Common rail type marine diesel injector

A common rail fuel injector and marine diesel engine technology, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problem of reducing the reinforcement effect of diesel fuel injector connections, not meeting the needs of diesel fuel injectors, and strengthening equipment Problems such as single function, to achieve the effect of ensuring service life, uniform force, and avoiding shortening of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

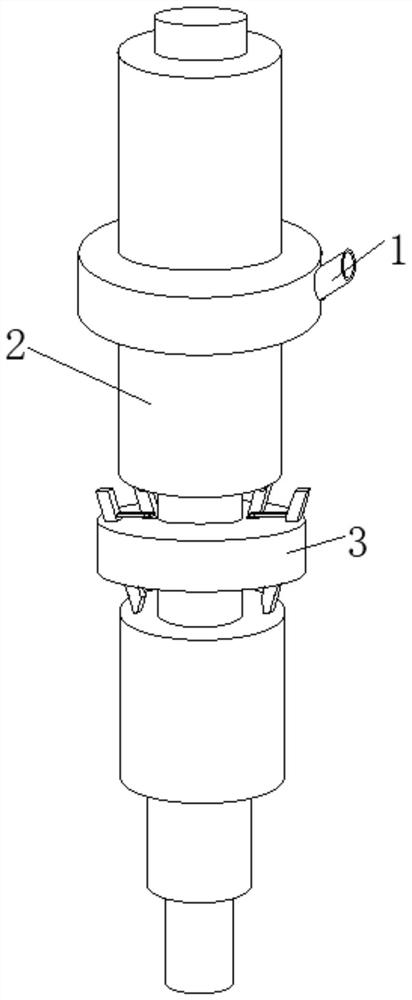

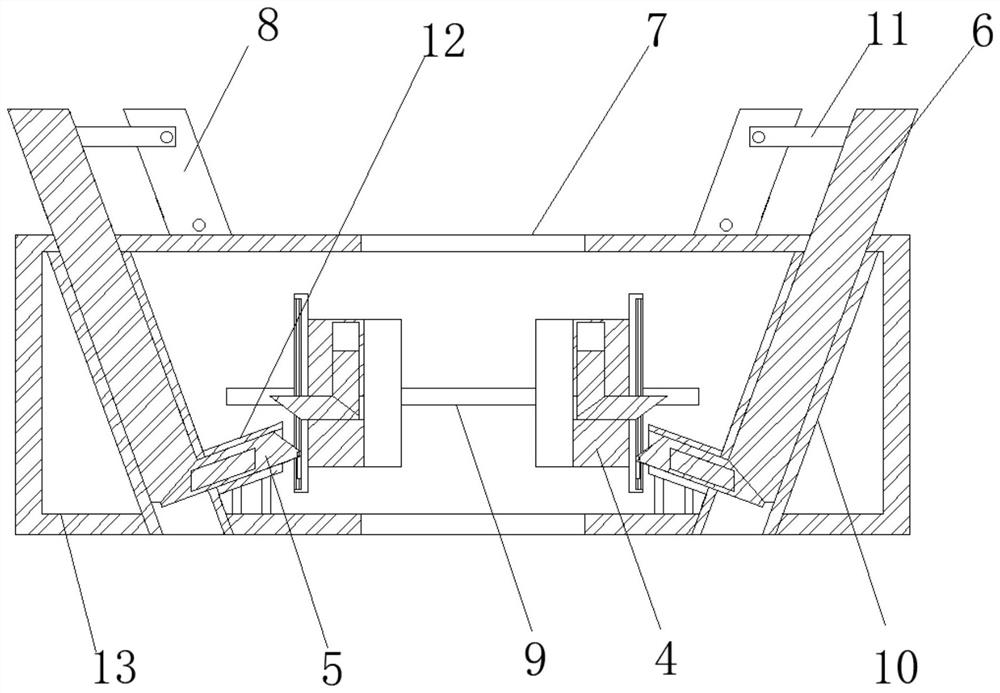

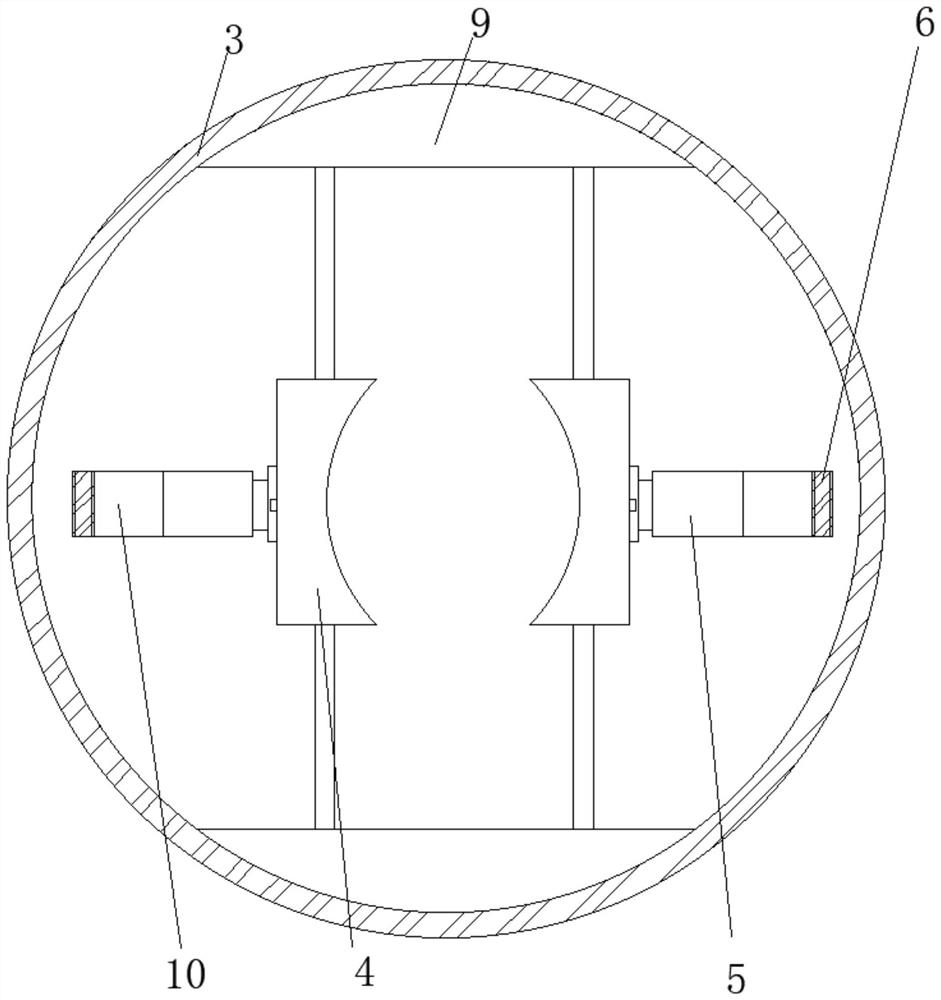

[0026] like figure 1 , figure 2 and image 3 As shown in the figure, a common rail type marine diesel engine fuel injector includes a common rail fuel injector body 2, an oil inlet pipe joint 1 located on the common rail fuel injector body 2, and a clamp located at the lower end of the common rail fuel injector body 2. Part 4 and a reinforcement mechanism 3 sleeved on the outside of the common rail injector main body 2 and used to reinforce the joint of the common rail injector main body 2 and support the groove of the joint of the common rail injector main body 2 respectively. The reinforcement mechanism 3 includes A casing 13 sleeved at the outer connection of the common rail injector body 2 and having a perforation 7, a horizontal guide rail 9 arranged on the inner wall of the casing 13, and a sliding connection with the horizontal guide rail 9 and used for the common rail injector body 2 The clamping member 4 for clamping and fixing, the No. 1 channel 10 and the No. 2 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com