Car body door cover plate edge rolling device and edge rolling method thereof

A car body and roll edge technology, which is applied to vehicle parts, transportation and packaging, etc., can solve problems such as low production efficiency, uneven product quality, staggered deformation of body door cover panels, etc., to improve production efficiency and ensure Product quality, the effect of preventing misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

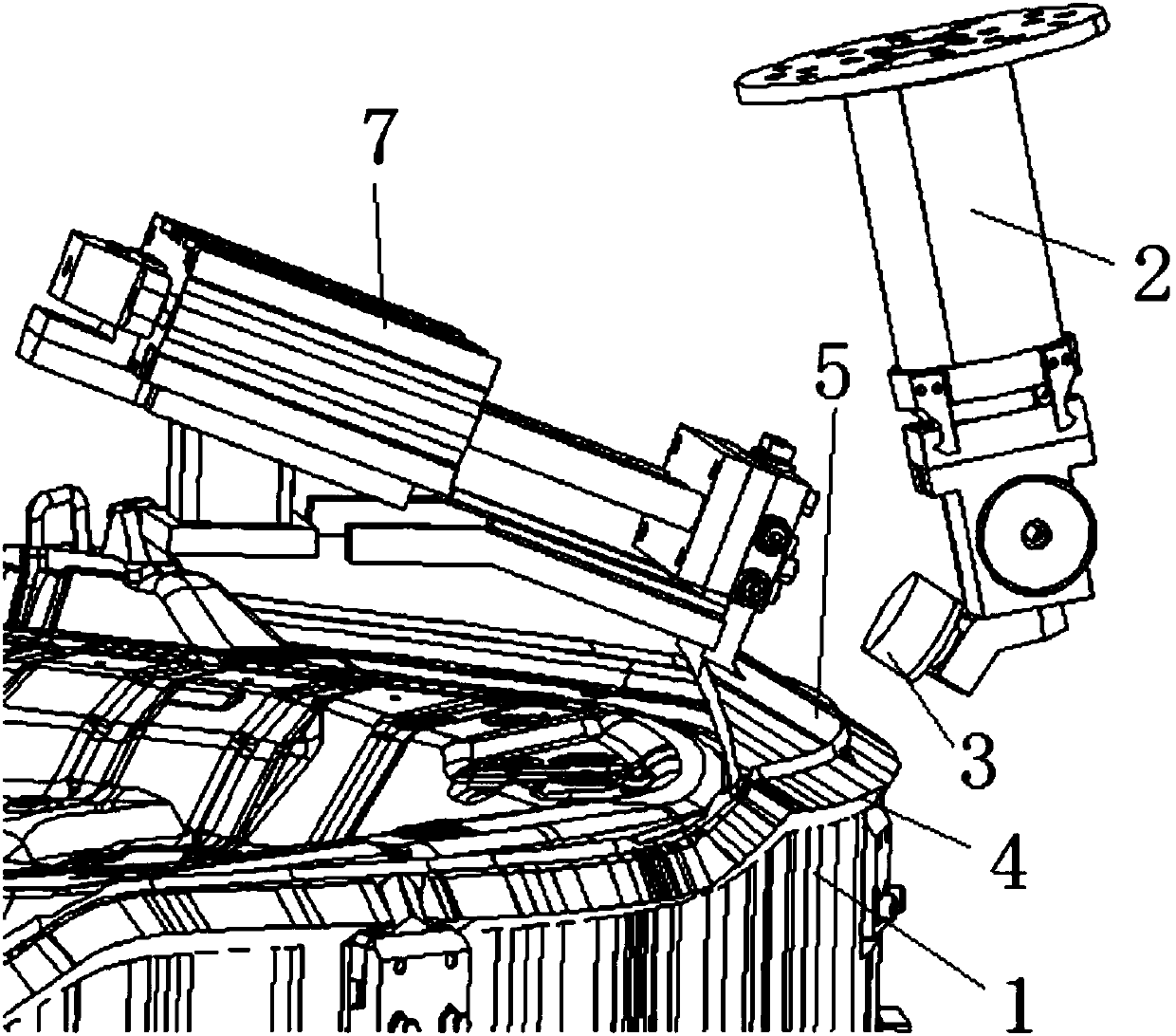

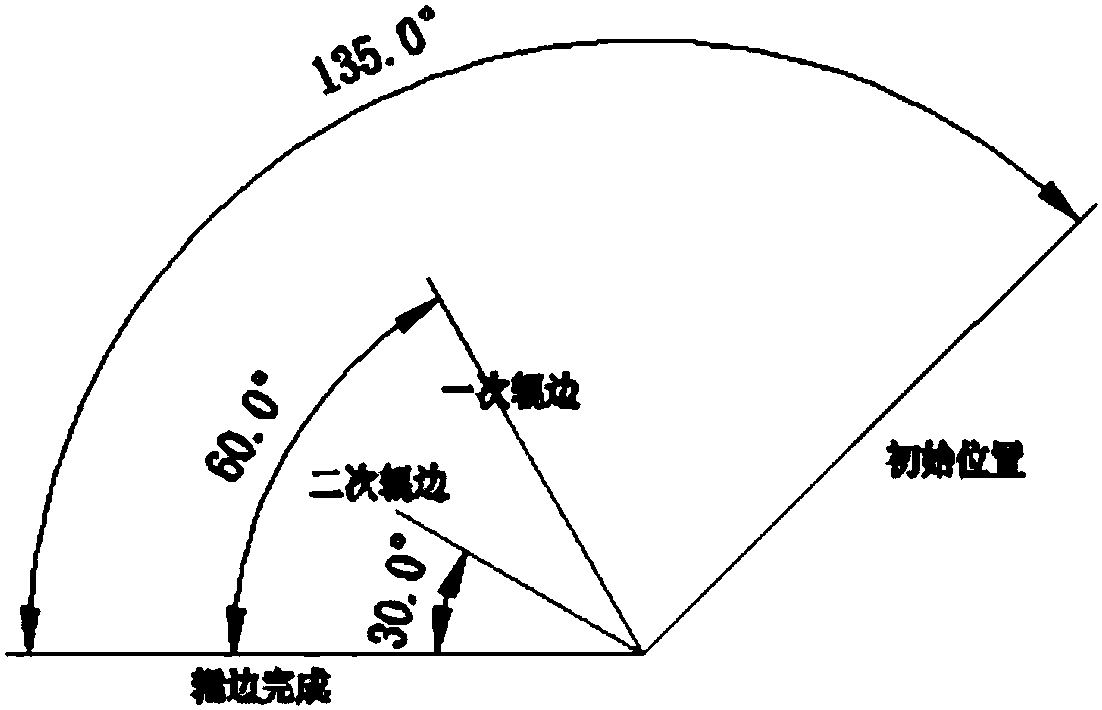

[0022] like Figure 1 ~ Figure 3 Shown is a rolling device for automobile body door cover sheet parts, including a support table 1, a robot rolling seat 2, a roller head 3 is connected to the lower end of the robot rolling seat 2, and the roller head 3 is a rolling tool, and the robot provides posture and strength , so that the roller head 3 rolls on the body door panel, so as to achieve the effect of deformation of the body door panel. The device generally has 3 to 4 roller heads. The roller edge device also includes a profiling mechanism, which is connected with the telescopic mechanism. The support table 1 is provided with a tire mold 4, and the workpiece to be rolled is placed on the tire mold 4; the tire mold 4 is attached to the body door cover sheet, To prevent the movement and deformation of the body door cover sheet during the rolling process.

