Intelligent feeding and discharging robot, system and control method for intelligent factory

A robot and intelligent technology, applied in two-dimensional position/channel control, control/regulation system, non-electric variable control, etc., can solve the problem of high path and environmental requirements, complex connection between robot and equipment, single control method, etc. problem, to achieve the effect of simple and clear operation steps, small space occupation and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] The autonomous mobile intelligent robot of the present invention can flexibly perform tasks such as retrieving, loading, and finished product warehousing through programming, path planning, and device transformation, replacing some traditional mechanical and manual operations, and can realize intelligence, flexibility, and multiple tasks. task assignment. Autonomous mobile robots can autonomously move materials within factories, hospitals, shopping malls, supermarkets and other industrial locations. In the SMT production line of the factory, intelligent loading and unloading robots can effectively improve the efficiency of the entire production line. The production process of the SMT production plant includes loading, marking, solder paste printing, placement, reflow soldering, AOI inspection, plug-in, wave soldering, and finished product inspection. , packaging, warehousing and other operations.

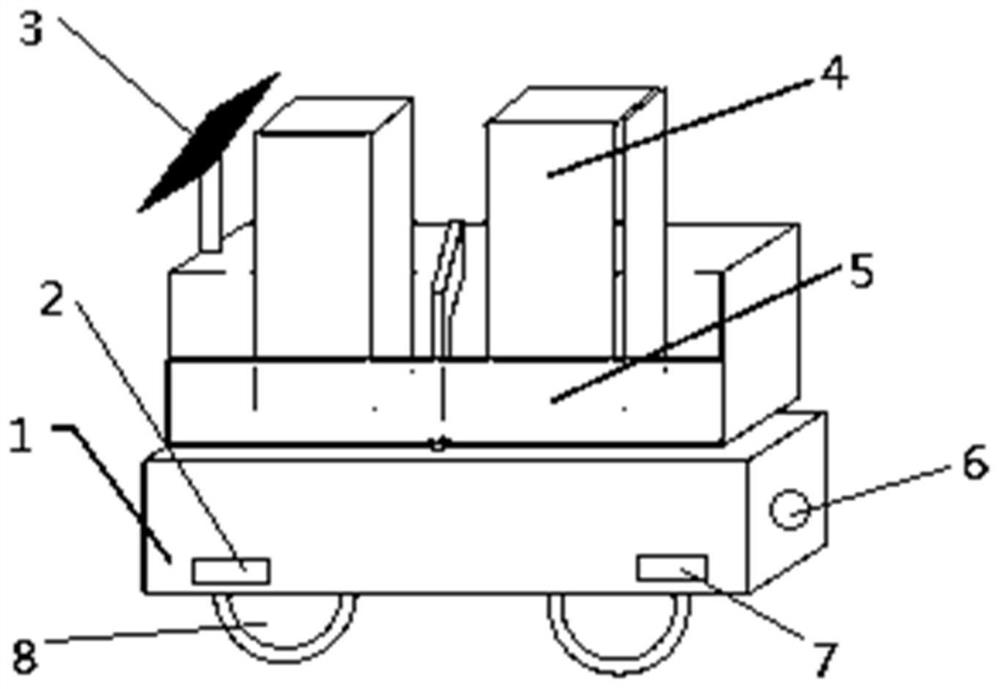

[0040] like figure 1 As shown, the intelligent loading and unloading r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com