Patents

Literature

33results about How to "Slow heat conduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

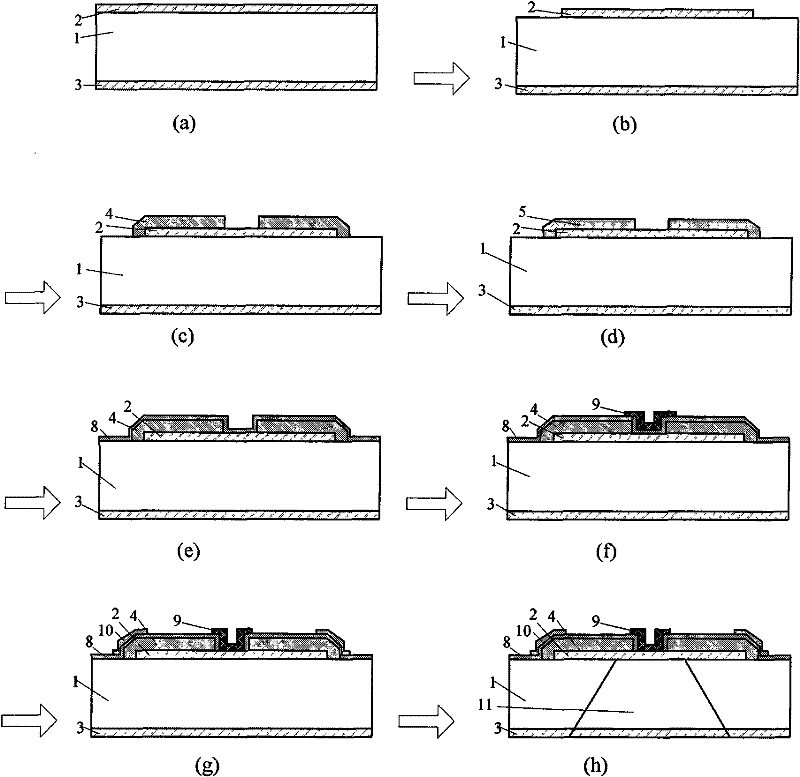

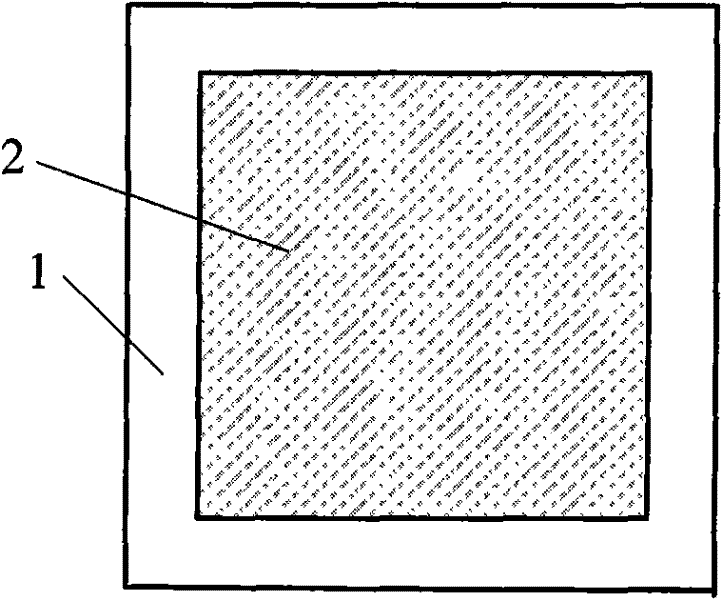

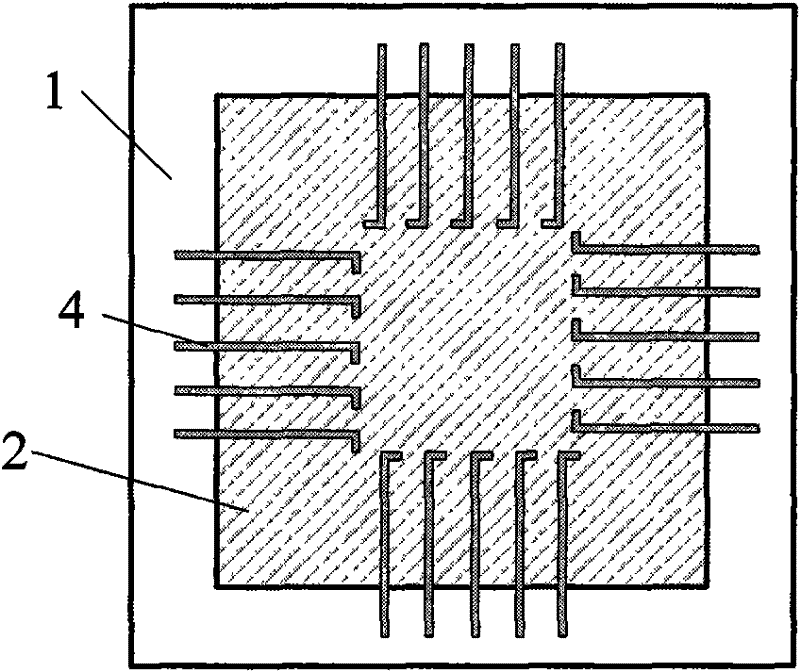

Micromachined thermopile infrared detector

ActiveCN101575083AReduce stressNo high temperature annealing requiredTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesThermopileReflective layer

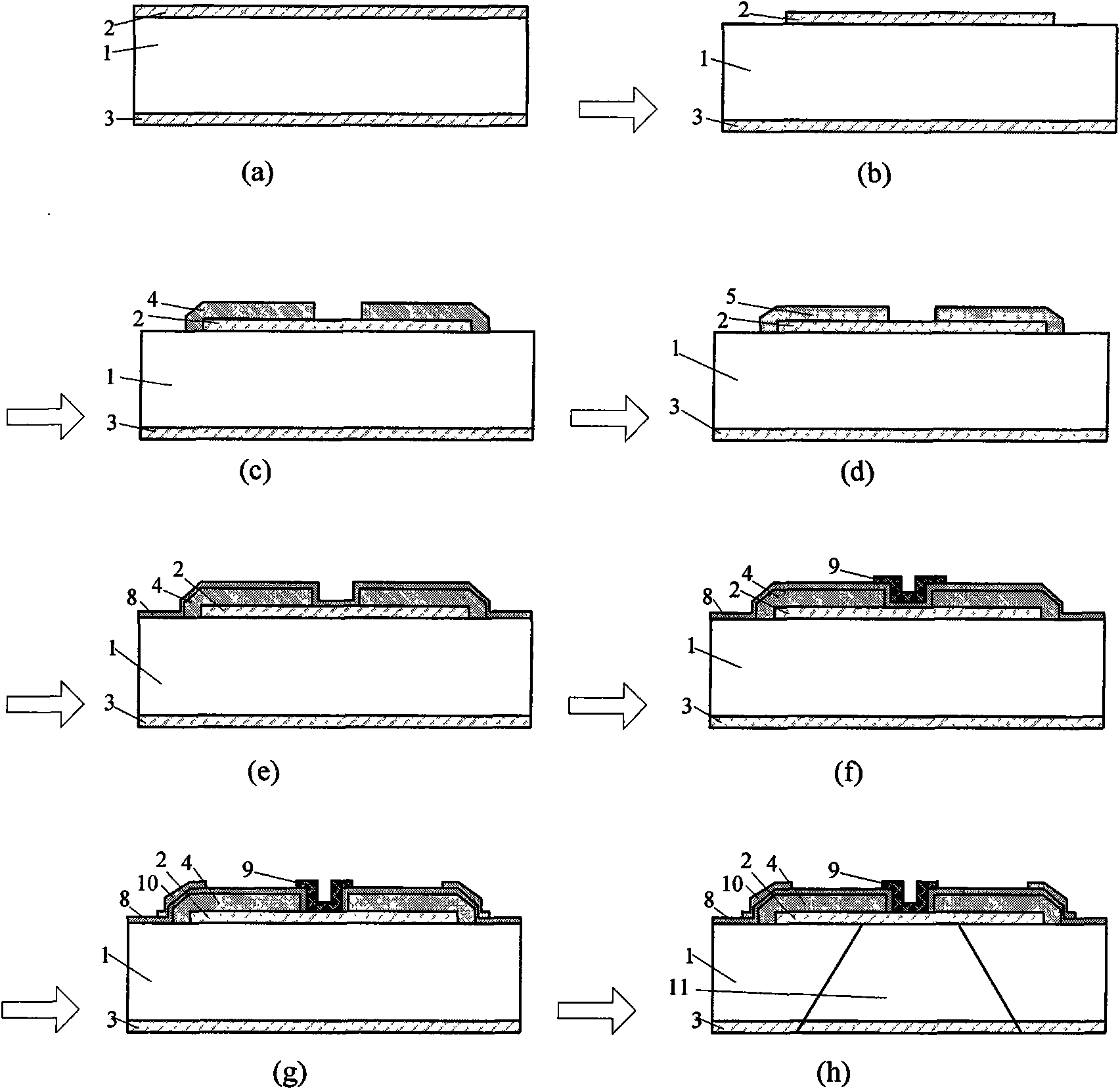

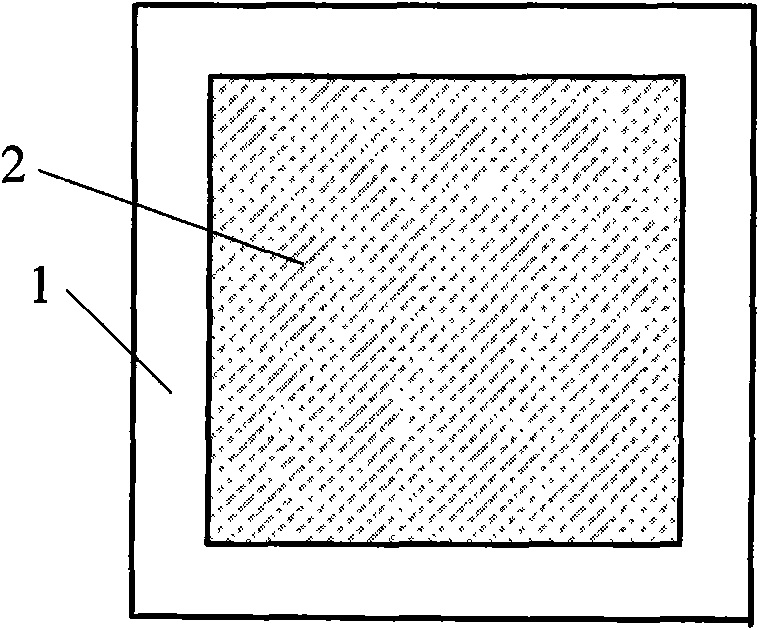

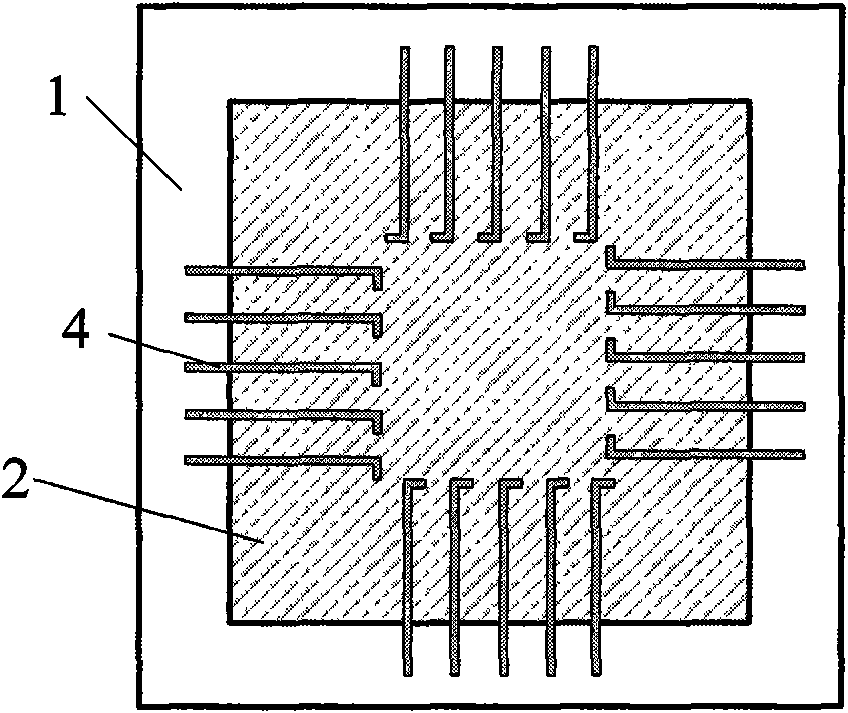

The invention relates to the field of an infrared detector, in particular to a micromachined thermopile infrared detector. The manufacturing technique is simplified and the performance and finished product rate are improved. The manufacture of the micromachined thermopile infrared detector comprises the following steps of: (1) depositing silicon nitride film on the both sides of a silicon substrate by an LPCVD method; (2) etching to remove peripheral silicon nitride film on the frontal side of the silicon substrate by lithography; (3) manufacturing a plurality of Poly-Si strips both ends of which are respectively arranged on the silicon nitride film and the silicon substrate by LPCVD method and photolithographic process; (4) manufacturing a plurality of aluminum strips which form a thermocouple with the plurality of Poly-Si strips by sputtering and photolithographic processes; (5) depositing the silicon nitride film on the frontal side of the silicon substrate by PECVD method; (6) manufacturing an infrared absorption layer (a carbonized photoresist layer) covering the hot junction area of the thermopile with photolithographic process; (7) manufacturing a metal reflective layer (a metal layer) covering the cold junction area of the thermopile with lift-off process; and (8) eroding the back side of the silicon substrate to form a square frustum pyramid shaped groove. The micromachined thermopile infrared detector has reasonable structure design, simple manufacturing process, high detector performance, high finished product rate, good development prospect and is easy to realize.

Owner:ZHONGBEI UNIV

Manufacturing method of recycled foam material using granite powder as raw material

InactiveCN102786316ANo chemical pollutionFully digestedSolid waste disposalCeramicwareThermal insulationGranolithic

The invention discloses a manufacturing method of a recycled foam material using granite powder as a raw material. The recycled foam material comprises the following formula and components: 70%-90% of granite powder, 6%-25% of flux filler, 1%-5% of pore-forming material, and 1%-5% of polymerization martial. The manufacturing method sequentially comprises the following steps of: controlling the fineness of the particles of the powder to be over 100 meshes; uniformly stirring and mixing; pressing mixture into a required granular material; stacking and forming the granular material; feeding into a high temperature furnace to heat; and finally cooling and taking out to obtain the recycled foam material finished product. A product produced by the manufacturing method has the advantages of fully consuming granite powder waste material, solving the problem of serious environmental pollution existing at a granite processing base for a long time and meeting environmental protection requirements, along with stable physical performance, light weight, thermal insulation, compression resistance, bending resistance, capabilities of being used for building wall or external wall decoration and fulfilling the aims of weight reduction and energy conservation of a building, fire prevention, water prevention and sound isolation performance and capability of being used as a fire-proof material and a wall isolating material.

