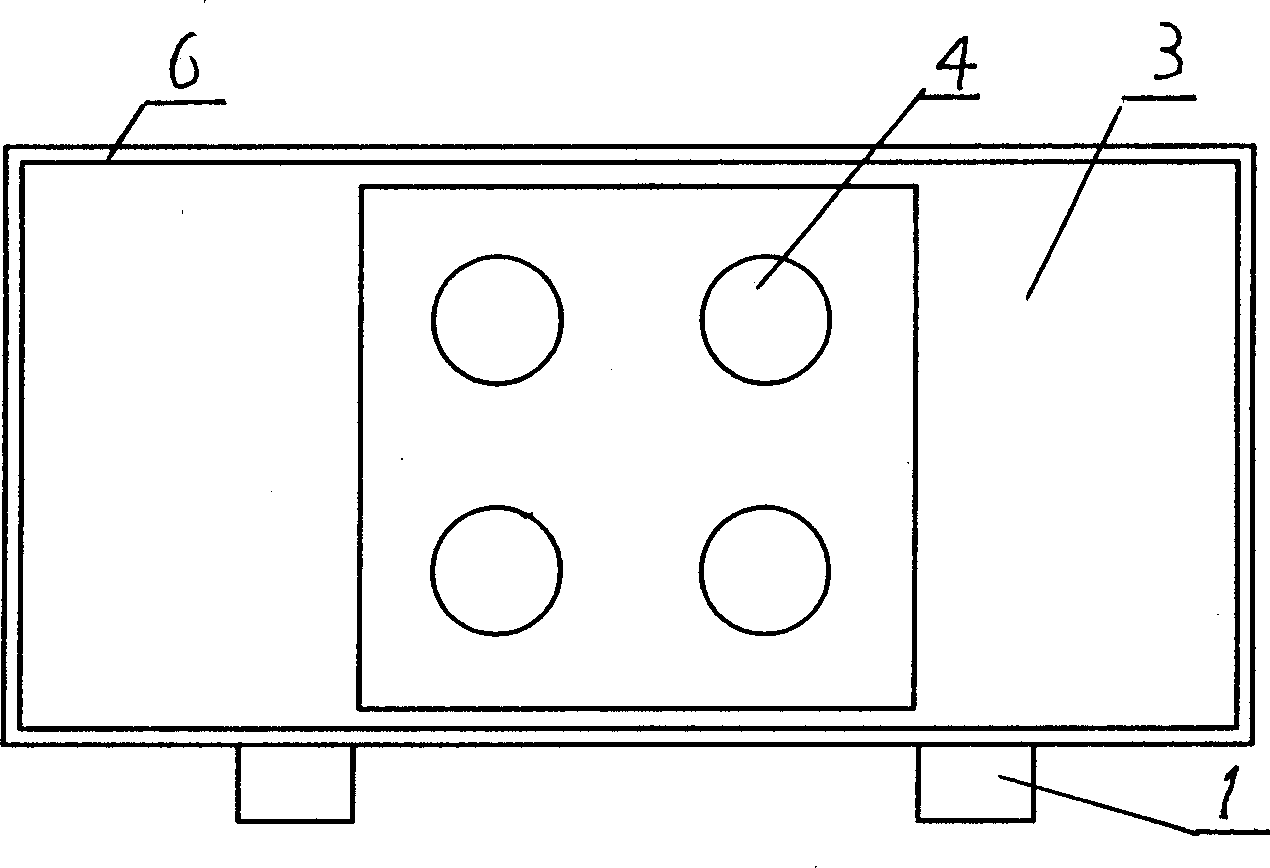

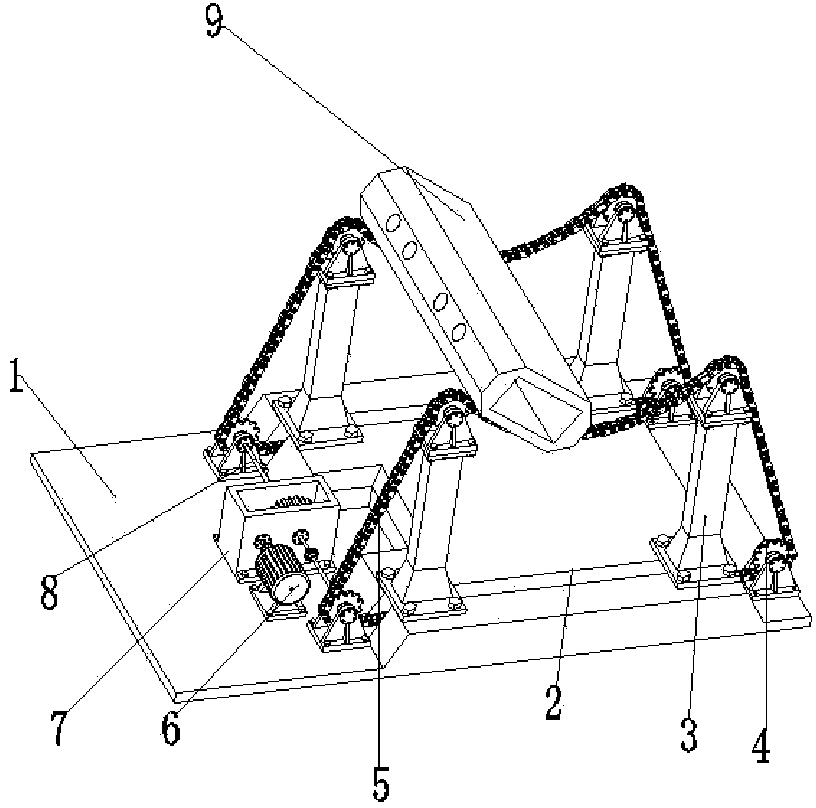

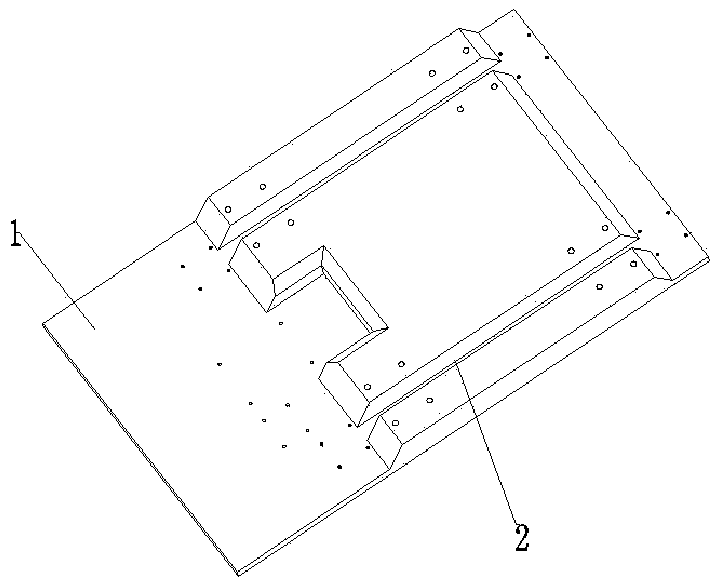

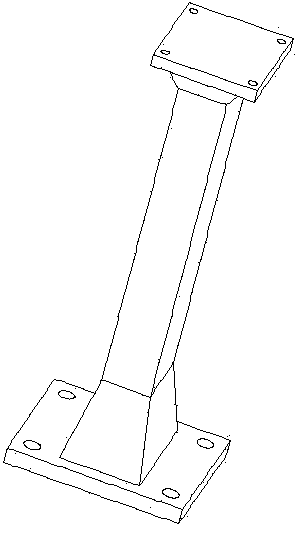

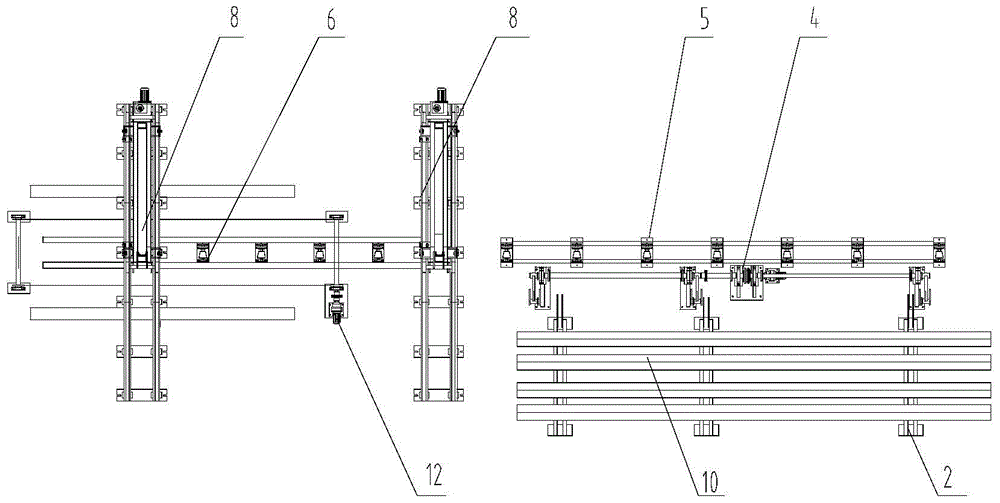

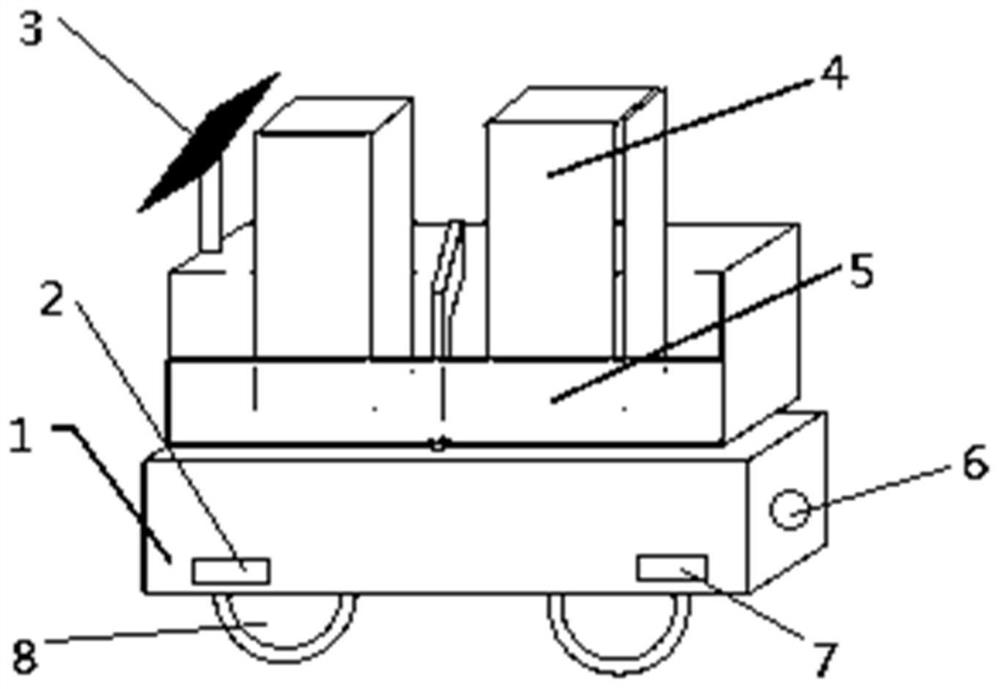

Large-sized workpiece overturning device

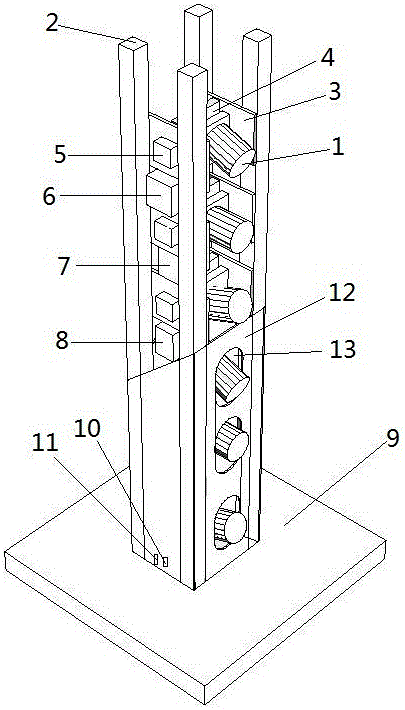

InactiveCN103658118AThe overall space occupied is smallIncrease productivityHollow article cleaningMetal working apparatusClosed loopEngineering

The invention discloses a large-sized workpiece overturning device. Two parallel grooves are formed in a base, two stand columns are fixed above each groove, the four stand columns are arranged in an equidistant mode, chain wheels are fixed to the top ends of the stand columns and the two ends of the grooves respectively, closed-loop chains pass through the tops of the grooves and the tops of the stand columns and are meshed with the chain wheels, each chain becomes concave between the tops of the corresponding two stand columns, and a power device synchronously drives chain wheel and chain mechanisms to operate. A workpiece is hung on the chains, the angle of the workpiece can be changed through operation of the chains, human assistance is not needed, the large-sized workpiece overturning device is small in occupied space, safe and reliable, and production efficiency is significantly improved.

Owner:CRRC DALIAN CO LTD

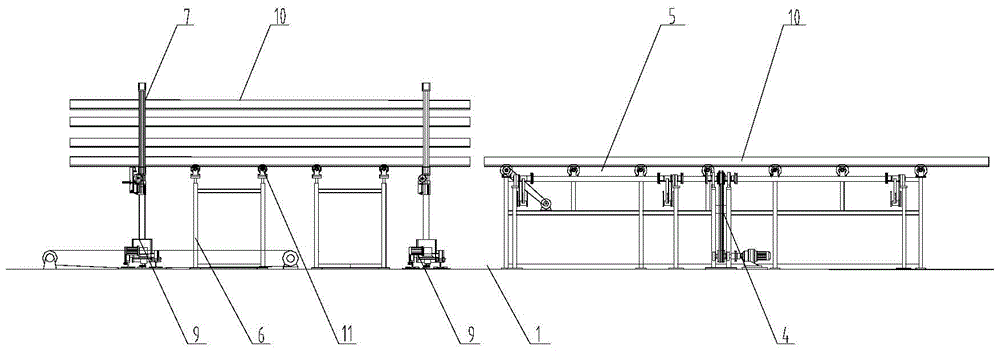

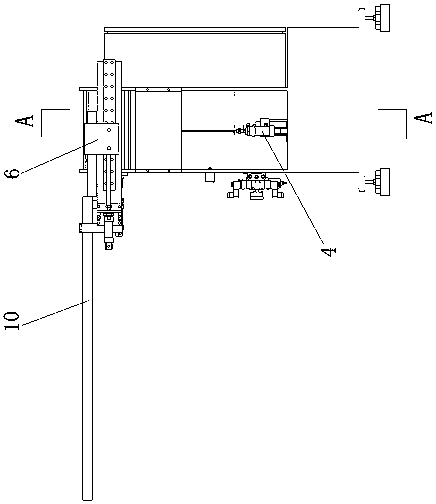

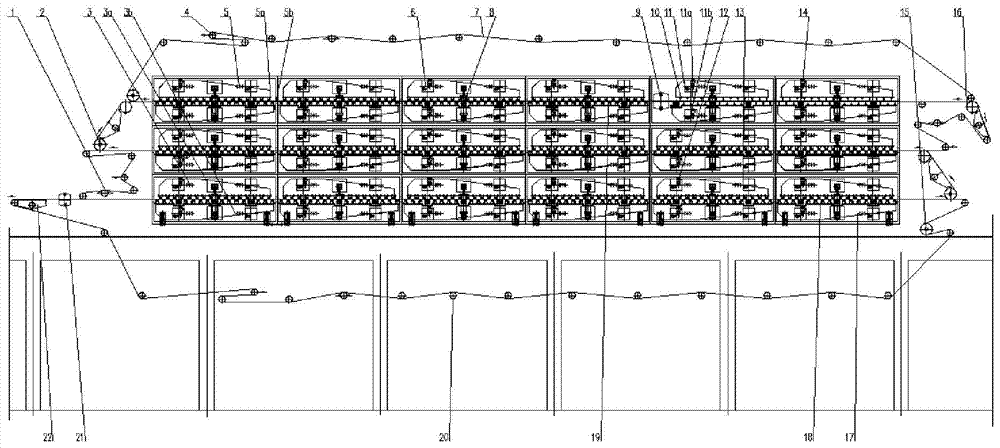

Angle steel galvanized numerical control threading and hanging device and threading and hanging process

ActiveCN104711501BNo manual deliveryImprove delivery efficiencyHot-dipping/immersion processesNumerical controlUltimate tensile strength

The invention relates to an auxiliary device for angle steel galvanization, in particular to a numerical control penetrating and hanging line device for angle steel galvanization and a penetrating and hanging process. The numerical control penetrating and hanging line device comprises a worktable, a material storage rack, an angle steel positioning seat, a material turnover device, a feeding roller way, a material-passing roller way, a material-penetrating comb, a movable guide rail and a comb clamping lifting traveling trolley, wherein the material turnover device is mounted between the angle steel positioning seat and the feeding roller way and can easily turn over and convey galvanized angle steel falling into the angle steel positioning seat to the preset feeding roller way, so that seamless connection of the angle steel and feeding and conveying processes is realized and the conveying efficiency and the conveying quality of the galvanized angle steel are improved. Angle steel feeding, conveying and penetrating-hanging processes are integrated on the same equipment, so that the occupied site space is small, the crane occupation time is short, and the safety coefficient is high; the whole penetrating and hanging operation does not need human assistance, and the galvanized angle steel is controlled through the numerical control device to realize the steps, so that the labor intensity of penetrating and hanging is greatly reduced and the penetrating and hanging efficiency is improved.

