Wear-resistant solid wood floor and manufacturing method thereof

A technology of solid wood floor and production method, applied in the field of wood floor, can solve the problem of solid wood floor being easily worn, and achieve the effect of improving quality, added value, high value, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

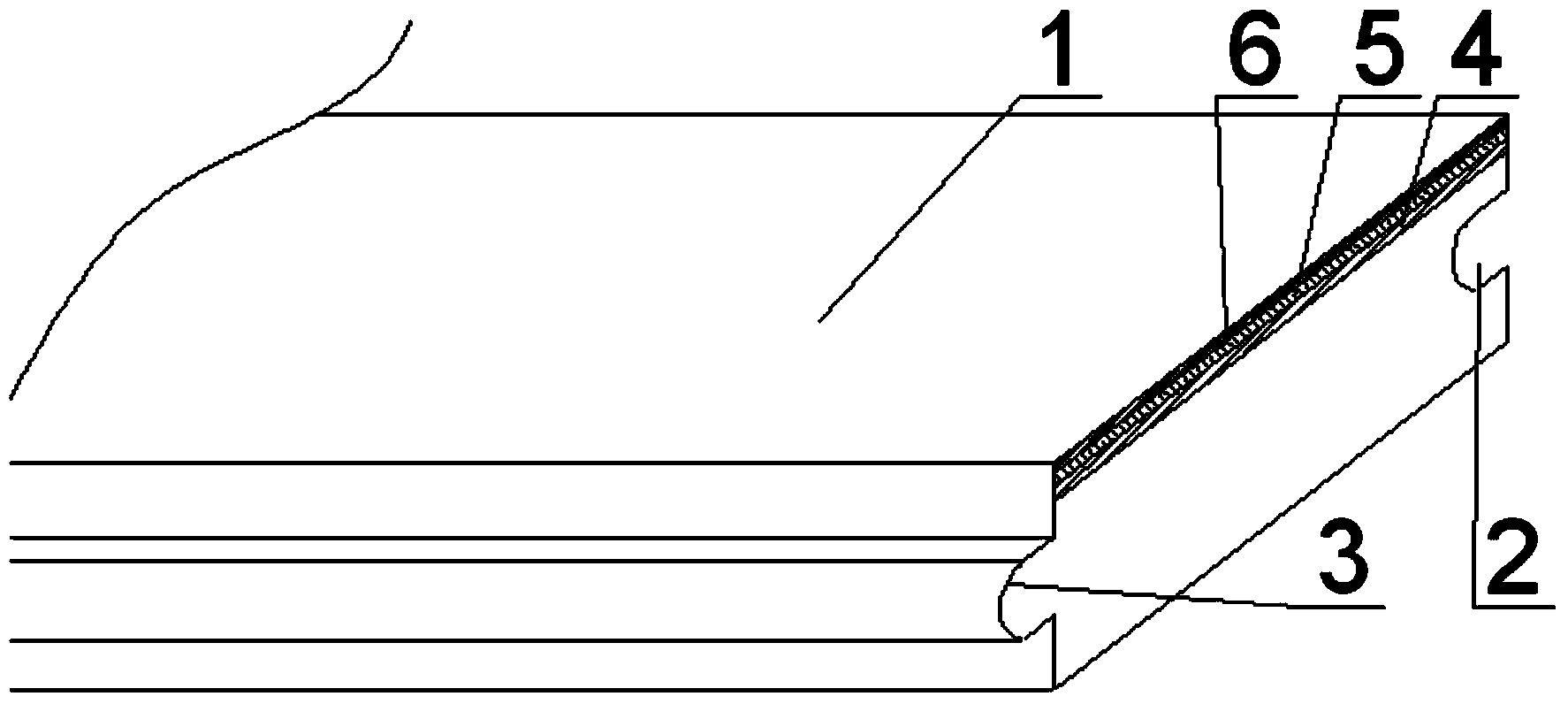

Image

Examples

Embodiment 2

[0020] Embodiment 2 of the present invention. A method for making wear-resistant solid wood flooring, comprising the following steps,

[0021] a. Drying, through natural drying and artificial drying of the wood, the moisture content of the wood is reduced to 6%;

[0022] b. Process the blank, cut and polish the wood to obtain the blank, and process the mortise and tenon on the side of the blank;

[0023] c, varnishing, roll-coating primer, topcoat and wear-resistant paint on the surface of the blank to obtain the board body of the wooden floor;

[0024] d. Vacuum coating: sand the surface of the board body, clean and dry, send it to the vacuum coating equipment for coating, and coat a layer of aluminum oxide vacuum coating layer on the board body to obtain a wear-resistant solid wood floor. The vacuum degree of the vacuum coating equipment is 2*10 -2 Pa, the coating time is 3 hours, and the thickness of the aluminum oxide vacuum coating layer is 3 microns.

[0025] The boa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com