Energy-saving and environment-friendly interior wall paint and preparation method thereof

An energy-saving and environmentally friendly wall paint technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of poor coating functions and effects, and achieve the effects of eliminating indoor odor, slow heat conduction, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

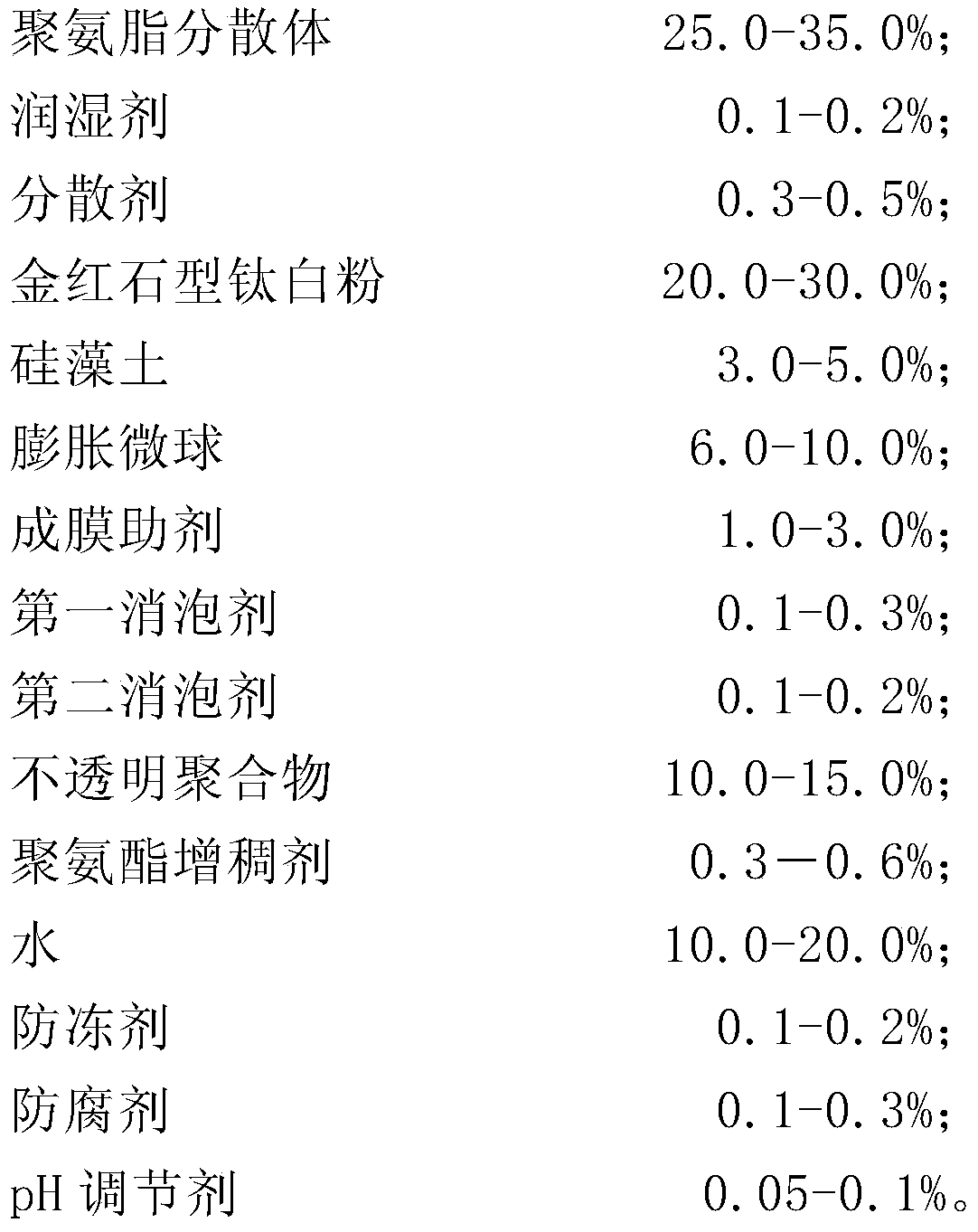

[0035] Components (weight) of energy-saving and environmentally friendly interior wall paint:

[0036]

[0037] The polyurethane dispersion adopts Archsol from Wanhua Chemical Group Co., Ltd. TM 8558 aliphatic water-based polyurethane dispersion, which is anti-yellowing, anti-hot sticking, delicate and soft to the touch.

[0038] The wetting agent is DOW's BD109, zero VOC, and does not contain APEO.

[0039] The dispersant is Orotan 1124 from DOW, which has excellent dispersing ability to titanium dioxide.

[0040] The rutile titanium dioxide is DuPont's R706.

[0041] The diatomite is Celite MW25, which is porous, high in porosity, light in weight, large in specific surface area and high in whiteness.

[0042] The expanded microspheres are AKZO's 461WE40d36, which has low specific gravity, low thermal conductivity and soft touch.