Owner:QINGDAO EAST STEEL TOWER

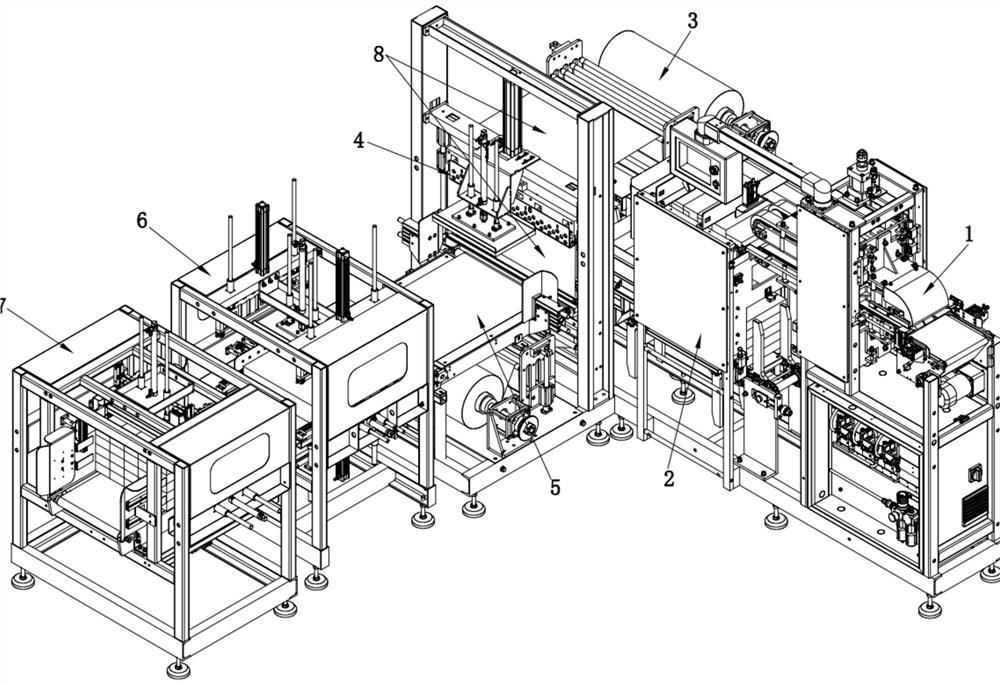

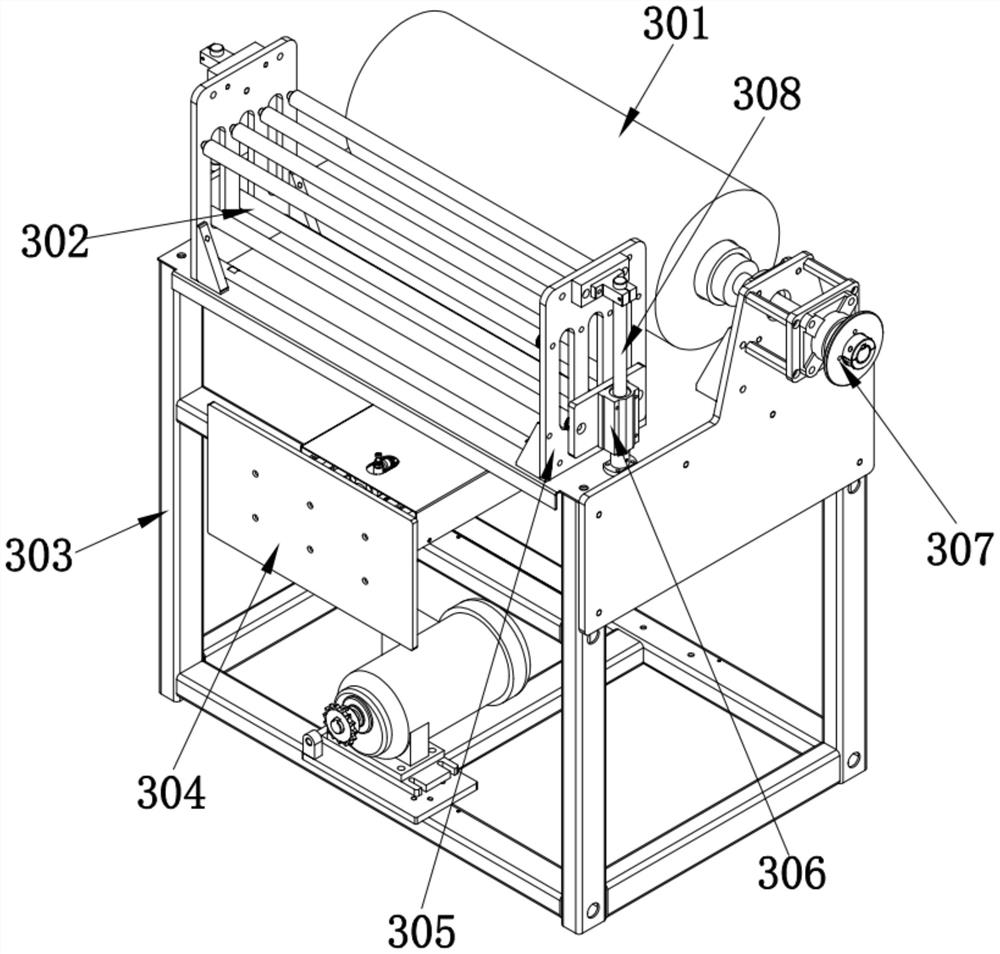

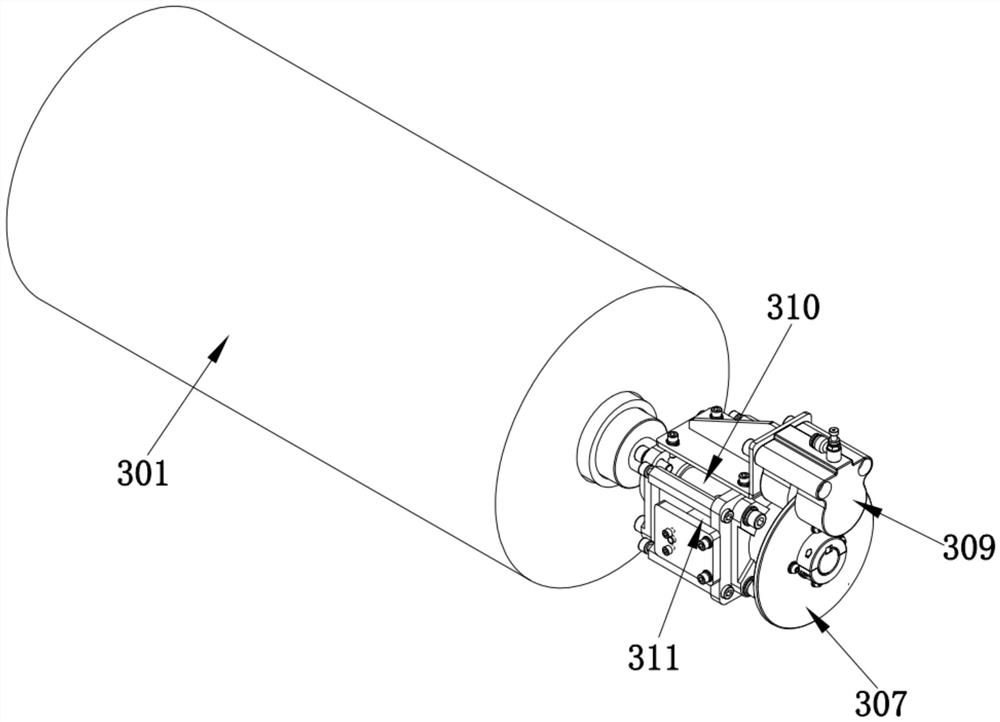

Full-automatic tarpaulin production line

PendingCN111058681ARealize automatic continuous productionIncrease productivityTents/canopiesSevering textilesHot pressContinuous production

