Special sealing device for cylinder body of high-temperature rotary kiln

A technology of sealing device and rotary kiln, which is applied in the direction of rotary drum furnace, furnace, lighting and heating equipment, etc., which can solve the requirements of sealing performance, working conditions can not meet the production requirements, the performance of cylinder sealing reliability decline, vacuum degree or pressure maintaining No high problems, achieve the effect of lowering temperature, easy maintenance, improving quality and grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

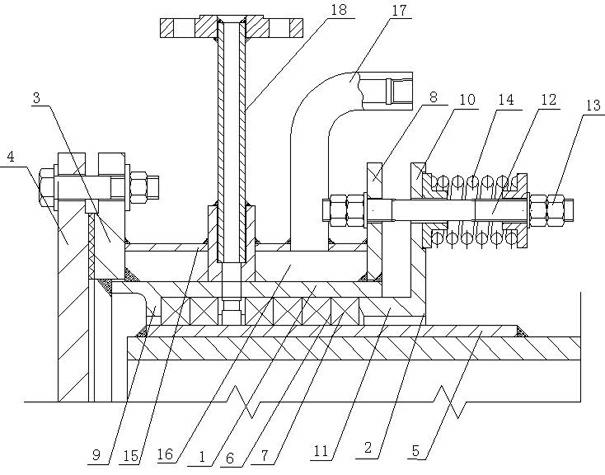

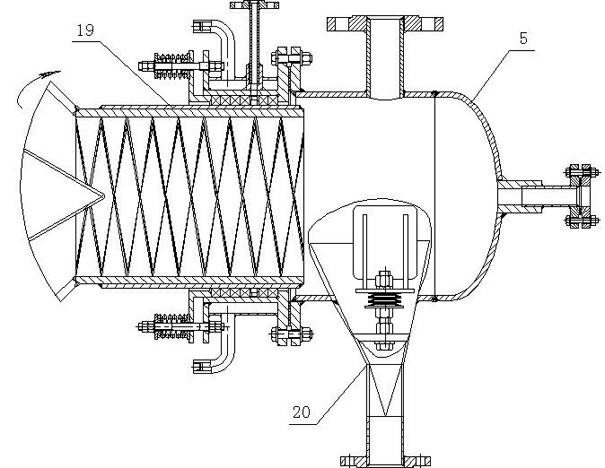

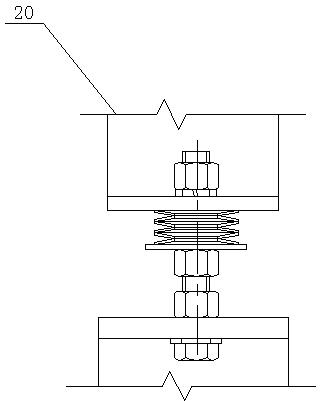

[0014] see figure 1 and figure 2 , the special sealing device for the high temperature rotary kiln shell, including a first gland 1 fixedly connected to the discharge box 4, a second gland 2 connected to the end of the first gland 1 away from the discharge box 4, and The sealing packing 7 placed in the sealed space 6 between the inner wall of the first gland 1 and the rotary furnace cylinder 5 and sandwiched by the first gland 1 and the second gland 2; the first gland 1 is close to One end of the second gland 2 has a first flange 8 protruding outward; the end of the first gland 1 near the discharge box 4 has a first protrusion 9 protruding inward; The cover 2 has a second flange 10 protruding radially outward and a second protrusion 11 protruding into the sealed space 6; the first flange 8 and the second flange 10 are connected by a packing clamping mechanism , when the filler clamping mechanism is tightened, the second gland 2 can be moved axially along the surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com