Device and method for integrally treating refractory organic wastewater

A technology for organic wastewater that is refractory to degradation, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems that ultrasonic treatment is difficult to effectively degrade organic pollutants and has low efficiency , achieve broad market prospects, easy to use, and accelerate the effect of ozonation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

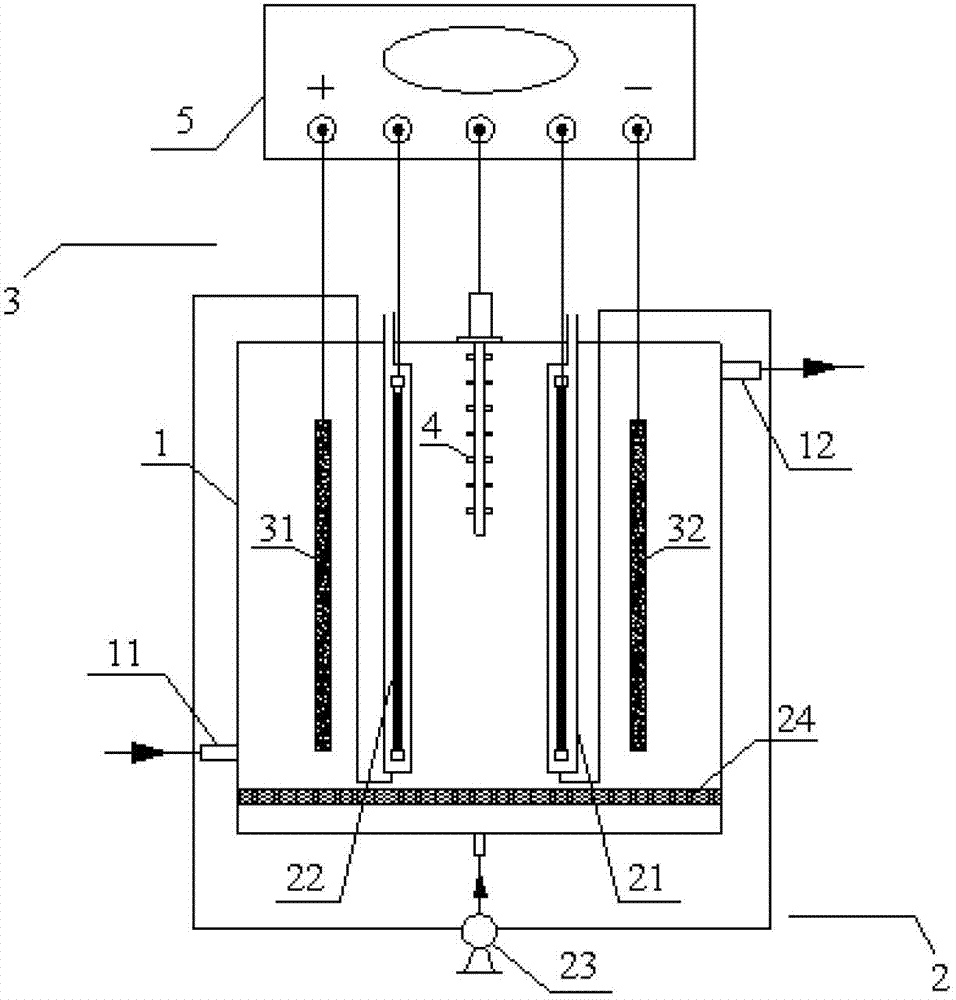

[0048] Integrated treatment of refractory organic wastewater equipment, see figure 1 , including a reaction device 1 , an ultraviolet / ozone generation and diffusion device 2 , an electrochemical catalytic device 3 , an ultrasonic device 4 and a power supply 5 .

[0049] The lower part of the reaction device 1 is provided with a water inlet 11, and the upper part is provided with a water outlet 12; the ultraviolet / ozone generation and diffusion device 2 includes a quartz sleeve 21, a gas pump 23 and a gas diffuser 24 connected in sequence, and an ultraviolet lamp is arranged in the quartz tube 21 Pipe 22 and gas diffuser 24 are arranged at the bottom of reaction device 1; quartz sleeve 21 is arranged in reaction device 1, and its one end is provided with inlet pipe, and the other end is provided with outlet pipe and is connected with gas pump 23, and inlet pipe leads out reaction Outside the device 1; in this embodiment, a pair of ultraviolet / ozone generation and diffusion devi...