Owner:宁波振强科技有限公司

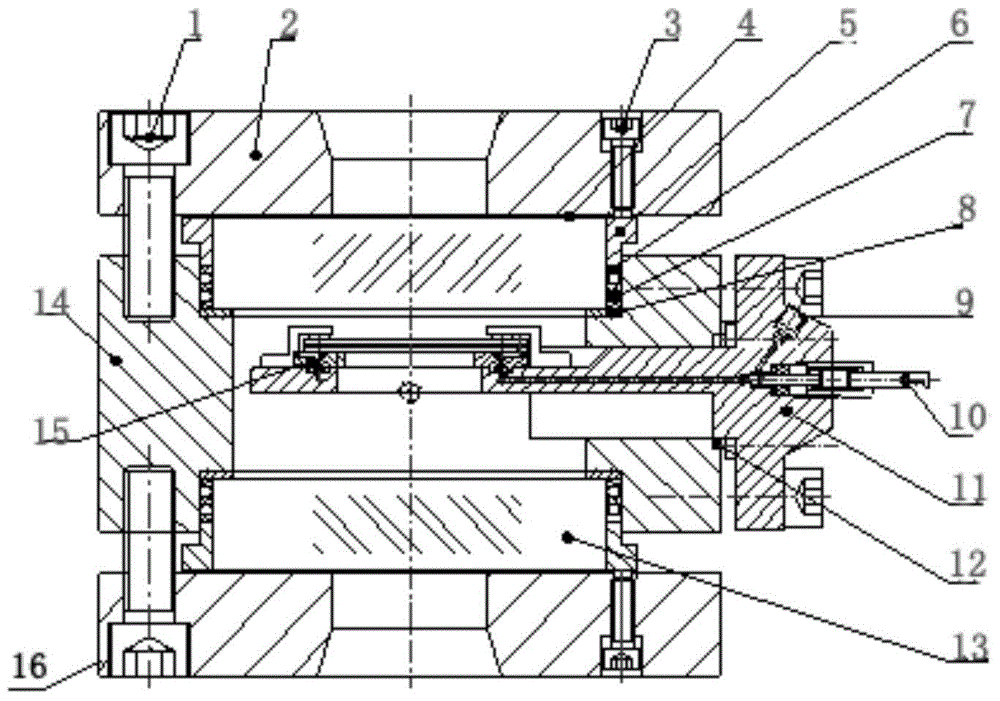

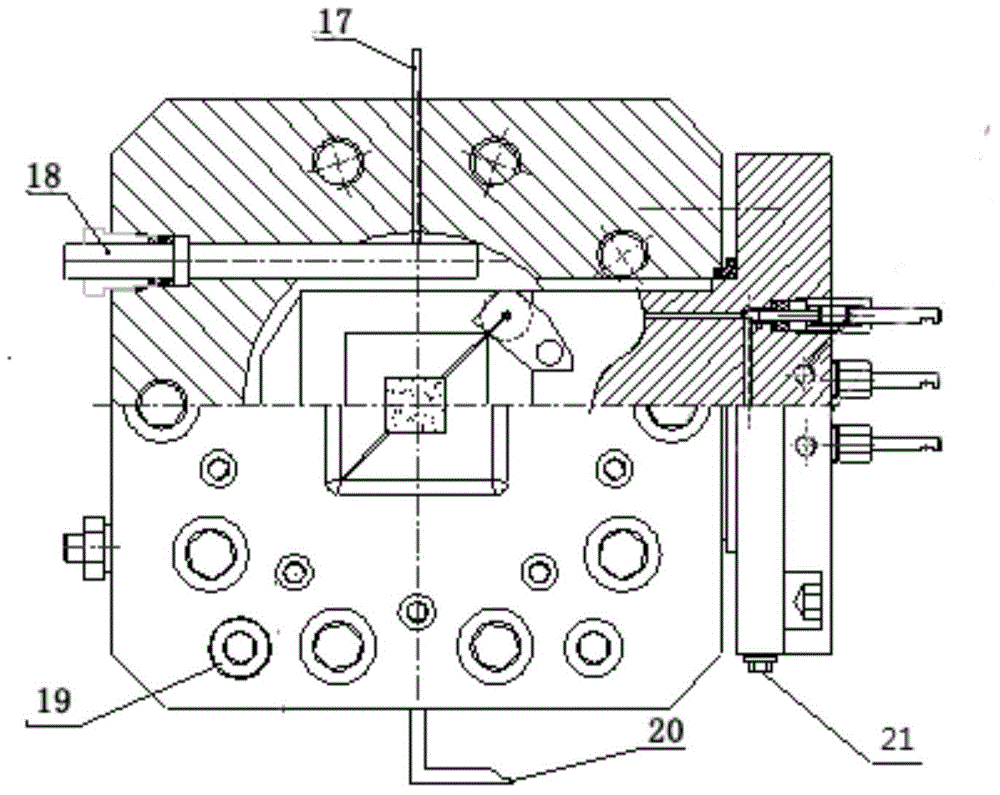

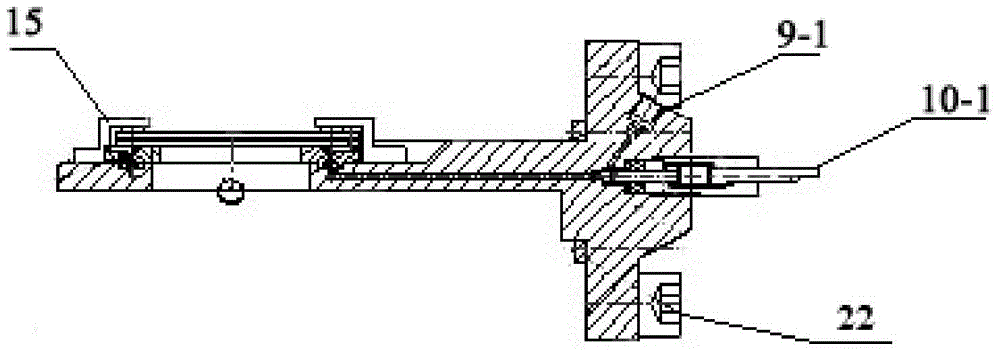

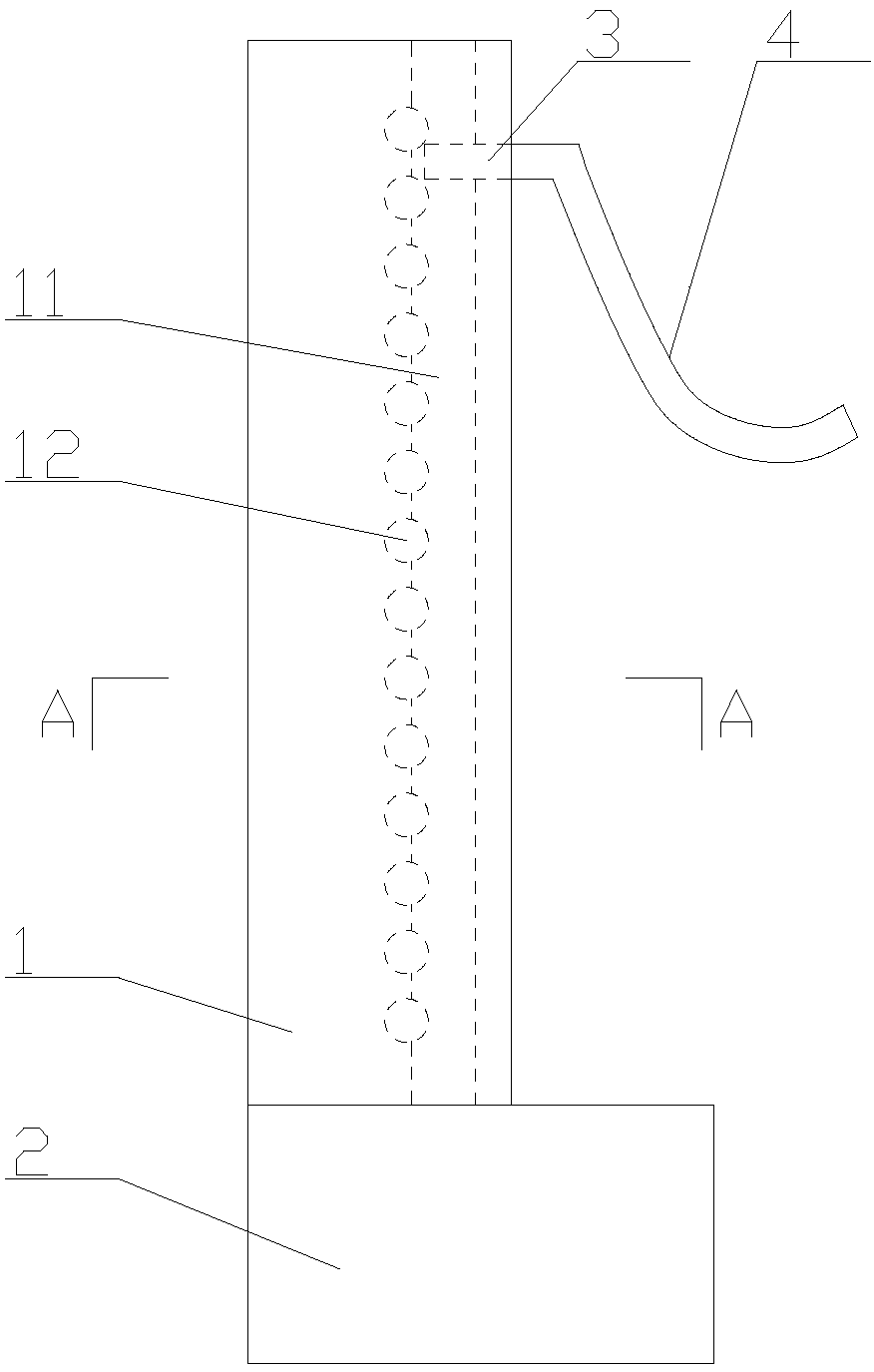

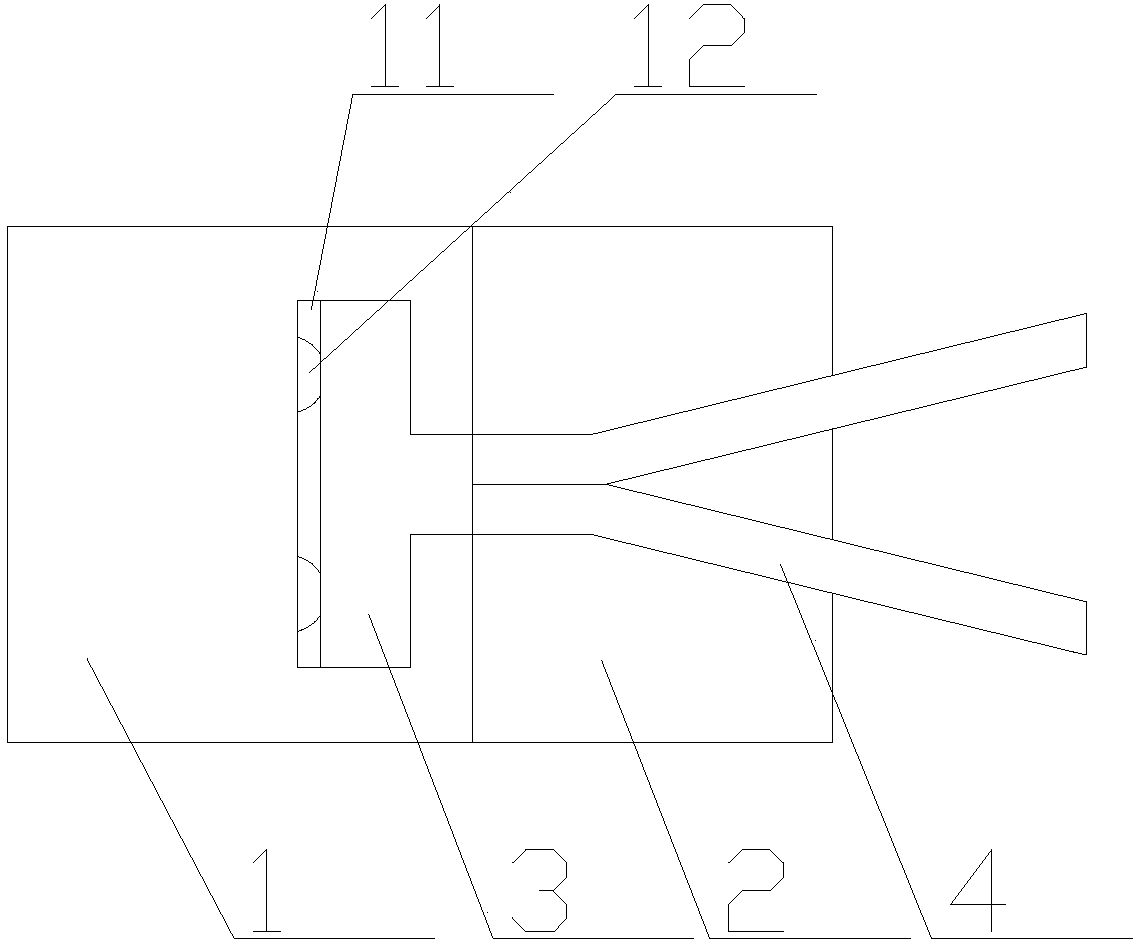

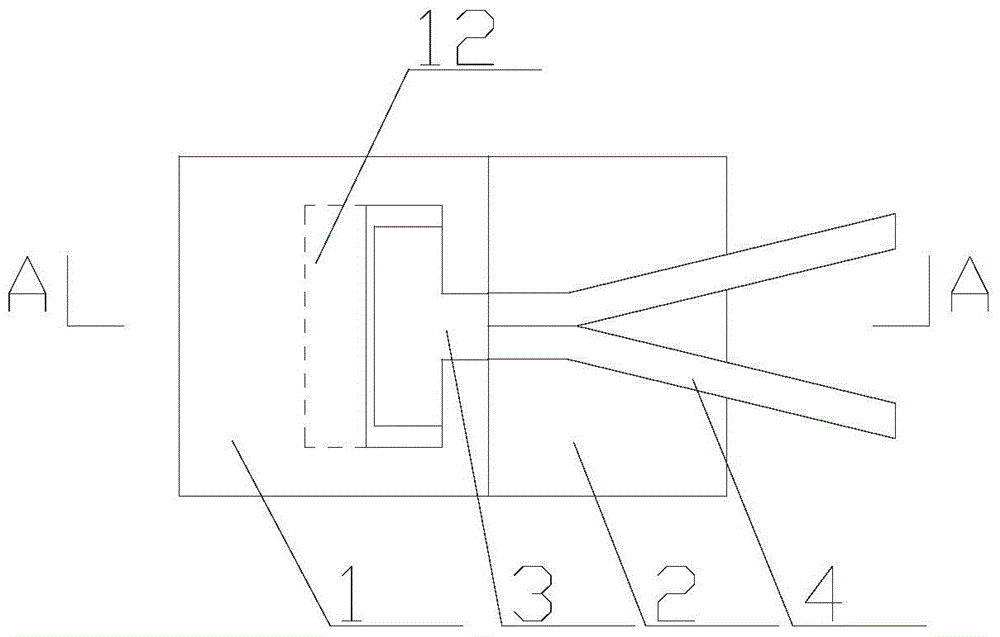

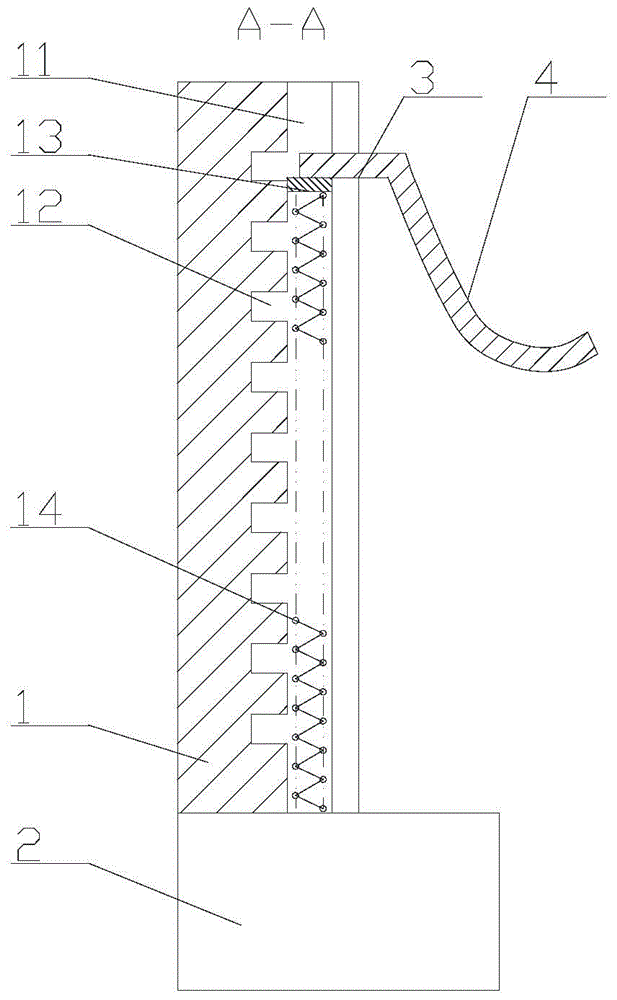

High-temperature high-pressure glass micro model gripper used for heavy oil thermal recovery

The invention discloses a high-temperature high-pressure glass micro model gripper used for heavy oil thermal recovery. The high-temperature high-pressure glass micro model gripper comprises a high-temperature high-pressure bin and high-pressure glass visual windows and further comprises a drawer type micro model support, upper pressing plates and lower pressing plates. The high-temperature high-pressure bin is a square-cylinder-shaped bin body. The upper portion and the lower portion of the inner wall of the bin body are each provided with an annular step. One high-pressure glass visual window is fixed to each annular step. The upper pressing plates and the lower pressing plates are arranged on the outsides of the high-pressure glass visual windows correspondingly. The high-temperature high-pressure bin is provided with a heater leading to an inner cavity of the bin body. The side face of the bin body is further provided with a model support inlet. The drawer type micro model support is pushed into the bin body from the model support inlet. Through the drawer type high-temperature high-pressure gripper, operation is simple, fast and convenient, and the problem of the unreliability of the leakproofness of the bin body due to repeated disassembly and assembly of the visual windows is avoided. A plurality of injection openings and control valves, bull plugs and back-pressure valves of the injection openings are adopted, so that noninterference between injection fluid is achieved, and meanwhile, the continuity of the injection fluid and pressure is ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

