Reproduced tobacco leaf raw material preprocessing peduncle and leaf separating and decontaminating device

A technology for separating stems and leaves and reconstituting tobacco leaves, which is applied in the directions of solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc. The effect of small site space, reduction of comprehensive cost, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

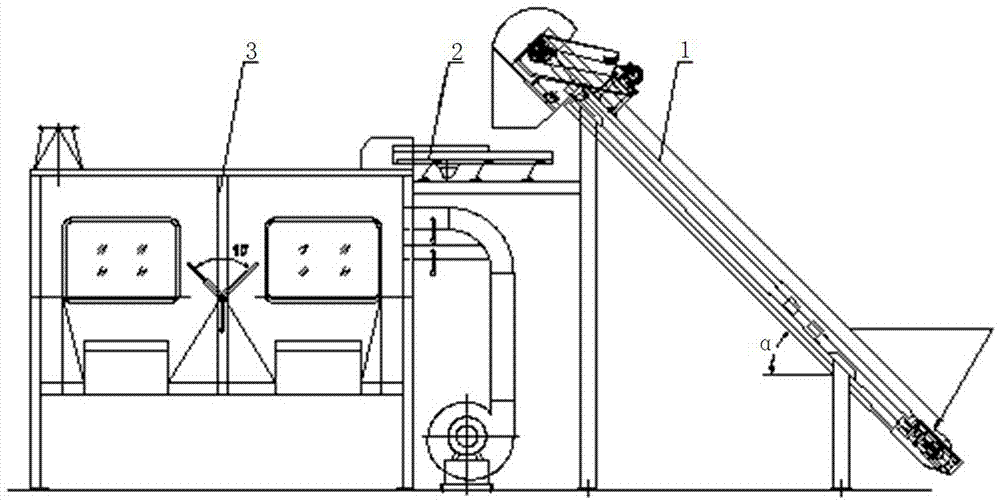

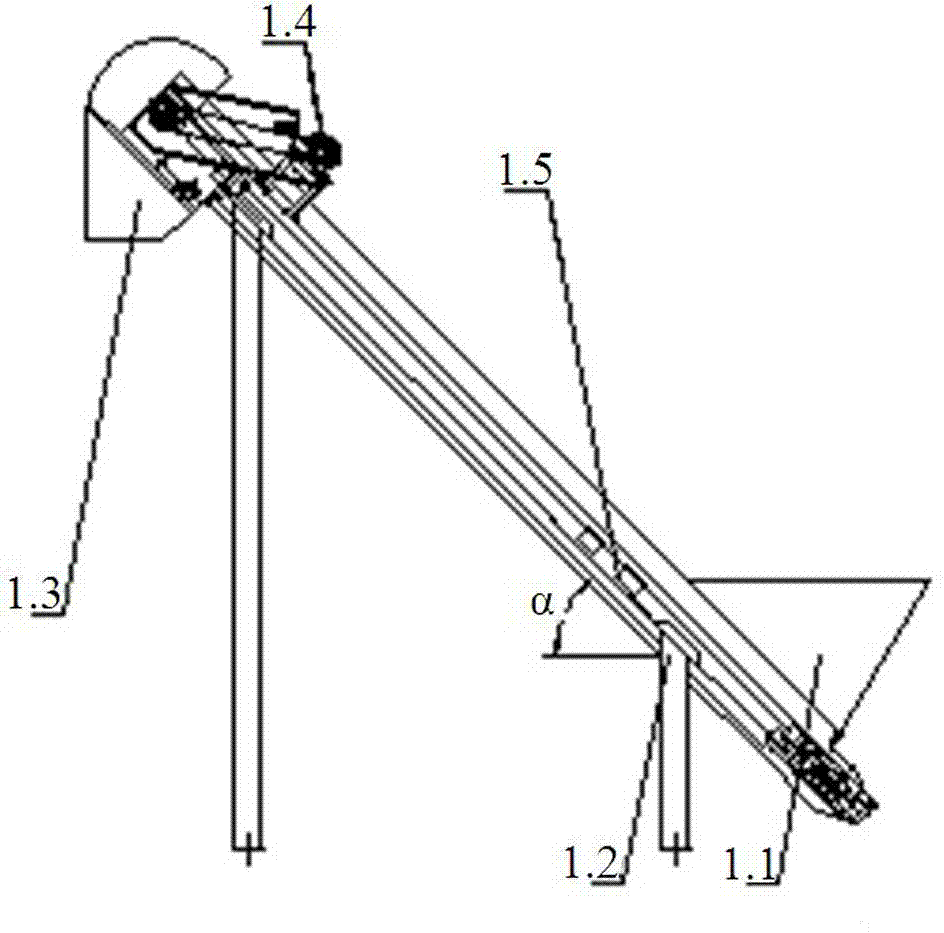

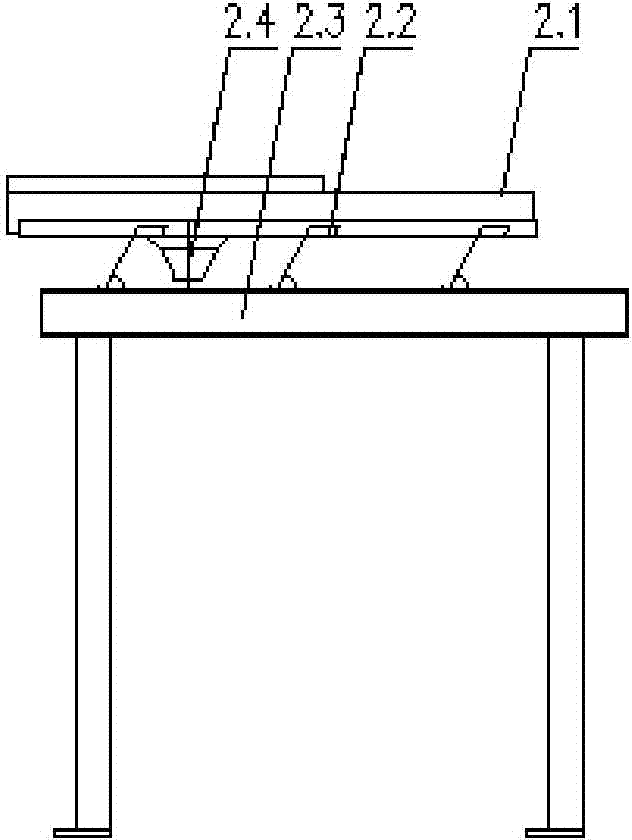

[0012] as attached figure 1 As shown: the present invention reconstituted tobacco raw material pretreatment stalk leaf separation and impurity removal equipment consists of a steep angle hoist 1, a feeding shrapnel vibrating conveyor 2, a wind sorting machine 3, and a bag-type pulse dust collector to form a system in order to complete Raw material pretreatment stem, leaf separation and impurity removal functions. Such as figure 2 As shown, the steep-angle hoist includes a feed bin 1.1 with a certain taper installed at the tail of the hoist, a frame 1.2 supporting the hoist, a discharge port 1.3 located at the head of the hoist, and a The conveyor belt 1.4 of the scraper, the transmission device 1.5 that is arranged on the lower section of the hoist to transmit the conveyor belt 1.4 with the scraper installed. In the transmission device, the reduction motor drives the main shaft sprocket and the driving roller, and drags the conveyor belt equipped with scrapers. The steep a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com