Continuous prebaked anode carbon block

A prebaked anode and carbon block technology, which is applied in the field of continuous prebaked anode carbon blocks, can solve the problems of electric energy waste, environmental pollution, and time-consuming replacement of anodes, and achieve the effect of reducing heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

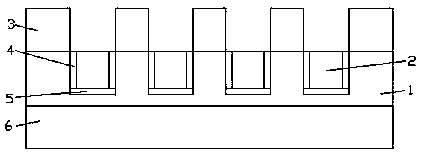

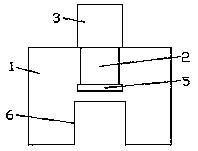

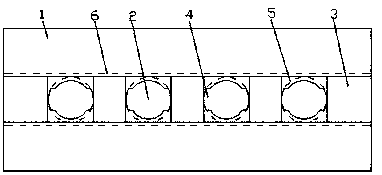

[0052] Example. A continuous prebaked anode carbon block consisting of Figure 1-9 As shown, it includes a carbon block body 1, a group of carbon bowls 2 are arranged on the long axis center line on the top of the carbon block body 1, a steel claw connecting ring groove 5 is provided at the bottom of the carbon bowl 2, and the long axis of the top of the carbon block body 1 above the carbon bowl 2 A connection protrusion 3 is provided on the center line, and a through connection groove 6 is provided at the bottom of the carbon block body 1 below the connection protrusion 3 .

[0053] The wall of the charcoal bowl 2 is provided with a mechanical steel claw channel vertical groove 4.

[0054] The thickness of the carbon block body 1 is 400-500 mm.

[0055] The carbon bowl 2 of the old carbon block ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com