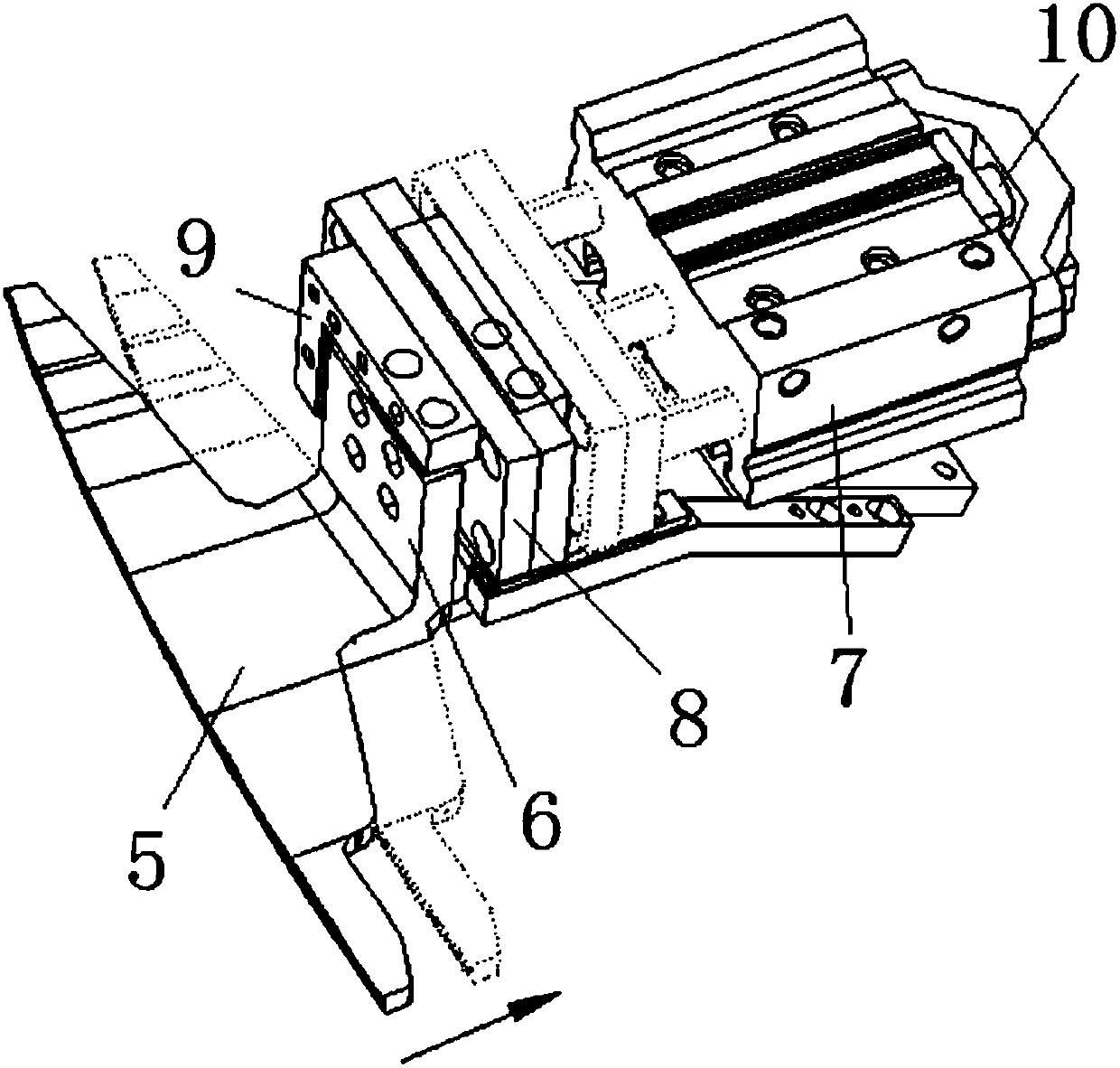

[0023] The profiling mechanism includes a pre-bending cam 5 and a connecting plate 6, one side of the pre-bending cam 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com