[0043] Coasol dibasic acid dibasic ester from DOW is used as the film-forming aid, which has a low odor and a boiling point of 287°C.

[0...

Embodiment 2

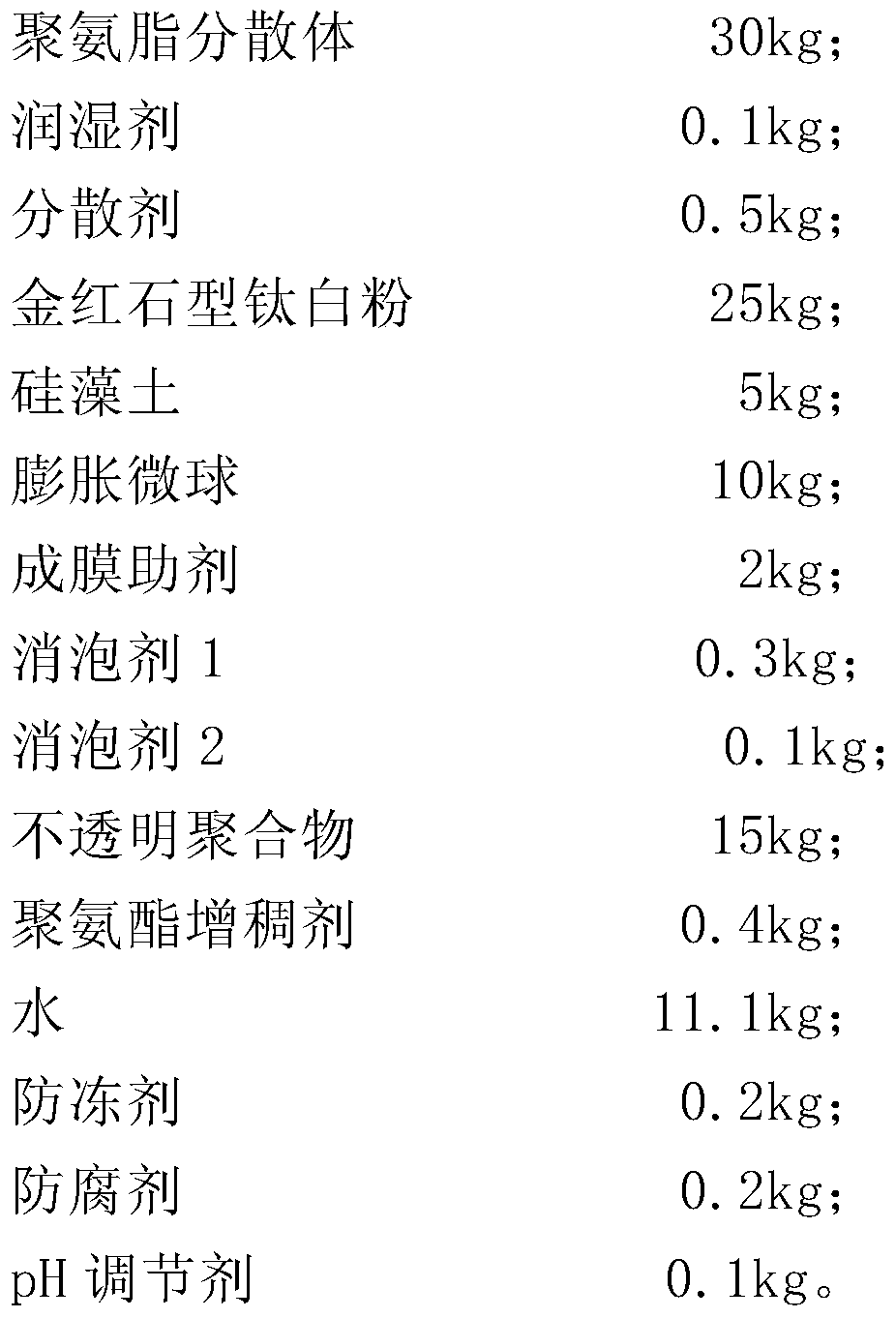

[0056] Components (weight) of energy-saving and environmentally friendly interior wall paint:

[0057]

[0058] Add the polyurethane dispersion, wetting agent, and dispersant in sequence according to the ratio, and stir evenly at a speed of 400-600rpm. While stirring, add rutile-type natural titanium dioxide, diatomaceous earth, and expanded microspheres in sequence at a speed of 1200rpm. - Disperse at high speed for 20-30min at 1500rpm, fineness≤60μm. Then add film-forming aids, defoamer 1, defoamer 2, opaque polymer, polyurethane thickener, water, preservative, and at a speed of 600 Stir at -800rpm for 15-20min until uniform, adjust the viscosity to 90-100KU / 30°C (Stormer viscometer) to obtain the finished product.

[0059] The detection performance of this embodiment is as follows:

[0060] 1. Test board production

[0061] Test plate production conditions as shown in the table

[0062] test board

Coating method

film thickness

...