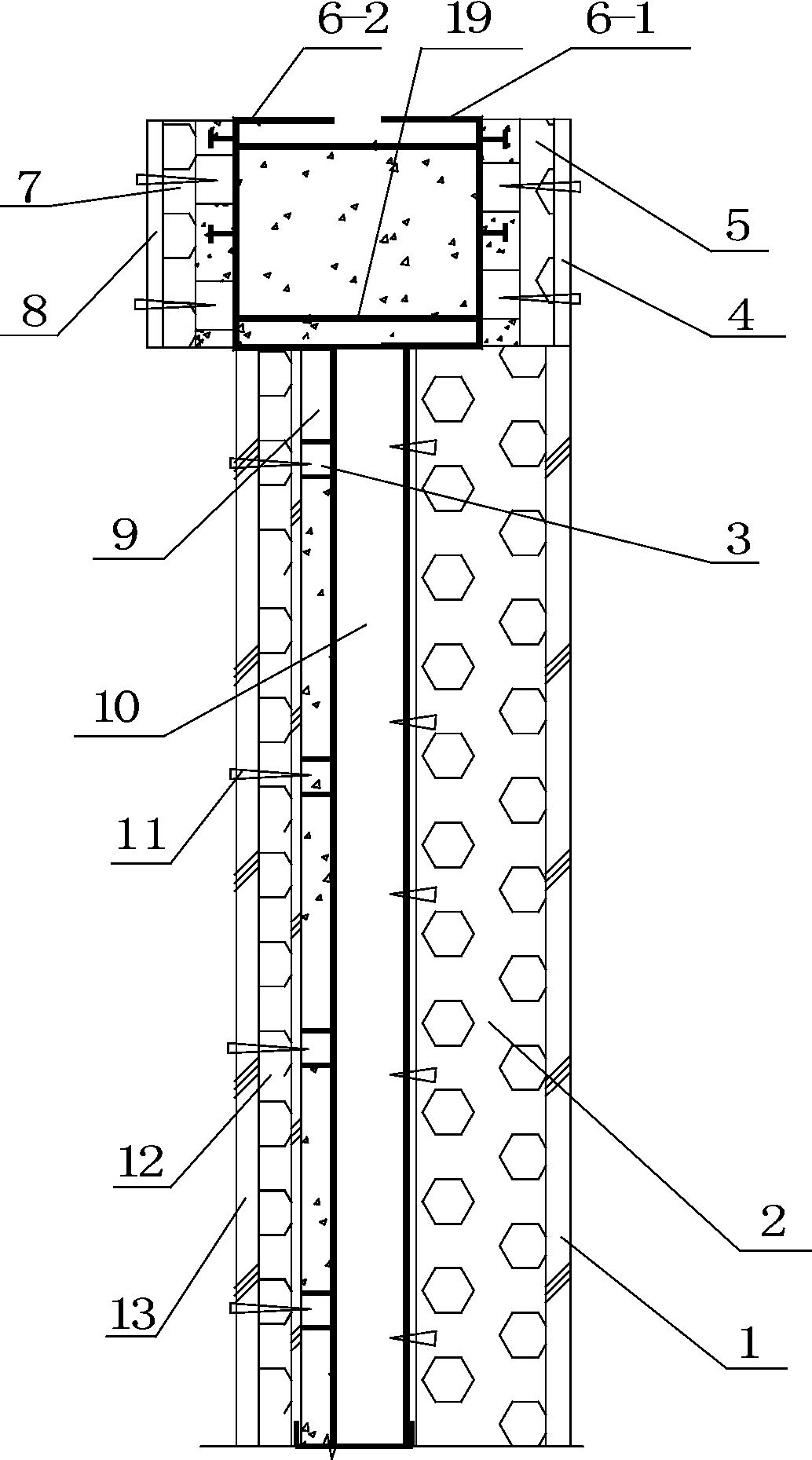

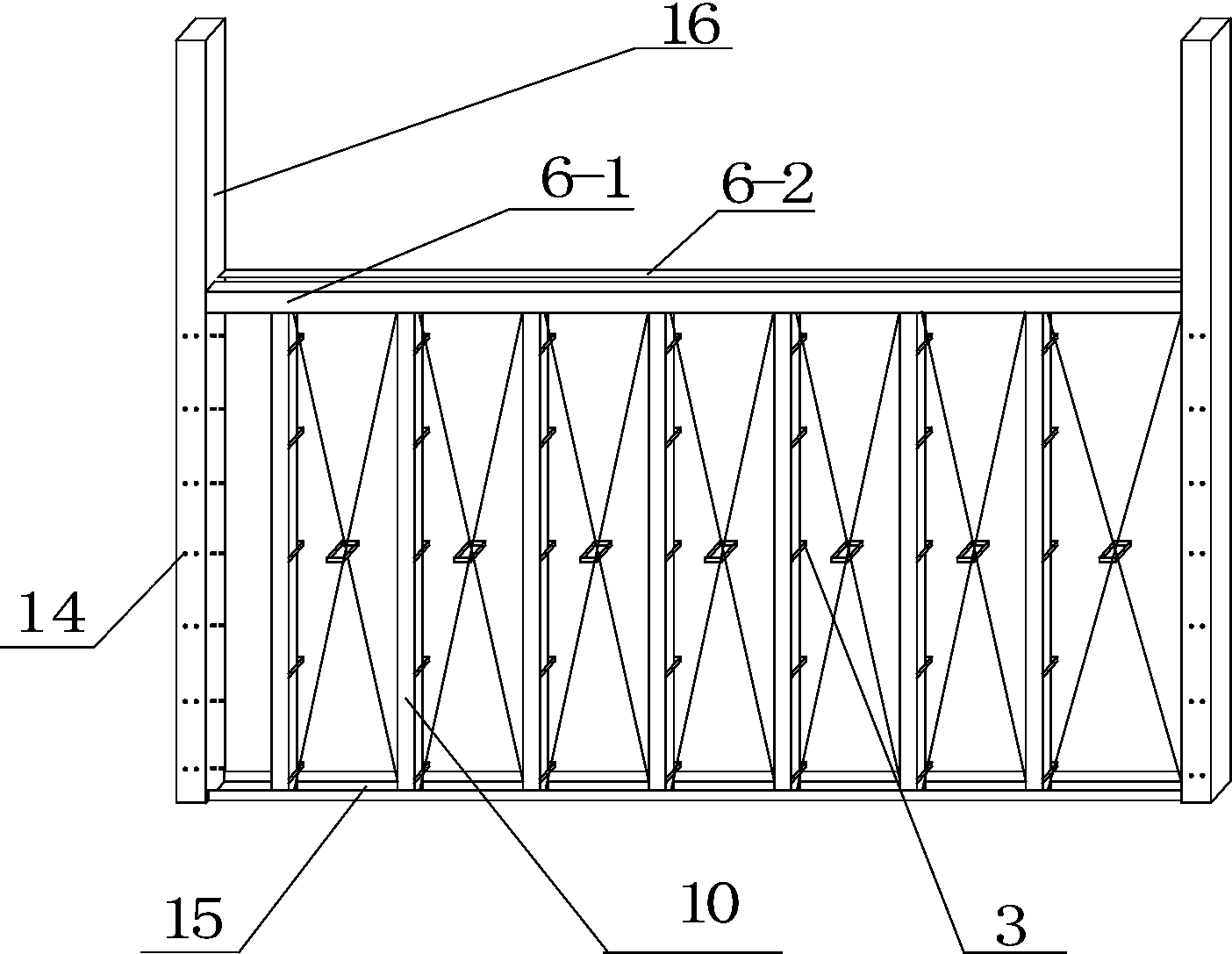

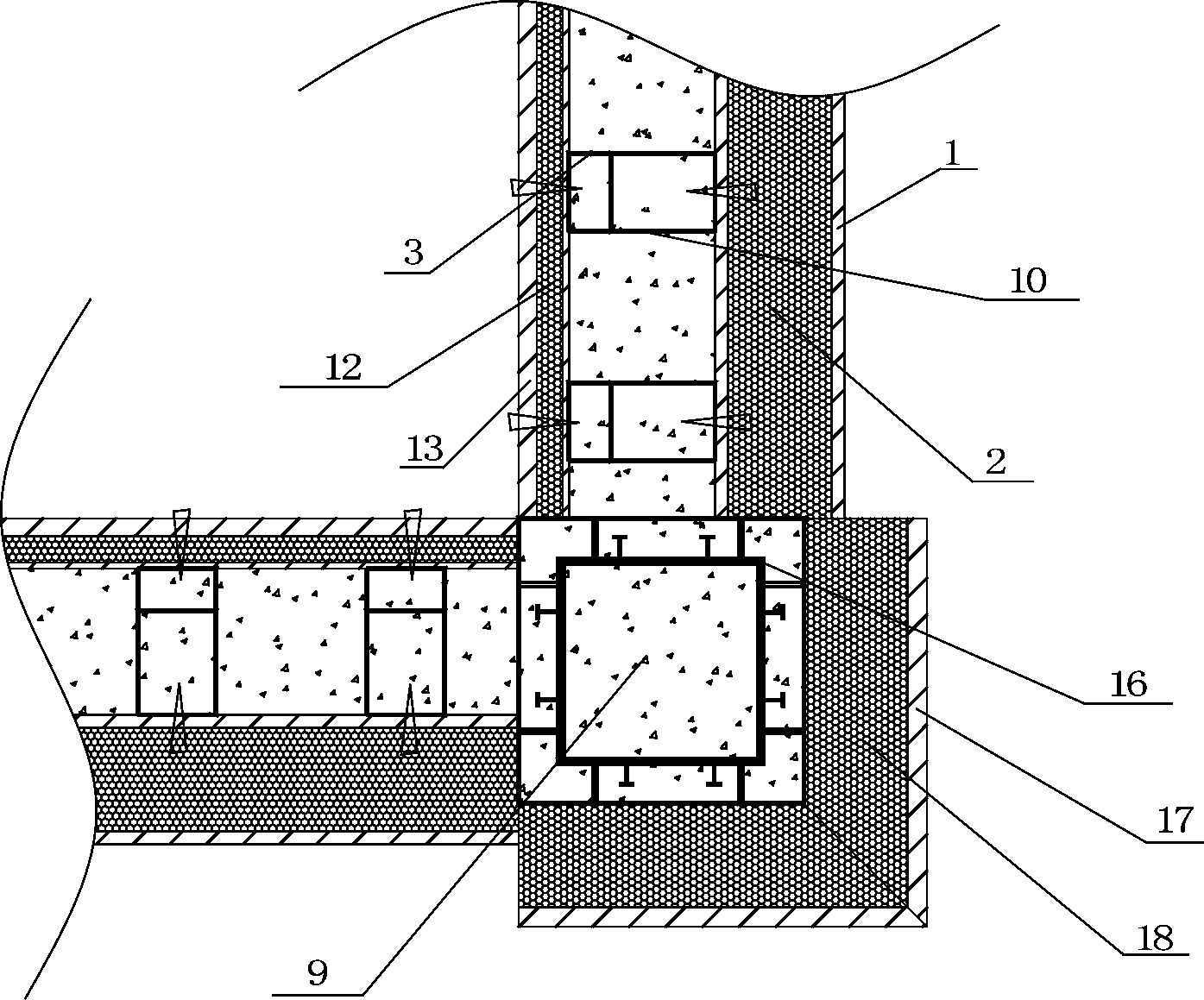

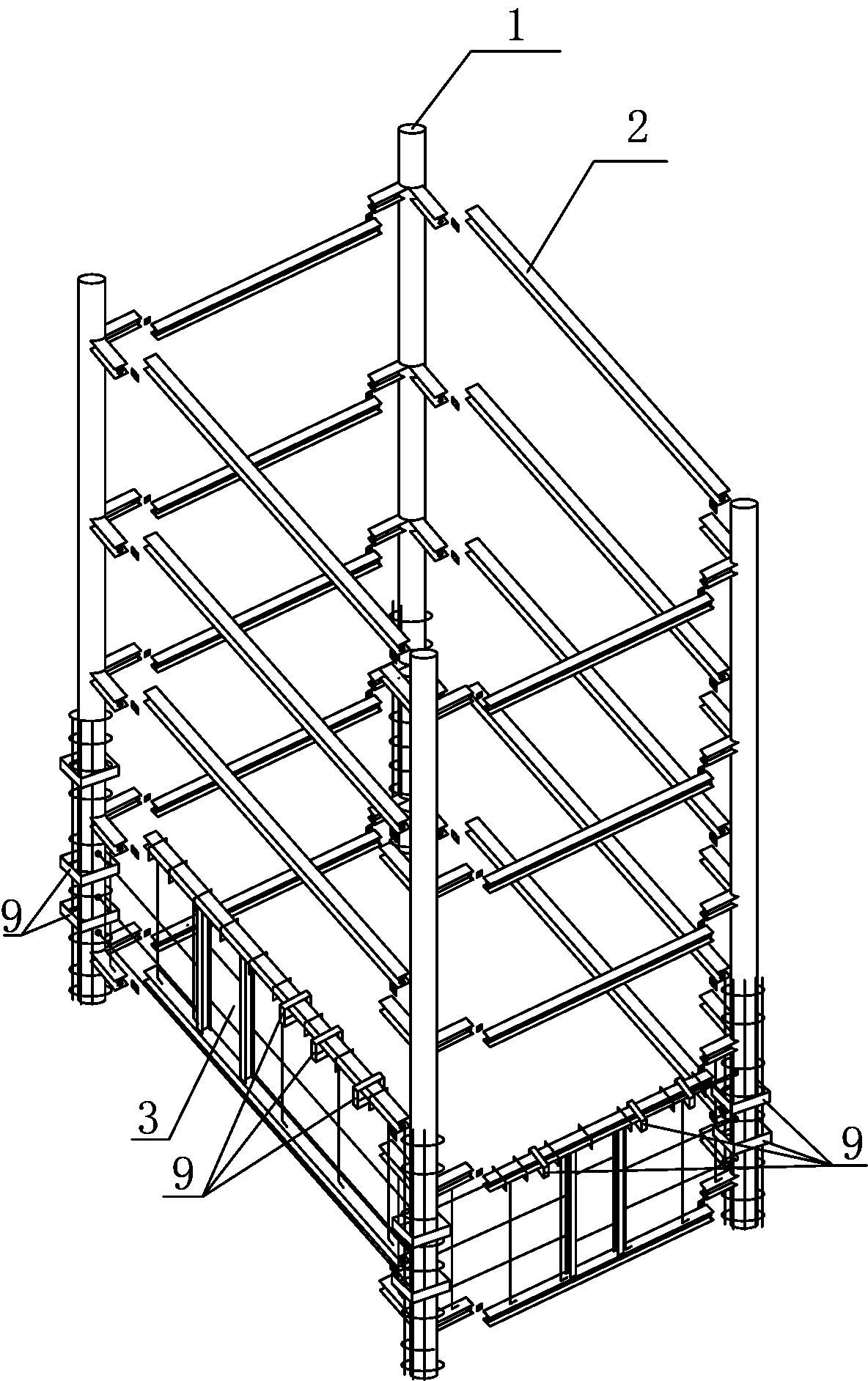

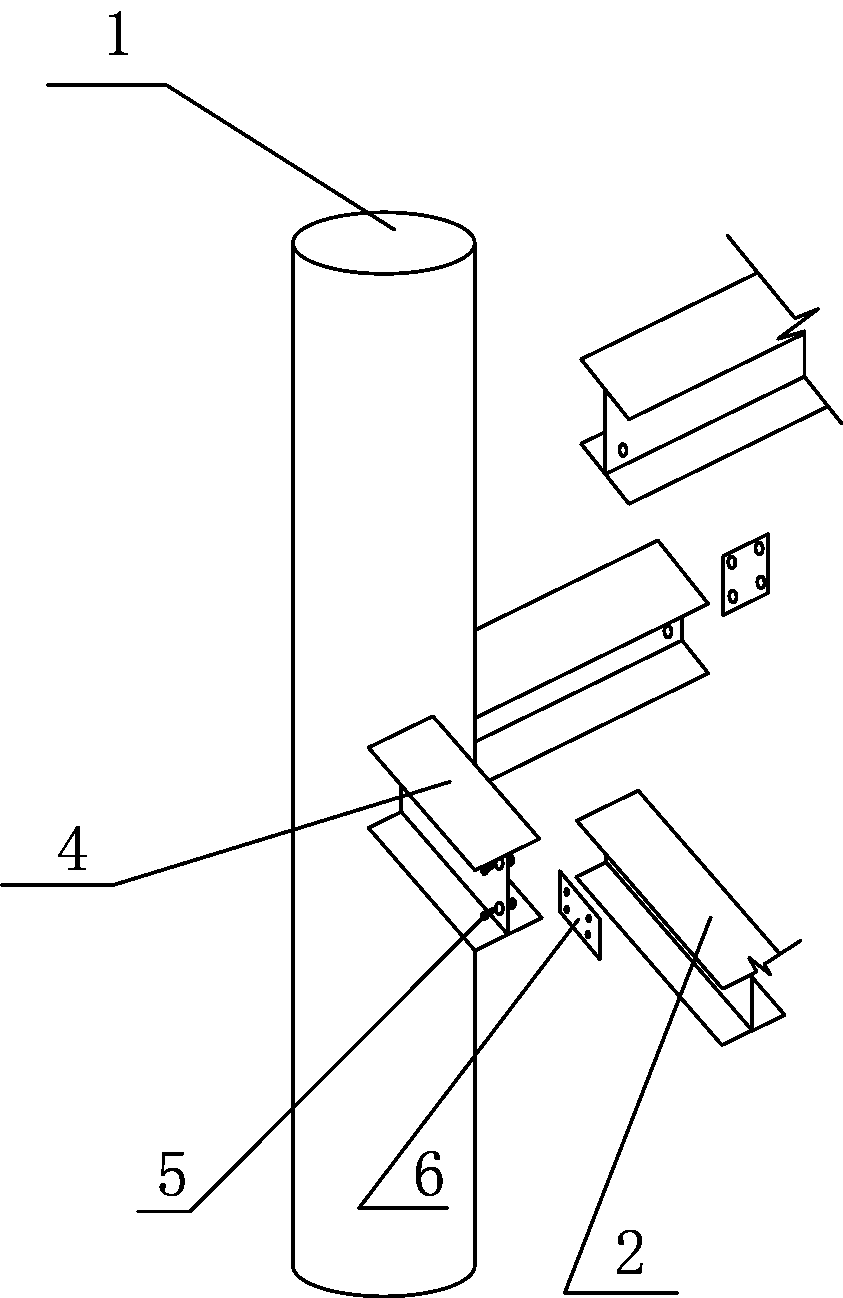

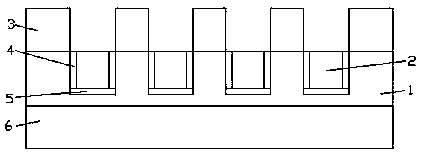

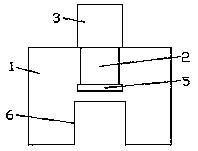

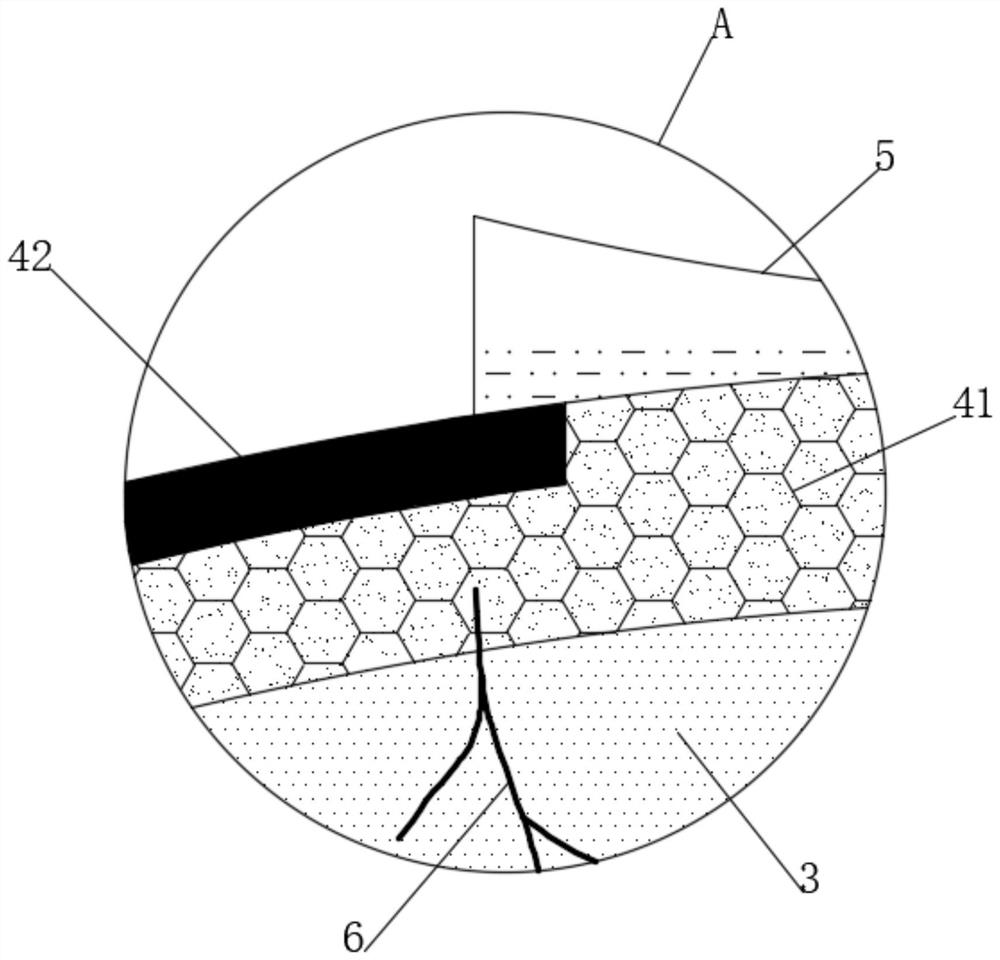

Steel structure concrete internal-external thermal insulation integration module house

ActiveCN103452187AImprove sealingImprove waterproof performanceWallsHeat proofingInsulation layerFloor slab

The invention relates to a steel structure concrete internal-external thermal insulation integration module house which is characterized in that channel steel is connected among section steel columns (16), longitudinal section steel (10) is connected between upper channel steel and lower channel steel to form a steel structure house framework. Thermal insulation layers and boards are connected to the side of the framework. Concrete is poured between opposite channel steel and between two thermal insulation layers. Concrete, filled the space between the internal beam thermal insulation layer (7) and the channel steel and the space between the external beam thermal insulation layer (5) and the channel steel, is poured at the contact of floors and beams, and the concrete is connected with that between two opposite channel steel. The house has the advantages that construction efficiency is high, construction cycle is short, the integration structure is formed after concrete pouring, good quality performance and long service life are achieved, the thermal insulation layers are as durable as the wall, and cement maintenance and steel structure anticorrosion and antirust processing during construction can be omitted.

Owner:烟台金田科技有限公司

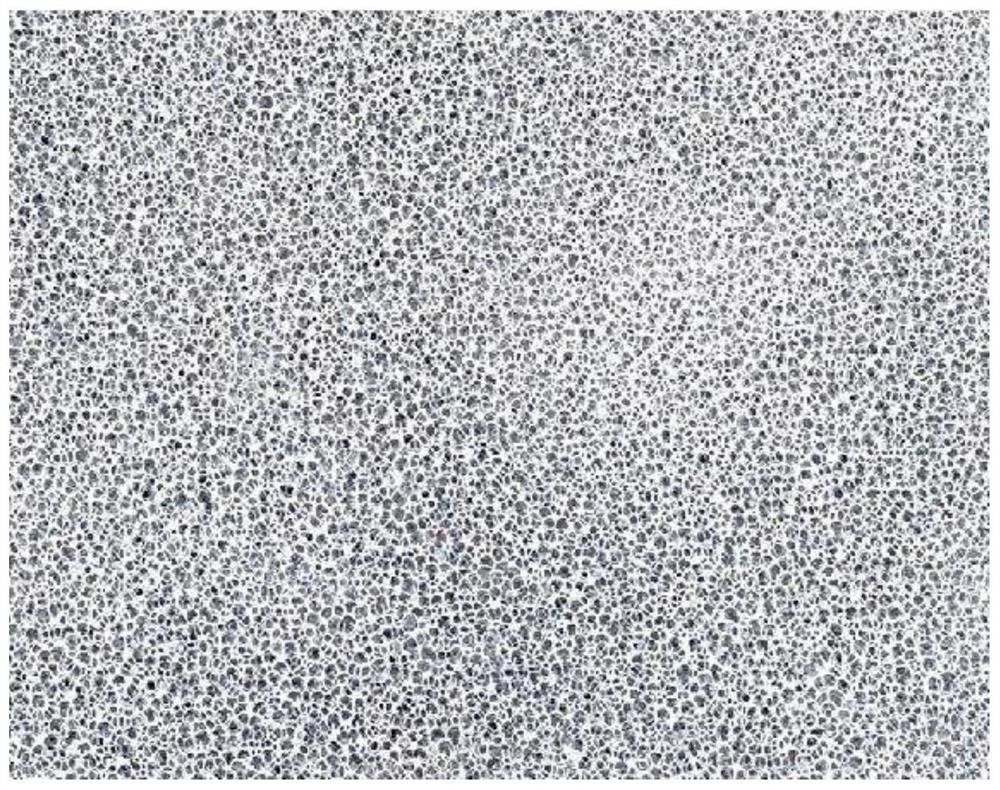

Recycled foam material using granite powder as raw material

InactiveCN102786317ANo chemical pollutionFully digestedWaste processingSolid waste disposalEnvironmental resistancePrill

The invention discloses a recycled foam material using granite powder as a raw material. The formula composition of the recycled foam material comprises the following components in percentage by weight: 70-90 percent of granite powder, 6-25 percent of fluxing filler, 1-5 percent of pore forming material and 1-5 percent of polymeric material. A manufacturing method of the recycled foam material sequentially comprises the following steps of: controlling the fineness of the particles of the powder to be over 100 meshes; uniformly stirring and mixing; pressing mixture into a required granular material; stacking and forming the granular material; feeding into a high temperature furnace to heat; and cooling and taking out to obtain a finished product. The recycled foam material has the advantages of fully consuming granite powder waste material, solving the problem of serious environmental pollution existing at a granite processing base for a long time and meeting environmental protection requirements. The product has the advantages of stable physical performance, light weight, thermal insulation, compression resistance, bending resistance, capabilities of being used for building wall or external wall decoration and fulfilling the aims of weight reduction and energy conservation of a building, fire prevention, water prevention and sound isolation performance and capability of being used as a fire-proof material and a wall isolating material.

Owner:宁波振强科技有限公司

Regenerative foam material taking granite powder as raw material and preparation method of regenerative foam material

The invention discloses a regenerative foam material taking granite powder as a raw material and a preparation method of the regenerative foam material. A formula of the regenerative foam material comprises the following components in parts by weight: 40-69 parts of granite powder, 2-8 parts of fly ash, 6-25 parts of fluxing filler, 1-5 parts of pore forming material, and 1-5 parts of polymeric material. The preparation method of the regenerative foam material sequentially comprises the following steps that grain fineness of the powder is controlled above 100 meshes; the powder is stirred and mixed uniformly; a mixture is pressed to a required granular material; the granular material is sent to a high-temperature furnace for warming, cooled and taken out; and a finished product is obtained. The regenerative foam material and the preparation method have the advantages that granite powder waste can be digested sufficiently; a long-term severe environmental pollution problem of a granite processing base can be solved; and environmental requirements can be met. The regenerative foam material is stable in physical property, light in weight, heat-insulated, compression-resistant and fracture-resistant, and can be used for building wall or external wall decoration; objectives of building weight reduction and energy saving can be achieved; in addition, the regenerative foam material has fireproof, waterproof and soundproof properties, and can be used for fireproof materials and wall partitioning materials.

