Assembly type combined mold platform

A combined mold and assembly technology, applied in the direction of workbench, manufacturing tools, etc., can solve the problems that non-professional manufacturers cannot repair, the production cost is high, and the energy consumption of motion is high, and the production cost is low, the weight is light, and the energy consumption of motion is low. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

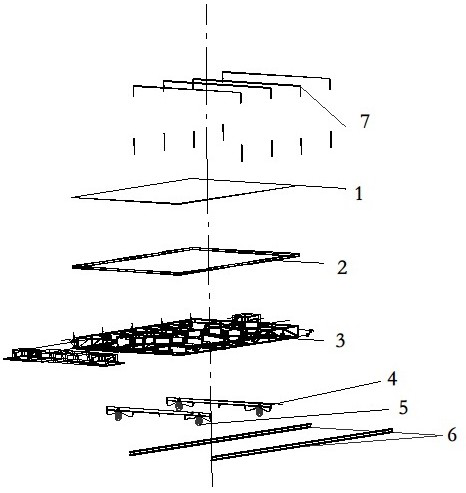

[0040] Refer to attached Figure 1-6 , the prefabricated combined mold platform includes wooden mold surface plate 1, GRC material (glass fiber reinforced concrete) load-bearing structural plate 2, composite shaped steel frame 3, load-bearing beam 4, track wheel 5 and track 6.

[0041] The upper part of the composite stereotyped steel frame 3 is provided with a GRC material (glass fiber reinforced concrete) load-bearing structural plate 2, and the upper part of the GRC material (glass fiber reinforced concrete) load-bearing structural plate 2 is compounded with a wooden mold surface plate 1. Composite stereotyped steel frame 3 is equipped with bearing beam 4, and track wheel 5 is equipped with on the lower part of bearing beam 4. Rail wheel 5 cooperates with track 6, is convenient to assembly type combination mold platform travel.

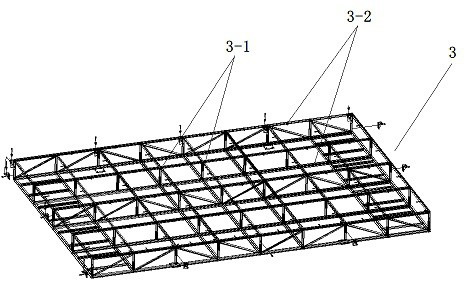

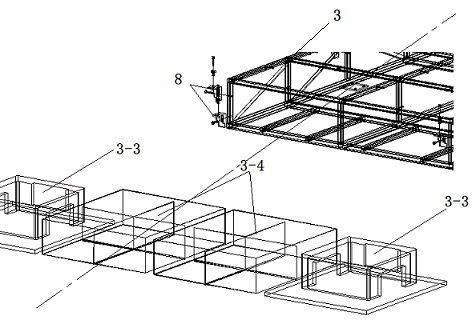

[0042] The composite shaped steel frame 3 has an overall qualitative structure formed by cross-stacking and welding of bending-resistant longitud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com