Micromachined thermopile infrared detector

An infrared detector and thermopile technology, applied in the field of infrared detectors, can solve the problems of increased temperature difference between the hot junction area and the cold junction area, lower detection sensitivity of the detector, complicated process, etc., and achieve high yield and good quality Development prospects, the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

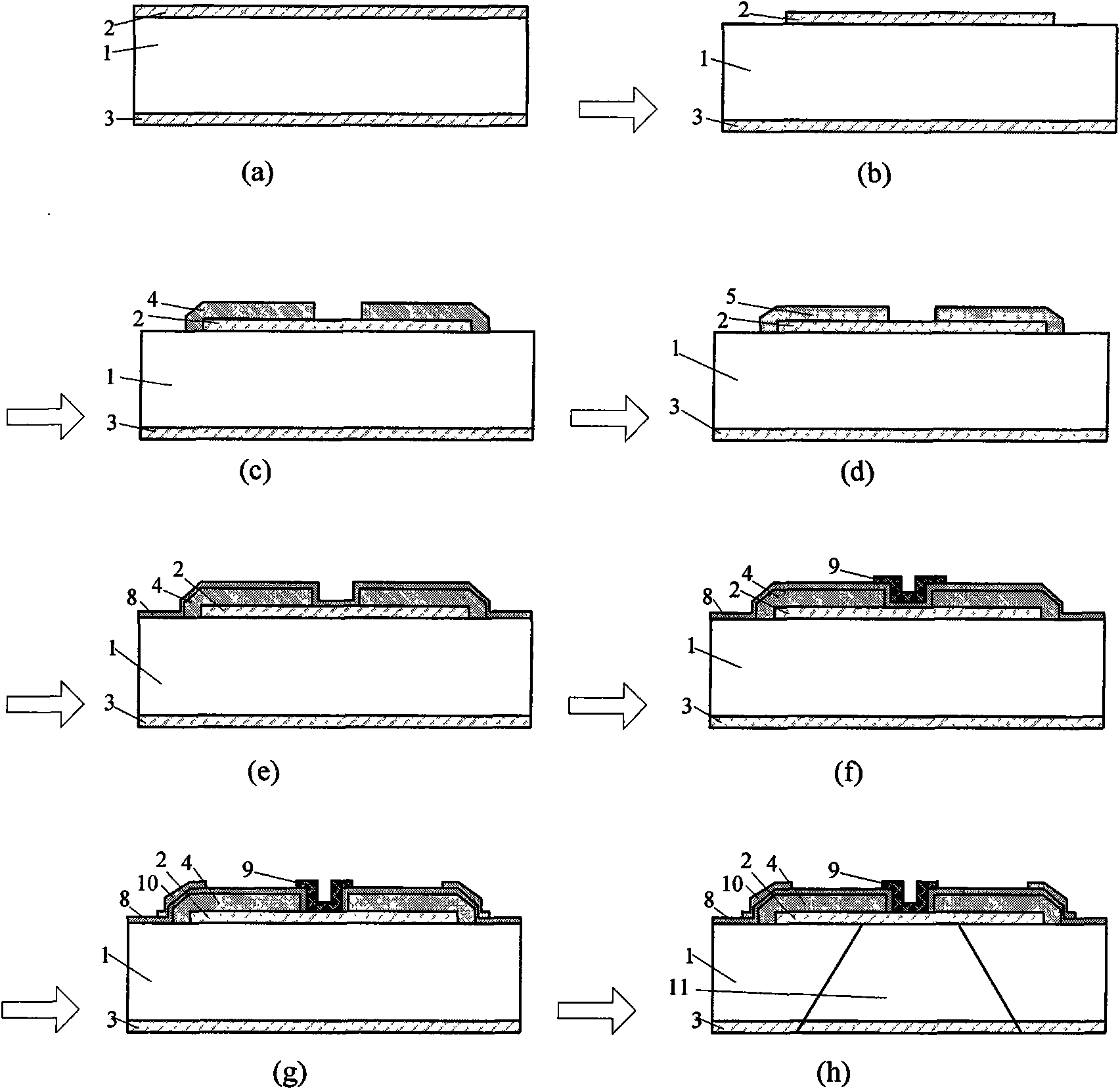

[0023] The thermopile infrared detector is made according to the following method:

