High-purity aluminum foil as well as preparation method and application thereof

An aluminum foil and high-speed technology, applied in the field of high-speed aluminum foil and its preparation, can solve the problems of unable to meet the requirements of mass production, incomplete removal of oil spots, leakage of coating on the surface of aluminum foil, etc., to improve the adhesion and oil removal effect. , the effect of no attenuation change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]A preparation method of high-grade aluminum foil, comprising the following steps:

[0040] (1) Rough rolling, intermediate rolling, and finishing rolling were performed on the aluminum foil material to obtain 0.015 mm aluminum foil. The mass percentage of each element of the aluminum foil material is Fe 0.25%, Si 0.05%, Cu 0.04%, Ti 0.02%, Mn 0.08%, Mg 0.03%, Ti 0.031%, and the balance is Al. The oil index of intermediate rolling and finishing rolling can ensure the initial wetting tension of the obtained aluminum foil, and its main indexes are shown in Table 1:

[0041] Various indicators Medium rolling Finishing Viscosity target value (mm 2 / s)

1.7-2.05 1.8-2.1 Transmittance(%) ≥80 ≥90 Gum (g / L) ≤20 ≤10 Alcohol content (%) 1.0-2.0 3.0-5.0 Ester content (%) 5.0-7.0 10.0-12.0

[0042] The roll standards for intermediate rolling and finishing rolling are shown in Table 2:

[0043] Table 2

[0044] Vario...

Embodiment 2

[0050] A preparation method of high-grade aluminum foil, comprising the following steps:

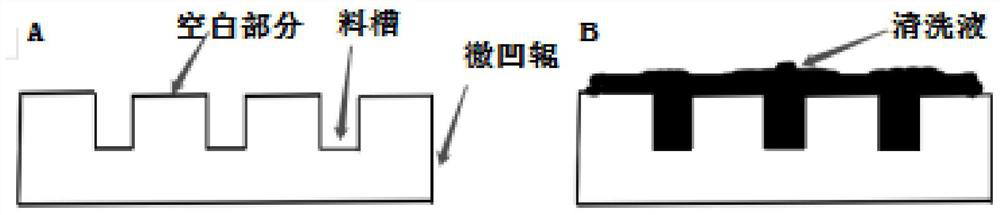

[0051] The difference between Example 2 and Example 1 is that in step (3), after the aluminum foil is dimpled and dried, the cleaning solution in the trough is removed, and after the water-based carbon-coated slurry is stirred and dispersed evenly, the micro-coated slurry is supplied through a feeding pump. In the trough of the gravure roll, the front and back sides of the aluminum foil are then coated and dried.

[0052] The rest was the same as that of Example 1, and a carbon-coated aluminum foil was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com