Owner:宁波振强科技有限公司

Sintering resisting type burnt-on sand coating and preparation method thereof

InactiveCN108526389APrevent infiltrationPrevent corrosionFoundry mouldsFoundry coresAluminum silicateSuspending Agents

The invention relates to the field of casting technical materials, and particularly relates to a sintering resisting type burnt-on sand coating and a preparation method thereof. The coating comprisesa refractory aggregate, a carrier, a suspending agent and an adhering agent, wherein the refractory aggregate comprises the following materials in parts by mass: 30-50 parts of kieselguhr, 30-50 partsof asbestos powder, 5-15 parts of talcum powder, 5-15 parts of mica powder, 5-15 parts of aluminum silicate, and 5-10 parts of kaolin; the mass of the carrier is 100-150% of the mass of the refractory aggregate; the mass of the suspending agent is 3-10% of the mass of the refractory aggregate; and the mass of the adhering agent is 5-15% of the mass of the refractory aggregate. The coating is highin high temperature strength and stability, and low in gas evolution; when coating a sand core with the coating, the refractory material in the coating is capable of insulating heat, so that the heating time of the sand core can be delayed, and the sand core is prevented from overheating sintering, and as a result, a casting product quality is obviously improved; the sintering preventing effect is obvious; and the problem of sintering burnt-on sand produced by pouring a jacket core of an engine cylinder body, a water channel core and air channel core of a cylinder cover, or a small core, a thin hole, a narrow hole and a blind of a hydraulic valve part, and the like can be effectively solved.

Owner:SHIYAN CHANGJIANG RIVER MOLDING MATERIAL

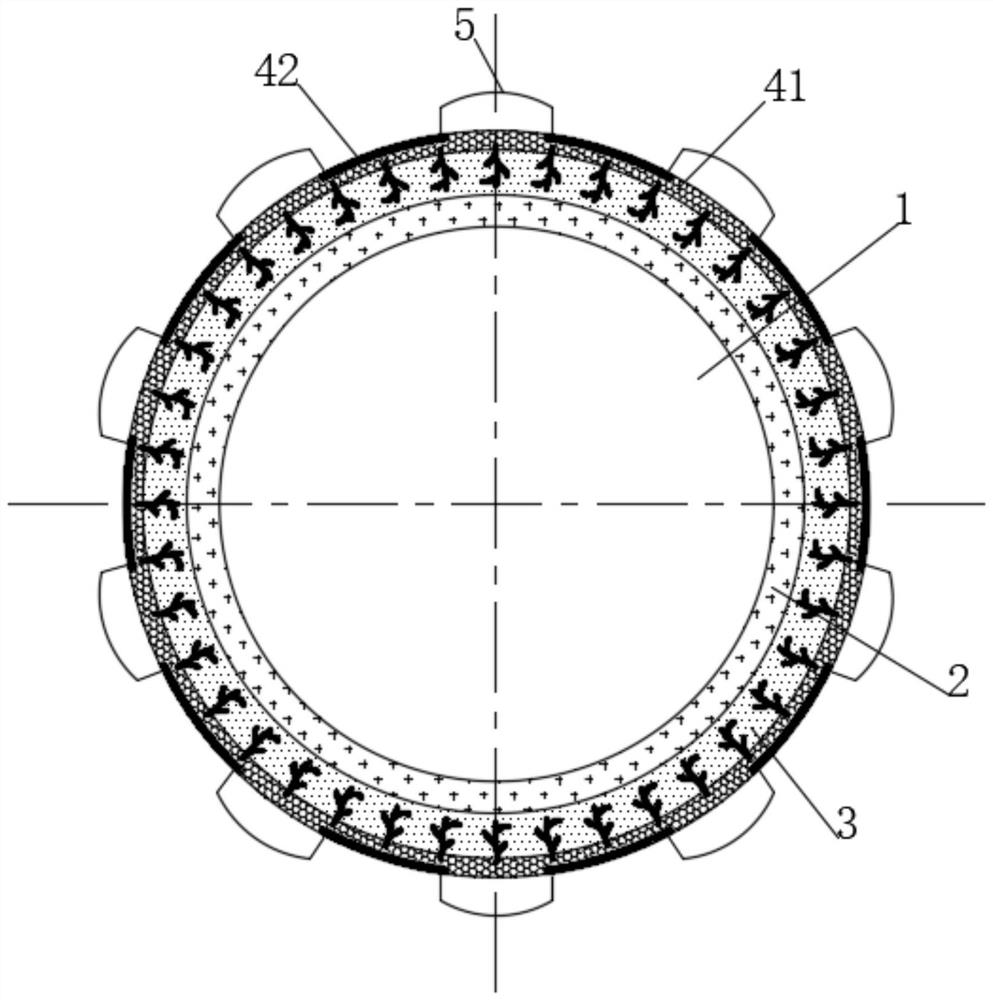

Steel structure concrete construction house

InactiveCN103469889AImprove sealingImprove waterproof performanceBuilding constructionsInsulation layerReinforced concrete

The invention relates to a steel structure concrete construction house, which comprises a reinforced concrete foundation (7), a plurality of steel stand columns (1) internally poured with stand column concrete (11), an inner side wallboard, an outer side wallboard, and a beam plate, wherein bottom ends of the steel stand columns (1) are arranged on the reinforced concrete foundation (7); a steel beam (2) is connected between each two steel stand columns (1); the inner side wallboard and the outer side wallboard are respectively arranged on inner sides and outer sides of the steel beams (2) and are used as wallboards (8); wall concrete (10) is poured between the inner side wallboard and the outer side wallboard; and the beam plate is connected onto the steel beam (2). The building construction efficiency is higher, the period is shorter, house concrete is poured to form an integral structure, better quality performance and longer service life are realized, an insulation layer and the wallboards have the same life, and cement maintenance and anti-corrosion and rust prevention of a steel structure have no need to be carried out during construction.

Owner:烟台金田科技有限公司

Dual-state temperature change type cold-proof anti-freezing cable

ActiveCN111816355AImprove high temperature resistanceExtended service lifeInsulated cablesInsulated conductorsSoft layerLiquid state

The invention discloses a dual-state temperature change type cold-proof anti-freezing cable and belongs to the cable field. The dual-state temperature change type cold-proof anti-freezing cable includes a core layer, the outer end of the core layer is wrapped with an insulating layer. The outer end of the insulating layer is coated with a sheath; and the outer surface of the sheath is coated witha semi-transparent soft layer. At high temperature, a gas-controlled oil part is partially gasified to generate gas, an outer air bulge bulges outwards and is filled with air, and compared with an entity, the gas conduction speed is lower, the external temperature can be effectively isolated, the overall high temperature resistance of the cable is effectively improved and the service life is prolonged; and at low temperature, light oil returns to liquid, animal oil is cured, the gas-controlled oil part is integrally in a solid state with certain viscosity under the adjustment of the liquid light oil, so that the defect that the outer layer of the cable is hardened and embrittled at low temperature can be effectively overcome, and compared with the prior art, the brittleness resistance of the cable in winter is remarkably improved, and the service life of the cable is further prolonged.

Owner:山东青江线缆有限公司

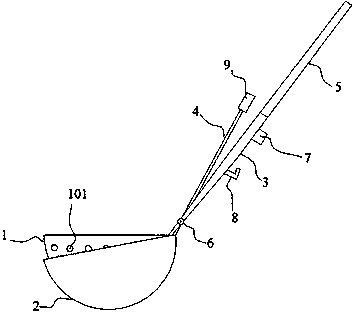

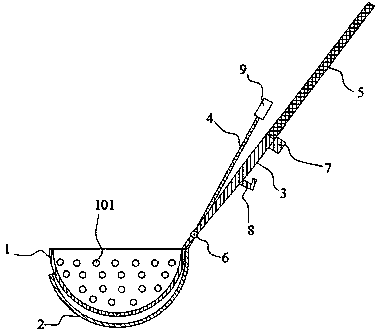

Spoon

The invention discloses a spoon. The spoon comprises a first spoon body, a second spoon body, a first handle body, a second handle body, and a wooden handle; the first spoon body and the second spoonbody are designed to be hemispherical; the first spoon body is a strainer; the second spoon body is a solid spoon; the first spoon body is sleeved by the second spoon body; the first handle body and the second handle body are arranged in a crossed manner, and are connected using an articulated shaft in hinge joint at the crossing part; the first spoon body and the second spoon body are arranged atthe same side of the articulated shaft; one end of the first handle body is connected with the edge of the first spoon body, and the other end is provided with a screw hole; the wooden handle is connected with the screw hole through threaded connection; one end of the second handle body is connected with the edge of the second spoon body; and the first handle body is provided with a boss can be used for lap joint with a pot edge. The spoon can be used for ladling soup, and filtering soup, and is convenient to use by users.

Owner:王海龙

Novel apron fabric

InactiveCN104163023AImprove surface strengthImprove wear resistanceSynthetic resin layered productsPolyesterFiber

The invention discloses a novel apron fabric which comprises a surface wear-resistant layer, an intermediate protective layer and an inner waterproof layer, wherein the surface wear-resistant layer is prepared by blending polyester fibers and polynosic fibers; the intermediate protective layer is prepared by blending linen fibers and polyvinyl chloride fibers; the inner waterproof layer is a polyurethane coating or a plastic film; the surface wear-resistant layer is arranged on the upper surface of the intermediate protective layer; the inner waterproof layer is arranged on the lower surface of the intermediate protective layer. According to the mode, the novel apron fabric provided by the invention is high in surface strength, high in wear resistance and durable in use, the intermediate layer is large in water absorption amount and slow in heat conduction, the inner layer is waterproof, contamination of clothes is eliminated, and the manufactured apron can effectively prevent skin from being scalded and is safe to use.

Owner:朱秀兰

Recycled foam material using granite powder as raw material

InactiveCN102786317BNo chemical pollutionSlow heat conductionWaste processingSolid waste disposalEnvironmental resistancePrill

The invention discloses a recycled foam material using granite powder as a raw material. The formula composition of the recycled foam material comprises the following components in percentage by weight: 70-90 percent of granite powder, 6-25 percent of fluxing filler, 1-5 percent of pore forming material and 1-5 percent of polymeric material. A manufacturing method of the recycled foam material sequentially comprises the following steps of: controlling the fineness of the particles of the powder to be over 100 meshes; uniformly stirring and mixing; pressing mixture into a required granular material; stacking and forming the granular material; feeding into a high temperature furnace to heat; and cooling and taking out to obtain a finished product. The recycled foam material has the advantages of fully consuming granite powder waste material, solving the problem of serious environmental pollution existing at a granite processing base for a long time and meeting environmental protection requirements. The product has the advantages of stable physical performance, light weight, thermal insulation, compression resistance, bending resistance, capabilities of being used for building wall or external wall decoration and fulfilling the aims of weight reduction and energy conservation of a building, fire prevention, water prevention and sound isolation performance and capability of being used as a fire-proof material and a wall isolating material.

