Automatic feed mechanism of numerical control lathe

A technology of automatic feeding and CNC lathes, which is applied in the direction of automatic in/out of workpieces, metal processing machine parts, metal processing, etc., which can solve the problem of increasing the time for opening and closing the door, the time for the arm to extend out of the machine tool, the different proficiency of the workers, and the difficulty of the operator Master and other issues to achieve the effect of fast and unified production cycle, improve operation efficiency, and improve work safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

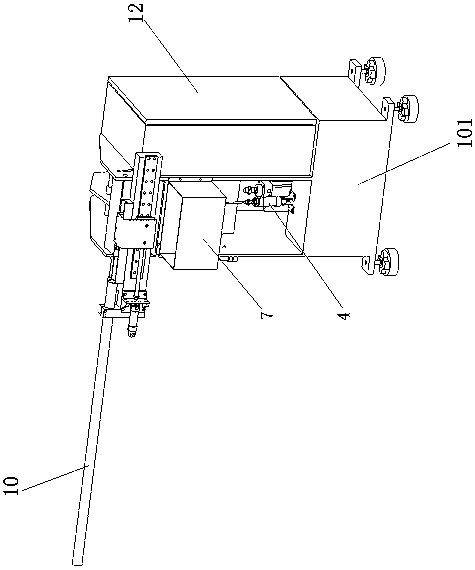

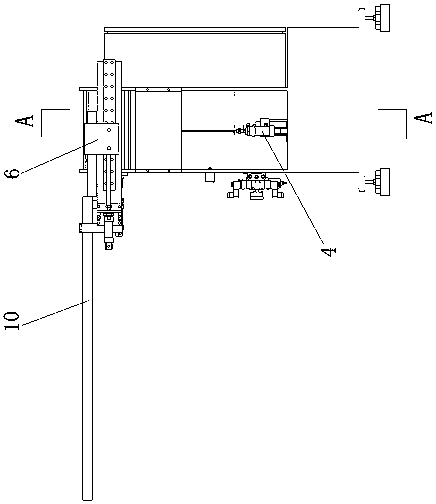

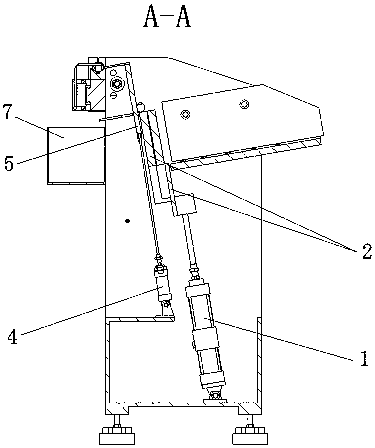

[0028] see Figure 1-Figure 5 As shown, a kind of CNC lathe automatic feeding mechanism of the present embodiment includes a workbench 101, the bottom of the workbench 101 is provided with a jacking cylinder 1, and the upper part of the workbench 101 is provided with a jacking plate 2, and the jacking cylinder 1 is used to push the lifting plate 2 to move, and the workbench 101 is provided with a detection position, and the lifter plate 2 is used to push the workpiece into the detection position on the workbench 101, and the workbench 101 is also provided with a positive Reverse identification device 3, the positive and negative identification device 3 is arranged at the detection position, the positive and negative identification dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com