Matt ink suitable for OGS full lamination process and preparation method thereof

A matte ink, full lamination technology, applied in the direction of ink, application, household utensils, etc., to achieve the effect of increasing crosslinking density, increasing adhesion, improving resistance to boiling water and acetone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

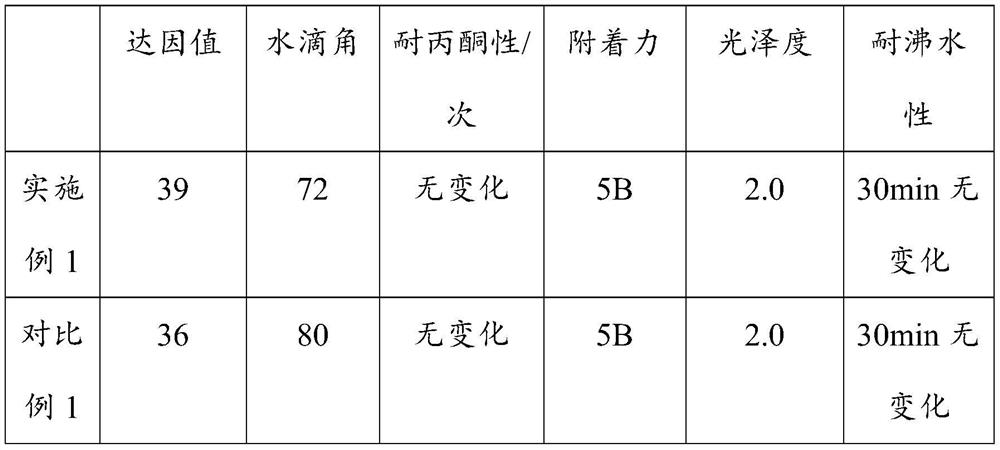

Examples

Embodiment 1

[0032] Embodiment 1 of the present invention provides a matte ink suitable for OGS full lamination process. In parts by weight, the raw materials include: 37 parts of thermosetting resin, 10 parts of filler, 15 parts of matting powder, and silicone-free 2 parts of foaming agent, 13 parts of isophorone solvent, 10 parts of ethylene glycol butyl ether, and 12 parts of carbon black.

[0033] The thermosetting resin is a mixture of epoxy resin and acrylic polyurethane resin. The weight ratio of the epoxy resin to the acrylic polyurethane resin is 25:12.

[0034] The epoxy resin was purchased from Nanya NPES-904, and the acrylic polyurethane resin was purchased from allnex UCECOAT2803.

[0035] The filler is talc powder, and the talc powder has an average particle size of 8000 meshes, purchased from Shenzhen Jinhaohui Industrial Development Co., Ltd.

[0036] The matting powder is a hydrophilic matting powder. The specific surface area of the matting powder is 125m 2 / g, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com