Production technology of S-shaped lateral waist tape

A production process and side waist technology, which is applied in the field of disposable hygiene products production equipment, can solve the problems of unstable material conveying, long conveying distance, continuous left and right deflection, etc., so as to improve conveying stability and cutting stability, reduce Process equipment, the effect of reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

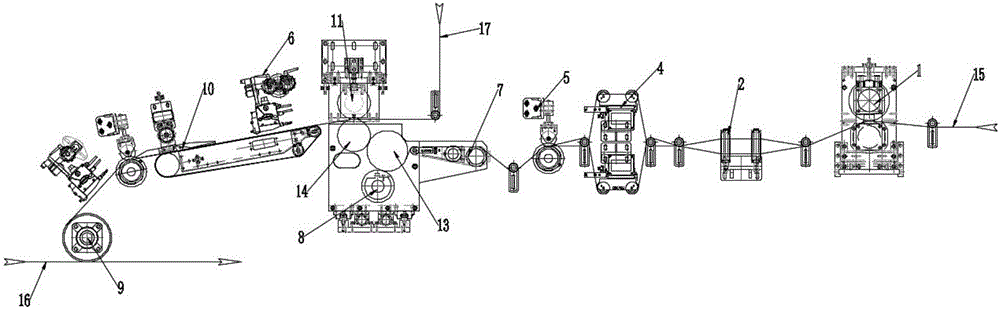

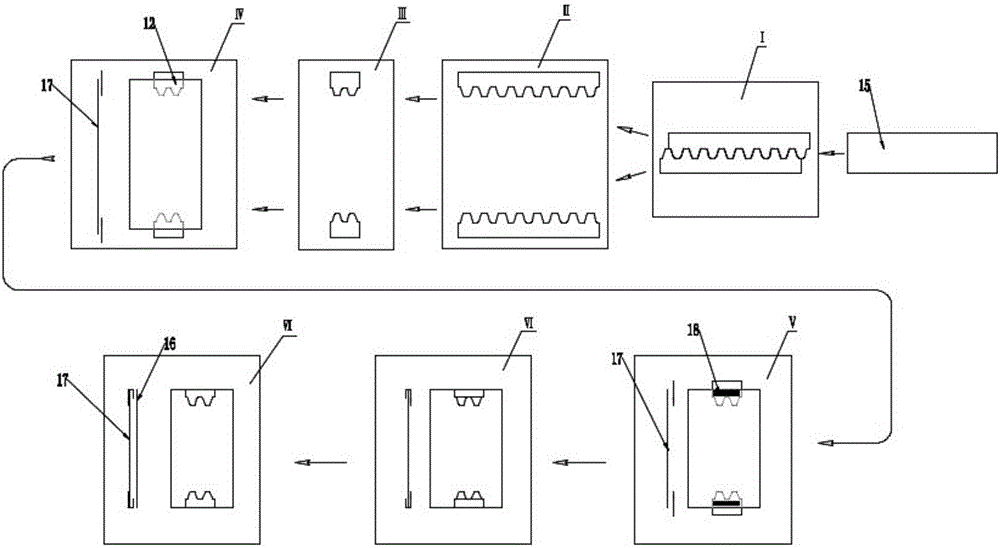

[0019] see Figure 1-2 , a kind of production technology concrete steps of S-shaped side waist sticker are as follows:

[0020] Step 1, after the side waist sticker material 15 passes through the S-shaped blade cutter 1, the side waist sticker material 15 is symmetrically divided into two left and right pieces as shown in I;

[0021] Step 2, the side waist sticker material 15 cut into two pieces is pulled apart by the pulling mechanism 2, and pulled to the actual required width of the adult diaper product, as shown in II;

[0022] Step 3, the side waist sticker material 15 is corrected by the deviation corrector 4, the active pressure feeding mechanism 5 and the negative pressure conveying groove 7 are transported to the cutter mechanism 8 at a fixed length, and the cutter mechanism 8 cuts the side waist sticker material 15 into a shape as shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com