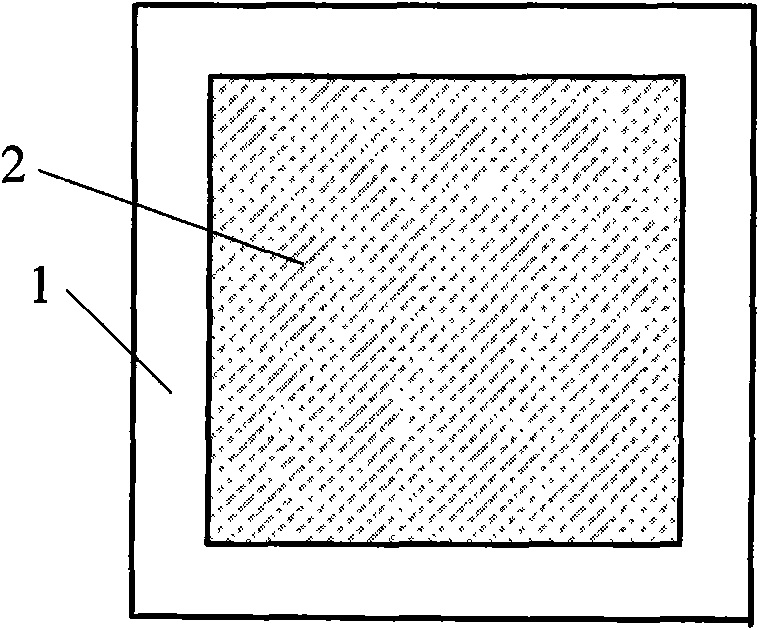

[0024] ①. At a temperature of 940°C, adjust the flow rate of the reaction gas source, and deposit low-stress silicon nitride films 2 on the front and back sides of the double-sided polished p-type high-resistance silicon substrate 1, respectively, by LPCVD. 3. No need for high temperature annealing; see figure 1 as shown in a;

[0025] ②. Using photolithography and etching processes to remove the peripheral silicon nitride film on the front side of the silicon substrate 1, and retain the silicon nitride film 2 in the central area; see figure 1 b, as shown in 2;

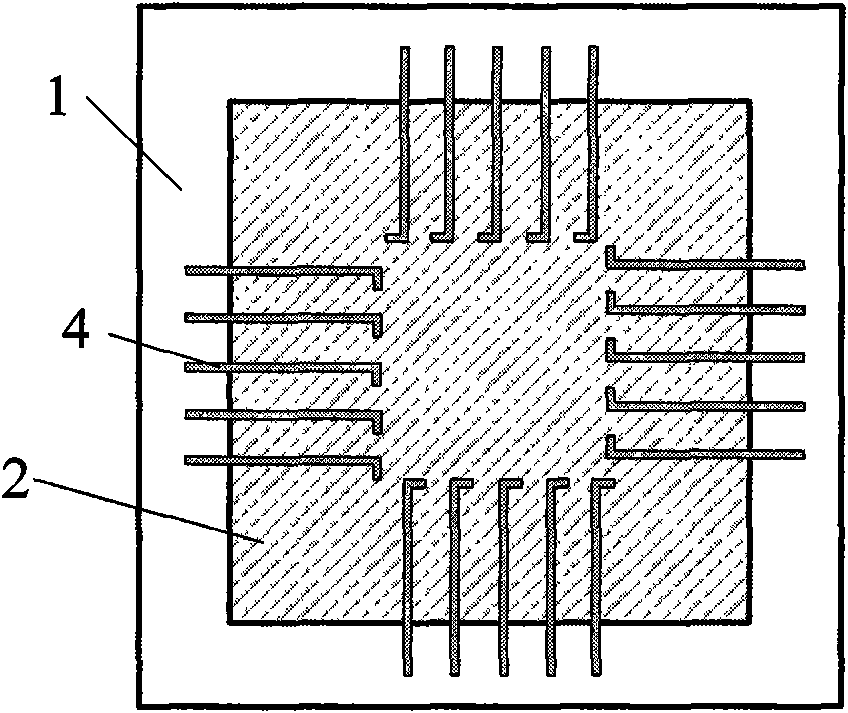

[0026] ③. Deposit a polysilicon layer on the surface of the silicon nitride film 2 in the central area of the front side of the silicon substrate 1 and the surface of the peripheral silicon substrate by LPCVD, and then use photolithography and dry etching to form a number of ends on the silicon nitride film 2, The other end is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com