Vertical tank strontium smelting process and plant

A vertical tank and process technology, applied in the field of metal reduction, can solve the problems of large space occupation, low utilization rate of heat energy, one-way sag deformation, etc., and achieve the effect of small space occupation, high utilization rate of heat energy, and increased service cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

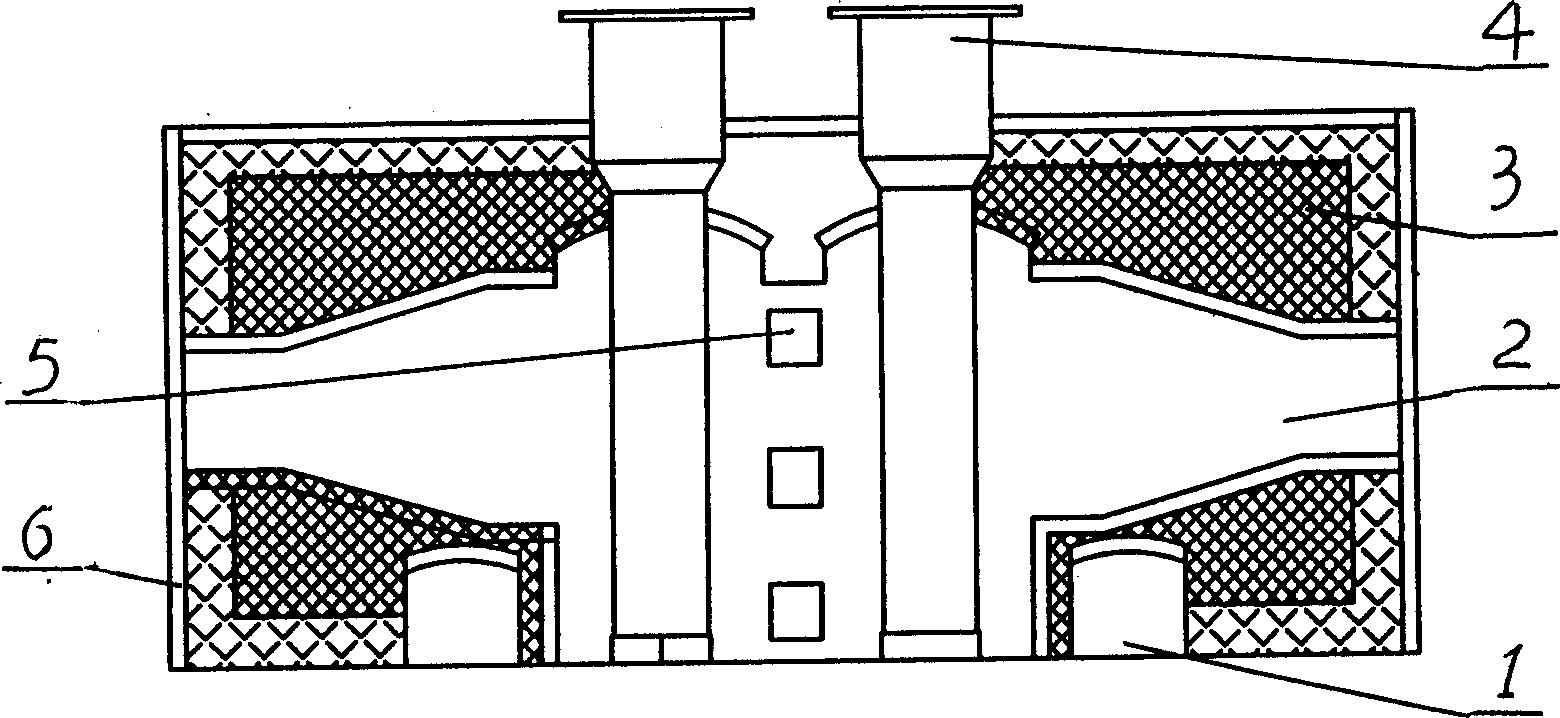

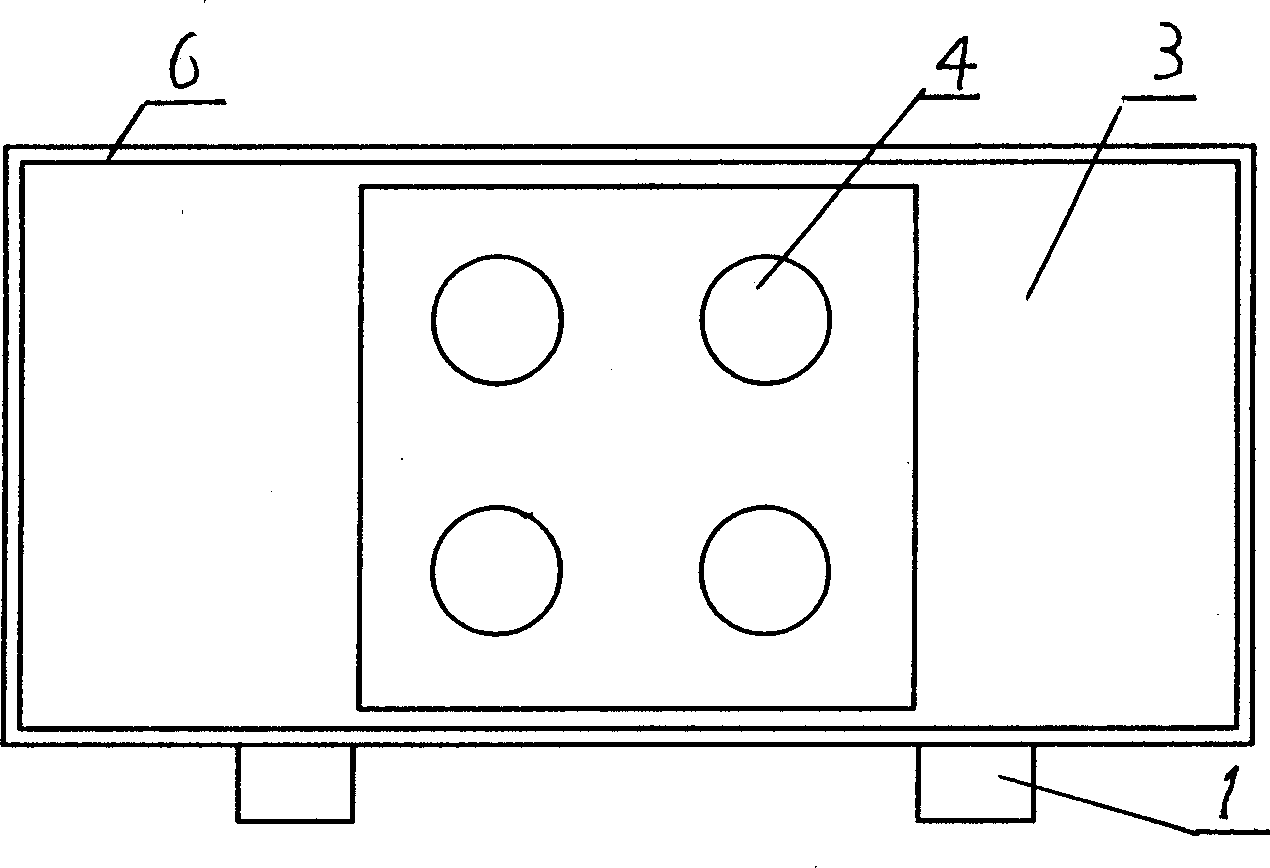

[0035] See Figure 1 to Figure 6 :

[0036] 1. Press figure 1 and figure 2 The strontium smelting device is made of masonry vertical tanks and dried.

