A local heat treatment process optimization and automatic temperature control method for a large pressure vessel

A local heat treatment and process optimization technology, applied in the field of heat treatment, can solve problems such as high labor intensity, high difficulty, and long heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

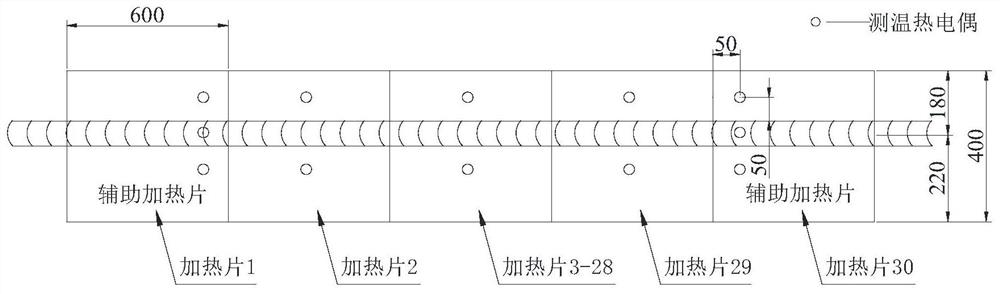

[0115] Heat treatment object: Local heat treatment of the butt weld between the large insert plate and the cylinder of an ultra-large pressure vessel.

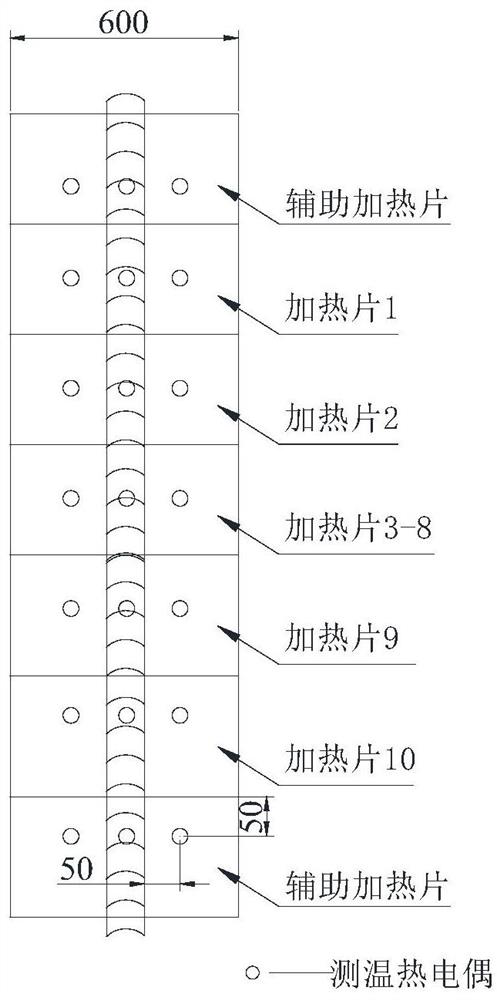

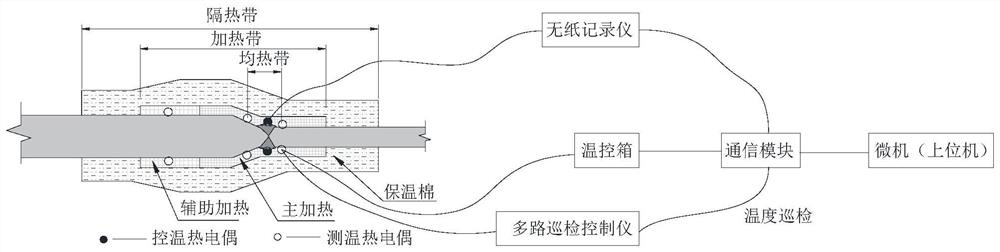

[0116] Preparation of heat treatment equipment: temperature measuring thermocouple at the welding seam, temperature controlling thermocouple on the heating plate, thermocouple compensation wire, paperless recorder, temperature control box, temperature multi-channel inspection controller, proportional controller, microcomputer and DCS control system.

[0117] Complete the steps of spot welding of heat treatment thermocouples and their connections, laying and fixing of heating sheets. According to the heat treatment process card, set the heat treatment temperature curve, and use the heat treatment DCS automatic temperature control system to complete the entire post-weld heat treatment process. Figure 4 The actual heat treatment temperature curve is given, and the field application shows that the system has the characteristics ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com