Blast Furnace Taphole Sliding Ventilation Device

A blast furnace tapping and air extraction device technology, applied in tuyere, dust collector, etc., can solve the problems of unfavorable installation of air duct support, deformation of cover body, low collection efficiency, etc., achieve simple and convenient control procedure, prevent deformation and damage, Simple effects with controls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

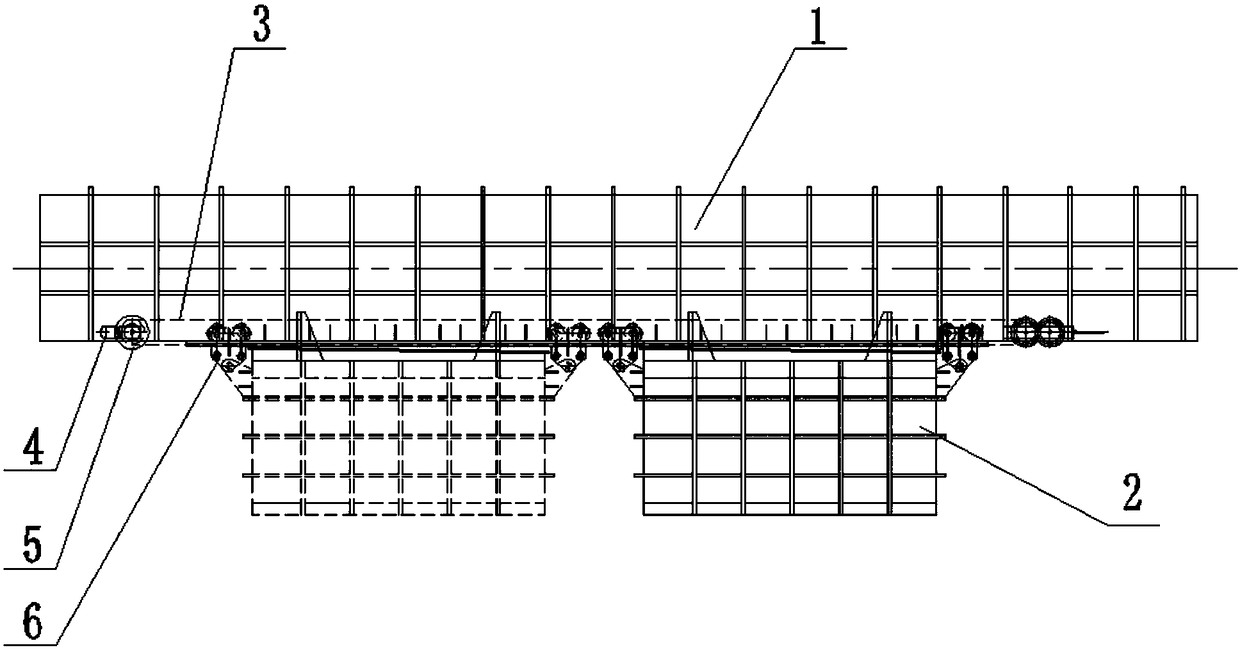

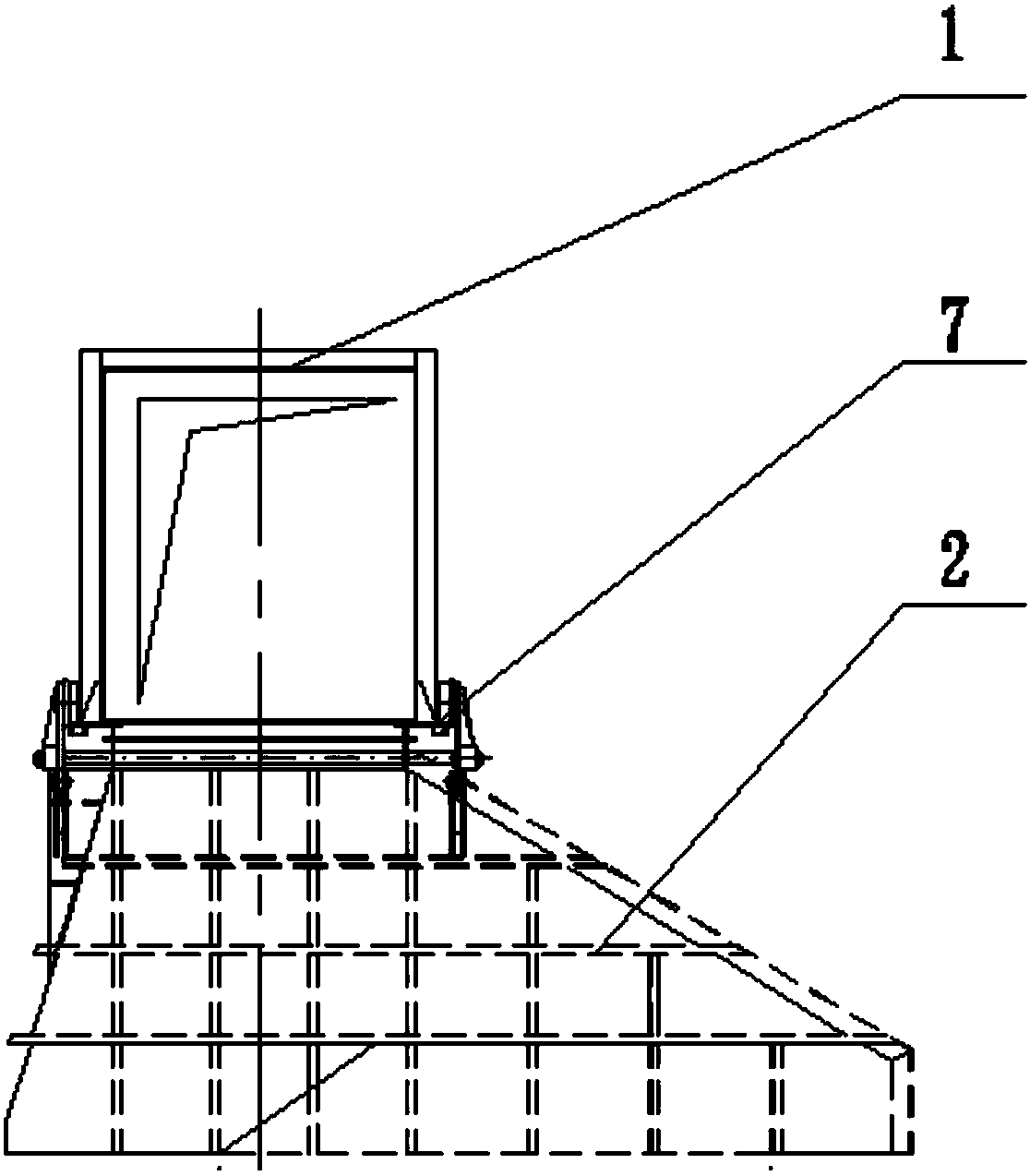

[0023] combined with figure 1 And attached figure 2 , a blast furnace taphole sliding exhaust device, which includes a rectangular beam exhaust pipe 1, a sliding exhaust fan 2, a wire rope 3, a power transmission device 4, a clamping device 5, a pulley 6 and a track 7; the rectangular The bottom of the beam exhaust pipe 1 is equipped with a track 7, and the top of the sliding exhaust fan 2 is equipped with a pulley 6; the pulley 6 is rollingly matched with the track 7; A power transmission device 4 is installed, and a steel wire rope 3 that can reciprocate around the power transmission device 4 is installed on the power transmission device 4; the steel wire rope 3 is connected with the sliding exhaust fan 2; the power transmission device 4 is also installed There is a clamping device 5 for keeping the steel wire rope 3 under tension.

[0024] As a prefere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com