Novel automatic assembly spinning and reverting device

A new type of automatic assembly technology, applied in the field of automation equipment, can solve the problems of not suitable for rubber support riveting assembly, high manufacturing cost, large space occupation, etc., and achieve the effect of compact structure, easy manufacture, and less space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

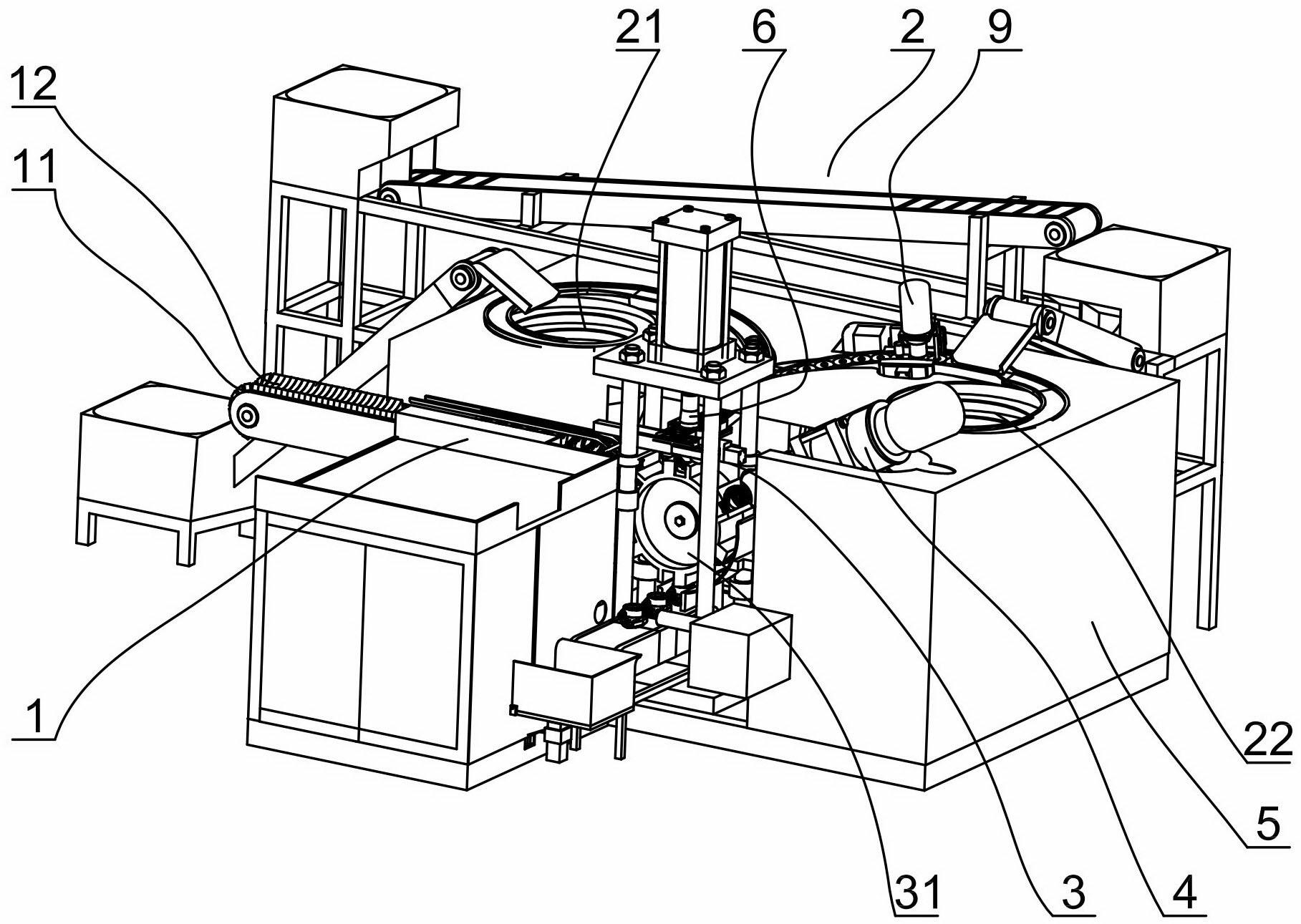

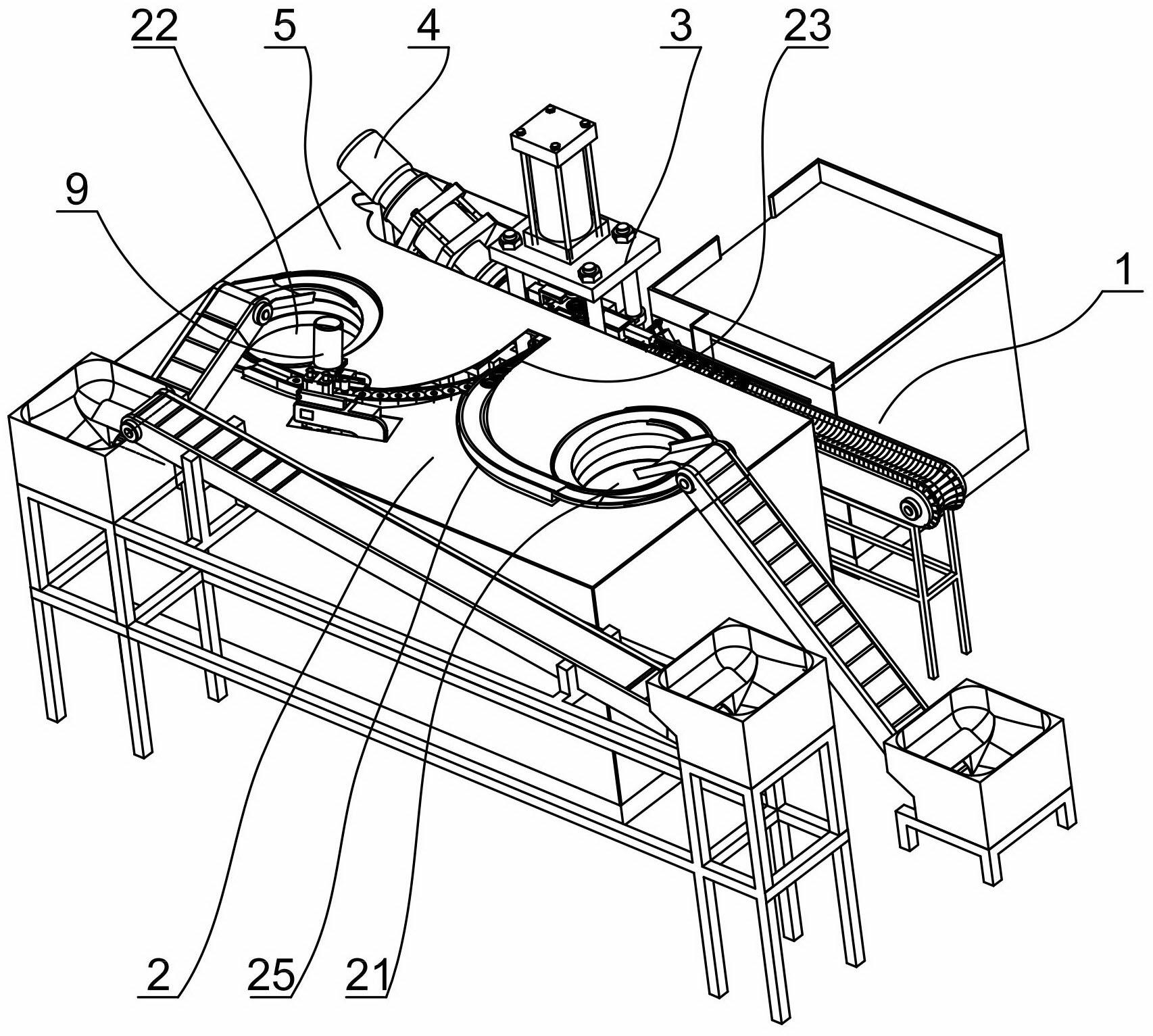

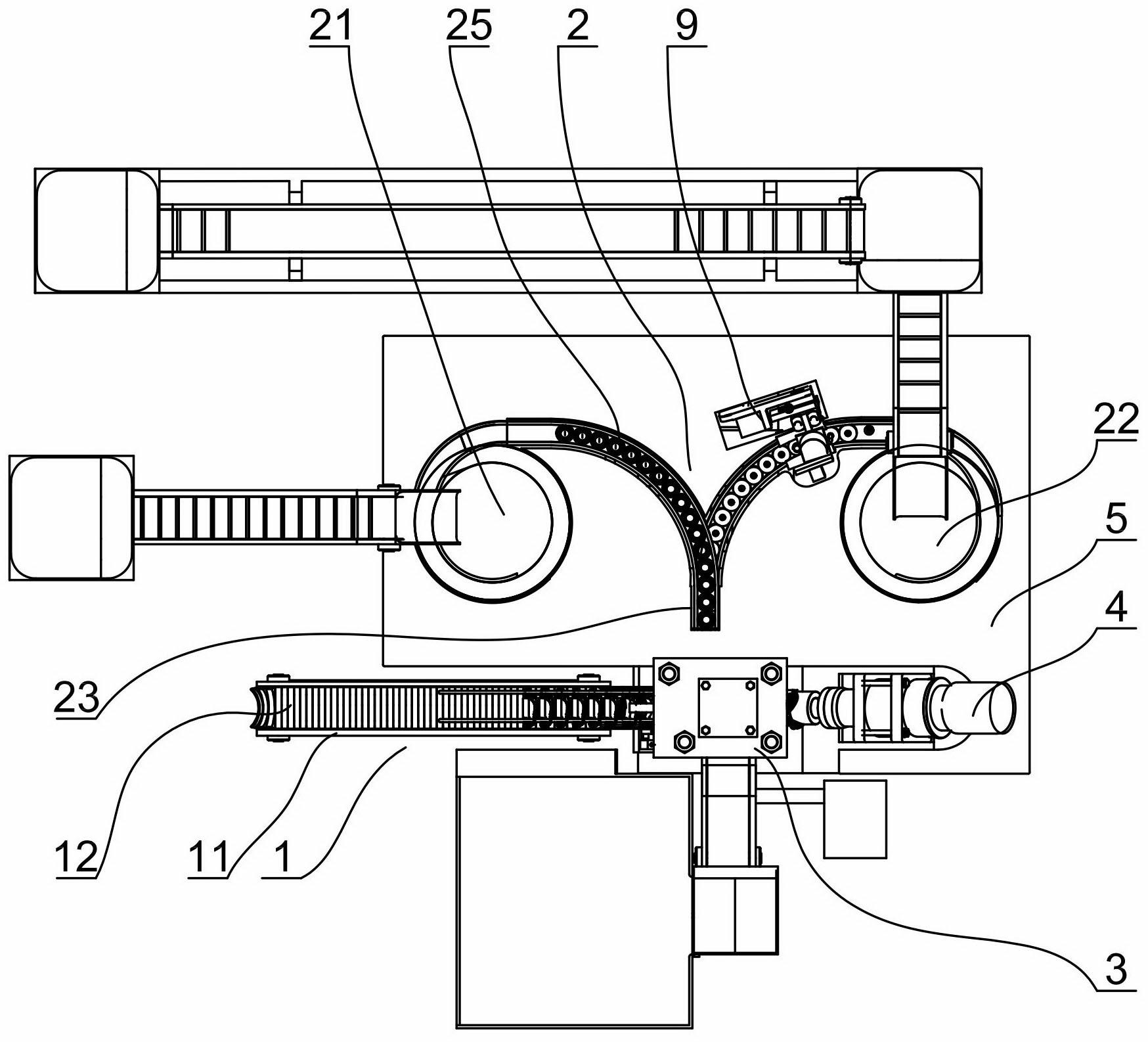

[0037] Embodiment 1: as figure 1 , figure 2 , image 3 A new type of automatic assembly and spin riveting device is shown, which is suitable for riveting and encapsulating the main part and the packaged part, especially for the rubber support on the car. The main part of the rubber support is a cylindrical shell. There is a