Embodiment 3

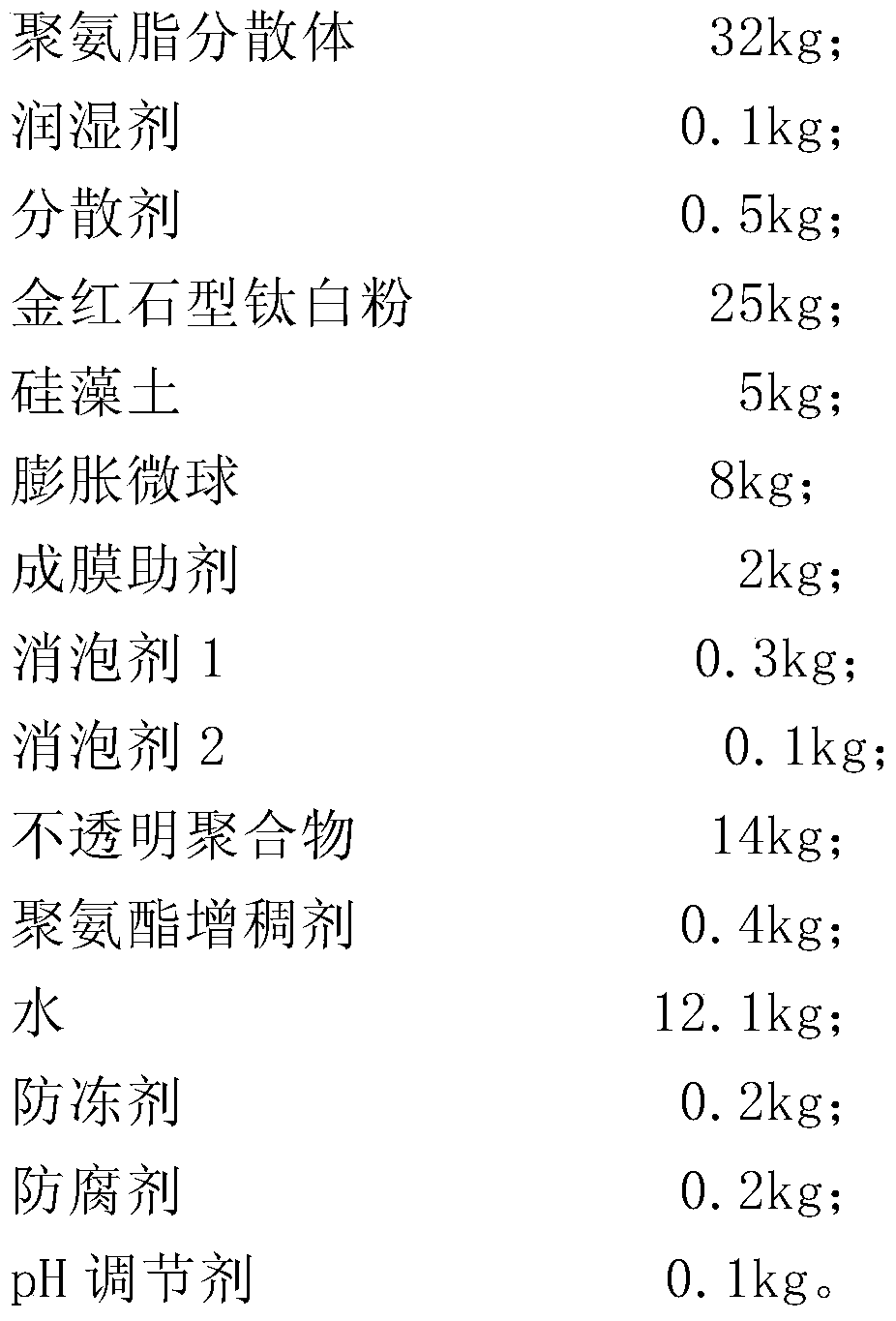

[0069] Components (weight) of energy-saving and environmentally friendly interior wall paint:

[0070]

[0071] Add the polyurethane dispersion, wetting agent, and dispersant in sequence according to the ratio, and stir evenly at a speed of 400-600rpm. While stirring, add rutile-type natural titanium dioxide, diatomaceous earth, and expanded microspheres in sequence at a speed of 1200rpm. - Disperse at high speed for 20-30min at 1500rpm, fineness≤60μm. Then add film-forming aids, defoamer 1, defoamer 2, opaque polymer, polyurethane thickener, water, preservative, and at a speed of 600 Stir at -800rpm for 15-20min until uniform, adjust the viscosity to 90-100KU / 30°C (Stormer viscometer) to obtain the finished product.

[0072] The detection performance of this embodiment is as follows:

[0073] 1. Test board production

[0074] Test plate production conditions as shown in the table

[0075] test board

Coating method

Coating viscosity

film thickness

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com