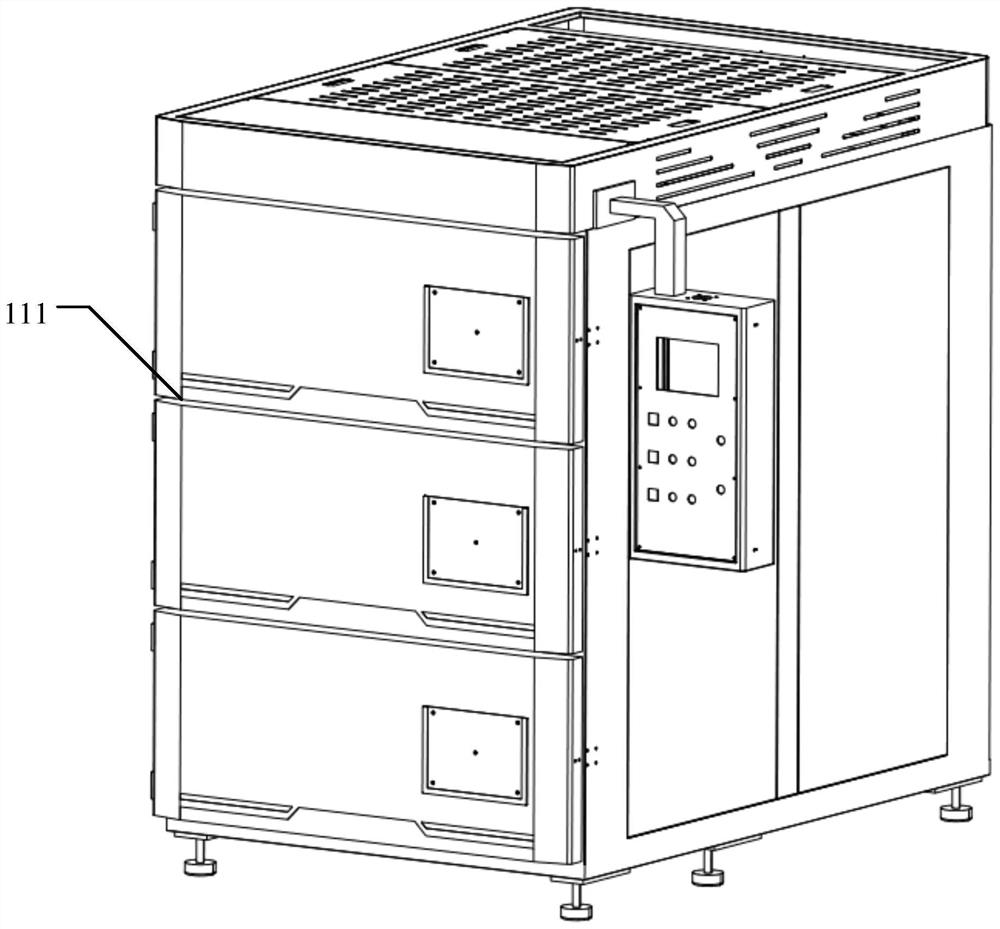

Vacuum oven

A vacuum oven, oven technology, applied in lighting and heating equipment, drying, drying solid materials and other directions, can solve problems such as difficult heating of door panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