through hole in the center of the housing, and an airfoil flange for installation and fixing is provided on the outside of the housing, while the packaging part is composed of a cylindrical rubber part placed in the housing and a disc-shaped cover. There are also through holes in the center of the parts and cover.

[0038] The present invention includes a main part delivery device 1 for delivering main parts, a packaging part delivery device 2 for automatically sorting and delivering packaged parts, a combination mechanism 3 for pressing packaged parts into main parts for assembly, a riveting machine 4 and a device for realizing automatic program control...

Embodiment 2

[0047] Embodiment 2, a kind of novel automatic assembly spin riveting device of this embodiment, such as Figure 11 , Figure 12 As shown, the automatic opening and closing device 7 includes a relatively horizontal left gate 71 and a right gate 72 and an opening and closing cylinder 73 that pushes the left and right gates to rotate. The left gate and the right gate adopt a double-layer structure, and the upper layer is attached to the The bottom surface of the main groove 231, the lower layer is attached to the bottom surface of the auxiliary groove 232 so as to close the outlet 26 of the packaging component. The middle part of the left gate and the right gate is provided with a vertical rotating shaft 74. spring, the relative inner surfaces of the tail ends of the left gate and the right gate are separated from each other and rollers 76 are respectively provided. , The roller at the tail end of the right gate is fitted. When the piston rod of the opening and closing cylinde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com