Embodiment 2

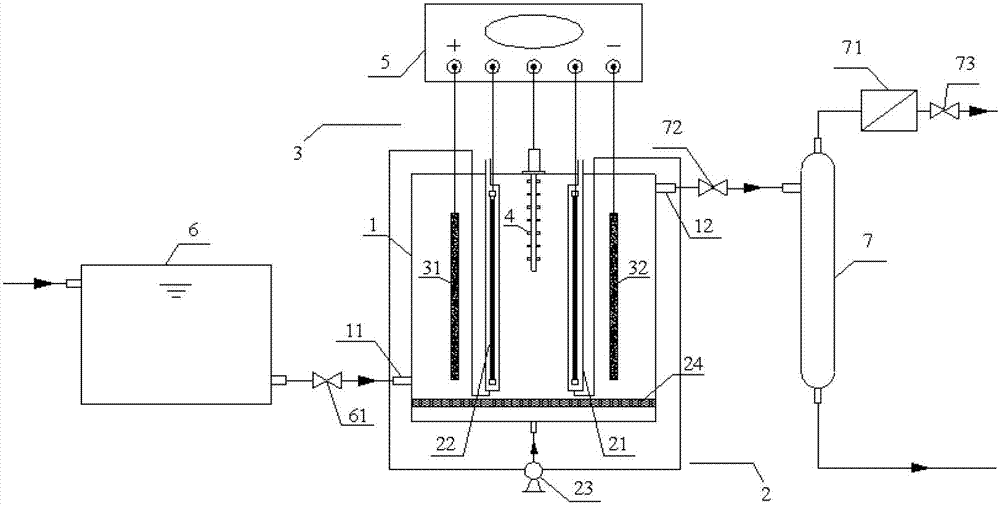

[0053] Integrated treatment of refractory organic wastewater equipment, see figure 2 , including a reaction device 1 , an ultraviolet / ozone generation and diffusion device 2 , an electrochemical catalytic device 3 , an ultrasonic device 4 , a power supply 5 , a pretreatment device 6 and a gas-liquid separator 7 .

[0054] The lower part of the reaction device 1 is provided with a water inlet 11, and the upper part is provided with a water outlet 12; the ultraviolet / ozone generation and diffusion device 2 includes a quartz sleeve 21, a gas pump 23 and a gas diffuser 24 connected in sequence, and an ultraviolet lamp is arranged in the quartz tube 21 Pipe 22 and gas diffuser 24 are arranged at the bottom of reaction device 1; quartz sleeve 21 is arranged in reaction device 1, and its one end is provided with inlet pipe, and the other end is provided with outlet pipe and is connected with gas pump 23, and inlet pipe leads out reaction Outside the device 1; in this embodiment, a p...

Embodiment 3

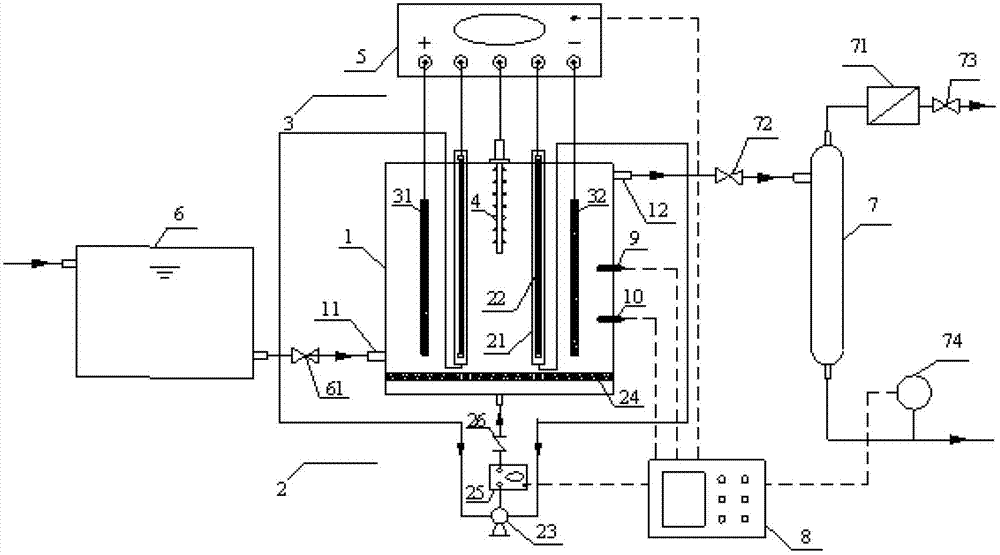

[0059] Integrated treatment of refractory organic wastewater equipment, see image 3 , is basically the same as Embodiment 2, the only difference is that it also includes a gas phase ozone concentration detector 25, a check valve 26, a residual oxide detector 74, an automatic control unit 8, a salinity / temperature sensor 9 and a pH sensor 10.

[0060] The gas outlet of the gas pump 23 communicates with the inlet of the gas-phase ozone concentration detector 25 , the gas outlet of the gas-phase ozone concentration detector 25 communicates with one end of the check valve 26 , and the other end of the check valve 26 communicates with the gas diffuser 24 .

[0061] The residual oxide detector 74 is arranged on the pipeline connected to the outlet pipe of the gas-liquid separator 7 . Automatic control unit 8 is connected with the signal interface of multifunctional power supply 5, salinity / temperature sensor 9, pH sensor 10, gas-phase ozone concentration detector 25 and residual ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com