Owner:宁波振强科技有限公司

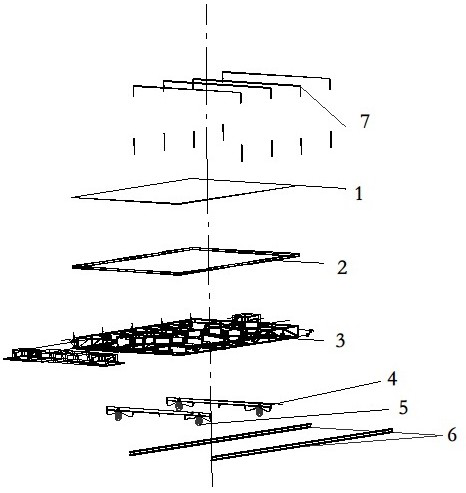

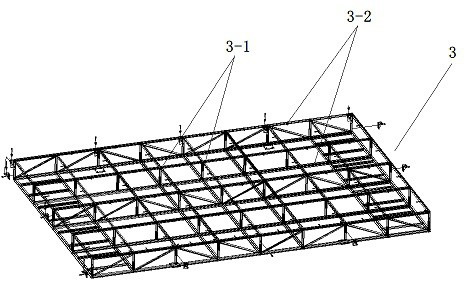

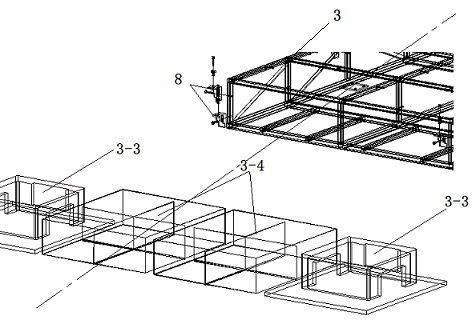

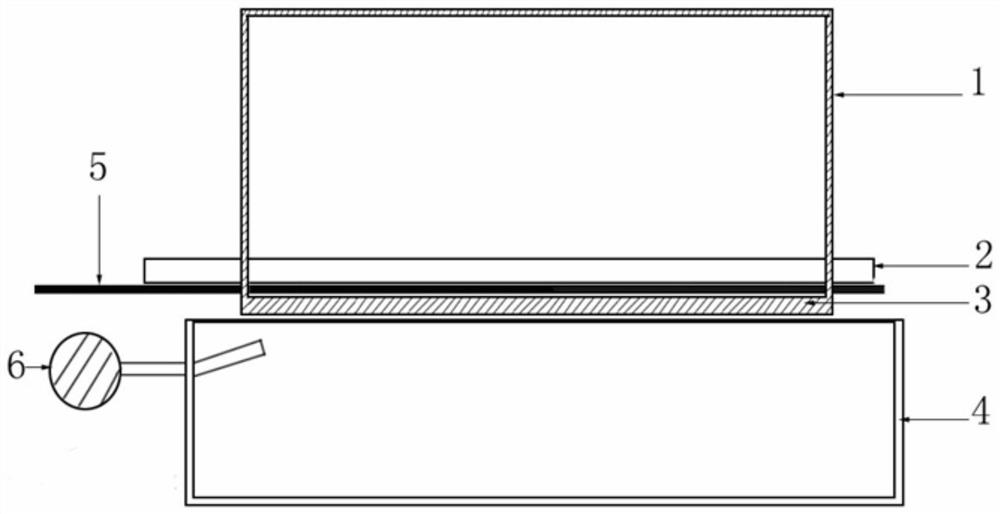

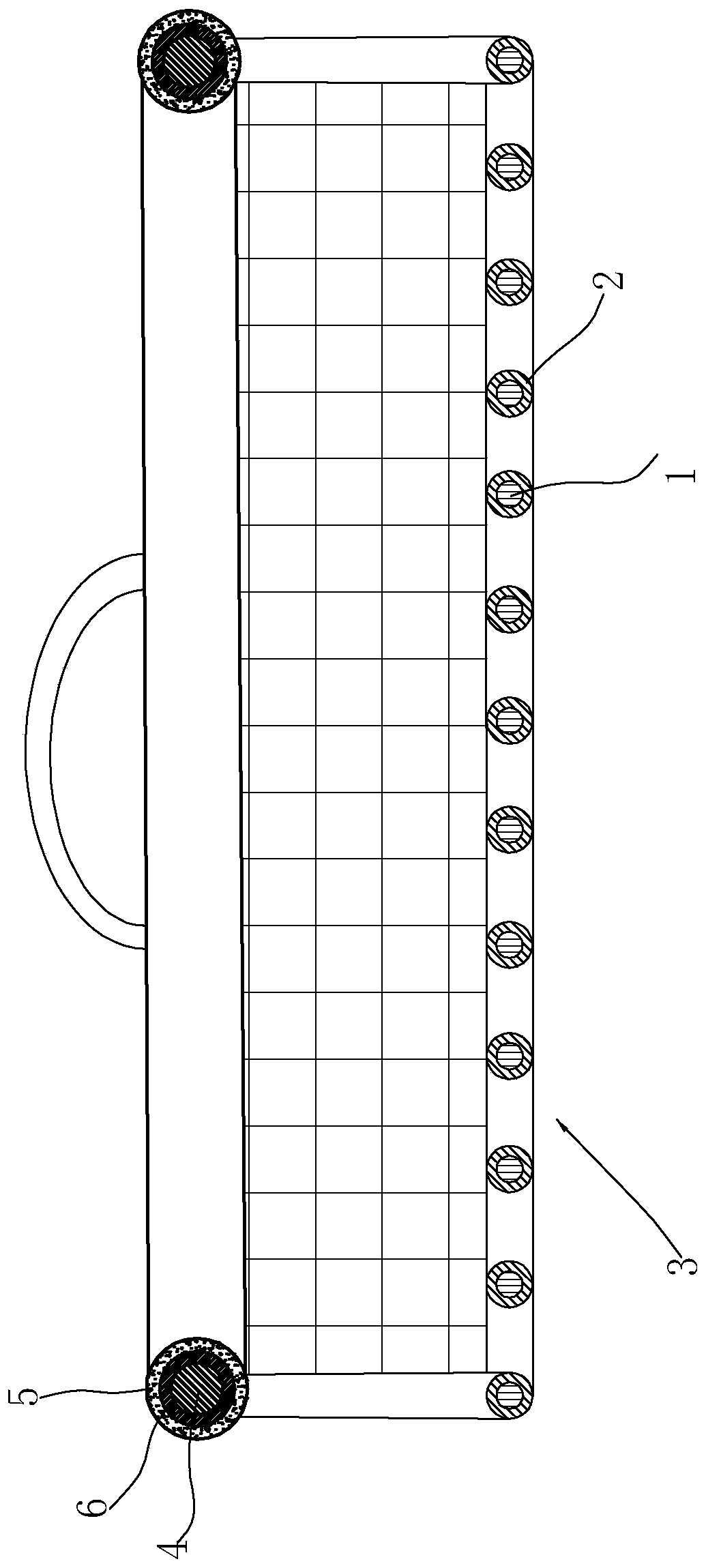

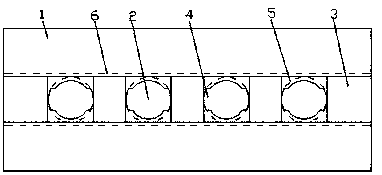

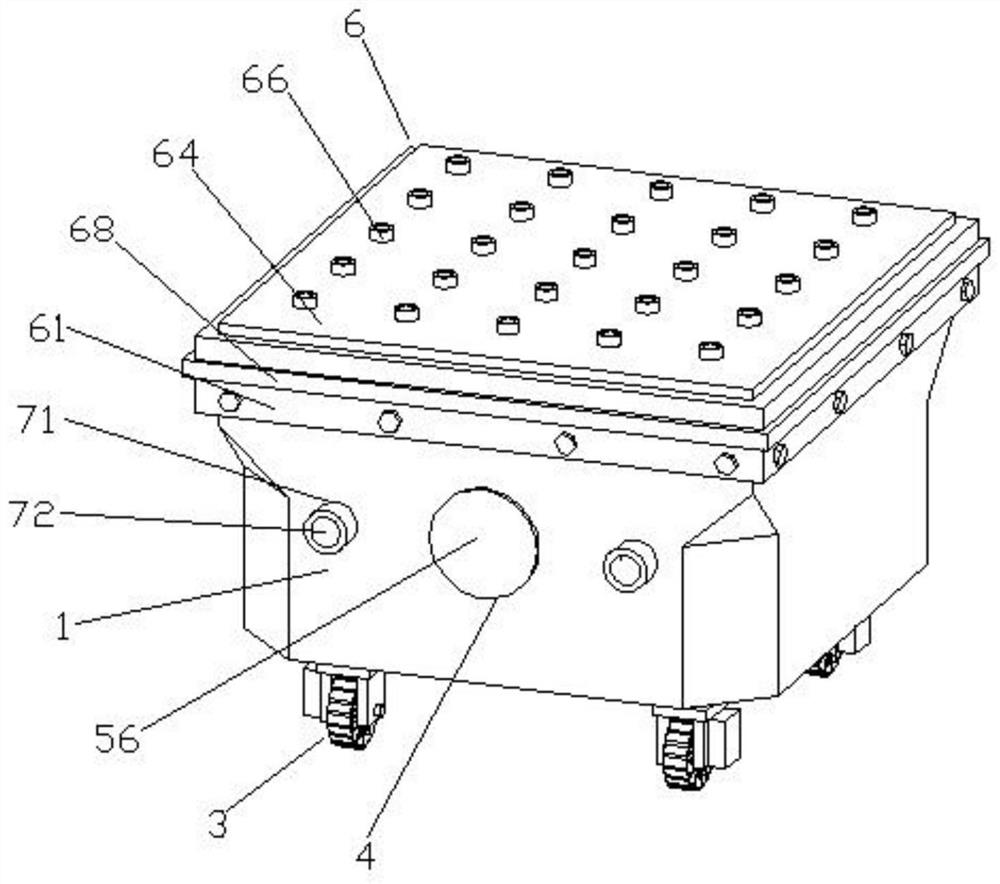

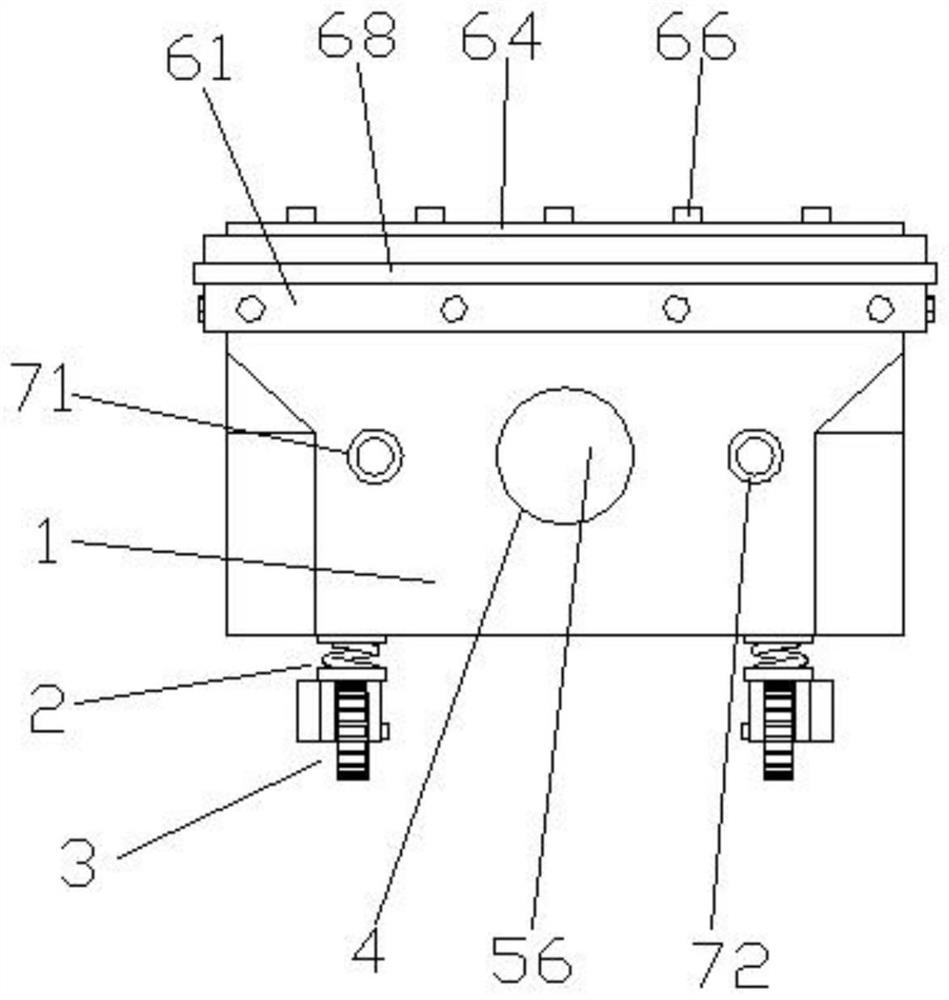

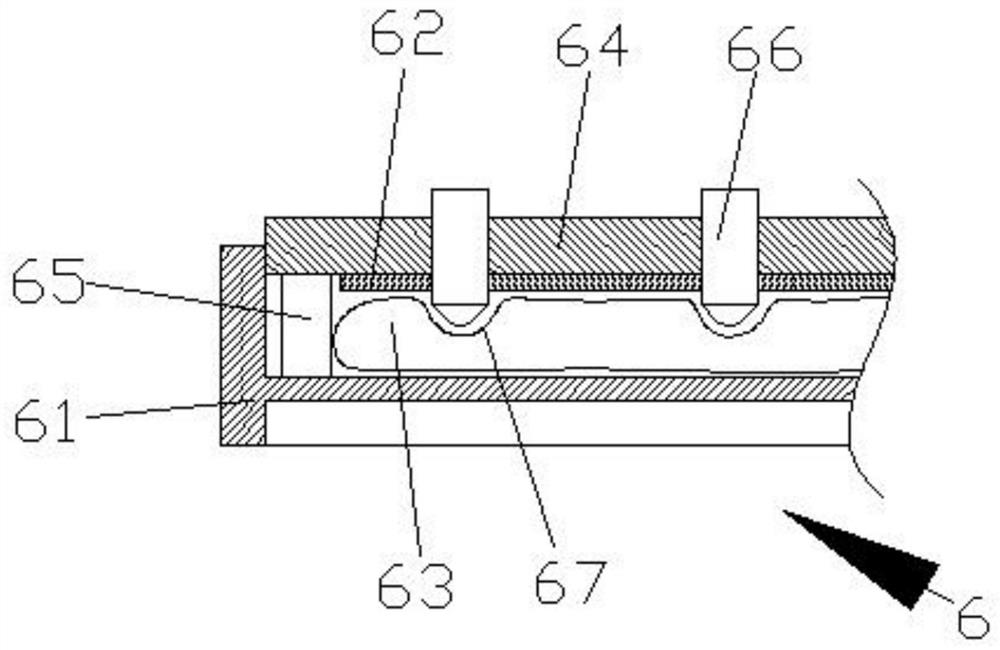

Assembly type combined mold platform

PendingCN111890314ASlow heat conductionNot affected by ambient temperatureWork benchesGlass fiberReinforced concrete

The invention discloses an assembly type combined mold platform, and relates to a production mold platform of a building assembly type component. The assembly type combined mold platform is particularly suitable for producing assembly type building components and GRC decorative components. The assembly type combined mold platform comprises a wood mold surface plate, a GRC material bearing structural plate, a composite shaping steel frame, a bearing beam and a rail wheel; the upper part of the composite shaping steel frame is provided with the GRC material bearing structural plate, the upper part of the GRC material bearing structural plate is compounded with the wood mold surface plate, the composite shaping steel frame is provided with the bearing beam, the lower part of the bearing beamis provided with the rail wheel, the rail wheel is matched with a rail, and the assembly type composite mold platform is convenient to run. According to the assembly type combined mold platform, a steel frame stable structure is adopted, GRC materials (glass fiber reinforced concrete) and composite wood boards are organically combined to form a surface, any combination and steering are realized byinnovative combined accessories, and small-range constant-temperature heating is realized by a special local framework to relieve the defects of a steel platform commonly used at present.

Owner:安徽倍立达住工科技有限公司

Placing table for hot pot strainer

Owner:刘寅东

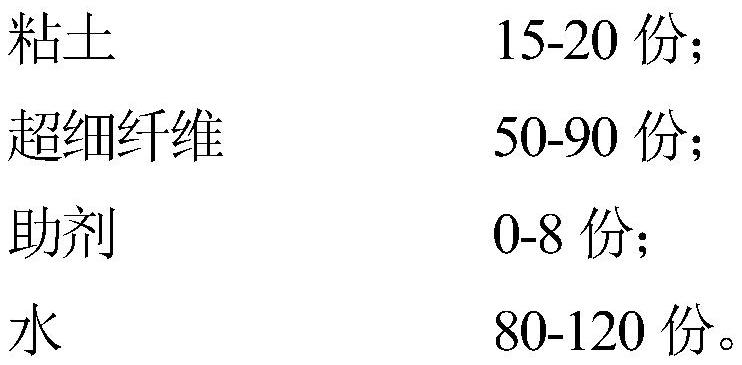

Vacuum insulation panel core material, preparation method thereof and vacuum insulation panel

InactiveCN111689722AImprove insulation effectStrong puncture resistanceSynthetic resin layered productsGlass/slag layered productsFiber diameterVacuum insulated panel

The invention discloses a vacuum insulation panel core material, a preparation method thereof and a vacuum insulation panel, and belongs to the field of vacuum insulation panel core materials. The core material is prepared from the following components in parts by weight: 10 to 15 parts of clay, 50 to 90 parts of superfine fibers and 0 to 8 parts of an auxiliary agent. The superfine fibers in thecore material are bonded by adopting the superfine clay, and the preferable fiber diameter is matched with the clay granularity, so that a better bonding effect can be achieved. During preparation, inthe drying process of a substrate containing the clay and the superfine fibers, the clay continuously shrinks while bonding the fibers, so that a core material formed after drying is of an open-porestructure, and the open-pore material can improve the heat-conducting property of the prepared vacuum insulation plate and improve stability. The core material is simple in composition, reasonable inproportion, low in cost and extremely easy to operate in preparation process, the production process of the vacuum insulation panel core material can be optimized, the production energy consumption isreduced, and the production cost is reduced.

Owner:辽宁东星节能新材有限公司

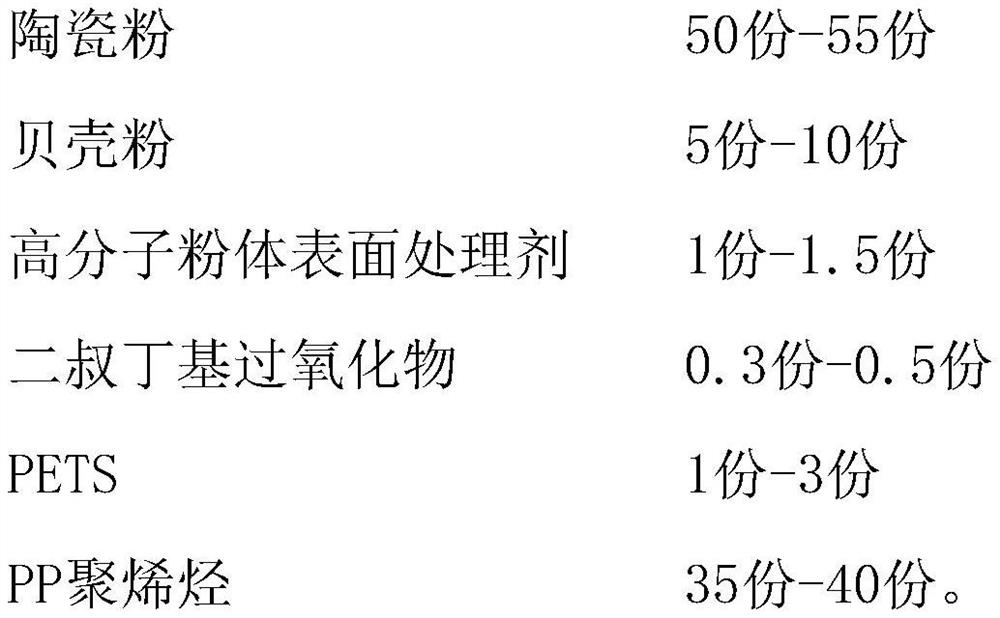

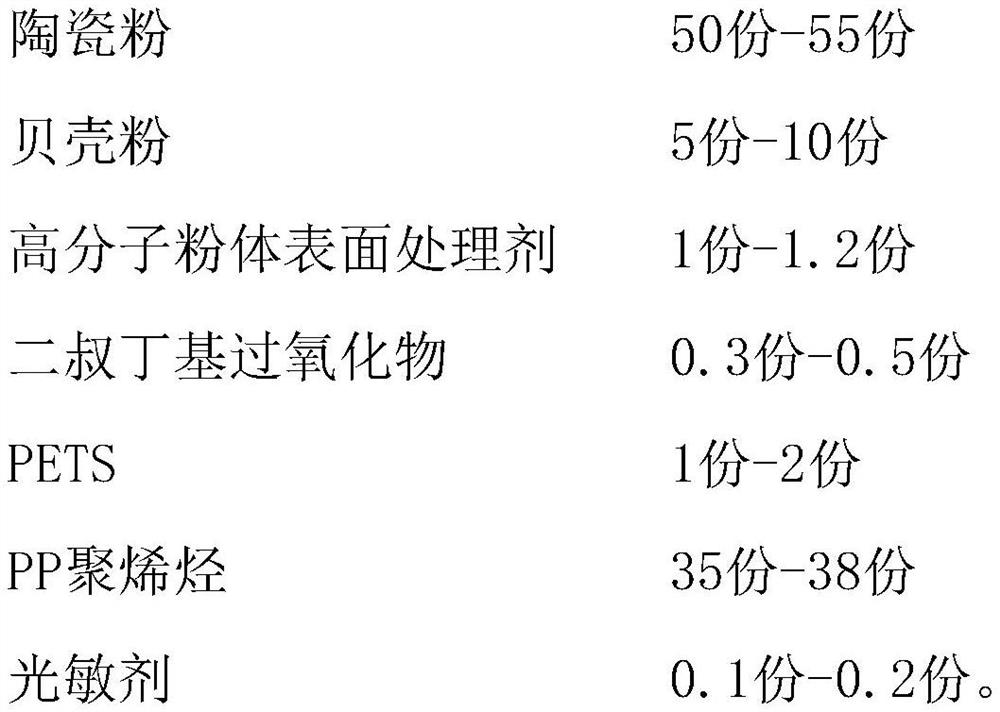

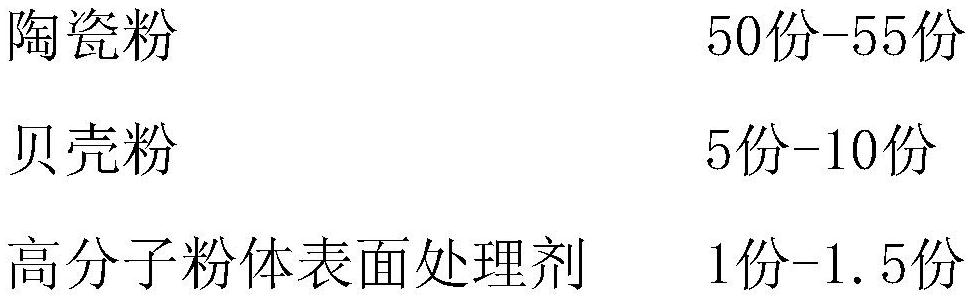

Thin-wall tableware resin for high-speed injection molding and preparation method thereof

The invention relates to the technical field of tableware resin, in particular to thin-wall tableware resin for high-speed injection molding and a preparation method thereof.The thin-wall tableware resin is prepared from, by weight, 50-55 parts of ceramic powder, 5-10 parts of shell powder, 1-1.5 parts of polymer powder surface treating agent, 0.3-0.5 part of di-tert-butyl peroxide, 1-3 parts of PETS and 35-40 parts of PP polyolefin. The thin-wall tableware resin is suitable for production of a high-speed injection molding machine, the production speed is larger than 5 seconds per mold number, and the thin-wall tableware resin is excellent in mechanical property, high in rigidity, resistant to heat, acid and alkali, oil, folding, tinting strength, solution flow index and other technical indexes and meets the standard of disposable degradation of thin-wall tableware.

Owner:东莞市柏林高分子材料有限公司

Regenerative foam material taking granite powder as raw material and preparation method of regenerative foam material

InactiveCN103073328BNo chemical pollutionSlow heat conductionCeramicwareEnvironmental resistanceGranolithic

The invention discloses a regenerative foam material taking granite powder as a raw material and a preparation method of the regenerative foam material. A formula of the regenerative foam material comprises the following components in parts by weight: 40-69 parts of granite powder, 2-8 parts of fly ash, 6-25 parts of fluxing filler, 1-5 parts of pore forming material, and 1-5 parts of polymeric material. The preparation method of the regenerative foam material sequentially comprises the following steps that grain fineness of the powder is controlled above 100 meshes; the powder is stirred and mixed uniformly; a mixture is pressed to a required granular material; the granular material is sent to a high-temperature furnace for warming, cooled and taken out; and a finished product is obtained. The regenerative foam material and the preparation method have the advantages that granite powder waste can be digested sufficiently; a long-term severe environmental pollution problem of a granite processing base can be solved; and environmental requirements can be met. The regenerative foam material is stable in physical property, light in weight, heat-insulated, compression-resistant and fracture-resistant, and can be used for building wall or external wall decoration; objectives of building weight reduction and energy saving can be achieved; in addition, the regenerative foam material has fireproof, waterproof and soundproof properties, and can be used for fireproof materials and wall partitioning materials.

Owner:宁波振强科技有限公司

Manufacturing method of recycled foam material using granite powder as raw material

InactiveCN102786316BNo chemical pollutionSlow heat conductionSolid waste disposalCeramicwarePrillMetallurgy

Owner:宁波振强科技有限公司

A kind of preparation method of high temperature resistant basket for food processing

The invention relates to a preparation method of a high temperature-resistant basket for food machining. The preparation method is characterized by comprising the following steps: 1) basket forming: the edge of a basket body is fixed on a metal frame to form a basket; 2) the metal frame is wrapped, and the edges thereof are sealed; 2.1) silica gel edge sealing bars matched with the metal frame are prepared; silicon rubber, a vulcanizing agent and color masterbatch are mixed as silicon resins; and then, silica gel blanks matched with the metal frame are prepared by an injection molding or compression molding mode, and are vulcanized by 2-5 min at 60-200 DEG C and 200-300 kg / cm2 to prepare the edge sealing bars; 2.3) the prepared silica gel edge sealing bars are put on an adhesive layer to wrap the metal frame, are put in a mold for hot pressing by 1-10 min at 120-330 DEG C, are put in an oven at 180-230 DEG C after demolding, and are heated by 30-180 min to prepare the high temperature-resistant basket.

Owner:NINGBO SUPERBRIGHT TECH

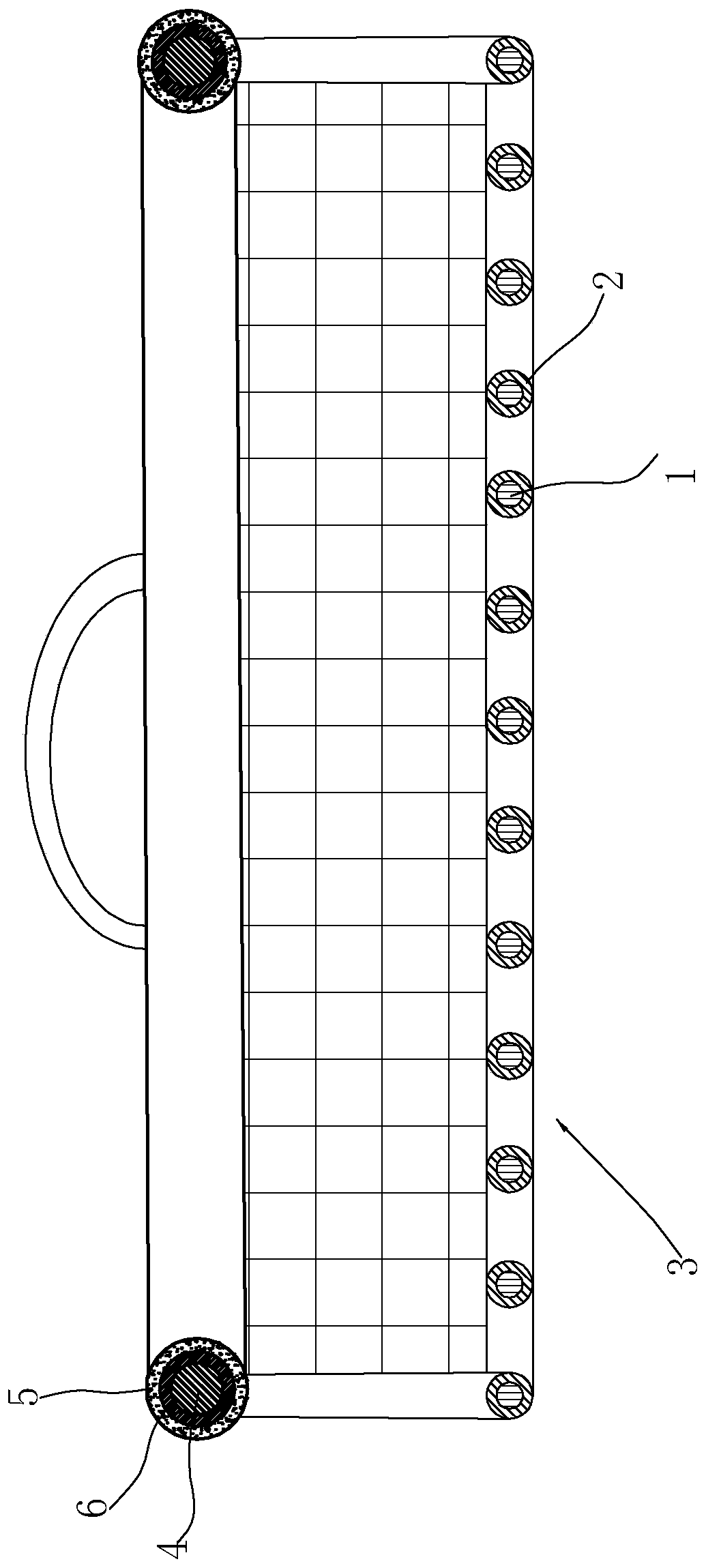

Health maintenance device

ActiveCN112336622AEasy to operatePrevent suck backDevices for heating/cooling reflex pointsPneumatic massagePharmacy medicineMedicine

The invention discloses a health maintenance device, which comprises a first jar body and a second jar body, wherein the first jar body and the second jar body are vertically arranged and are connected through a middle plate; the middle plate is provided with a first through hole; a gas pump is arranged in the first jar body; the gas pump used for evacuating gas in the second jar body communicateswith the first through hole; a heating plate (i.e. an element plate) and a medicine bag containing cavity are arranged in the second jar body; the heating plate (i.e. the element plate) and the medicine bag containing cavity are arranged in sequence from top to bottom; the bottom of the second jar body is opened; the top of the first jar body is provided with a control device; and the control device is used for controlling opening and closing of the heating plate and the gas pump. The health maintenance device has the beneficial effects that the health maintenance device combines cupping andmedicine hot fumigation into a whole, has a simple structure and is convenient to operate. Since the health maintenance device adopts a material of purple sands, the health maintenance device has goodthermal insulation performance, a moderate body feeling and low heat conduction speed and is unlikely to scald a user.