The invention relates to the technical field of tarpaulin production, in particular to a full-automatic tarpaulin production line. The production line comprises a punching device and a machining device, wherein the machining device comprises a rack, an operating platform arranged under the rack, a machining forming mechanism arranged on the rack, a supporting base used for connecting the machiningforming mechanism with the rack in a sliding mode, and a power transmission mechanism driving the supporting base, the machining forming mechanism comprises a fixed plate and a sliding plate, a cutter is arranged under the sliding plate, the machining forming mechanism further comprises a rope arranging device, a flanging device, a heat sealing device, a hot pressing device, a clamping device, amoving device and a cutting device, the sliding plate slides on the fixed plate through a driving device, and the machining forming mechanism further comprises a length control device, a controller and a detecting element. The production line is high in automatic integration degree, the quality of finished products is guaranteed, automatic continuous production can be effectively achieved, manpower is saved, the occupied space is small, and the production line can adapt to dotting of tarpaulins of different sizes, and meet different production requirements.

Owner:青岛铭宇智能设备有限公司

Automatic feed mechanism of numerical control lathe

PendingCN108405889AReduce the chance of misuseImprove operational efficiencyAutomatic workpiece supply/removalMetal working apparatusEngineeringMechanical engineering

The invention relates to the technical field of machines, in particular to an automatic feed mechanism of a numerical control lathe. The automatic feed mechanism comprises a workbench. A jacking air cylinder is arranged at the bottom of the workbench. A jacking plate is arranged on the middle upper portion of the workbench. The jacking air cylinder is used for pushing the jacking plate to move. Adetection station is arranged on the workbench. The jacking plate is used for pushing a workpiece to enter the detection station on the workbench. A forward and backward recognition device is furtherarranged on the workbench and is arranged at the detection station and used for recognizing the direction of the workpiece. A material return gate is arranged on one side of the workbench and is opened and closed through a material return air cylinder. A material return box is arranged at an outlet of the material return gate. A feed groove is formed in the top of the workbench. One end of the feed groove is connected with a feed pipe. A feed air cylinder and a feed push rod are arranged on one side of the feed groove. The jacking plate pushes the workpiece to enter the feed groove. The feed push rod pushes the workpiece to horizontally move along the feed groove. The automatic feed mechanism is low in misoperation probability, low in manufacturing cost, high in safety and simple in operation.

Owner:福鼎市三宏机车部件有限公司

Clamping and moving device and method of cross beam of horizontal type tensile and compression testing machine

InactiveCN102967503AFast clampingMake full use of the site spaceStrength propertiesHydraulic cylinderEngineering

The invention discloses a clamping and moving device and method of a cross beam of a horizontal type tensile and compression testing machine. The device comprises a column, the cross beam and cross beam clamping cylinders, wherein the cross beam clamping cylinders are installed on the four corners of the cross bean; and the cross beam is clamped or released from the column through the cross beam clamping cylinders. The device further comprises a push-pull oil cylinder, a fixing plate and fixing plate clamping cylinders, wherein the fixing plate is arranged in parallel to the cross beam; the fixing plate is clamped or released from the column through the fixing plate clamping cylinders; the push-pull oil cylinder is arranged inside a frame and positioned between the cross beam and the fixing plate; the push-pull oil cylinder is a double action hydraulic cylinder; the piston and the cylinder barrel of the push-pull oil cylinder are respectively linked with the cross beam and the fixing plate; and hydraulic oil paths of the fixing plate clamping cylinders, the push-pull oil cylinder and the cross beam clamping cylinders are switched under electric control so as to clamp, release and move along the column in a stepless adjustment mode. By combining cross beam hydraulic clamping and hydraulic pushing, the resource of a testing machine is sufficiently utilized, occupied field is small and operation is convenient.

Owner:JINAN SHIDAI SHIJIN TESTING MACHINE GRP

Automatic drying equipment for textile auxiliary production

ActiveCN114322524AImprove drying and heat dissipation efficiencyImprove uniformityDrying gas arrangementsDrying solid materialsIndustrial engineeringBelt conveyor

The invention relates to the technical field of textile auxiliary production and processing, in particular to textile auxiliary production automatic drying equipment which comprises a belt conveyor used for conveying materials, a baffle frame used for limiting the materials, a feeding mechanism used for feeding the materials and a material overturning mechanism used for overturning the materials. The material turning mechanism comprises a material turning driving mechanism installed on the belt conveyor rack and a plurality of material turning plate assemblies arranged between the two partition plates. Compared with an existing belt dryer, the equipment provided by the invention has the advantages that the drying efficiency is higher when the textile auxiliary agent is dried, the compact design of the equipment structure is more favorably realized, and the purpose of reducing the occupied field space of the equipment is achieved.

