Intelligent chuck

A chuck, intelligent technology, applied in welding equipment, laser welding equipment, metal processing equipment and other directions, can solve the problems of high procurement cost, high labor intensity, large clamping mechanism, etc., to achieve simple and efficient on-site management, labor intensity The effect of reduction and transportation cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention and its beneficial technical effects will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

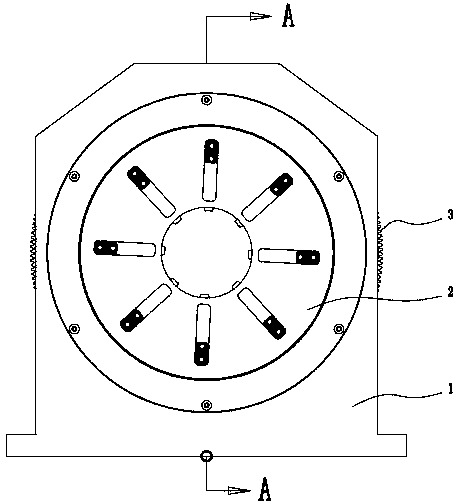

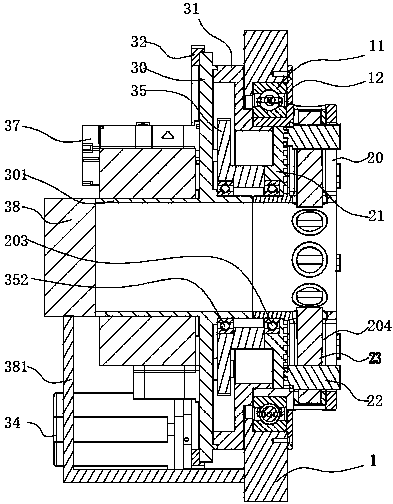

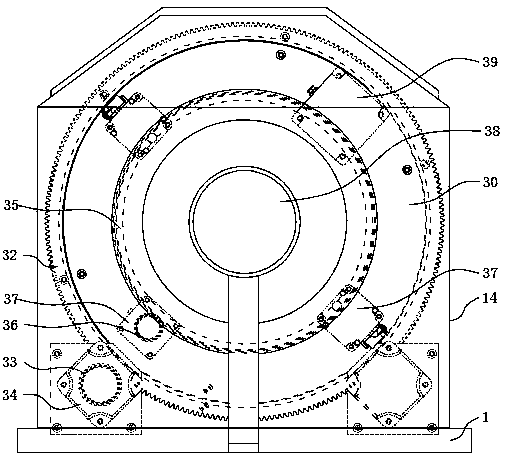

[0053] see Figure 1~Figure 20 , the intelligent chuck preferably implemented in the present invention includes a fixed base 1, a clamping mechanism 2 for clamping pipes, a driving mechanism 3 for driving the clamping mechanism 2 to rotate, the driving mechanism 3 is arranged on the rear side of the fixing base 1, and clamps The mechanism 2 is arranged on the front side of the fixed base 1; its characteristics are:

[0054] see figure 2 , the fixed base 1 is provided with a chuck mounting hole 5 through front and back, and the chuck mounting hole 5 is embedded with a chuck bearing 11;

[0055] see figure 2 , the clamping mechanism 2 includes a rotary chuck 20, a jaw locking disc 21, jaws 22, and a workpiece clamping head 24;

[0056] see figure 2 , the drive mechanism 3 includes a motor mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com