Segment prefabricated assembled pier steel member and construction method and application

A technology of prefabricated assembly and construction method, which is applied in bridge parts, erection/assembly of bridges, bridges, etc., can solve the problems of large construction noise and surrounding environment interference, low turnover and reuse rate of steel formwork, and insufficient durability of splices. Achieve the effect of high assembly efficiency, high construction efficiency and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

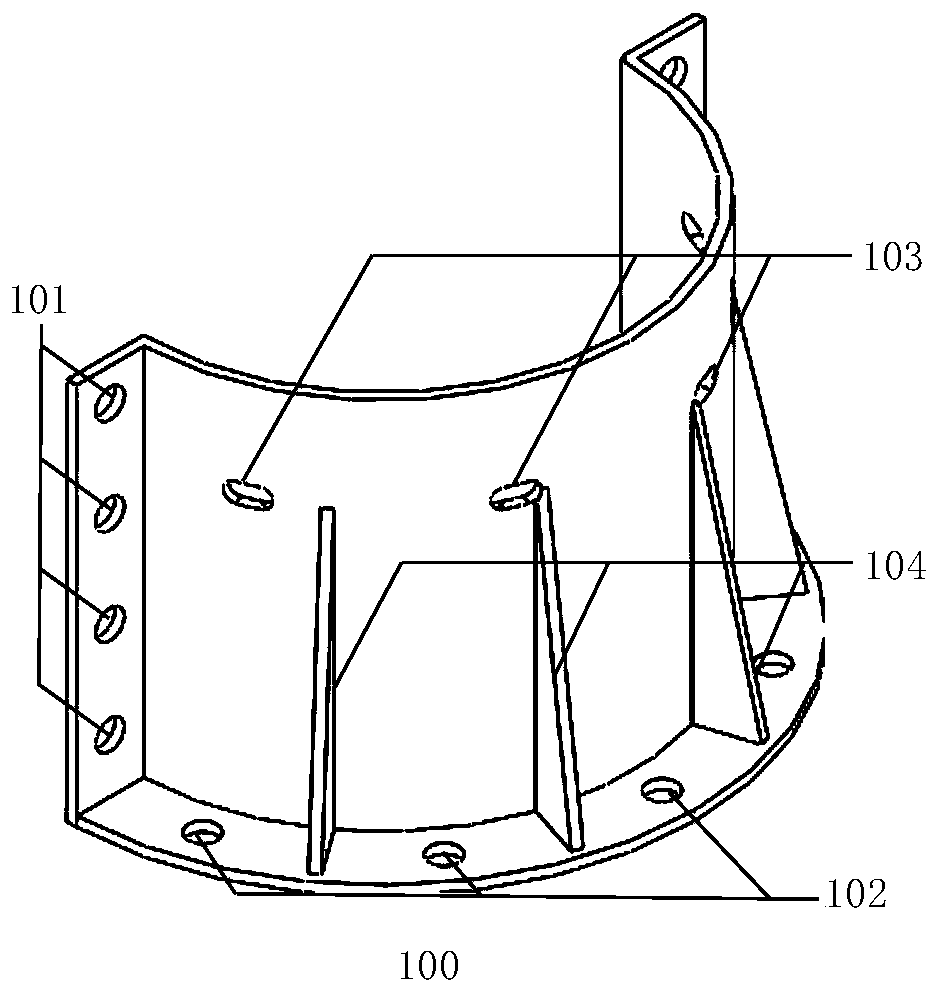

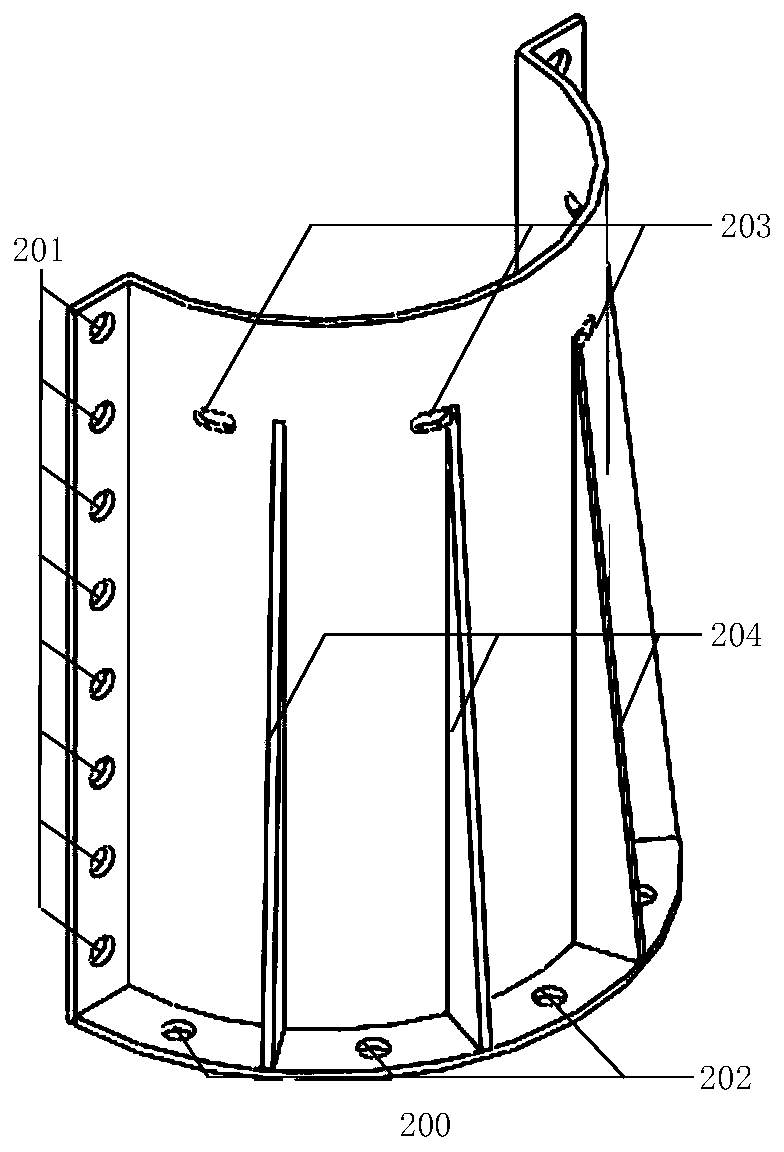

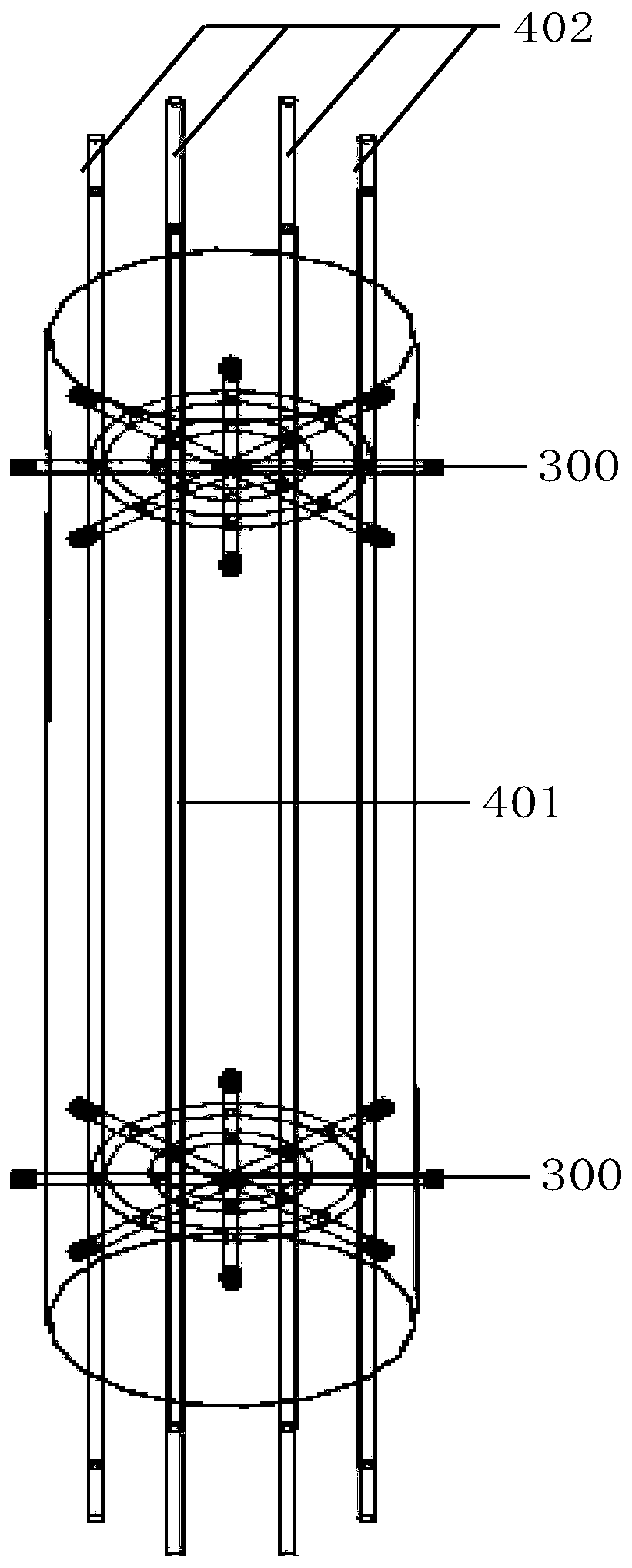

[0033] In one embodiment of the present invention, as Figure 1-8 As shown, a segmental prefabricated assembled pier steel member is provided, including a short steel member 100, a long steel member 200 and an anchoring and fixing steel bar 300, the short steel member 100 and the long steel member 200 are both semicircular, and the short steel member 100 There are a number of stiffeners 104 on the top, a number of vertical bolt holes 101 at the joints of the two ends of the short steel member 100, and a number of horizontal bolt holes 102 on the lower steel plate; Two 204, a number of vertical bolt holes 201 are arranged at the joints of the two ends of the long steel member 200, and a number of horizontal bolt holes 202 are arranged on the steel plate at the lower end, the size of the horizontal bolt hole 1 102 and the horizontal bolt hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com