Owner:江苏华晟国联科技有限公司

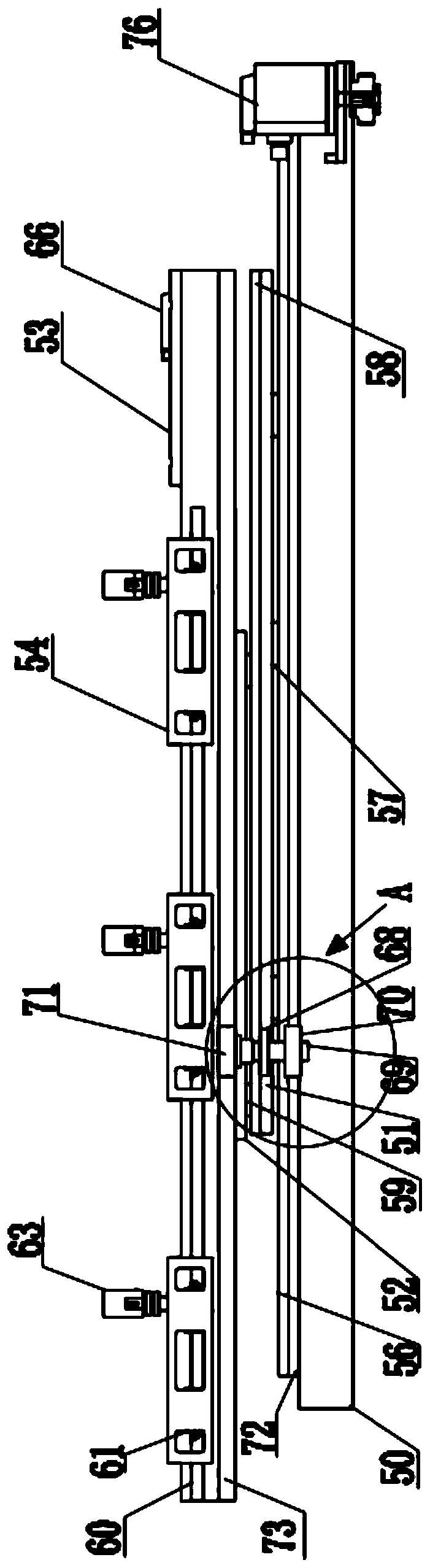

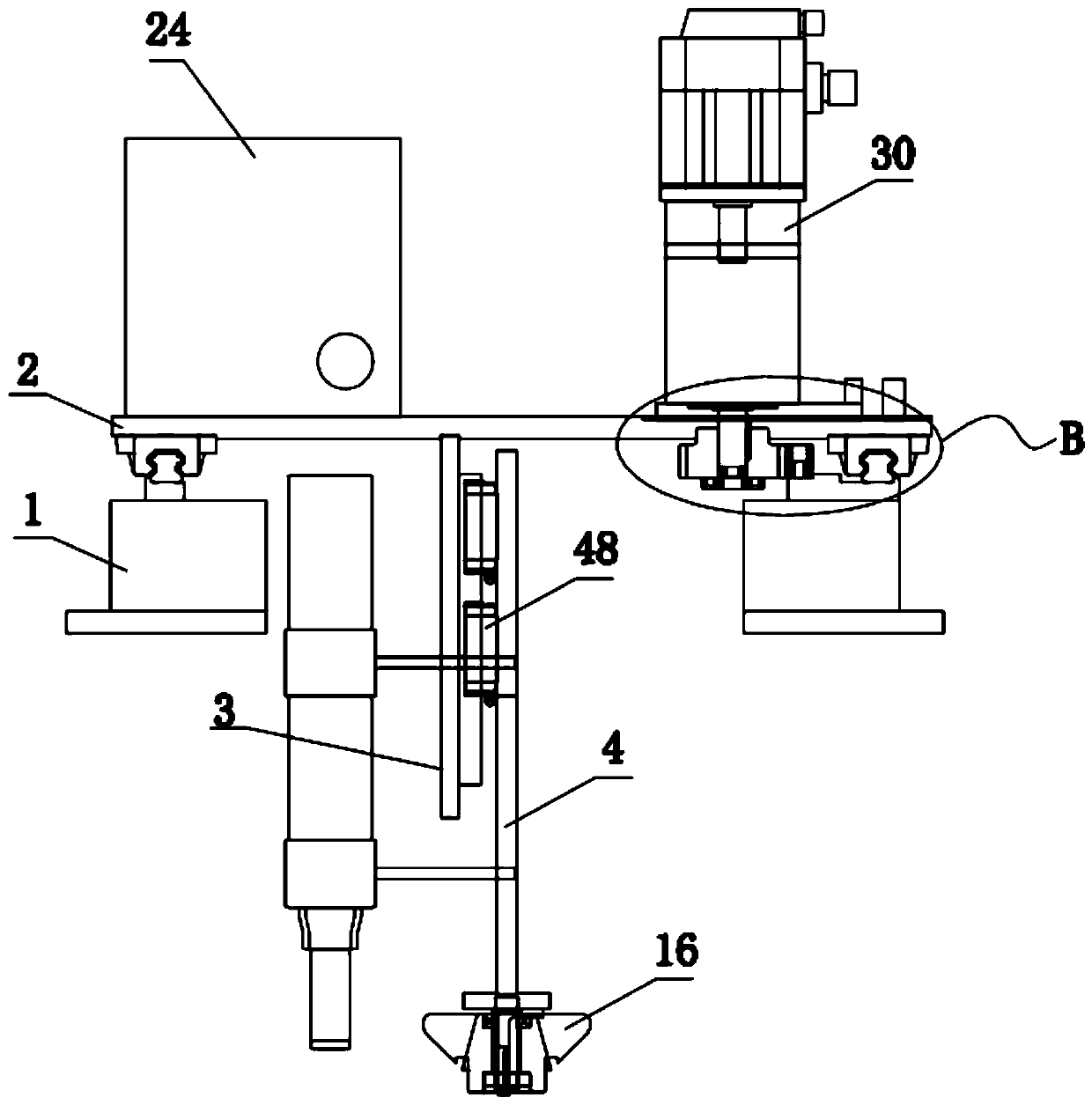

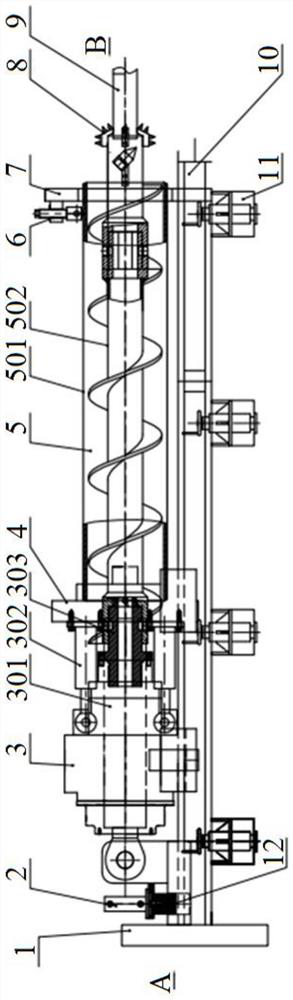

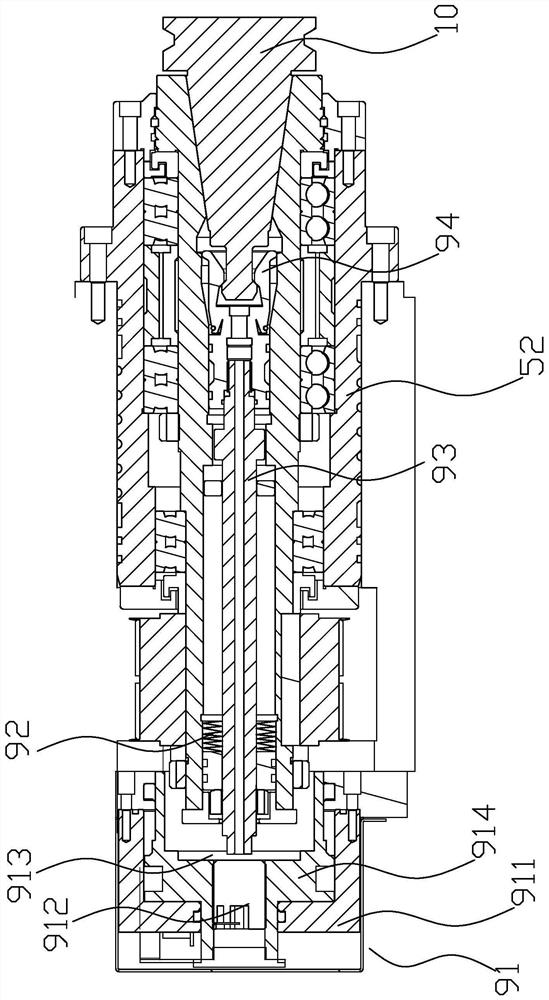

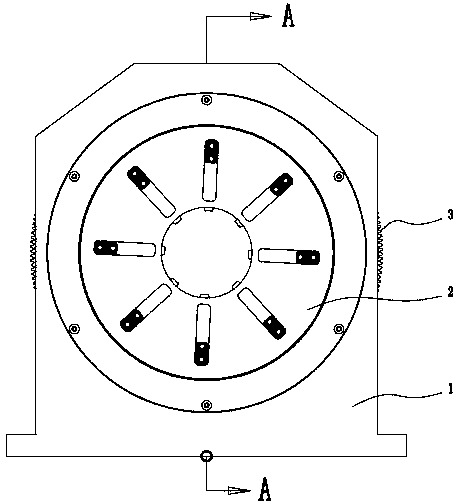

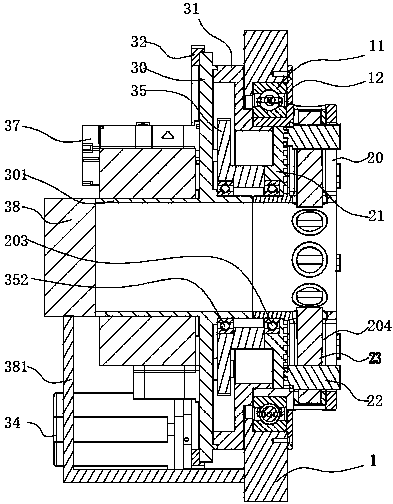

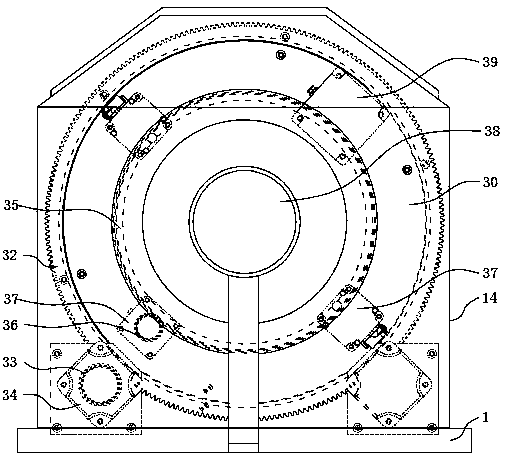

Spiral pipe jacking machine

PendingCN112593969AImprove construction efficiencyThe overall space occupied is smallTunnelsStructural engineeringMechanical engineering

The invention discloses a spiral pipe jacking machine. The spiral pipe jacking machine comprises a driving device, a spiral casing pipe device, an excavating device and a guiding device, wherein the driving device is connected with the spiral casing pipe device and the guiding device, the guiding device is located at the front end of the spiral casing pipe device, the spiral casing pipe device isconnected with the excavating device, and the excavating device is located at the front end of the spiral casing pipe device and the rear end of the guiding device. According to the spiral pipe jacking machine, high-precision guiding and deviation correction are achieved through the guiding device; and in addition, the spiral pipe jacking machine has the advantages of being small in occupied spaceand high in construction efficiency.

