Electric slag furnace provided with water cooling system and dust collecting system

A technology of water cooling system and dust collection system, applied in the field of electroslag furnace, can solve the problems of lack of water cooling system and dust collection system, increasing equipment cost, occupying site space, etc. of electroslag furnace, achieving simple structure, saving site space, ensuring The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

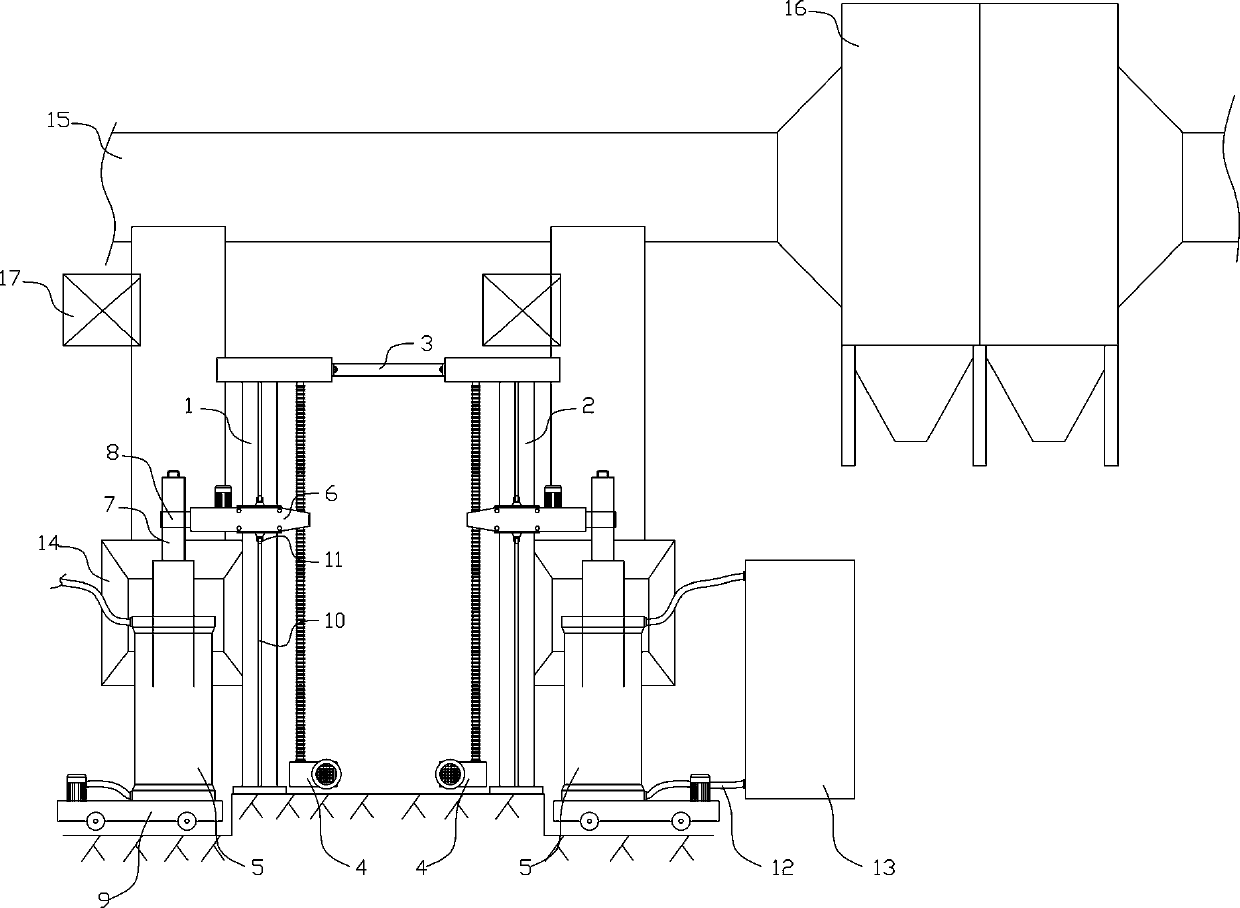

[0010] see figure 1 , an electroslag furnace equipped with a water cooling system and a dust collection system, has left and right guide frames 1, 2 symmetrically arranged, and the top ends of the left and right guide frames 1, 2 are connected as one by a connecting piece 3; The inner and outer sides of the left and right guide frames 1 and 2 are respectively equipped with a screw drive mechanism 4 and an electroslag furnace body 5; The sliding seat 6 that moves up and down, and the outside of the sliding seat 6 is provided with a clamping mechanism 8 for clamping the smelting steel material 7; the electroslag furnace body 5 is stored on a flat trolley 9; the furnace body of the electroslag furnace body 5 The wall is set as a jacket structure, and is connected to a water cooling system 13 through a cooling water pipeline 12; System 16, negative pressure fan 17 is housed on ventilation duct 15.

[0011] In this embodiment, the left and right guide frames 1 and 2 are provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com