Exposed heating type riser tube

A liquid riser and heating technology, applied in the field of exposed heated liquid riser, can solve the problems of liquid leakage, riser deformation, long time consumption, etc., achieve good process repeatability, prevent deformation and misalignment, and increase adaptability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

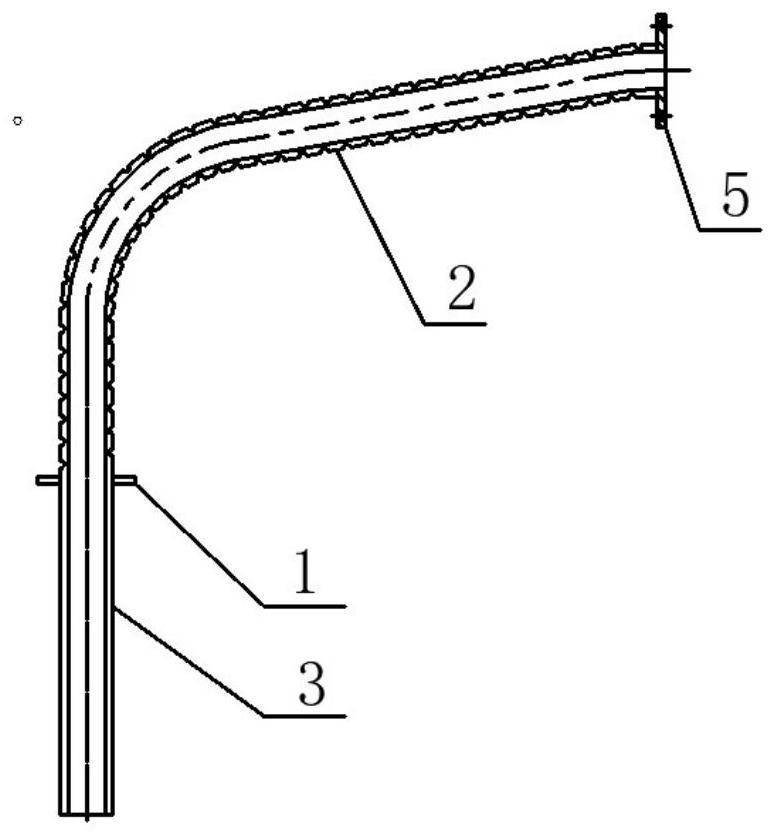

[0034] Such as Figure 1 to Figure 4 Shown is an exposed heated liquid riser provided according to the present invention,

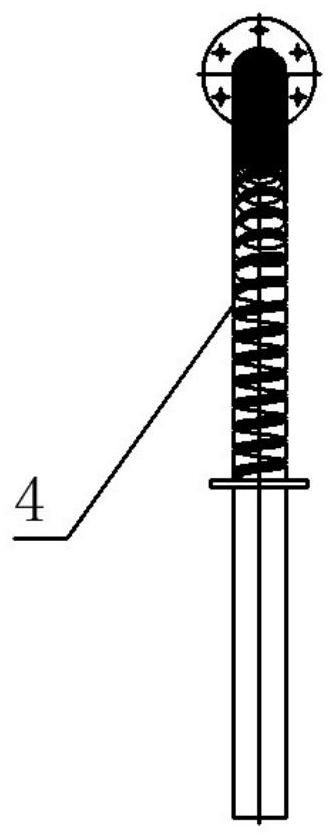

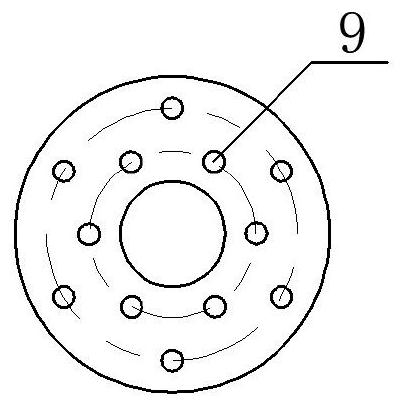

[0035] It includes: a riser body, a riser head, and a heating mechanism; the riser body includes two parts inserted into the molten pool section 3 and an exposed air section 2, and the end of the exposed air section 2 is connected to the riser head , the outer side of the exposed air section 2 is provided with a spiral groove 4, a plurality of blind holes 9 are built in the head of the liquid riser, and the heating mechanism is installed between the exposed air section 2 of the liquid riser and the liquid riser proper head position.

[0036] The heating mechanism is divided into two parts. A part of the heating mechanism is evenly wound on the spiral groove 4 of the riser pipe body; another part of the heating mechanism is inserted into the built-in blind hole 9 of the riser pipe head.

[0037] Specifically, the lower end of the riser body inserted int...

no. 2 example

[0039] Such as Figure 5 to Figure 9 The supporting centering mechanism shown includes: a liquid-rising pipe body support 10 and a supporting centering plate 11; one end of the liquid-rising pipe body support 10 is supported on the furnace cover 15, and one end supports the exposed air section 2; the supporting centering plate There is a through hole 12 in the center of 11, the diameter of the through hole 12 is larger than the diameter of the riser pipe head, and the inclination angle of the through hole 12 is suitable for the riser pipe head; the thickness of the support aligning plate 11 is smaller than the length of the straight line section (6) .

[0040] Specifically, one end of the riser pipe body support 10 is installed at a suitable position below the exposed air section 2 of the liquid riser body, and the other end of the support 10 falls on the furnace cover 15. The support 10 is used to provide a Support point: a through hole 12 is provided in the middle of the supp...

no. 3 example

[0042] Such as Figure 7 Shown is an exposed heated liquid riser provided according to the present invention, comprising: the exposed air section 2 is covered with a high-temperature heat-resistant insulation layer, and the inner surface of the through hole 12 is also provided with a conformal heat-resistant heat-insulation layer 14 .

[0043] Specifically, the heat insulation material covered by the high temperature heat insulation layer of the exposed air section (2) can effectively prevent the heat from being lost too quickly, and play a role of heat preservation inside. Unfavorable thermal influence, its insulation material can be asbestos cover; Through hole 12 inner surface is provided with a compressible follow-up heat-resistant insulation material 14, when the riser pipe head passes through from the through hole 12 place of support self-aligning plate 11, The compressible conformal heat-resistant thermal insulation material 14 can buffer the relative movement of the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com