Owner:CHINA RAILWAY CONSTR HEAVY IND

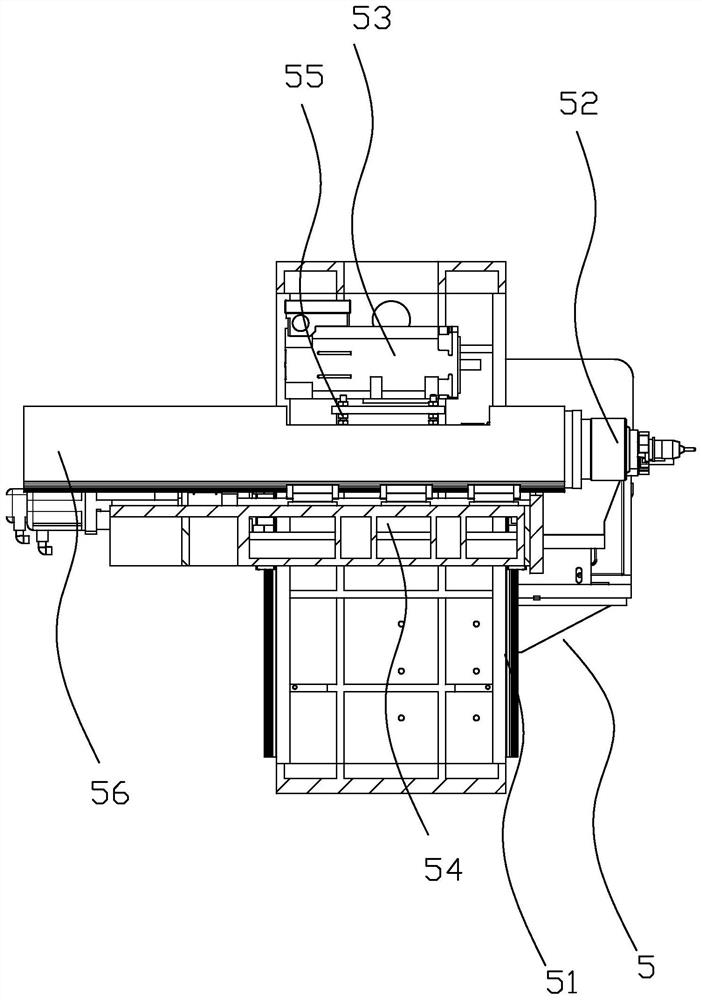

Numerical control vertical and horizontal compound machine

PendingCN112589539AThe overall space occupied is smallReduce auxiliary processing timeMetal working apparatusNumerical controlVertical plane

The invention relates to a numerical control machine tool, and provides a numerical control vertical and horizontal compound machine. The numerical control vertical and horizontal compound machine comprises a machine frame, a work table, a fixing seat, a cross slide table, a first driving unit, a horizontal main shaft box, a vertical main shaft box, a horizontal tool magazine and a vertical tool magazine, wherein the the horizontal main shaft box comprises a stand column, a power head, a main shaft motor, a sliding table, a supporting base, a transverse rod, a second driving unit and a third driving unit, the stand column is an n-shaped stand column provided with a hollow groove, the sliding table is arranged on the hollow groove of the stand column in an up-down sliding mode through the second driving unit, the transverse rod is arranged on the upper surface of the sliding table in a horizontal sliding mode through the third driving unit, the upper surface of the transverse rod perpendicularly intersects with the vertical plane of the hollow groove of the stand column, the main shaft motor is arranged on the supporting base, and an output shaft of the main shaft motor is connectedwith and drives a main shaft of the power head to rotate to machine a to-be-machined workpiece on the work table. The numerical control vertical and horizontal compound machine solves the problems that an existing vertical and horizontal combined machining center is large in occupied space and high in manufacturing cost.

Owner:泉州市创佳自动化设备有限公司

Cigarette degradation film packaging machine and packaging method thereof

PendingCN114872988AGuaranteed tightOvercoming slack wrinklesWrapping material feeding apparatusConveyor wrappingPolymer scienceCarton

The invention relates to the technical field of carton cigarette packaging, in particular to a carton cigarette degradation film packaging machine and a packaging method thereof, and the carton cigarette degradation film packaging machine structurally comprises a conveying speed difference mechanism. An existing PE cigarette film is replaced with the degradable film, the national call for energy conservation and consumption reduction is responded, the environment-friendly and resource-saving effects are achieved, the degradable film is tightened, collected and released through the degradable film tightening device, the degradable film on a cigarette stack is more compact, more uniform and better in wrapping performance when the film is fused, and the film fusing efficiency is improved. Therefore, the defect that the degradable film can be tightened, fused and wrapped on the tobacco stack without thermal shrinkage is overcome, meanwhile, the thermal shrinkage process of a thermal shrinkage machine is omitted, the process is simpler, after the degradable film is fused, the first tobacco stack film sealing device and the second tobacco stack film sealing device can be used for separating and sealing the tobacco stacks with different layers, the applicability is higher, the limitation is reduced, and the production efficiency is improved. And meanwhile, it can be guaranteed that cigarette packets are tightened for a long time and are not loosened, and then the problem that hard box packaging films are loosened and wrinkled by ordinary cigarette films is solved.

Owner:福建东亮智能装备科技有限公司

Multi-camera device for human body 3D scanning

PendingCN107438147AImprove efficiencyBig angleTelevision system detailsColor television detailsHuman bodyData acquisition

The invention discloses a multi-camera device for human body 3D scanning. The multi-camera device comprises more than one camera units, more than one steering engines, a signal processing board, a router, a switch power, and wire rod; the multi-camera is connected with the computer through a cable; the multi-camera is used for acquiring a human body image and transmitting the same to the computer to perform the image processing. The invention aims at providing data acquisition equipment with simple structure, low cost, convenient operation, high scanning efficiency, accurate scanning result, and small floor area for the problem existent in the existing human body 3D modeling scanning equipment; the data acquisition equipment is mainly used for 3D photo studio (3D printed portrait, crystal inter-carven), films and games, augmented reality, virtual fitting, medical assistance, reforming prediction, human body form parameter measurement and like fields.

Owner:师嘉麟

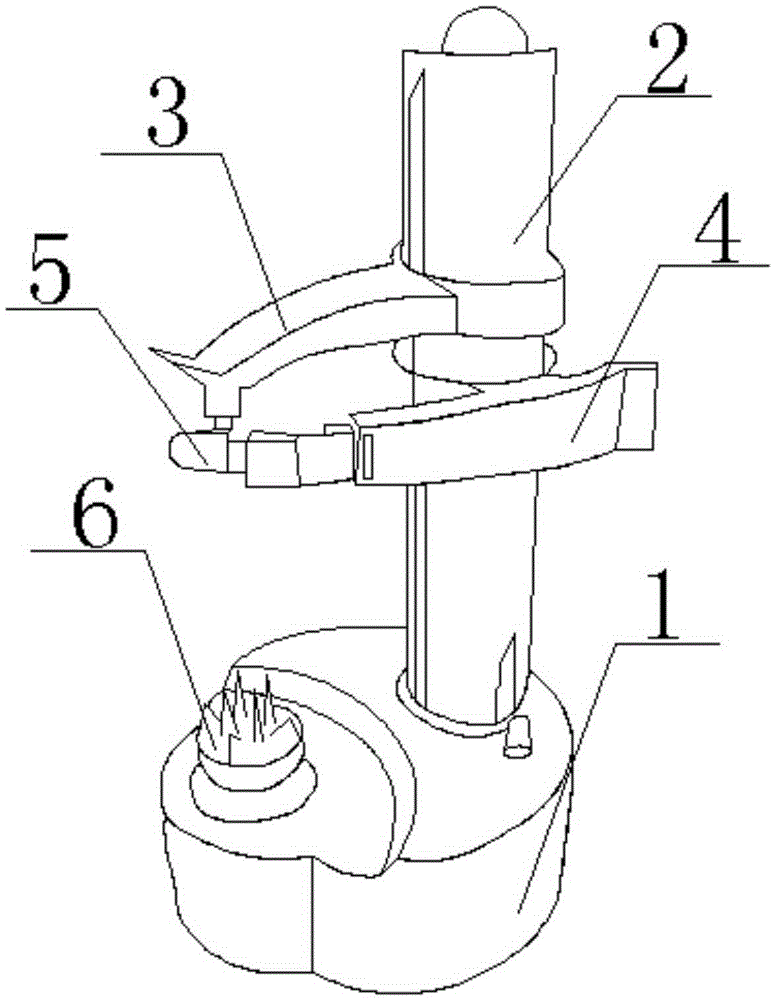

Electric peeler

The invention relates to an electric peeler. The electric peeler comprises a base, a spindle, a fixator, a connecting rod, a tool bit and a bottom fixator. The base is fixedly connected with one end of the spindle, the connecting rod is detachably connected with the spindle in a sleeving mode, the tool bit is detachably connected with one end of the connecting rod, the fixator is fixedly connected to one end of the spindle, and the bottom fixator is fixedly connected with the base. The electric peeler is easy and convenient to use, short in consumed time, sanitary, safe, small in occupied space when placed and convenient to carry, and the tool bit can be replaced.