Owner:山东耒耜健康产业有限公司

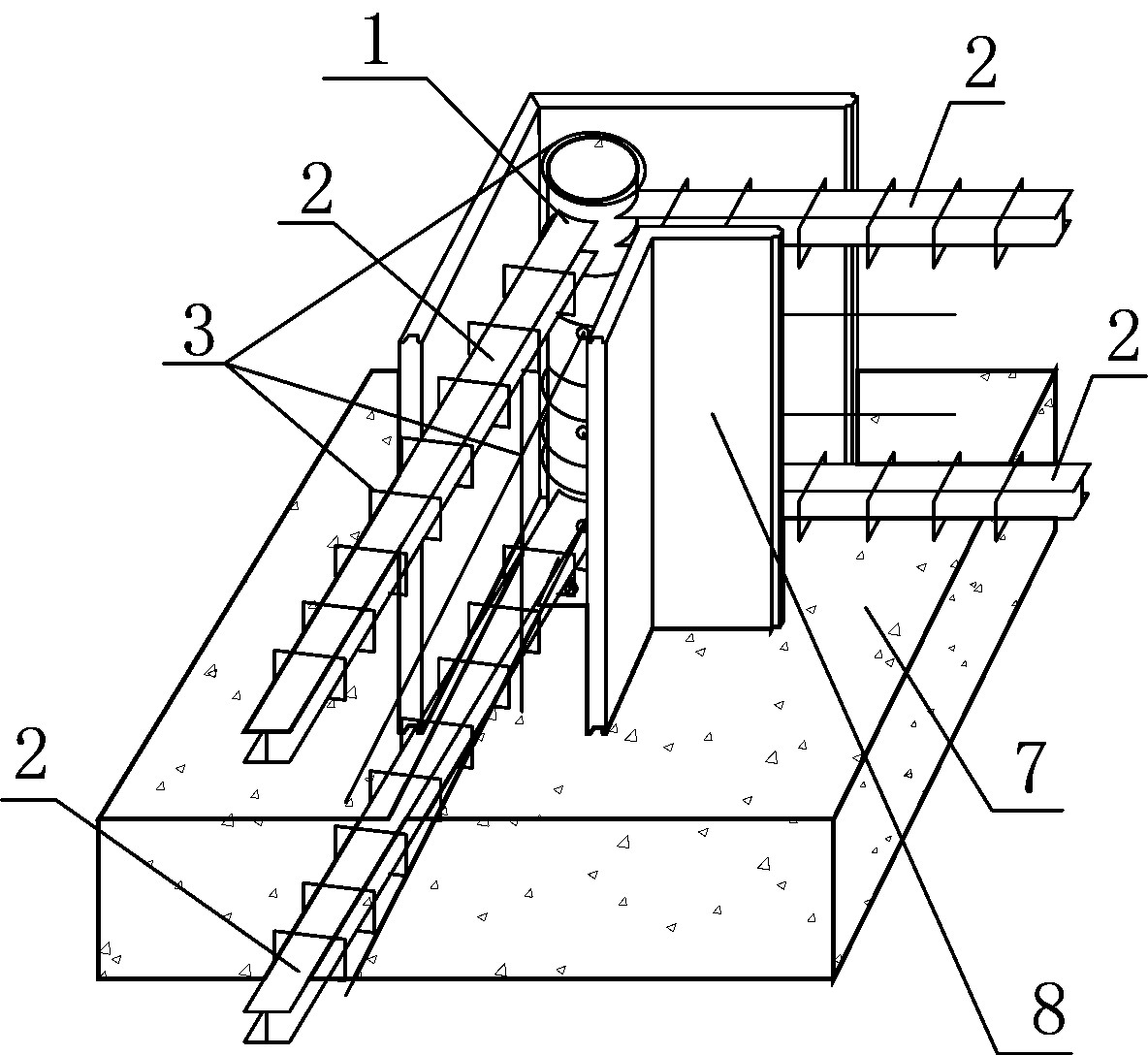

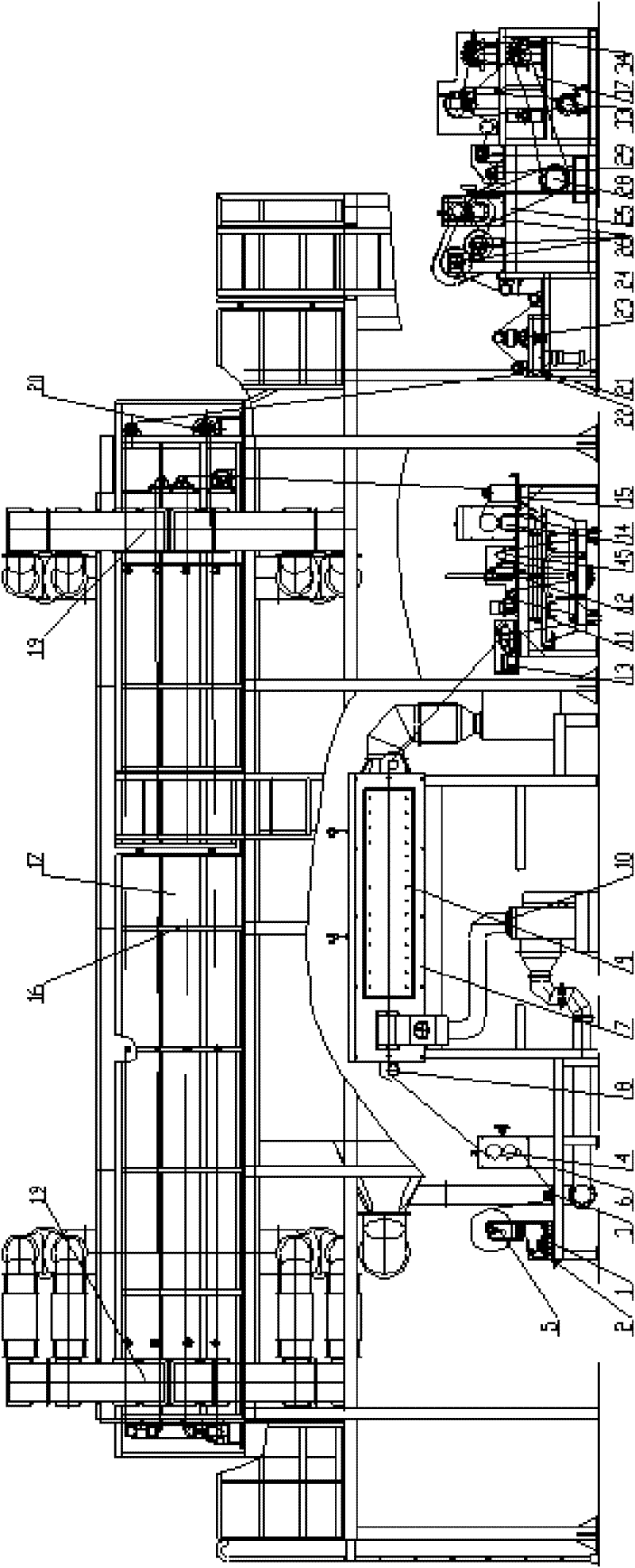

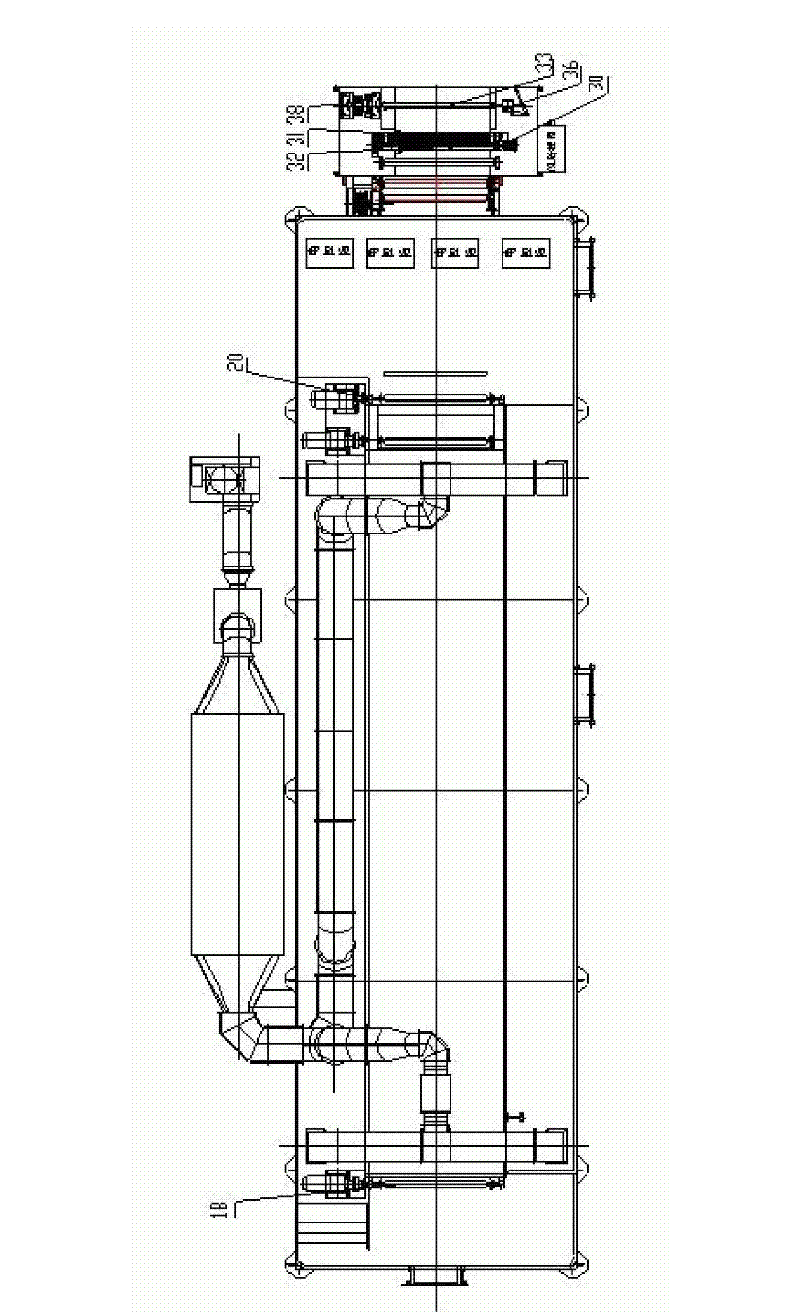

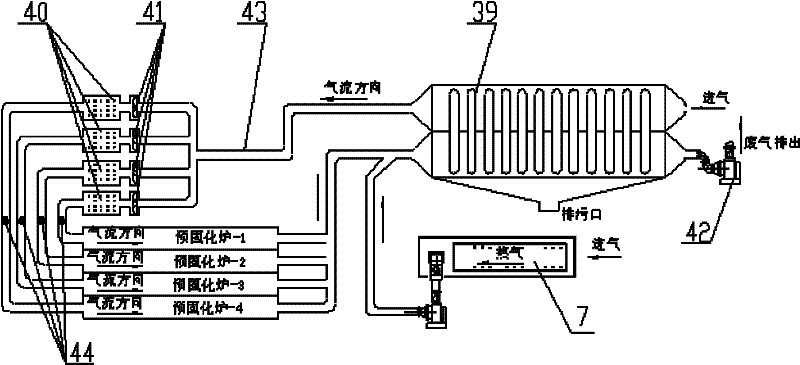

Dipping pre-curing production equipment for braided fiber cloth tapes

InactiveCN101597866BRealize double-layer layout structureSolve the lack of spaceAir heatersTextile/flexible product manufactureFiberCold air

The invention relates to production equipment for performing impurity removal, dipping and pre-curing treatment on braided fiber cloth tapes, which comprises a cloth feeding mechanism, a heat treatment furnace, a dipping device, a pre-curing furnace, a hot wind heating system, a deviation-correcting device, a tractor, a cloth cutting device, a winding device, an electrical control system and the like, wherein the pre-curing furnace comprises a main frame of a furnace body; and the pre-curing furnace body is arranged in an upper-layer space by the main frame of the furnace body. The equipment adopts a double-layer arrangement structure, fully utilizes the space, and saves the floor area of the equipment; the equipment adopts a heat exchanger mode, utilizes the heated air containing removedimpurities to preheat the cold air to be heated, and improves the utilization efficiency of energy sources; the equipment adopts infrared heating technology, and the braided fiber cloth tapes have high temperature rise speed and even heating; and the linear velocity of the traction is greatly improved, and the equipment has high production efficiency. In addition, the equipment also has the advantages of high automation degree, high control accuracy of temperature, tension, linear velocity and the like.

Owner:HONGYANG MACHINERY FACTORY

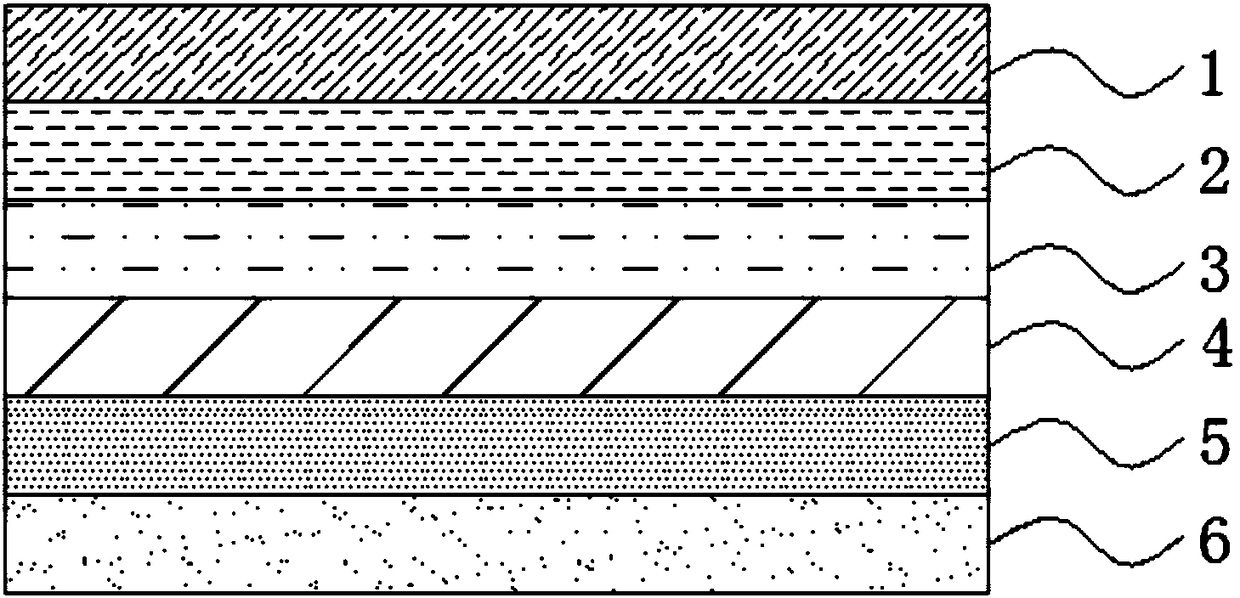

Waterproof wallpaper

InactiveCN108086609APrevent moistureGuaranteed service lifeCovering/liningsGlass/slag layered productsInsulation layerComposite material

The invention discloses waterproof wallpaper. The waterproof wallpaper comprises an antistatic layer, a waterproof layer, a fireproof layer, a sound insulation layer, a heat preservation layer and a mothproof layer; the antistatic layer is located on the upper surface of the waterproof layer, the waterproof layer is located on the upper surface of the fireproof layer, the fireproof layer is located on the upper surface of the sound insulation layer, the sound insulation layer is located on the upper surface of the heat preservation layer, and the heat preservation layer is located on the uppersurface of the mothproof layer; the thickness of the antistatic layer is 0.2-0.3 mm, the thickness of the waterproof layer is 0.1-0.15 mm, the thickness of the fireproof layer is 0.1-0.2 mm, the thickness of the sound insulation layer is 0.5-0.8 mm, the thickness of the heat preservation layer is 0.5-1 mm, the thickness of the mothproof layer is 0.2-0.3 mm, and the sum of the thicknesses of the antistatic layer, the waterproof layer, the fireproof layer, the sound insulation layer, the heat preservation layer and the mothproof layer is 1.8-2.5 mm. According to the waterproof wallpaper, the wallpaper and the surface of a wall are prevented from being wet, the service life and attractiveness of the wallpaper are ensured, and the wallpaper has the effects of sound insulation and heat preservation.

