Alkaline pocket type battery shell seal welding fixture

A battery and sealing welding technology, applied in the field of clamping and fixing components, can solve the problems of easy deformation and dislocation of welding seams, uneven stress, waste of raw materials, etc., and achieves the effect of flexible and convenient use, avoiding waste and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

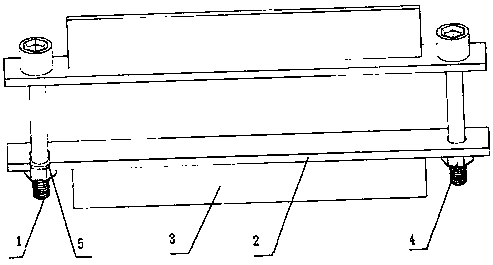

[0007] The embodiment is described in detail in conjunction with the accompanying drawings, which includes two strip-shaped splints 2, and a space that can be loaded into the battery case is vacated in the middle of each strip-shaped splint near the two ends, and a bolt with a nut 4 at one end is respectively connected. 1. A baffle plate 3 is horizontally and vertically installed in the middle of the outer surfaces of the two splints. There is a screw rod transverse inlet and outlet 5 at the corresponding place of a bolt on one of the splint side walls. When in use, first unscrew the nuts on both sides, put a certain distance between the mouth of the battery case and put it between the two splints, adjust the position so that the splint is close to the outer wall of the case, and then tighten the nuts on both sides, you can use the hot welding plate. Seal welding. It has the advantages of flexible and convenient use, uniform stress on the welding surface, and guaranteed weldi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com