Owner:QINGDAO HAITE XINLAN BIOTECH CO LTD

Intelligent chuck

PendingCN111055034ASmall volumeCompact structureLaser beam welding apparatusComputer hardwareGear wheel

The invention discloses an intelligent chuck. A driving mechanism of the intelligent chuck is divided into two drivers for driving clamping mechanisms to work, wherein one driver is a chuck rotating driver which comprises an external disk servo motor, an external small spur gear, an external large gear, a motor mounting disk, and a chuck rotating sleeve and is used for driving a rotating chuck torotate; and the other driver is a locking disk rotating driver which comprises an internal disk servo motor, an internal small gear and an internal big gear and is used for driving clamping jaw locking disks to rotate. The internal disk servo motor of the locking disk rotating driver is used for driving the clamping jaw locking disks to rotate; and the clamping jaws linearly slides through the rotary movement of the clamping jaw locking disks, so that workpiece clamping heads are driven by the clamping jaws to inwards clamp a pipe. The intelligent chuck has the advantages that the internal disk servo motor is used as a power source of the chuck for clamping the pipe to realize the digital control; the intelligent chuck is suitable for various types of pipes with different outer diameters;the clamping force of the clamping jaws has good consistency; a series of matched shaft sleeves are not needed; the space is saved; the working efficiency is improved; and the equipment cost is reduced.

Owner:何翔

Reproduced tobacco leaf raw material preprocessing peduncle and leaf separating and decontaminating device

InactiveCN103769368AImprove puritySolve the problem of diversity handlingGas current separationEngineeringSmall footprint

The invention relates to a reproduced tobacco leaf raw material preprocessing peduncle and leaf separating and decontaminating device. A system is sequentially composed of a steep angle lifter (1), a feeding elastic sheet vibration conveyor (2), a winnowing machine (3) and a bag type impulse dedustor. The reproduced tobacco leaf raw material preprocessing peduncle and leaf separating and decontaminating device is compact in structure, little in occupied area, little in investment, low in production cost, and capable of ensuring stability of the quality of produced raw materials after peduncle and leaf separating and decontaminating so as to ensure the stable quality of the reproduced tobacco leaves with the paper making method.

Owner:CHINA TOBACCO YUNNAN REMFG TOBACCO CO LTD

Intelligent feeding and discharging robot, system and control method for intelligent factory

ActiveCN112550521AImprove securityThe overall space occupied is smallElectric/hybrid propulsionPosition/course control in two dimensionsRobotic systemsLaser scanning

The invention relates to an intelligent feeding and discharging robot for an intelligent factory. The robot is used for transporting material frames in a factory and comprises a communication module,a control module, a base, driving wheels installed below the base, a laser scanning sensor, an ultrasonic sensor and a 3D camera which are installed on the side face of the base, a material frame anda support, and the material frame and the support are installed above the base. The support is arranged on the material frame and used for placing a control terminal, a plurality of grooves are formedin the material frame and used for placing the material frames, the grooves match the bottom of the material frames in shape, the communication module and the control module are arranged in the base,the communication module is connected with the control terminal, and the control module is connected with the laser scanning sensor, the ultrasonic sensor and the 3D camera. Compared with the prior art, the robot has the advantages of being simple in structure, flexible, efficient and the like.

Owner:SHANGHAI SIIC LONGCHUANG SMARTER ENERGY TECH CO LTD

An automatic drying equipment for the production of textile auxiliaries

ActiveCN114322524BImprove drying and heat dissipation efficiencyImprove uniformityDrying gas arrangementsDrying solid materialsProcess engineeringIndustrial engineering

The invention relates to the technical field of production and processing of textile auxiliaries, and specifically proposes an automatic drying equipment for the production of textile auxiliaries, including a belt conveyor for material transportation, a baffle frame for limiting materials, and a baffle frame for material input. A material feeding mechanism and a material turning mechanism for material turning; the material turning mechanism includes a turning driving mechanism installed on the belt conveyor frame and a number of turning materials arranged between the two partitions Plate assembly; Compared with the existing belt dryer, the equipment provided by the invention has higher drying efficiency when drying textile auxiliaries, and is more conducive to realizing the compact design of the equipment structure, and achieving the purpose of reducing the space occupied by the equipment.

