High-temperature high-pressure glass micro model gripper used for heavy oil thermal recovery

A high-temperature, high-pressure, microscopic model technology, applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve problems such as inability to visualize the effect, excellent thermal insulation performance, inability to ensure pressure continuity, and inconvenient operation of the gripper device, etc. , to achieve the effect of superior sealing performance, light weight and good thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

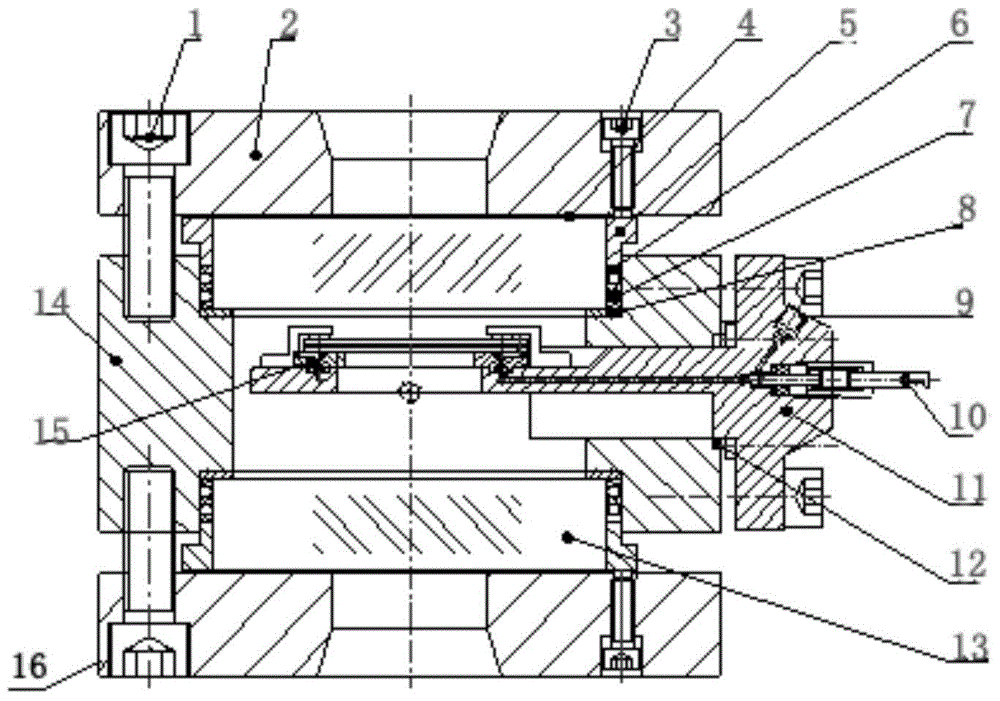

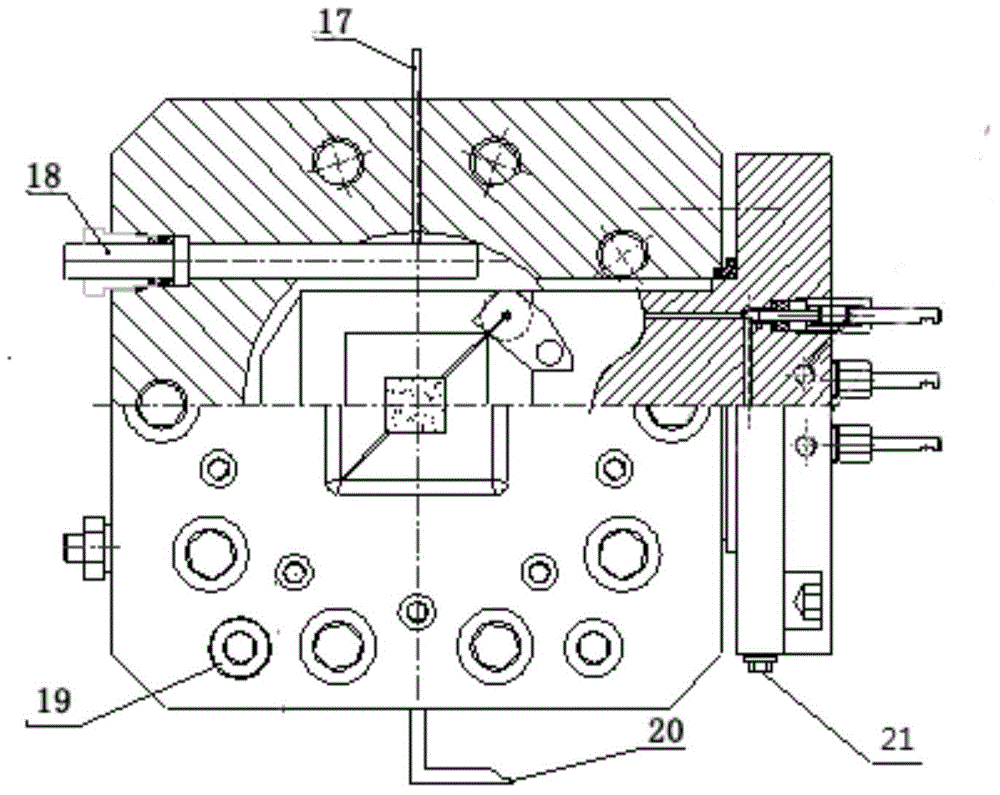

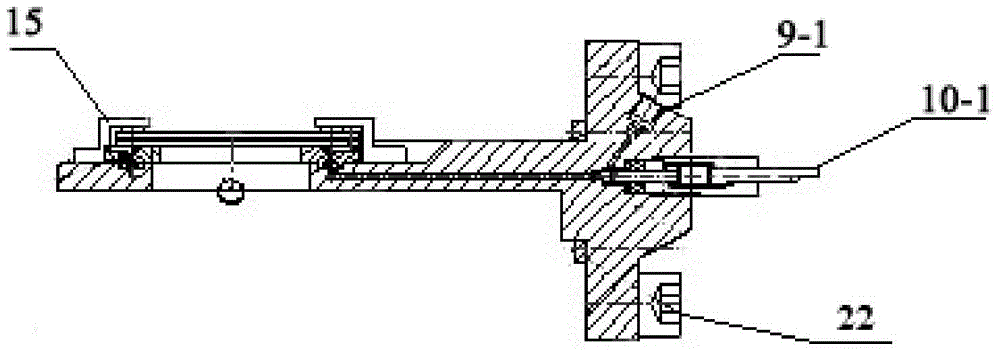

[0028] Refer to attached Figure 1-5 , Heavy oil heat adopts high temperature and high pressure glass microscopic model holder, which is divided into bin body installation and model installation.

[0029] For warehouse installation, refer to the attached figure 1 and figure 2 . A new high-temperature and high-pressure glass microscopic model holder, the lower platen is made of 16 high-temperature titanium alloys, with a length of 170 mm, a width of 170 mm, a thickness of 30 mm, and a 45° chamfer. The upper platen 2 has the same size and structure as the lower platen. Upper pressing plate 2, upper pressing plate 2 and lower pressing plate 14 center all have through holes, respectively have a high pressure glass w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com