Easily-detachable structure of water inlet valve

An easy-to-disassemble, water-inlet valve technology, applied to the valve shell structure, valve details, valve device, etc., can solve the problems of difficult maintenance and disassembly, and achieve the effects of fast assembly and adjustment, convenient maintenance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

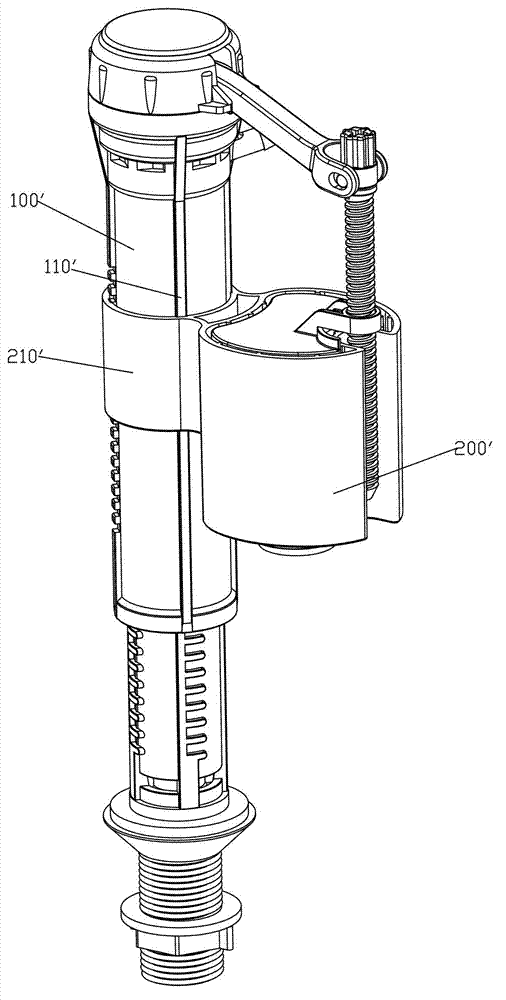

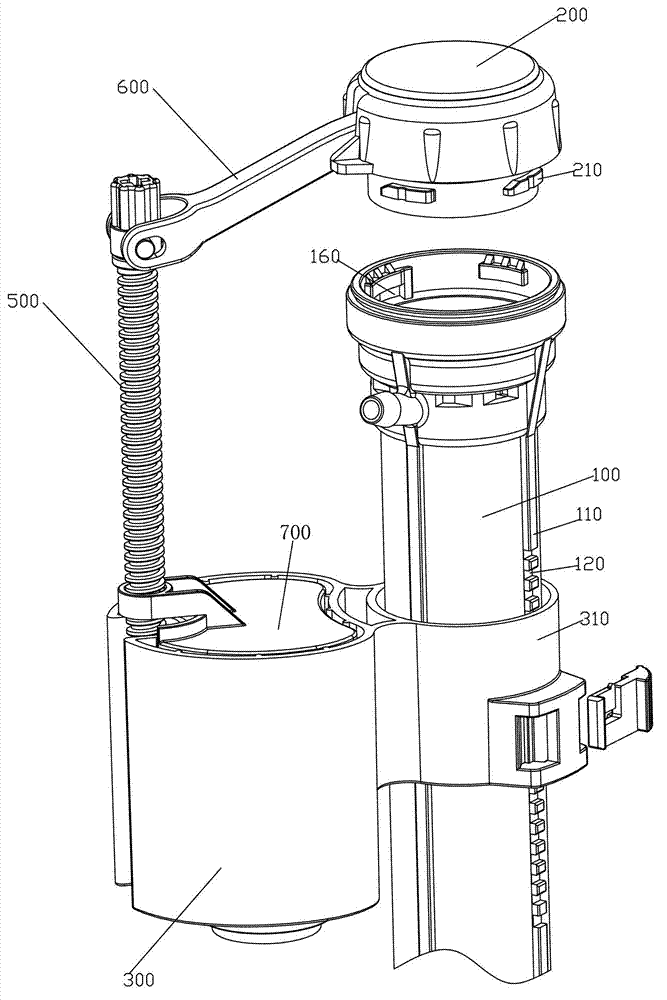

[0039] Such as Figure 1 to Figure 7 , The first preferred embodiment of the easy-to-detach structure of the water inlet valve, the easy-to-detach structure of the water inlet valve includes a valve body 100 and a rotating unit.

[0040] The outer periphery of the valve body 100 is provided with at least one guiding rib 110 , the guiding rib 110 is arranged with a plurality of locking teeth at intervals, and a locking groove 120 is formed between two adjacent locking teeth.

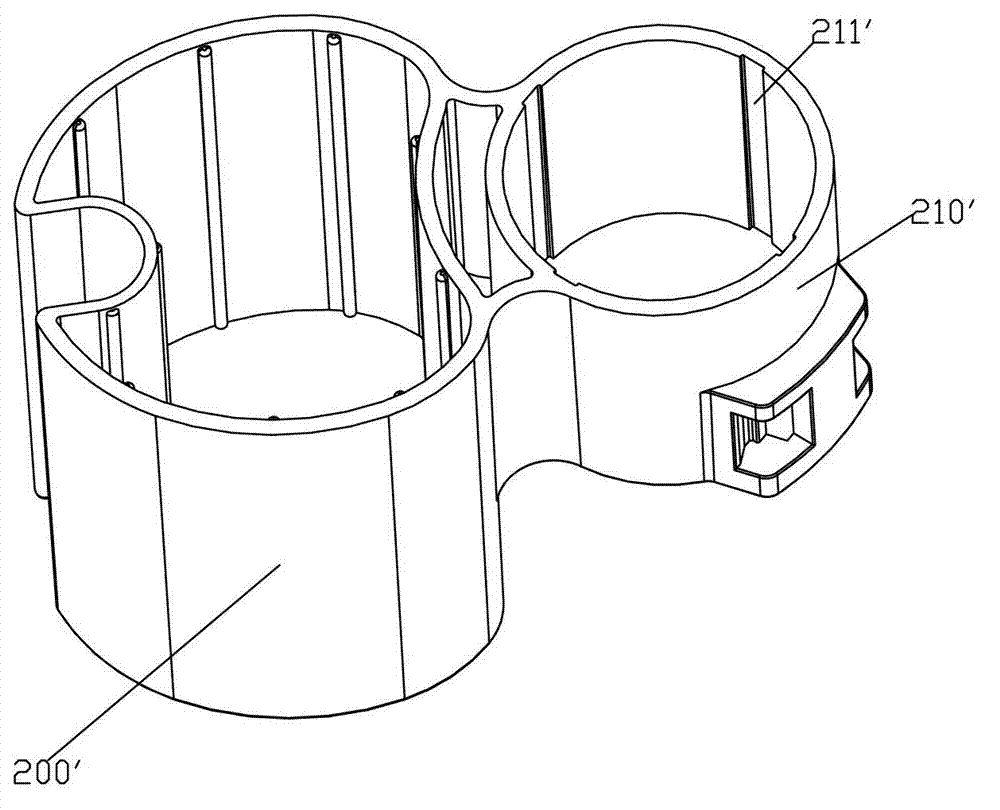

[0041] The rotating unit includes an upper cover 200 and a water stop cup 300 connected to the upper cover 200 by transmission. The upper cover 200 can be detachably attached to the top of the valve body 100, the water stop cup 300 can be rotatably attached to the valve body 100, and the rotation of the upper cover 200 drives the water stop cup 300 to rotate synchronously so that the upper cover 200 can be attached or Leave the valve body 100. In this embodiment, the upper cover 200 is provided with sev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com