Reconstituted tobacco integrated tunnel dryer

A technology for reconstituted tobacco leaves and tunnel drying, applied in progressive dryers, dryers, drying solid materials, etc., can solve the problems of occupying site space, high civil construction cost, unfavorable coating liquid absorption, long drying section, etc. Small footprint, good drying effect and high drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

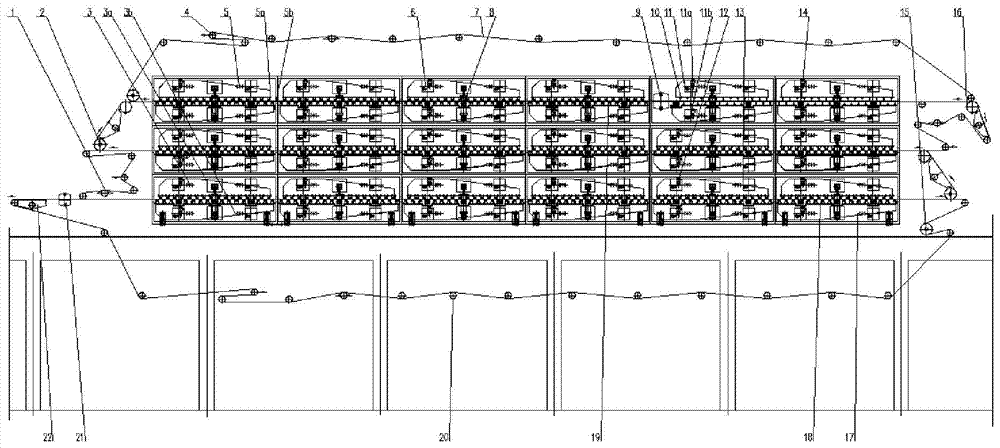

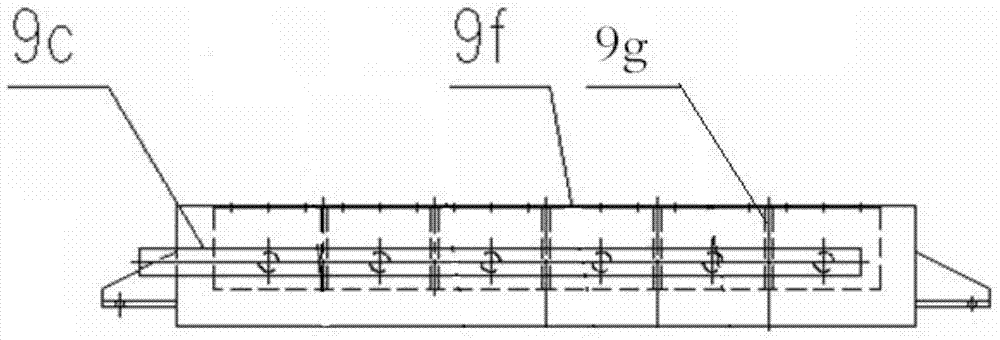

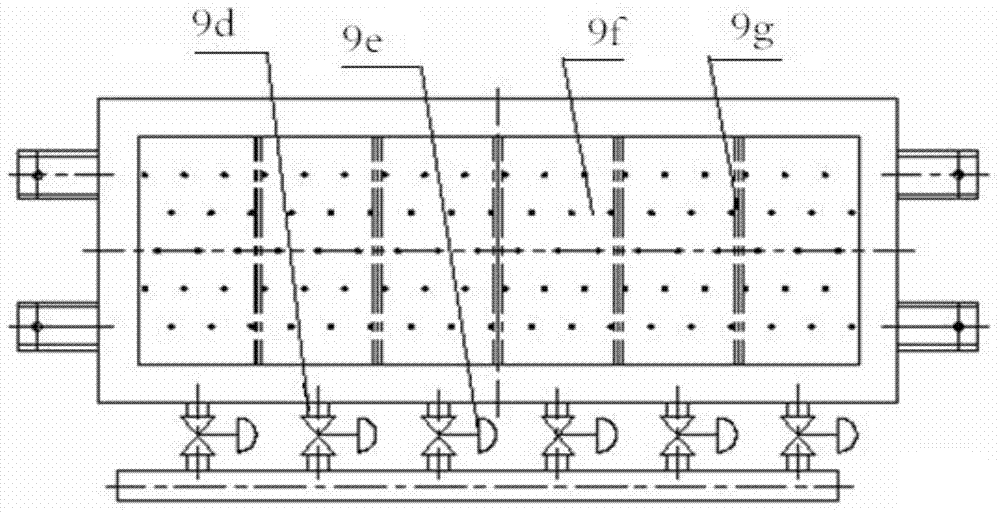

[0017] Such as figure 1 As shown, the integrated tunnel dryer for reconstituted tobacco leaves of the present invention consists of at least two layers of drying boxes. The drying box is divided into a low-temperature drying box 3 , a high-temperature drying box 5 and a cooling oven 11 according to the drying requirements for the reconstituted tobacco leaves. The low-temperature drying box 3 is arranged on the bottom or the top floor, the high-temperature drying box 5 is arranged above or below the low-temperature drying box, and the cooling oven 11 is arranged behind the high-temperature drying box. The low-temperature drying box includes a low-temperature upper box 3a and a low-temperature lower box 3b. The low-temperature drying box is equipped with a low-temperature air nozzle 18 that blows obliquely towards the reconstituted tobacco leaves at a certain angle. The hot air blows from the low-temperature air nozzle at a certain angle. Spraying produces a lower static pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com