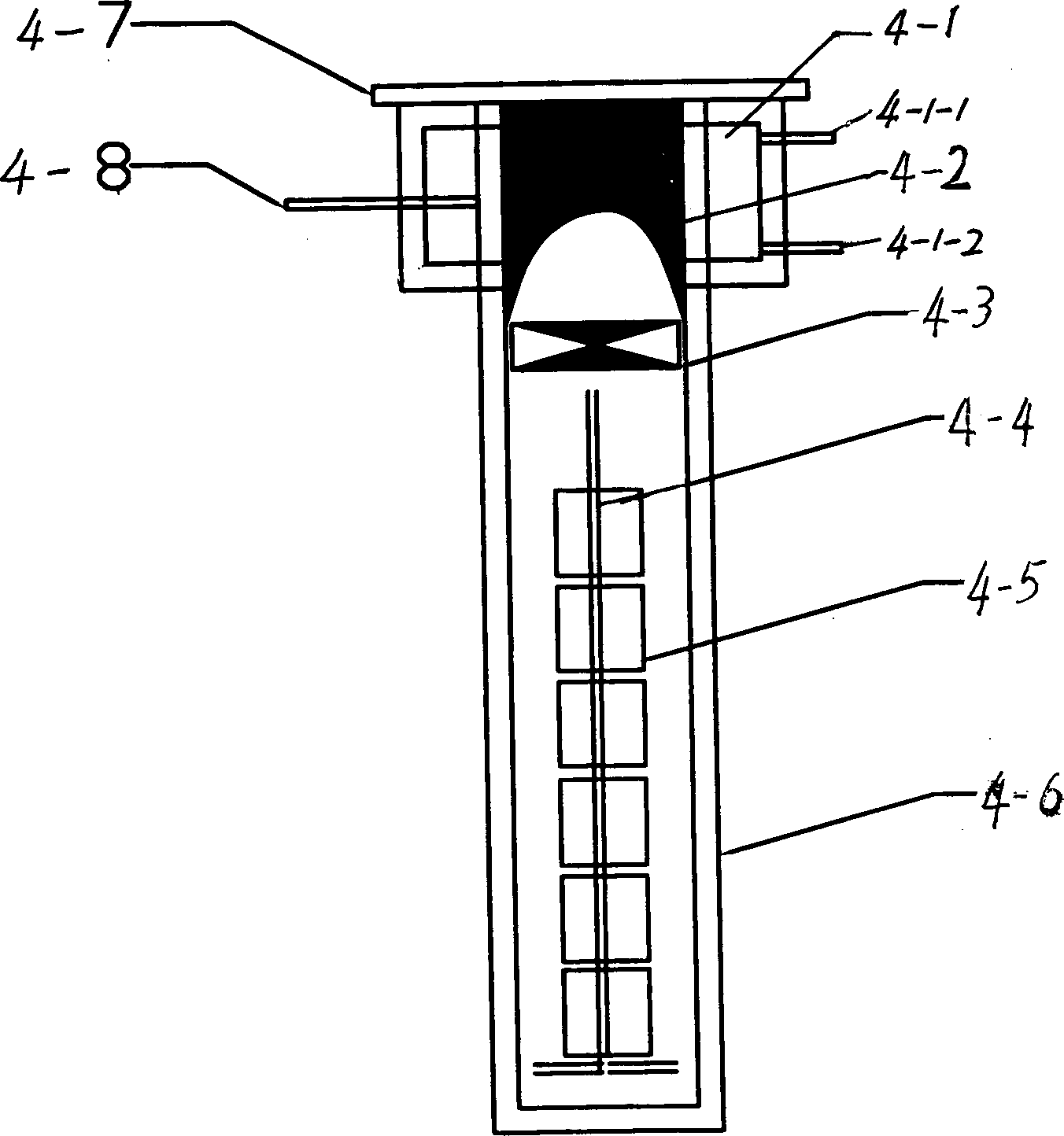

[0037] 2. Put the cooling water jacket (4-1) on the upper part of the vacuum reduction tank (4-6) and fix it, and connect the cooling water outlet pipe (4-1-1) and the cooling water inlet pipe (4-1-2) At the top and bottom of the cooling water jacket (4-1), another vacuum tube (4-8) is connected to the upper outer wall of the vacuum reduction tank (4-6).

[0038] 3. Hang the above four vacuum reduction tanks (4-6) vertically on the figure 1 or figure 2 Evenly distributed on both sides of the hearth (2) central hearth partition wall (5) in the middle.

[0039] 4. Connect the cooling water inlet pipe (4-1-2) and cooling water outlet pipe (4-1-1) of the cooling water jacket (4-1) on the vacuum reduction tank (4-6) to the water circulation cooling system , at the same time, connect the vacuum tube (4-8) with the vacuum pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com