A kind of manufacturing method of low temperature shrink film laser label material

A low-temperature shrinkage and label material technology, applied to cardboard items and other directions, can solve problems such as being difficult to achieve, not having grating anti-counterfeiting partial metal grating anti-counterfeiting effect, etc., and achieve the effect of improving grade, low economic cost, and no secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

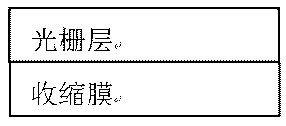

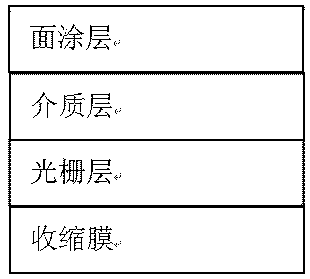

Image

Examples

Embodiment 1

[0022] Embodiment 1, according to the first preparation method:

[0023] A method for making a low-temperature shrinkable film laser label material. (1) First wrap an anti-counterfeit grating laser BOPP film on the first unwinder, and coat the wound anti-counterfeit grating laser BOPP film with a mixture of environmentally friendly hydroxyl resin and isocyanate resin. The resulting solution, the mass ratio of environmentally friendly hydroxyl resin and isocyanate resin is 1:1.8; the coated anti-counterfeiting grating laser BOPP film is heated in an oven, and the temperature in the fourth section of the oven reaches 60°C-85°C-95°C- 85°C; the speed of the anti-counterfeit grating laser BOPP film is controlled at 100m / min when it passes through the oven; The synthetic material needs to be cured by heating again; (3) The cured composite material is separated from the low-temperature shrink film and BOPP laser anti-counterfeiting film by the stripping equipment, and the grating cop...

Embodiment 2

[0024] Embodiment 2, according to the first preparation method:

[0025] A method for making a low-temperature shrinkable film laser label material. (1) First wrap an anti-counterfeit grating laser BOPP film on the first unwinder, and coat the wound anti-counterfeit grating laser BOPP film with a mixture of environmentally friendly hydroxyl resin and isocyanate resin. The resulting solution, the mass ratio of environmentally friendly hydroxyl resin and isocyanate resin is 1:1.9; the coated anti-counterfeiting grating laser BOPP film is heated in an oven, and the temperature in the fourth section of the oven reaches 65°C-80°C-90°C- 90°C; the speed of the anti-counterfeit grating laser BOPP film is controlled at 90m / min when it passes through the oven; The synthetic material needs to be cured by heating again; (3) The cured composite material is separated from the low-temperature shrink film and BOPP laser anti-counterfeiting film by the stripping equipment, and the grating copy...

Embodiment 3

[0026] Embodiment 3, according to the first preparation method:

[0027] A method for making a low-temperature shrinkable film laser label material. (1) First wrap an anti-counterfeit grating laser BOPP film on the first unwinder, and coat the wound anti-counterfeit grating laser BOPP film with a mixture of environmentally friendly hydroxyl resin and isocyanate resin. The resulting solution, the mass ratio of environmentally friendly hydroxyl resin and isocyanate resin is 1:2; the coated anti-counterfeiting grating laser BOPP film is heated in an oven, and the temperature of the 4th section of the oven reaches 55°C-90°C-85°C-80°C ; The speed of the anti-counterfeit grating laser BOPP film is controlled at 110m / min when it passes through the oven; It needs to be heated and cured again; (3) The cured composite material is separated from the low-temperature shrink film and BOPP laser anti-counterfeiting film by the stripping equipment, and the grating copy of the low-temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com