Owner:江苏华晟国联科技有限公司

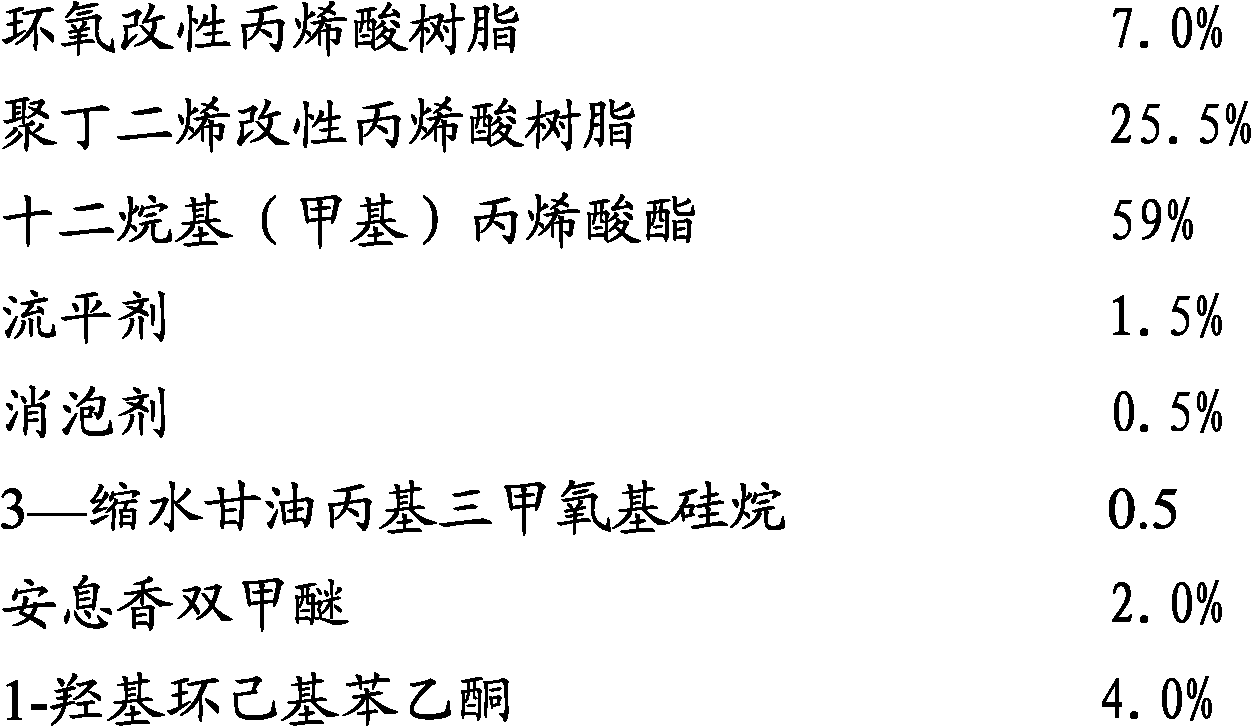

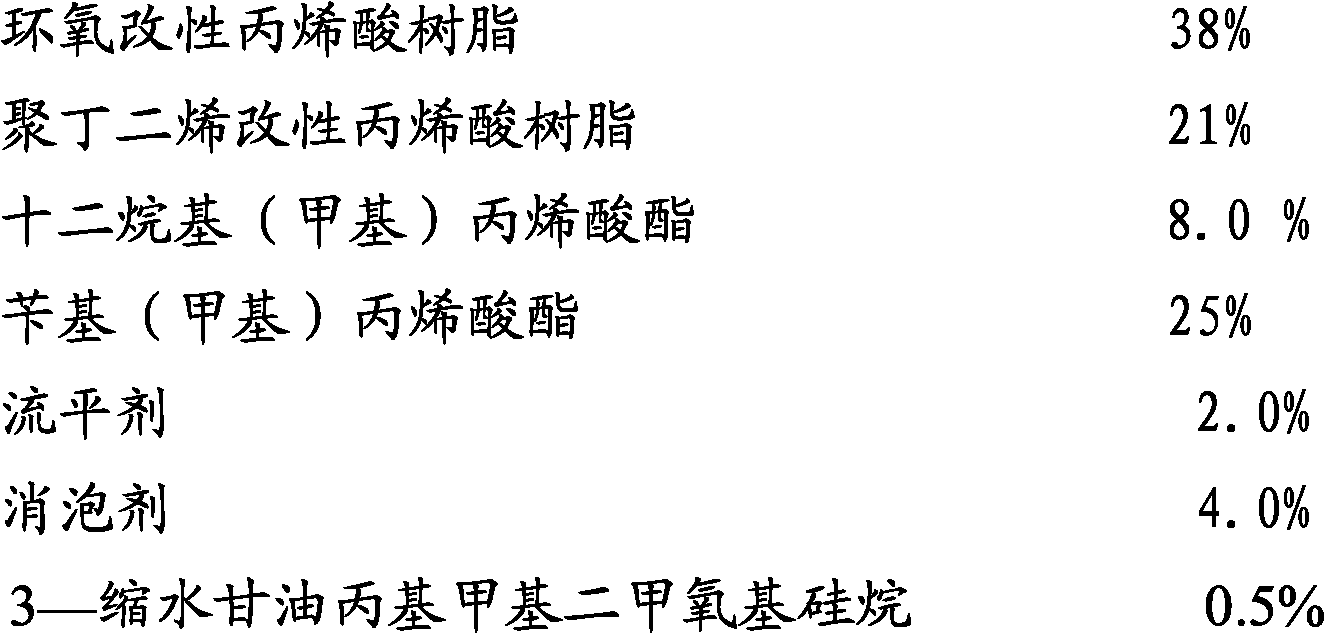

Ultraviolet curable adhesive with high light transmittance

ActiveCN102516889BThe overall space occupied is smallIncrease productivityOrganic non-macromolecular adhesiveUV curingOptical property

The invention discloses an ultraviolet curable adhesive with high light transmittance. The ultraviolet curable adhesive provided by the invention is prepared from the following raw materials of: by weight, 5.8-59% of modified acrylic acid oligomer resin, 5.8-59% of an acrylic acid monomer, 2-10% of an auxiliary agent, 0.5-15% of a silane coupling agent, and 1.5-10.5% of a photoinitiator. With the adoption of the above components in proportions, the adhesive provided by the invention has fast curing rate and excellent optical properties, the glue solution is colorless and transparent, its light transmittance after curing is greater than 95%, cure shrinkage is small, the internal stress is low, and caking capability is strong.

Owner:SHENZHEN PROSPER DOBOND TECH

Electric slag furnace provided with water cooling system and dust collecting system

The invention discloses an electric slag furnace provided with a water cooling system and a dust collecting system. The electric slag furnace is provided with a left guide frame and a right guide frame, wherein the left guide frame and the right guide frame are symmetrically arranged left and right, and the top ends of the left guide frame and the right guide frame are connected into a whole through a connecting piece; screw rod transmission mechanisms and electric slag furnace bodies are arranged on the inner sides and the outer sides of the left guide frame and the outer side of the right guide frame respectively; sliding seats driven by the screw rod transmission mechanisms to move up and down are arranged on the left guide frame and the right guide frame, and clamping mechanisms used for clamping smelting steel materials are arranged on the outer sides of the sliding seats; and the electric slag furnace bodies are stored on flat trolleys. The electric slag furnace is simple in structure and convenient to operate, the two sets of electric slag furnaces are combined into a whole to be used, so that the stability of the overall structure is ensured, and a large amount of site space is saved.

Owner:湖北志联模具科技有限公司

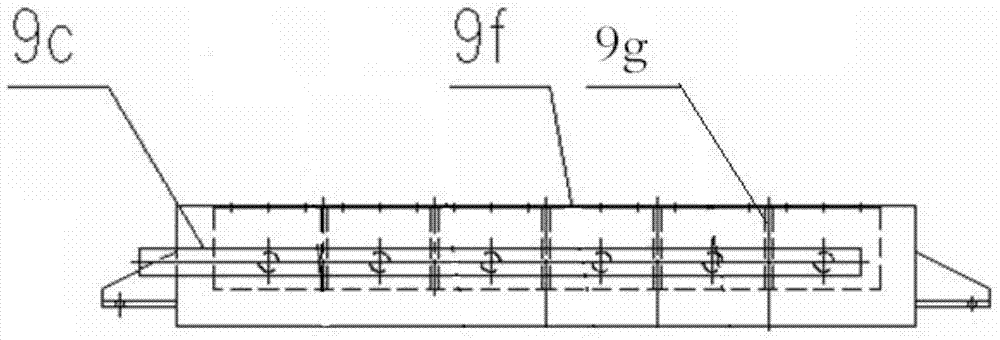

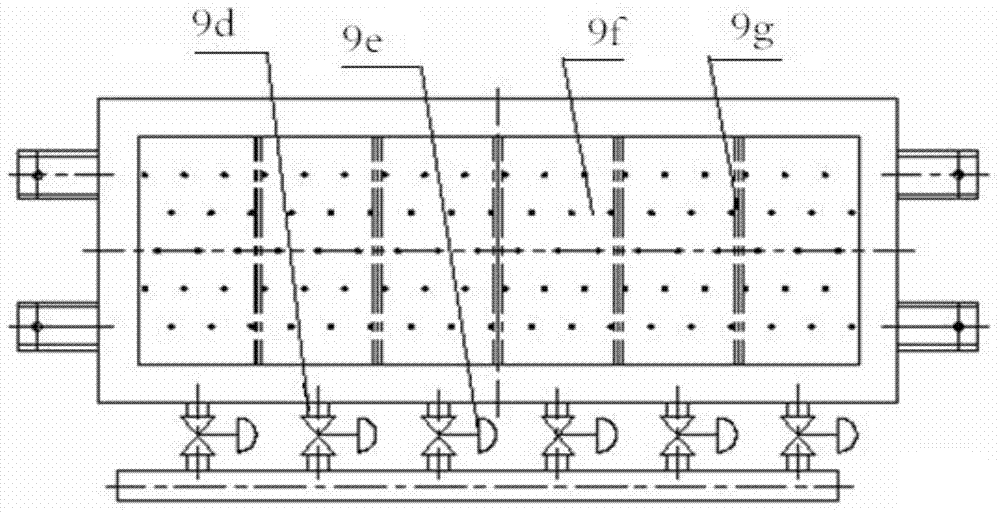

Reconstituted tobacco integrated tunnel dryer

ActiveCN103727760BAvoid stickingImprove drying efficiencyTobacco preparationDrying machines with progressive movementsProcess engineeringTobacco product

A reconstituted tobacco integrated tunnel dryer comprises at least two layers of drying boxes and the like. The dryer is characterized in that drying boxes include low-temperature drying boxes (3), high-temperature drying boxes (5) and cooling dry boxes (11) arranged behind the high-temperature drying boxes; the low-temperature drying boxes include upper low temperature boxes, lower low temperature boxes and low temperature air blowing nozzles (18); the high-temperature drying boxes include upper high temperature boxes, lower high temperature boxes and high temperature air blowing nozzles (19); each layer of drying boxes are formed by a plurality of pairs of insulated upper boxes and lower boxes which are arrayed in sequence; the cooling dry boxes (11) include upper cooling boxes, lower cooling boxes and cooling air nozzles (10) and are formed by a plurality of pairs of insulated upper boxes and lower boxes which are arrayed in sequence; dampening devices (9) are arranged in the first pair of the drying boxes. The reconstituted tobacco integrated tunnel dryer can be used for moistening, drying, cooling, shaping squeezed reconstituted-tobacco sheets and coated reconstituted-tobacco products and preventing adhesion.

Owner:CHINA TOBACCO YUNNAN REMFG TOBACCO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com