Thin-wall tableware resin for high-speed injection molding and preparation method thereof

A thin-walled, high-speed technology, applied in the field of tableware resin, can solve the problem that thin-walled injection-molded tableware cannot be applied, and achieve the effect of excellent mechanical properties and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

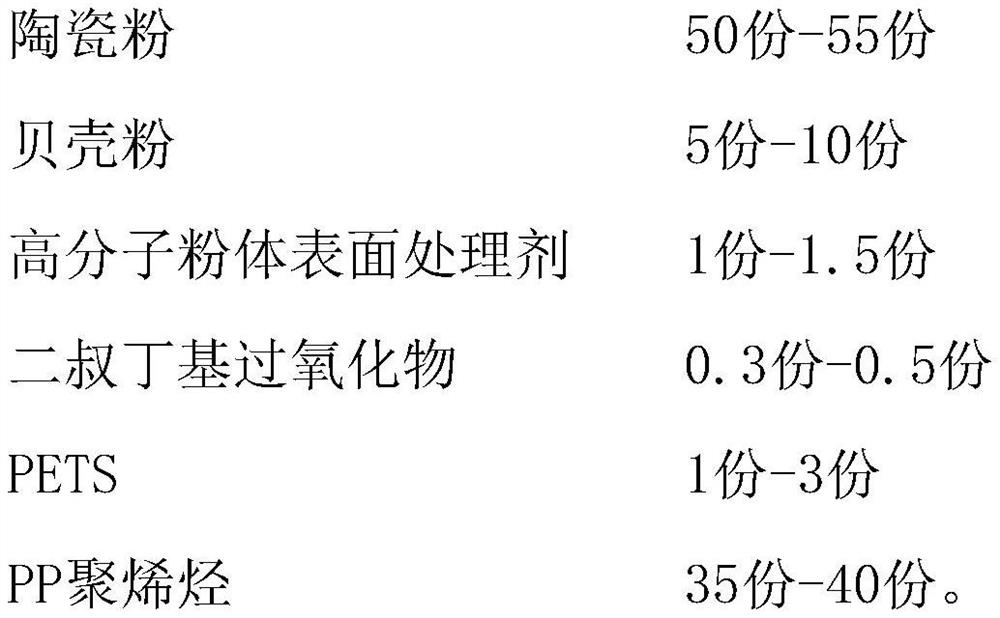

[0042] A thin-walled tableware resin for high-speed injection molding, comprising the following raw materials by weight:

[0043]

[0044]

[0045] The preparation method of thin-wall tableware resin for high-speed injection molding comprises the following steps:

[0046] (1) put ceramic powder and shell powder into high-speed mixer for mixing and stirring, then add polymer powder surface treatment agent, carry out surface treatment, and obtain primary material;

[0047] (2) drop remaining raw material into the primary material of step (1), carry out mixing, obtain mixed material;

[0048] (3) The mixture prepared in step (2) is extruded and granulated through a twin-screw extruder to obtain the thin-wall tableware resin for high-speed injection molding.

[0049] A thin-walled tableware resin for high-speed injection molding. When preparing thin-walled tableware, a high-speed injection molding machine is used for injection molding. 255°C.

Embodiment 2

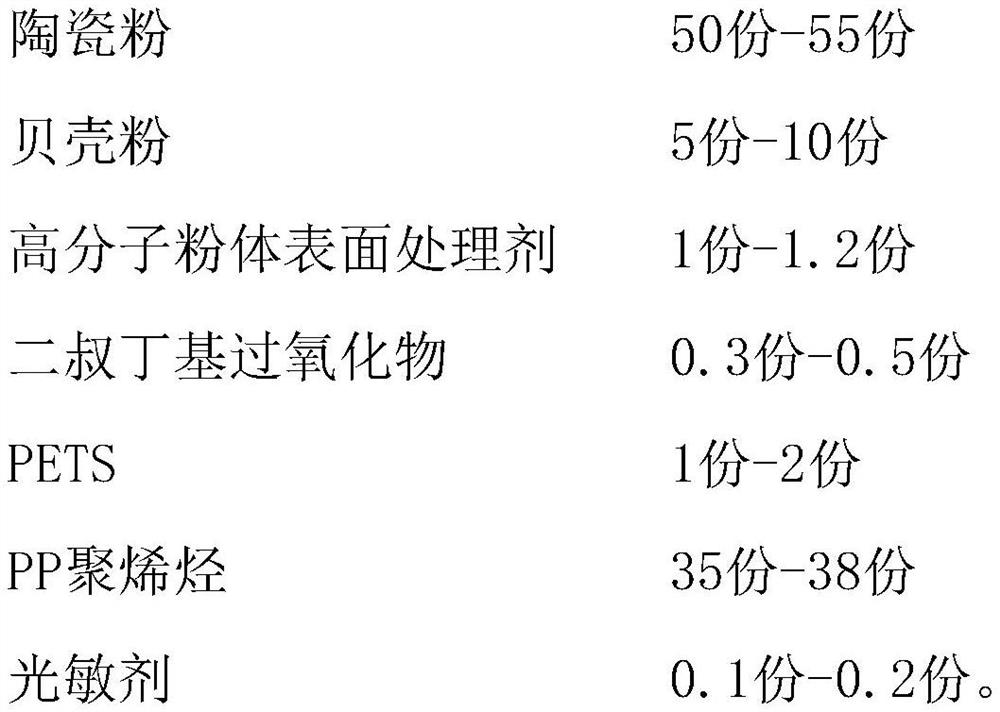

[0051] A thin-walled tableware resin for high-speed injection molding, comprising the following raw materials by weight:

[0052]

[0053] The preparation method of the thin-wall tableware resin for high-speed injection molding in this example is the same as that in Example 1.

Embodiment 3

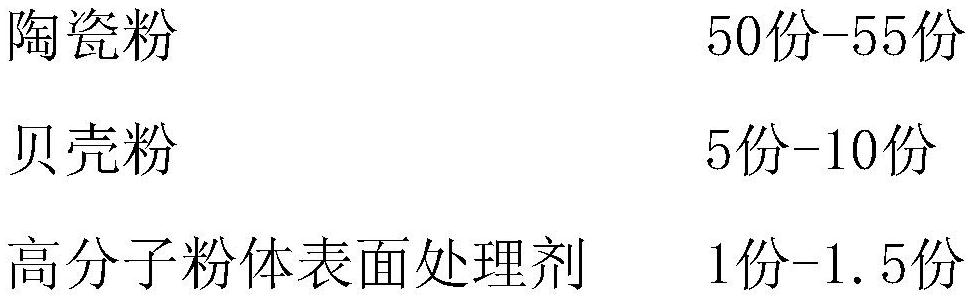

[0055] A thin-walled tableware resin for high-speed injection molding, comprising the following raw materials by weight:

[0056]

[0057]

[0058] The preparation method of the thin-wall tableware resin for high-speed injection molding in this example is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com