A kind of coating for electronic product shell and its preparation method and application

A technology for electronic products and shells, which is applied in the field of coatings for electronic product shells and its preparation, can solve the problems of incompatibility of high factor value and high leveling property at the same time, and achieve excellent post-machinability, high leveling property, and high dyne value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

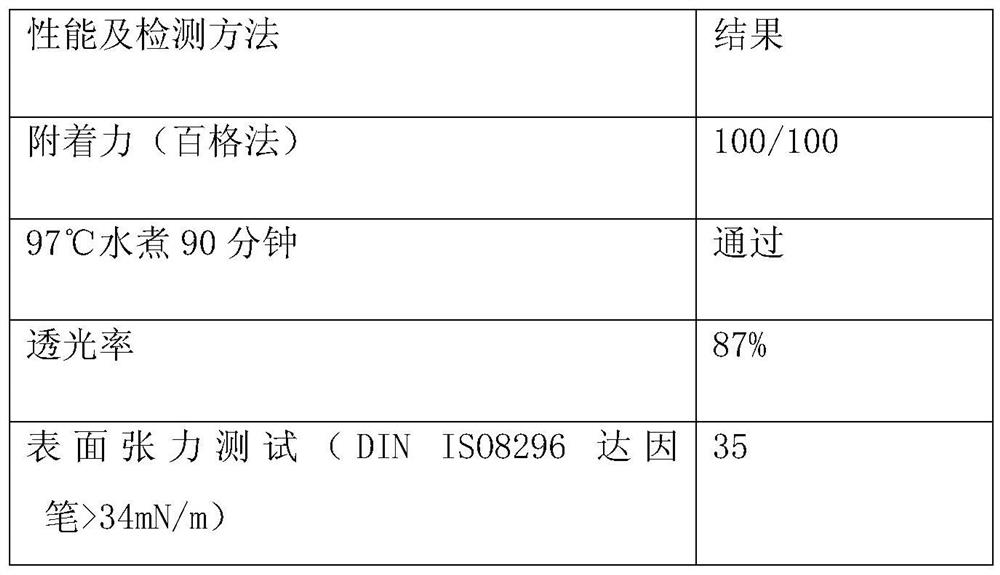

Examples

Embodiment 1

[0046] The electronic product housing coating of the present embodiment comprises the effective raw material components of following weight ratio:

[0047]Component A: polyester resin 35%, butyl acetate 20%, hydroxyacrylic resin 15%, polycarbonate diol 5%, silicone surface additive 5%, methyl isobutyl ketone 10%, diacetone alcohol 5%, ethyl acetate 5%, the sum of the mass percentages of each raw material is 100%;

[0048] B component: curing agent HDI trimer;

[0049] Component B is 10% of the total weight of component A.

[0050] The polyester resin is a saturated polyester resin with a hydroxyl value of 25 mg KOH / g and a number average molecular weight Mn of 6000-7000. Studies have shown that a low hydroxyl value corresponds to a high molecular weight resin, on the contrary, a high hydroxyl value corresponds to a low molecular weight resin, but too high a molecular weight is not conducive to the leveling of the coating surface. The adhesion cannot be guaranteed; in this e...

Embodiment 2

[0065] The types and proportions of raw materials in this embodiment are listed in Table 2, and the performance test results after film formation are listed in Table 3. Unless otherwise stated, other conditions are the same as in Example 1.

[0066] figure 2 It is the rendering of the paint obtained in Example 2 of the present invention after adding pink colorant and applying it to the rear cover of the mobile phone case.

Embodiment 3

[0068] The types and proportions of raw materials in this embodiment are listed in Table 2, and the performance test results after film formation are listed in Table 3. Unless otherwise stated, other conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com