Owner:JIANGSU HENGHUI FOOD CO LTD

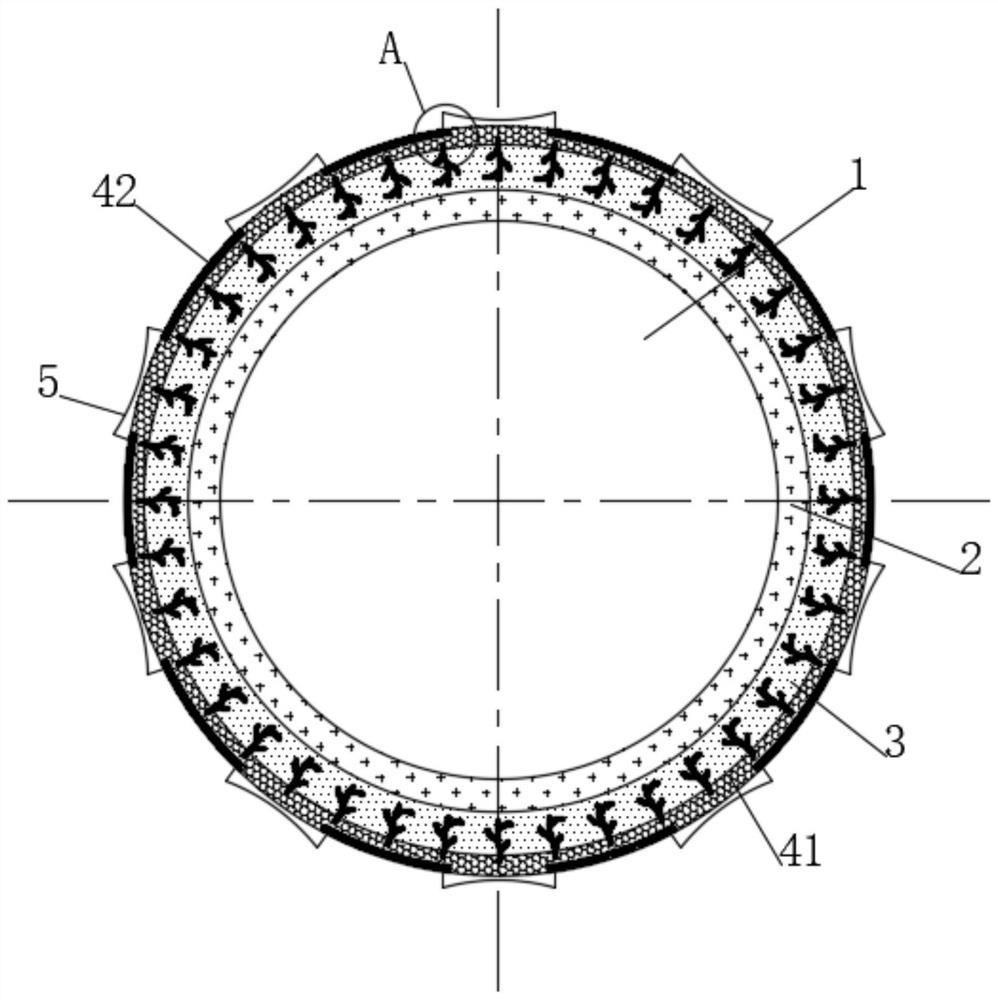

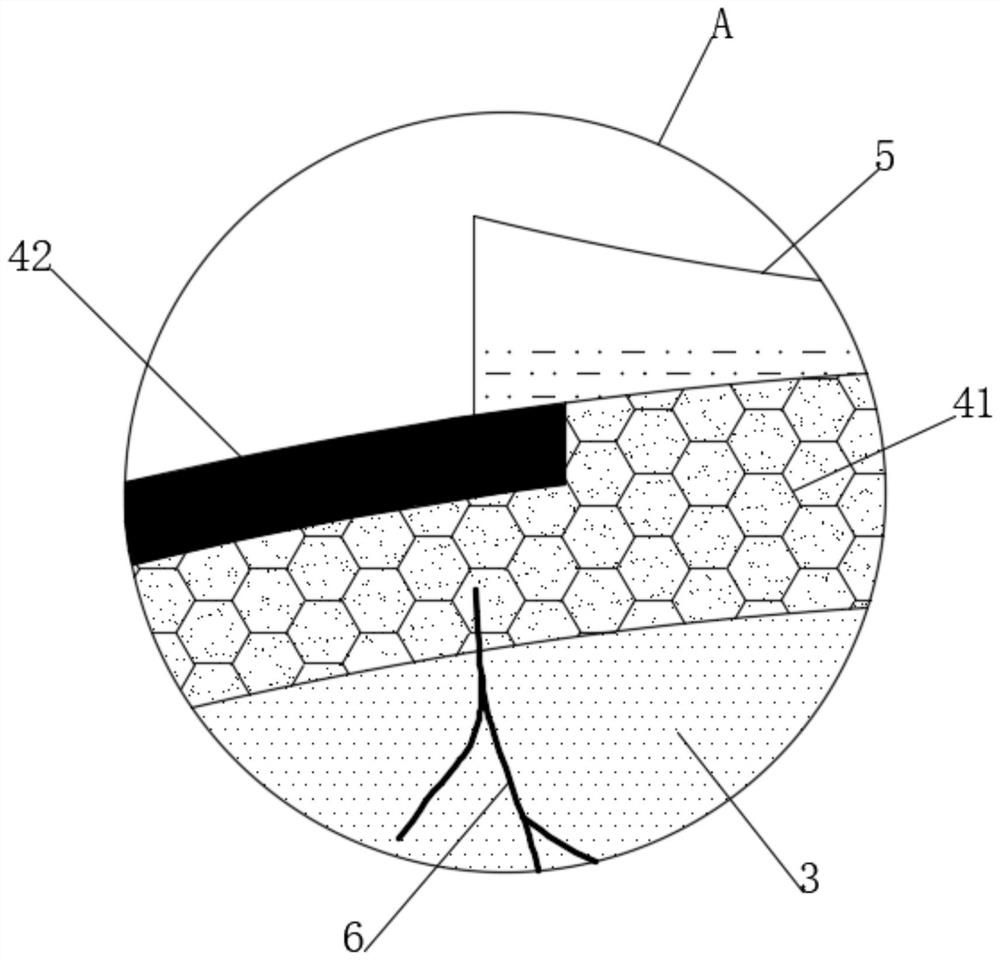

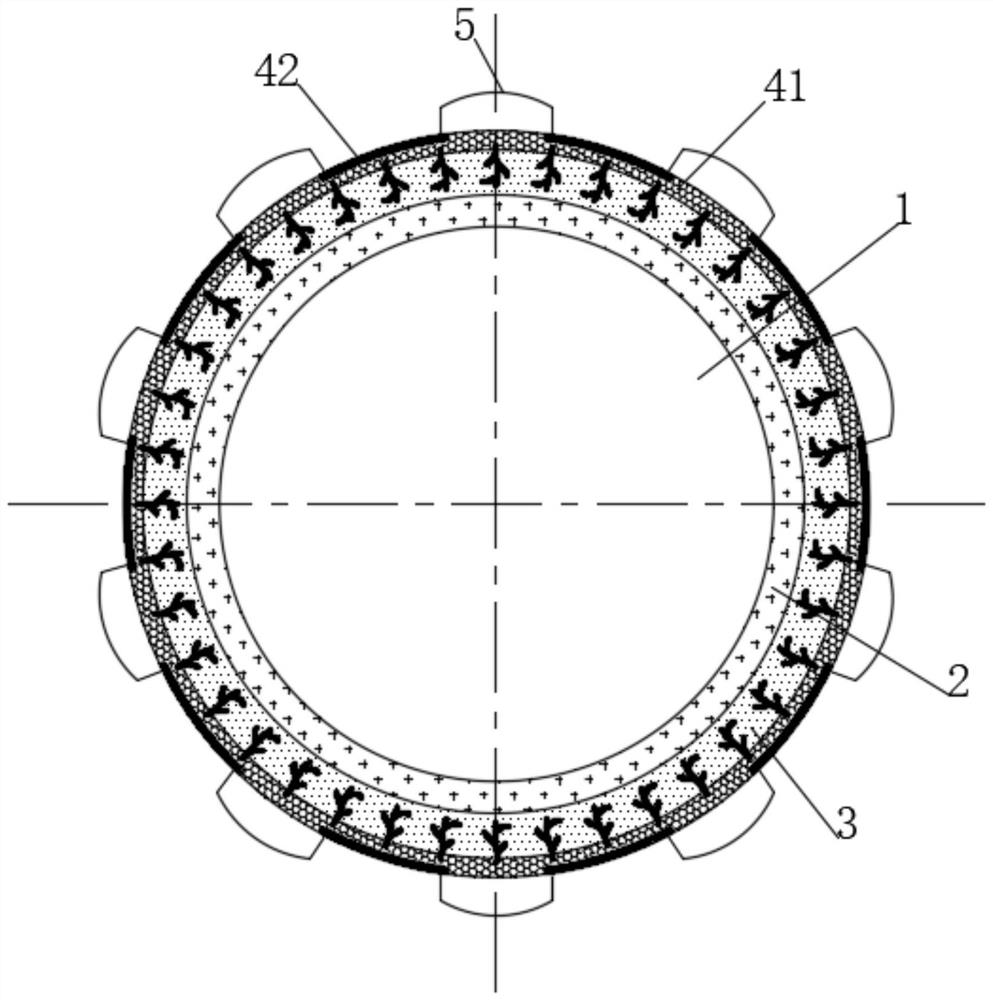

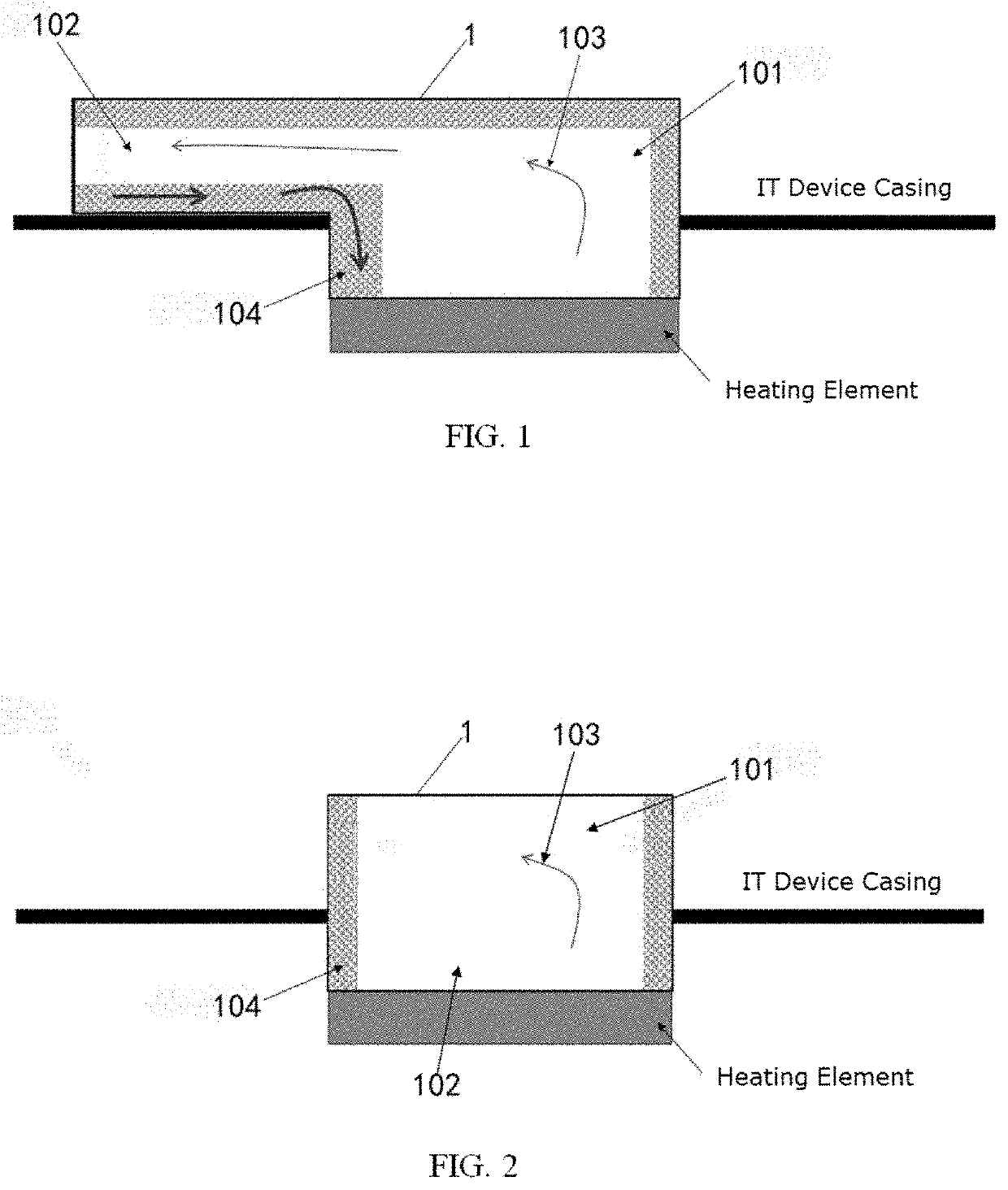

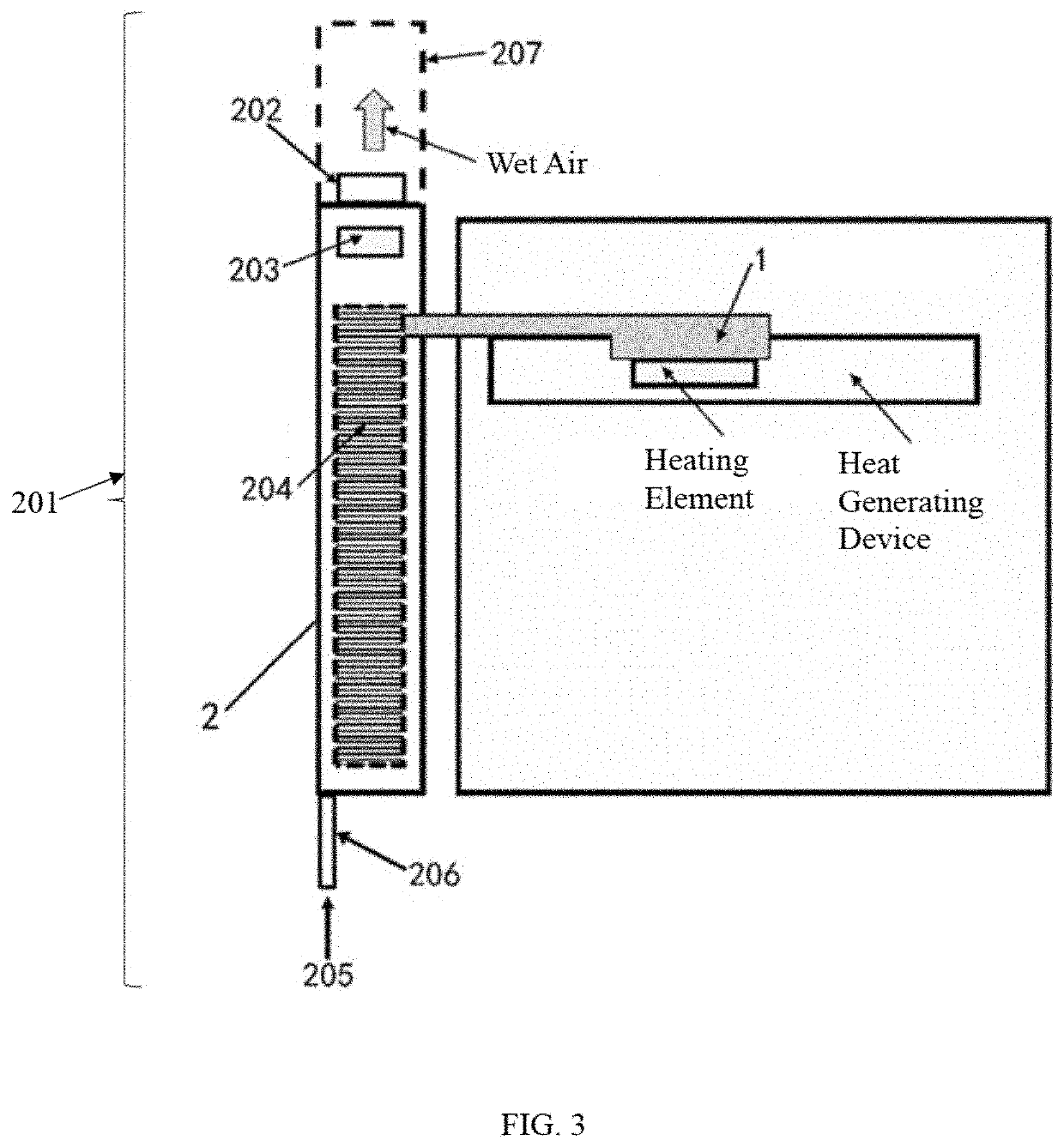

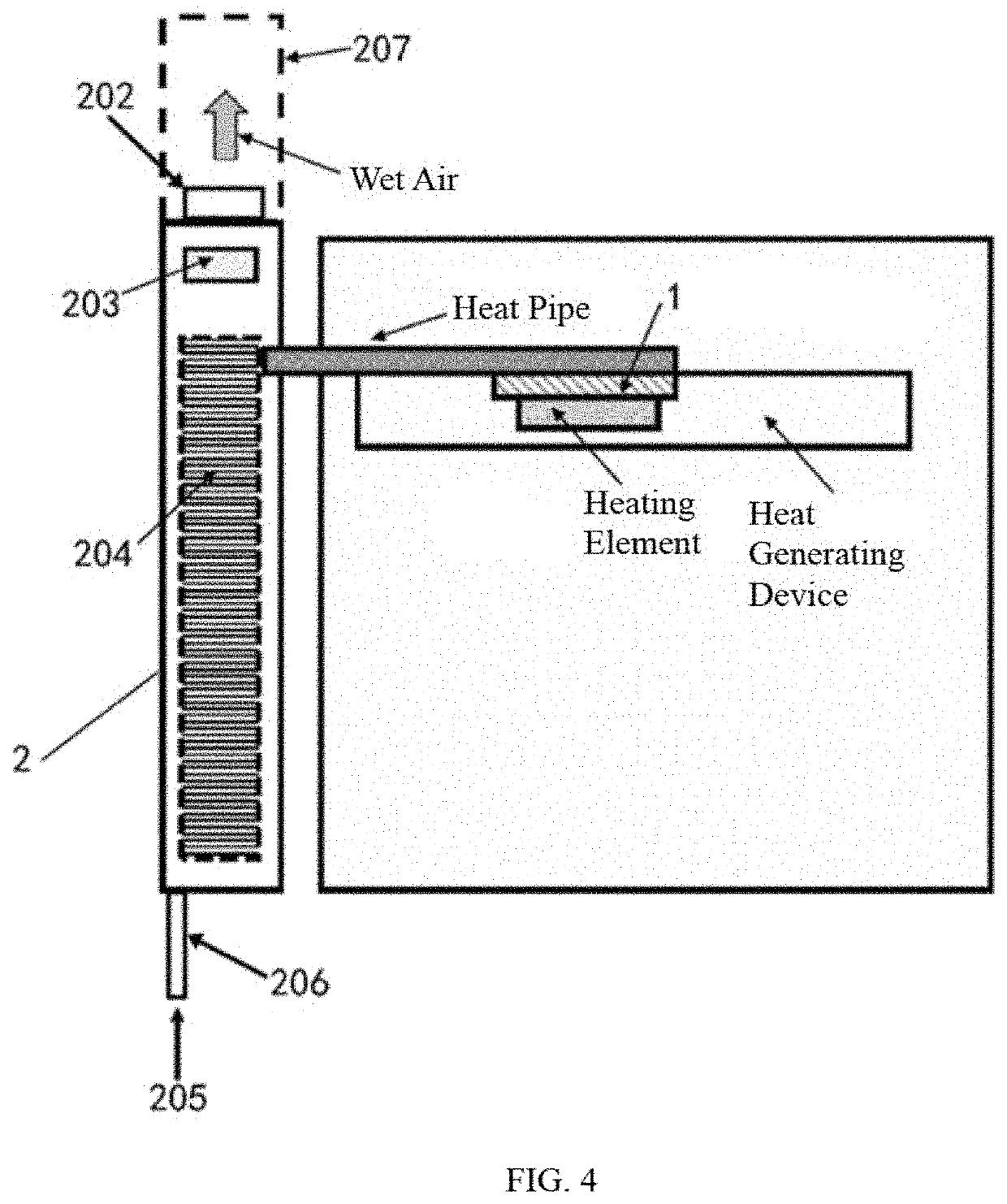

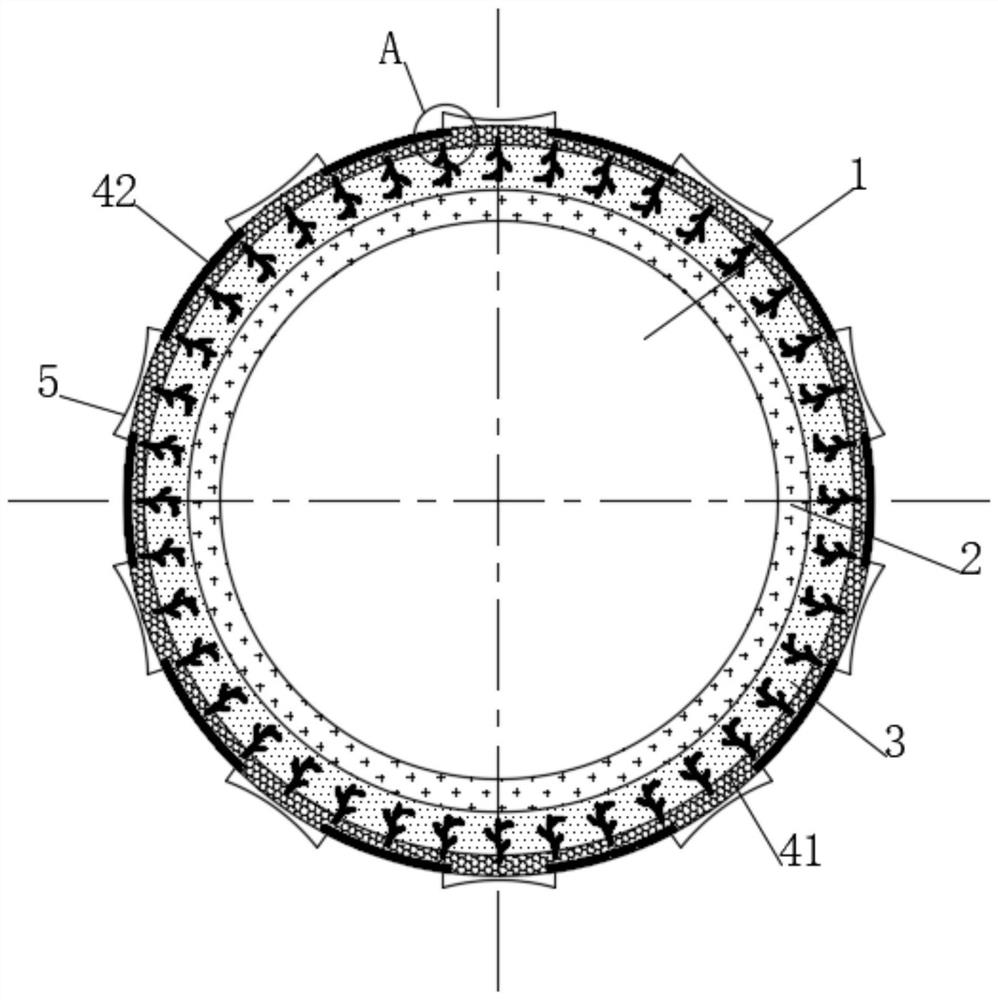

Evaporative cooling system

ActiveUS11441847B2Slow heat conductionImprove securitySemiconductor/solid-state device detailsEvaporators/condensersHeat conductingEngineering

An evaporative cooling system having a heat conducting device, the heat conducting device being capable of coupling to a heating element to be cooled and the heat conducting device comprising a first medium; a heat dissipating device having one or more heat dissipating outlets; and an evaporator disposed in the heat dissipating device and arranged in relation to the heat conducting device that is arranged at least partially outside the heat dissipating device. The heat dissipating device comprises a second medium, and the evaporator is configured to receive heat from the heat conducting device to heat the second medium of the heat dissipating device and discharge the heat from the one or more heat dissipating outlets of the heat dissipating device.