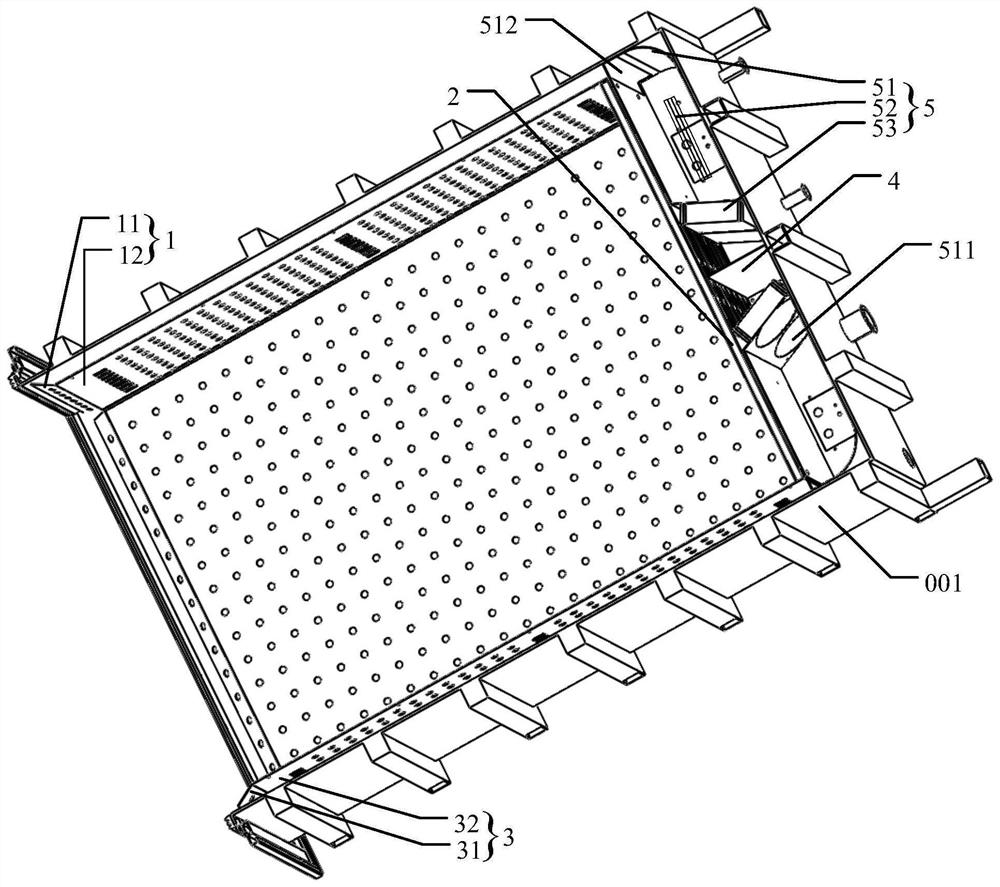

Embodiment Construction

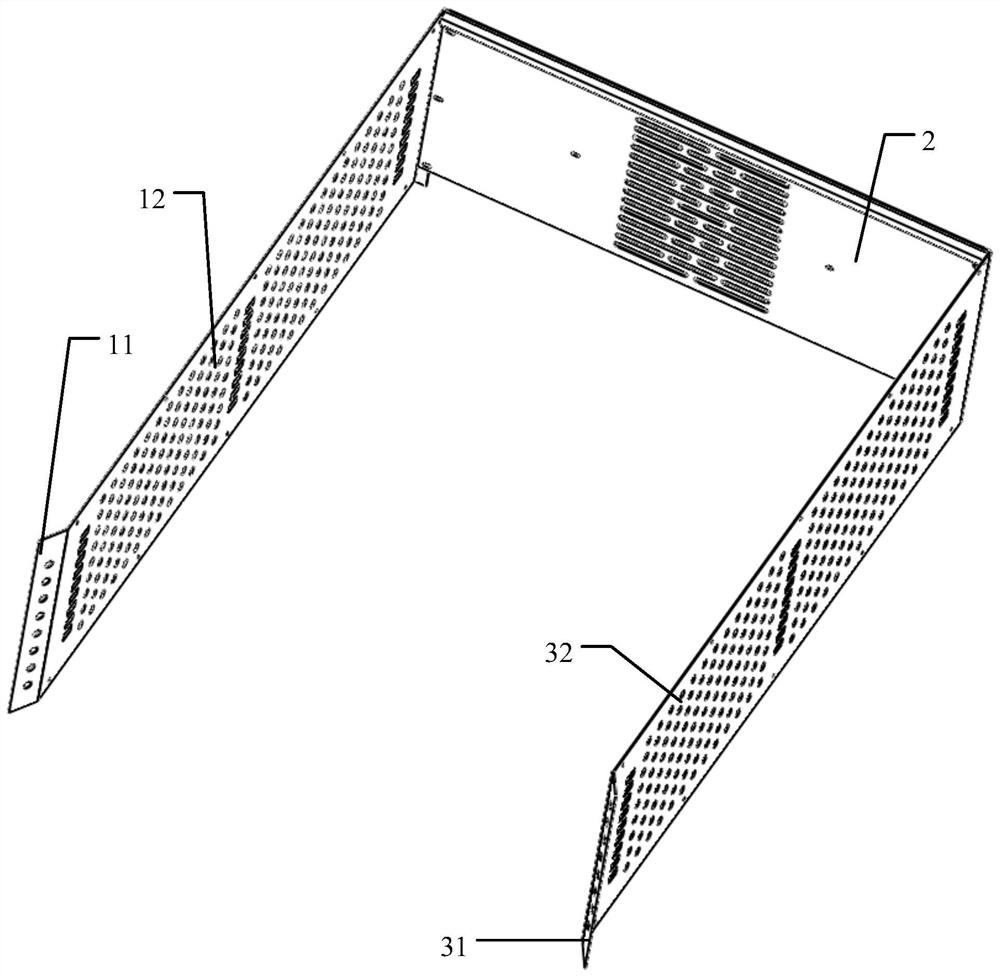

[0054] The invention discloses a vacuum oven. Through the arrangement of a circulating air duct and a heating package, after the heating tube group generates heat, it is blown out to the left side plate and the right side plate through a fan, and the heat is continuously transmitted from the left inclined plate, the left straight plate, and the right inclined plate. The panel and the right straight panel reach various positions in the inner chamber, and enter the fan again from the back panel to form a heat cycle, which can quickly balance the heat in each position of the inner chamber, and can also solve the problem of difficult heating at the door panel.

[0055] The technical solutions in the embodiments of the present invention will be described clearly and in detail below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com