Owner:LENOVO (BEIJING) LTD

Dumbbell set structure

A dumbbell set structure comprises two metal connecting rods and dumbbell heads. The connecting rods are connected with the dumbbell heads, and the two connecting rods are connected to the two ends of a wood handle in a threaded connection mode. In the use process, the hand holds the wood handle, the heat conducting speed of wood materials is lower than that of metal, and a user cannot feel cold.

Owner:XIAN DAOHENG TRANSPORTATION EQUIP TECHCO

Novel hotpot strainer holding rack

The invention discloses a novel hotpot strainer holding rack, and relates to the field of dinner ware. The novel hotpot strainer holding rack comprises a supporting rod, a balancing base, a T-shaped sliding block and a pair of hooks, wherein the supporting rod is vertically arranged and is fixedly connected to the top face of the balancing base; a T-shaped sliding groove, which is matched with the T-shaped sliding block, is formed in the supportin rod; the T-shaped sliding groove is vertically arranged; the T-shaped sliding block is slidably connected into the T-shaped sliding groove and one end of the T-shaped sliding block extends out of the supporting rod; the pair of hooks are symmetrically arranged along the T-shaped sliding block, and the top ends of the pair of hooks are fixedly connected to the end, extending out of the supporting rod, of the T-shaped sliding block; a plurality of accommodating grooves are additionally formed in the supporting rod; the accommodating grooves are horizontally arranged and are formed in the end face of the side, away from the hooks, of the T-shaped sliding groove; and the plurality of accommodating grooves are uniformly distributed from top to bottom. The novel hotpot strainer holding rack disclosed by the invention has the characteristics of being slow in heat conducting speed, free from cleaning and free from hand-holding, long in service life and good in stability.

Owner:张鑫

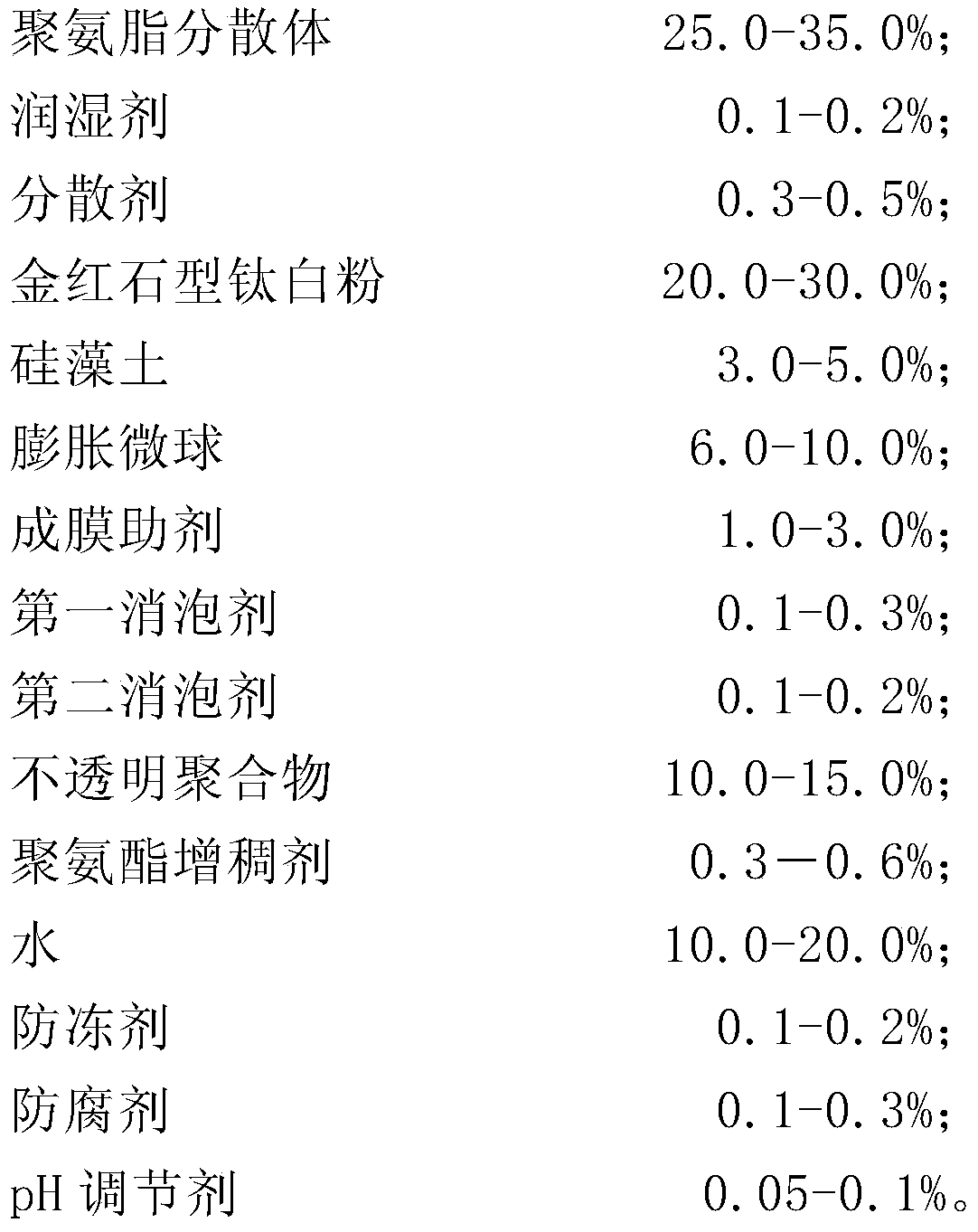

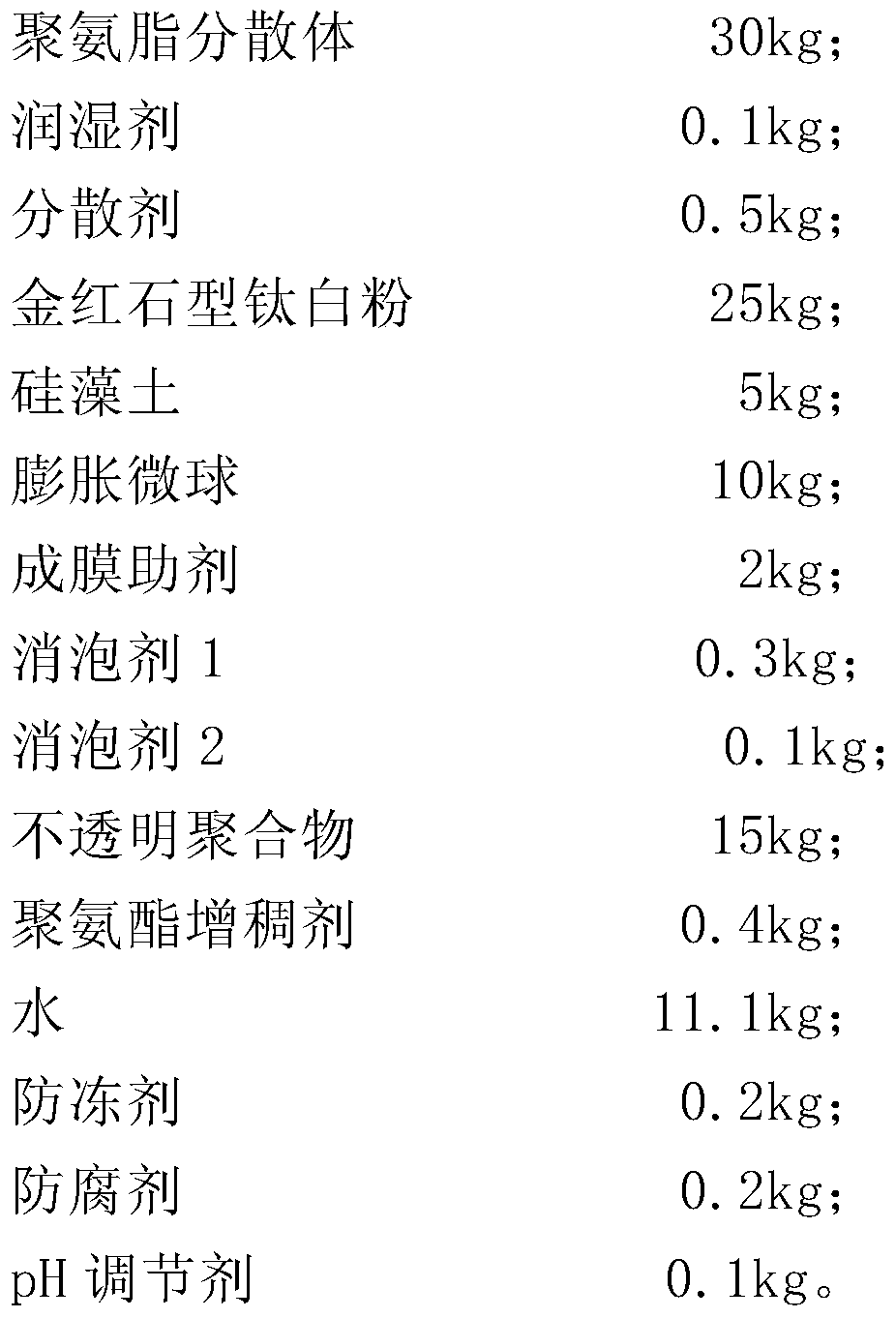

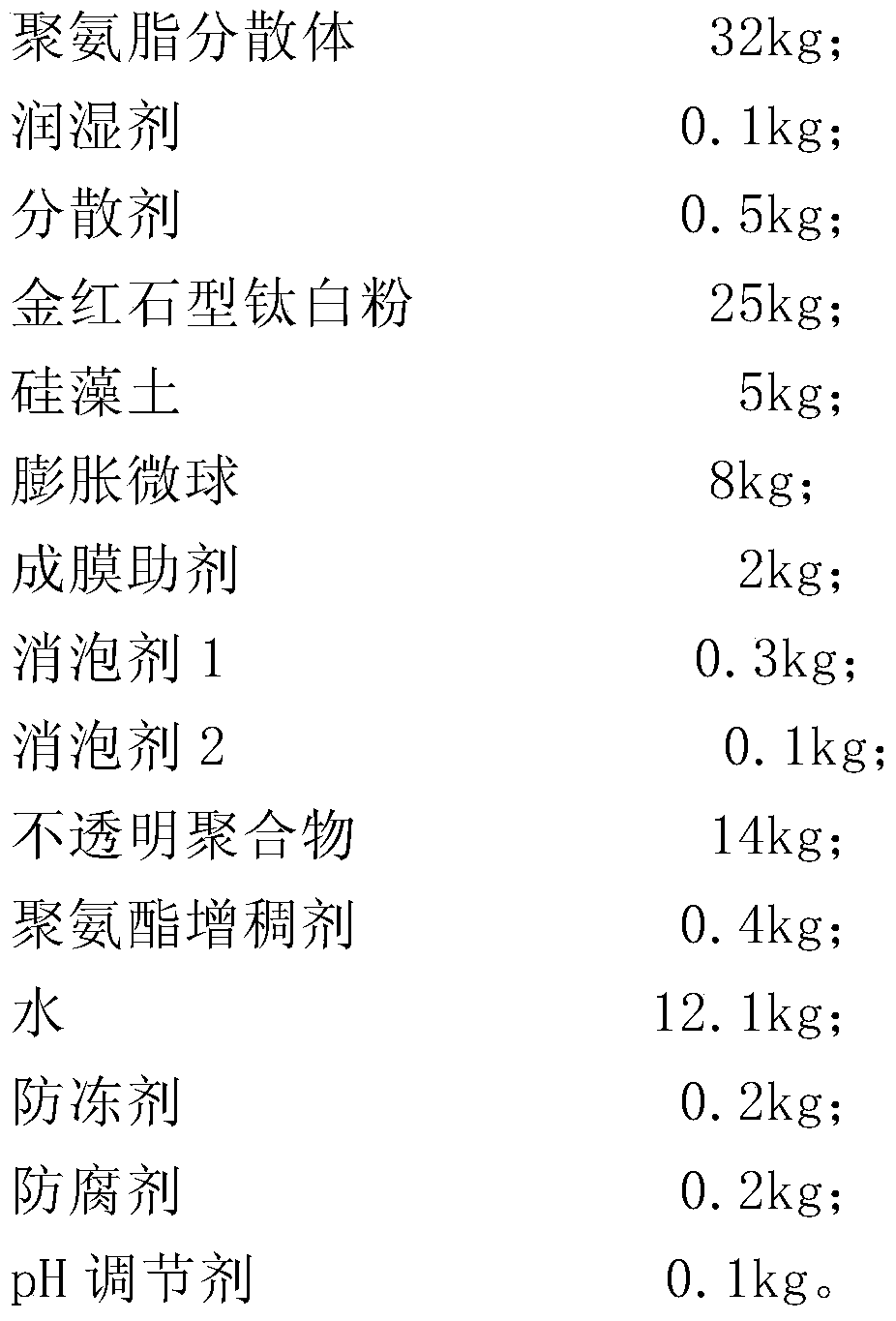

Energy-saving and environment-friendly interior wall paint and preparation method thereof

ActiveCN104962186BSoft and delicateIncrease in sizePolyurea/polyurethane coatingsMicrosphereEngineering

The invention provides interior wall paint with an energy conservation and environment protection function and a soft touch, wherein the interior wall paint is prepared from polyurethane dispersion, wetting agent, dispersing agent, rutile type titanium dioxide, diatomite, expanded microsphere, coalescing agent, defoamer, opaque polymer, polyurethane thickening agent, water, antifreezing agent, preservative and pH conditioning agent. The invention discloses the interior wall paint with the energy conservation and environment protection function, the heat conductivity coefficient is low, and the VOC (Volatile Organic Compounds) is not contained, meanwhile, the interior wall paint with the energy conservation and environment protection function has villi-like feel. The interior wall paint with the energy conservation and environment protection function provided by the invention can ensure stable room temperature, reduce air-conditioning energy consumption, the environmental performance is high, and the touch of a paint film is exquisite and soft.

Owner:SHANGHAI CARPOLY PAINT

Micromachined thermopile infrared detector

ActiveCN101575083BThe Seebeck coefficient is not affectedDissipate quicklyTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesThermopileReflective layer

The invention relates to the field of an infrared detector, in particular to a micromachined thermopile infrared detector. The manufacturing technique is simplified and the performance and finished product rate are improved. The manufacture of the micromachined thermopile infrared detector comprises the following steps of: (1) depositing silicon nitride film on the both sides of a silicon substrate by an LPCVD method; (2) etching to remove peripheral silicon nitride film on the frontal side of the silicon substrate by lithography; (3) manufacturing a plurality of Poly-Si strips both ends of which are respectively arranged on the silicon nitride film and the silicon substrate by LPCVD method and photolithographic process; (4) manufacturing a plurality of aluminum strips which form a thermocouple with the plurality of Poly-Si strips by sputtering and photolithographic processes; (5) depositing the silicon nitride film on the frontal side of the silicon substrate by PECVD method; (6) manufacturing an infrared absorption layer (a carbonized photoresist layer) covering the hot junction area of the thermopile with photolithographic process; (7) manufacturing a metal reflective layer (a metal layer) covering the cold junction area of the thermopile with lift-off process; and (8) eroding the back side of the silicon substrate to form a square frustum pyramid shaped groove. The micromachined thermopile infrared detector has reasonable structure design, simple manufacturing process, high detector performance, high finished product rate, good development prospect and is easy to realize.

Owner:ZHONGBEI UNIV

Continuous prebaked anode carbon block

The invention discloses a continuous prebaked anode carbon block. A carbon block body is included. The middle line of the long axis of the upper portion of the carbon block body is provided with a setof carbon bowls. The bottoms of the carbon bowls are provided with casting-mechanical composite steel claw connecting ring grooves. The middle lines of the long axes of the tops of the parts, on thetwo sides of the carbon bowls, of the carbon block body are provided with connecting convex heads. The bottoms of the parts, below the connecting convex heads, of the carbon block body are provided with penetration connecting grooves. The continuous prebaked anode carbon block has the beneficial effects that the continuous prebaked anode carbon block is matched with a casting-mechanical compositesteel claw, continuous usage of a prebaked anode can be achieved, the anode carbon block connecting time is short, usage is convenient, electrolysis energy consumption is reduced, anode scraps are eliminated, the labor intensity is lowered, and new and old carbon block bonding is firm. After an old carbon block is connected with the convex heads and cooled, the old carbon block is connected with anew carbon block, new and old carbon block bonding and connecting reliability and firmness are ensured, and bonding layer shearing is prevented; and through the structures and the usage manners of the connecting convex heads, the carbon bowls and filling blocks, usage of the casting-mechanical composite steel claw is effectively matched, and an existing electrolytic cell can be directly connectedwith the anode carbon block.

Owner:贵州铝城铝业原材料研究发展有限公司

A double-state temperature-changing cold-proof and frost-proof cable

ActiveCN111816355BImprove high temperature resistanceExtended service lifeInsulated cablesInsulated conductorsEngineeringElectric cables

Owner:山东青江线缆有限公司

Special robot for fire scene video acquisition

InactiveCN112337014ASlow heat conductionAvoid failureTelevision system detailsDomestic cooling apparatusPhysicsFirefighting

The invention relates to the technical field of fire fighting, in particular to a special robot for fire scene video acquisition. The special robot for fire scene video acquisition comprises a machinebody; a group of buffer devices are arranged on the lower side of the machine body; a wheel body is arranged on each buffer device; a first mounting hole is formed in one side of the machine body; acamera device is mounted in the first mounting hole; an emergency cooling device is arranged above the machine body; two oppositely-arranged fire extinguishing devices are arranged on the side, provided with the first mounting hole, of the machine body; a dry powder box and a cooling liquid box are arranged in the machine body; and a water pump is arranged in the cooling liquid box. According to the special robot for fire scene video acquisition, a first rim is supported through a V-shaped spring plate, so that heat conduction between a wheel shaft and the ground is slowed down, circulating water is controlled to take away heat in a water-cooled lens in a water-cooled cavity in the water-cooled lens, the cooling effect of the device is further improved, and the high-temperature adaptability of the device is improved.

Owner:安徽晟东科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com